The use of mineral fiber materials has a huge number of both ardent fans and those who consider insulating a balcony with mineral wool a waste of time and unacceptable for such premises. Building codes and regulations allow the use of mineral insulation, but only if the warm layer is reliably insulated with absolutely impermeable materials.

Insulating a balcony is cost-effective

Is it possible to insulate a balcony with mineral wool?

Nevertheless, the idea of insulating a balcony with mineral wool with your own hands is extremely popular, primarily due to the low cost and availability of thermal insulation. True, such insulation is most often done handicraft, according to one’s own understanding of exactly how mineral wool and protective film slabs should be laid, hence all the problems.

Two factors speak in favor of insulating the floor on the balcony with mineral wool:

- Insulating a balcony is quite simple and reliable. If you do everything according to technology, this thermal insulation on a balcony or loggia can last a couple of decades;

- Formally, balconies and loggia do not belong to residential premises; parapets and walls are blown by air currents, which means that there will be no problems with removing water vapor if properly insulated with mineral wool.

It is possible and necessary to insulate a loggia with mineral wool, since the material has zero flammability and looks like an ideal candidate when compared with polyethylene foam or expanded polystyrene. If you are looking for an option that is balanced in price and durability, then it will probably be difficult to find something more affordable than insulating a balcony in a Khrushchev-era building with mineral wool with your own hands.

Mineral wool insulation scheme

Important information

It is very important to carefully consider the insulation of all areas of the balcony, only in this case will it fulfill its role fully. If there are clearings or gaps in some places, then mineral wool will no longer give the expected effect.

It is necessary to understand that the balcony is insulated in order to retain heat, and not to create it. Therefore, during the cold season, you can install a heater on the balcony or open the balcony door, allowing heat from the room to enter there. You can also place an air conditioner or battery there.

Such an insulated and heated balcony will help expand the area of the apartment: it can be turned into a full-fledged small room. Depending on the size, it can accommodate a couple of chairs and a table. Get a cozy place to relax. True, in this case you will also have to take care of lighting.

Also, an insulated balcony is an excellent place for growing flowers, and with the proper level of heating and sufficient space, you can make an additional sleeping place there. This solution will be especially relevant for small-sized and one-room apartments.

Insulation with rolled mineral wool is more difficult - but still possible, see how this is done in our video:

Pros and cons of insulating a balcony with mineral wool

It cannot be said that mineral wool is an absolutely ideal heat insulator; you can find many different opinions and expert opinions, advice and just tales from experts, which tell about all the defects that exist in nature.

To be objective, mineral wool has two serious disadvantages:

- Watering as a result of absorption and condensation of water vapor in the thickness of the material. As a result, the insulation freezes and loses its heat-insulating qualities;

- In order to professionally insulate a balcony with mineral wool with your own hands, you need to know exactly the sequence of actions and strictly follow the instructions.

Unlike expanded polystyrene or roll thermal insulation, any mistake will make insulating a loggia with mineral wool with your own hands a pointless waste of time and money. Mineral fiber very quickly becomes a wet rag, and it will be impossible to retain heat.

Important! Many do-it-yourselfers note an unpleasant chemical smell emanating from the material; it can be easily gotten rid of if you leave the packages of mineral wool in a dry and ventilated room several days before the start of the insulation process.

In addition, you will need to get a vacuum cleaner and use it in the process of insulating the walls with mineral wool. When laying and, especially, cutting the material, a large amount of fine dust is obtained, which will remain in the loggia or balcony. Otherwise, cuttings and dust may spread throughout the apartment.

In addition to being cheap and non-flammable, the positive qualities of the material include high resistance to mice, ants, cockroaches and pathogens.

Finishing

After completing the thermal insulation of the loggia, it is worth thinking about finishing work, which also affects the degree of thermal insulation in the room. When all layers are laid and sealed, the metal hangers must be returned to their original position, and then the aluminum profiles must be attached to them.

It is convenient to attach almost any of the materials available on the modern construction market to these profiles. Wooden, cork and metal slatted panels, PVC structures, siding and many other options are perfect as finishing materials for loggia walls.

Moisture-resistant drywall has proven itself quite well. The advantages of this material are its lightweight structure, which “breathes” well. Drywall is very affordable in terms of price, and it is also easy to process, paint, fix, and stick wallpaper on its surface.

At first, insulating a loggia may seem like a rather complicated and time-consuming process. However, if you decide to try, you will quickly realize that there are no particular difficulties here. All operations are quickly mastered and do not require special construction skills.

The balcony can also be turned into a comfortable and useful room. For example, equip it with an office, a workshop, a small sports corner or a comfortable relaxation room.

Preparatory work

Of course, the loggia or balcony must first be glazed with window frames, it can be plastic or wooden, it doesn’t matter. The second step is to make a concrete floor and parapet; the walls must be repaired, the cracks must be sealed with a cement-sand mixture and covered with acrylic or polyurethane primer.

The floor on the balcony can be leveled with a mesh and concrete screed at the horizon level. This will make it easier to assemble the frame and insulate the floor on the balcony with mineral wool yourself.

The balcony wall will need to be lined with foam blocks or tiles

Thermal insulation with penofol

Laying insulation on the ceiling is not always carried out as the final element of installing a loggia. Sometimes it is completely absent, which is why the owner of the room loses coziness, comfort and quality of heat.

The simplest method, which does not require much time for thermal insulation, is laying with penofol. This installation looks like this:

- We take accurate measurements of the length and width of the surface.

- We transfer the dimensions onto a roll of construction foam foam, and then cut off the required amount of material.

- We install the first layer of thermal insulation using transverse wooden slats (3-4 pieces are enough).

- We remove all recesses and joints with a special sealant or polyurethane foam.

- We wait until the surface is completely dry.

- We install the second layer of insulation using longitudinal slats. The finished ceiling structure must be connected without defects to the thermal insulation of the walls.

- The finish can be fixed using external slats that form a flat surface.

Thermal insulation of the loggia ceiling with penofol, including high-quality insulation of the floor and walls, will retain a significant part of the heat in your apartment in the winter. And installing loggia insulation yourself will save you a good amount of money, because... penofol is one of the easiest materials to process and relatively inexpensive.

Is vapor barrier necessary?

The key issue of any wall insulation is the arrangement of a vapor barrier layer. You can find a lot of advice about installing or not using standard vapor barriers, but you shouldn’t delve too deeply into such advice. The insulation and vapor barrier system should be built according to the same scheme as in the case of insulating the walls of a house:

- If the balcony does not have a concrete or plastic parapet, like a loggia, then the outer part of the insulation is equipped with a ventilation gap and windproof film. In other cases, you can insulate with mineral wool directly onto the wall;

- On the inside, the vapor barrier is laid directly on the mineral wool, but a ventilation gap of 10-15 mm wide must be made between the film and the cladding.

If there is no heating in the balcony or loggia room and there are no ventilation windows - vents through which warm, moist air will be removed, then the use of a vapor barrier membrane is mandatory.

Important! Due to the specifics of laying vapor barrier film, insulation of a glazed balcony or loggia must be done before installing the window sill.

Installation of insulation materials

After applying the glue, the mineral wool slabs are placed on the insulated surface between the sheathing guides, pressing lightly. Each element of mineral wool should be laid adjacent to the previously installed one.

If there are cracks and gaps, they are filled with small pieces of insulation. The laying of thermal insulation material begins from the ceiling, and after that they move on to the wall surfaces.

If the thickness of the loggia walls allows, then it is better to use additional fasteners.

The more securely the system is reinforced, the longer it will last. After the glue has dried, the cotton wool is secured with dowels.

Vapor barrier

Upon completion of installation of insulation materials, a vapor barrier membrane is installed. Place it with the foil side inside the room to reflect heat. The edges of the material are joined without overlap. The joints are taped with metallized tape.

How to properly insulate a balcony from the inside with mineral wool

To arrange the insulation of a balcony room, first of all, it is necessary to purchase materials that are recommended by leading manufacturers for this type of work. The list will include:

- Wooden slats, section 50x50 mm, for a standard balcony you will need at least 20 pieces of 4 m each;

- Mineral wool rolled or in the form of slabs;

- Double-sided and single-sided tape;

- Mounting stapler with staples, screwdriver with a set of screws 75-100 mm;

- Vapor barrier film.

In addition, after insulating the floor on the balcony with mineral wool, you will need to sew a rough base made of plywood or OSB panels. It is recommended to cover the walls of the balcony with clapboard or wooden slats. It is clear that it is better to buy all of the above as a kit specifically for installing insulation indoors, but you can also use leftover building materials from laying the roof of a summer house. The general technology for insulating a balcony with mineral wool is shown in the video:

Warm “pie” for the balcony

Insulation of balcony walls and ceilings with mineral wool

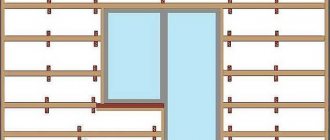

First of all, it is necessary to sew vertical pine bars of the supporting frame onto the walls and ceiling. The slats are attached to the walls using self-tapping screws and a screwdriver. The horizontal distance between the beams is chosen within 58-59 cm, if the width of the mineral wool slab is standard, 60 cm. It is not necessary to follow any specific order of installation, the main thing is that the size is 10-15 mm smaller than the width of the mineral wool piece, otherwise the insulation will simply fall out of the sheathing.

We attach the timber to the wall

Each beam is fastened at two or three points, first at the top, then leveled vertically according to the building level and sewn at the bottom and in the center. On the ceiling, the lath for insulating the concrete slab with mineral wool is attached with overlapping ends.

The next step is to lay the mineral wool into the wall sheathing; the thickness of a standard mineral wool slab is 50 mm, so the surface of the laid insulation is obtained from the cut of the vertical slats.

Next, we sew horizontal beams on top, the height between levels is selected in the range of 400-600 mm. A second layer of mineral wool is placed in the resulting niches; double laying ensures the absence of cold bridges.

A second layer is sewn on top of the first layer of insulation.

Laying vapor barrier film

The next stage is the most critical; it is necessary to lay a vapor barrier for insulation on the walls. It looks like polyethylene film reinforced with mesh. The roll is unwound horizontally, the upper edge is placed under the window frame and on the walls. The edges of individual panels must be laid with an overlap of 100 mm and secured with double-sided tape. The panel itself is attached to the mineral wool sheathing using construction staples and a stapler.

The film is sewn to the horizontal post of the balcony

The edges of the laid vapor barrier are glued to the surface of the walls and ceiling with special adhesive tape. To prevent the insulation protection from steam from being torn off in strong winds, secondary slats with a cross-section of 20x20 mm are sewn onto the horizontal beams.

Sewn-on bars make it possible to press the vapor barrier film in places where the brackets are installed, and at the same time serve as a lathing for hanging decorative cladding.

Lathing for eurolining

Technology for insulating loggia floors with mineral wool

Laying mineral wool on a concrete slab is carried out according to a similar scheme. Initially, the slats of the future sheathing are laid on the floor for laying mineral wool. To insulate the floor, choose a size of 50x50 cm or even 40x40 cm. The section of the beam is 50x70 mm; usually, after insulation, the loggia room is used as part of the living space, so the base is made with a small margin of safety.

Mineral wool is laid directly on concrete, without any gaskets or additional insulation from roll insulation. A vapor barrier is laid over the mineral fiber insulation, the edges are run onto the walls and taped with wall insulation insulation.

If the thickness of the mineral wool slab is selected according to the level of the beam, then you will additionally need to fill the counter-lattice slats, the step is taken to be 20-25 cm. Only after this can you sew on the plywood of the subfloor and stuff the eurolining on the walls.

Advice from professionals

Important information about wool insulation:

- It is not allowed to have gaps through which heat will escape. It will not be possible to achieve high-quality thermal insulation;

- thermal insulation allows you to save thermal energy inside the room, but not create it. It is recommended to regularly open the door from the apartment or place a heating device on the loggia;

- thermal insulation allows you to turn a loggia and balcony into an additional small room - a full-fledged living space. Depending on their size, it is possible to design a workplace or a comfortable relaxation area with soft armchairs and a hanging table. Morning coffee with a view of the metropolis will make a great start to a new day;

- the resulting space can be turned into a beautiful botanical garden. In winter, this will make you feel like summer. Plunge into the green kingdom;

- For additional fixation of the slabs, it is allowed to use special clamps - butterflies.

Mineral fiber-based wool as thermal insulation allows you to turn the loggia into a real living space, comfortable for living. In the new room you can arrange a place for relaxation, a study and even a winter garden. The main thing is to decide on the wishes of the owners.

Common mistakes

In this scheme, the insulation structure approximately corresponds to that used when installing a warm roof. Most often, home-made workers make the same mistake - they lay mineral wool without waterproofing the outer surface. In this example, the walls perform the functions of a water barrier. In addition, there must be a gap between the vapor barrier and the decorative cladding to ensure normal escape of still warm air, but supersaturated with water vapor, from the surface of the vapor barrier membrane. Otherwise, condensation will appear, and the lining will become damp and swell with moisture.

Material characteristics

Mineral wool is a fibrous insulation material produced from molten rocks, most often basalt. This material has high thermal insulation qualities, good noise-absorbing abilities, does not burn, and is durable.

Among the disadvantages is the ability to absorb moisture, therefore, when using mineral wool, it is necessary to install vapor and waterproofing. When processing this material, harmful dust is generated, so they work with it in special clothing, gloves and a respirator.

Advantages of mineral wool

Mineral wool is a group of thermal insulation materials made from a melt of various rocks and minerals.

This category includes:

- Glass wool;

- Slag;

- Basalt or stone wool.

Despite the diversity of composition, the term “mineral wool” usually means basalt or stone . It is the safest material for home insulation. The characteristics of the heat insulator set it apart from the list of other similar materials. Mineral wool has important advantages:

- High heat-saving qualities;

- Mineral wool is a reliable sound insulator;

- Light weight;

- Does not burn and does not support combustion;

- Does not rot, does not contribute to the formation of mold and mildew;

- Available in rolls and slabs, this helps facilitate installation.

- Relatively low price.

The only drawback of the insulator is its ability to absorb moisture, losing its performance. The problem is solved by installing a protective membrane. A suitable choice is insulation with stone wool produced in slabs and mats. They are quite rigid, easier to install, and do not lose their shape over time.

Facing

When the vapor barrier layer is installed, you can proceed to the cladding of the structure. Plywood, chipboard, MDF, lining, and plasterboard are usually used as facing materials for balconies. If the walls are supposed to be plastered, then a reinforcing mesh is installed on top of the insulation.

Floor insulation

Laying of insulation boards on the floor is carried out between pre-arranged joists. There is no need to additionally fasten the material. After the glue has hardened, a film vapor barrier is installed and then the floor is sewn up.

After arranging the thermal insulation system, you can move on to decorative finishing of the room.

Methods for laying insulation on the floor

To lay the insulation layer on a small balcony floor, two methods can be used. About them below:

- on wooden racks (logs). The construction of such a structure is necessary to pre-level the coating before further laying. The logs are raised to a height equal to the thickness of the insulation layer. The structure can be supported on metal corners or special brackets;

- insulation of the floor using the heating function. Its role will be played by a heating cable or infrared film. It can also be a water structure, which is connected to stationary heating.

Knocking off beacons for installing logs on the balcony under insulation Source transkribator.guru

Below in this section we will talk about methods for arranging each of these two options.