Penoplex and mineral wool

“The wise power of a builder is hidden in every person, and one must give free rein to its development.” (Maksim Gorky).

A huge hello to all blog readers! I hope you have already “come to your senses” from the holidays and are ready for the next portion of construction information. If yes, then read on, if your health still leaves much to be desired, close the site, turn off the computer and go to visit friends for “treatment.” Well, we will continue...

Today I decided to choose the topic of choosing two main “ideological competitors”, well, like a car with front or rear wheel drive. Or something similar, which has approximately an equal percentage of supporters on both sides. I’ll try to make a neutral comparison, and the choice is clearly yours. So, penoplex or mineral wool, which is better?

The right question is - what are we going to insulate? Well, let's take a little look at the main structures: walls, foundation, floor.

Variety of mineral wool

Subtle point. If penoplex* is, in fact, the name of the final product, then mineral wool is a broad concept, including glass wool, slag and stone wool. Therefore, as the Germans say, “apples must be compared with apples,” which means we’ll focus on one thing. I choose stone mineral wool, which is more often called basalt. It has better thermal insulation properties in comparison with its “slightly backward brothers”.

*There is another subtype of penoplex - technoplex. This is a bird of a feather. True, there is not a big difference in the name and minor parameters, but we will not go into these details. That's it, let's begin. In the red corner of the ring there is penoplex, in the blue corner there is mineral wool. Gong!

Expanded polystyrene

Expanded polystyrene is a material obtained by foaming. It consists of 98% air and 2% polystyrene with various additives. Essentially, many air bubbles are enclosed in a polystyrene shell. Since the static sealed air layer is an excellent insulator, this material is widely popular among insulation materials.

Here are some characteristics of polystyrene foam:

- The thermal insulation coefficient ranges from 0.028 to 0.036 W/(m K).

- Vapor permeability - 0.015-0.05 Mg/(m h Pa).

- It is resistant to alcohol and ether.

- Mechanical tensile strength - no less than 20 MPa.

- Soundproofing effect. A sheet of polystyrene foam 3 cm thick can reduce noise penetration by 25 dB.

- Low moisture absorption - no more than 6%.

Expanded polystyrene is produced in sheets measuring 1 m * 1 m. The thickness of the sheet can be different, depending on the needs of the buyer. The most commonly used sheets are 5 and 10 cm thick; they are also available in 3 or 2 cm thick.

Foam plastic in different sizes

However, sheets of greater thickness or different sizes can be produced to order. To increase the thermal insulation qualities, 12 cm polystyrene foam can be used.

Types of material

In addition to differences in size and thickness of the material, it is also distinguished by density. One special type is extruded polystyrene foam. It has a very fine structure and is produced by extrusion. This material has high compressive strength. It is more durable.

Extruded polystyrene foam

One of the characteristics of expanded polystyrene is density. It varies from 15 to 35 kg/m3.

Advantages

Here are some reasons why polystyrene foam is preferred to mineral wool in certain cases:

- If polystyrene foam needs to be plastered (this applies to façade finishing), it is much more convenient to work with it rather than with mineral wool. It is much easier to glue sheets of foam plastic evenly due to their smooth surface, and when applying the adhesive mixture, it will not roll off.

- Polystyrene foam is safe for health. When working with it, you do not need to use a respirator, long sleeves and glasses, as is necessary when working with mineral wool.

- Polystyrene foam has a low water absorption coefficient.

- Low price.

- Light weight.

Flaws

In addition to the advantages, polystyrene foam also has disadvantages:

- It is susceptible to rodents and other animals. If the material is not protected from external influences (for example, by plastering), mice can chew it. Another pest is geese, which can significantly damage an unplastered façade.

- Flammability. If a fire occurs, it will help the fire spread by slowly smoldering. And the substances that are released when polystyrene foam burns are very harmful to health.

- It is vapor-tight, so to maintain a comfortable microclimate in the room you will need to ventilate frequently.

- Foam plastic is negatively affected by the sun's rays - it begins to collapse. An unplastered facade can become 0.5 cm thinner over a few years.

Therefore, when choosing polystyrene foam, you should weigh the pros and cons.

Composition and environmental friendliness

Mineral wool is the general name for glass, slag and basalt (stone) wool. It is produced most often in the form of soft mats or rolls (layer thickness up to 200 mm), rarely in the form of felt, granules and shells.

Penoplex consists of polystyrene - an environmentally friendly (as manufacturers say) material, and it in turn consists of very toxic styrene, some amount of which can remain in the finished product (theoretically).

Mineral wool consists of a thin inorganic substance glued together with synthetic glue. Danger is caused by dust that is always present in mineral wool. Once dust gets into your lungs, it stays there forever.

Mineral wool

Mineral wool has a fibrous structure. Fiber thickness is from 4 to 15 microns, length is from 15 to 50 mm. The fibrous structure does an excellent job of dampening sound waves.

There are:

- Glass wool.

- Stone.

- Slagovat.

Mineral wool in slabs

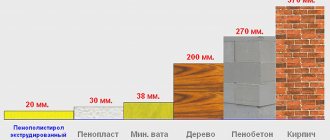

The thermal conductivity of mineral wool is 0.040 W/m*°C. Therefore, the answer to the question: what is warmer - mineral wool or polystyrene foam - can be answered with polystyrene foam. Although, of course, a lot depends on the thickness and density of the material.

Types of mineral wool

Mineral wool is used in various areas of insulation; the material is available in different forms:

- Rolled. It is spread on horizontal surfaces that are insulated, or attached with staples to vertical surfaces to prevent rolling.

- Slab. It is stiffer and heavier and is not prone to rolling. The most common slab shape is 60*120 cm.

Mineral wool in rolls

Advantages

Among the advantages of mineral wool, the following points are worth noting:

- It doesn't burn. Therefore, if a fire occurs, it will not contribute to its spread.

- Mineral wool is not susceptible to pests such as mice or other animals.

- It does not emit toxic substances at temperatures up to 650°C.

Flaws

Here are some disadvantages of mineral wool:

- It is unsafe, so you need to wear a respirator, gloves and long sleeves when working with it.

- Mineral wool is hygroscopic. If rain falls on the material before it is protected, its thermal insulation properties will be significantly reduced. Therefore, when insulating a facade with mineral wool, it is advisable to immediately protect it.

We are trying to answer the pressing question - which is better: penoplex or mineral wool?

“The wise power of a builder is hidden in every person, and one must give free rein to its development.” (Maksim Gorky).

A huge hello to all blog readers! I hope you have already “come to your senses” from the holidays and are ready for the next portion of construction information. If yes, then read on, if your health still leaves much to be desired, close the site, turn off the computer and go to visit friends for “treatment.” Well, we will continue.

Today I decided to choose the topic of choosing two main “ideological competitors”, well, like a car with front or rear wheel drive. Or something similar, which has approximately an equal percentage of supporters on both sides. I’ll try to make a neutral comparison, and the choice is clearly yours. So, penoplex or mineral wool, which is better?

The right question is - what are we going to insulate? Well, let's take a little look at the main structures: walls, foundation, floor.

Subtle point. If penoplex* is, in fact, the name of the final product, then mineral wool is a broad concept, including glass wool, slag and stone wool. Therefore, as the Germans say, “apples must be compared with apples,” which means we’ll focus on one thing. I choose stone mineral wool, which is more often called basalt. It has better thermal insulation properties in comparison with its “slightly backward brothers”.

*There is another subtype of penoplex - technoplex. This is a bird of a feather. True, there is not a big difference in the name and minor parameters, but we will not go into these details. That's it, let's begin. In the red corner of the ring there is penoplex, in the blue corner there is mineral wool. Gong!

From this article you will learn:

Comparison of characteristics

When comparing which insulation is better, polystyrene foam or mineral wool, let’s consider several basic technical and operational characteristics:

- environmental cleanliness;

- thermal conductivity;

- lifetime;

- ease of installation;

- resistance to biological effects;

- price;

- insulation density;

- water absorption;

- strength;

- Fire safety;

- soundproofing properties.

Which is more environmentally friendly?

Under normal operating conditions, both insulation materials are absolutely harmless to human health. But with increasing temperature, and even more so when exposed to an open flame, polystyrene foam can become dangerous.

When polystyrene melts, the active release of toxic and poisonous gases begins. And therefore, in most European countries, the use of PPS boards for insulation is prohibited by law. Although in our country it is used everywhere.

Which retains heat better?

Both insulation materials have excellent thermal insulation characteristics. But if we compare the thermal conductivity coefficients, we can say for sure that polystyrene foam is a more effective insulation material.

Which is cheaper?

The cost of basalt mats ranges from 1400 to 2300 rubles/m3. Expanded polystyrene is sold for 1900-2300 rubles/m3, i.e. the price is almost the same. But, as mentioned above, polystyrene foam is warmer and will require 40-50% less of it. It turns out that PPS slabs are cheaper than mineral wool.

Which will last longer

When considering the technical characteristics, it was already said that the service life of PPS slabs is 25, and that of basalt wool is 50 years. Here the clear leader is cotton wool. However, when choosing insulation, you should take into account the finishing method used. Thus, a facade plastered using the “wet” method will last no more than 25 years. Therefore, the use of expensive durable cotton wool simply loses its meaning.

The easier it is to insulate

The installation technology for both insulation is identical. The insulation is initially placed on glue and then additionally secured with plastic mushroom-type nails.

What is less attractive to pests

Both polystyrene and mineral wool are not susceptible to mold and mildew. But rodents very willingly make burrows in polystyrene foam, which is significantly inferior in this regard to basalt fibers.

Which material is more harmful to health?

Under standard operating conditions, both materials are not harmful to humans. However, when the ambient temperature rises or an emergency situation occurs (fire), the foam becomes extremely dangerous for humans.

In the heat, it releases harmful styrene, which accumulates in the body, and in the event of a fire, toxic substances that can quickly render people unconscious in a room on fire. Therefore, the Stockholm Convention on Hazardous and Poisonous Substances directly prohibits the use of foam plastic for attic insulation. In Russia little attention is paid to this, but in the West there is a categorical ban.

Conclusion: under standard operating conditions, both materials do not pose a health hazard. However, you should refrain from insulating walls with foam plastic from the inside of the apartment (house) in the nursery and kitchen, where the risk of fire is higher than in other rooms. And also do not put your health at risk when insulating the attic. Here basalt wool has no competition.

Resistance to microorganisms and rodents

Both types of insulation do not serve as a basis for the growth of mold and mildew. But their relationship with mice and rats is different: they avoid basalt, and polystyrene foam serves as their favorite habitat. Nests are made in it. Adding special additives to expanded polystyrene does not solve the problem.

Conclusion: basalt wool is completely protected from adverse biological effects. Polystyrene foam should not be used where there is a high probability of mice and rats (dacha).

What's worse is burning

Basalt wool belongs to class NG (non-flammable materials), and polystyrene foam belongs to class G3 (normally flammable). Attempts by manufacturers to reduce the flammability class have been successful. Products from BASF, Polimeri Europa, Styrochem, etc., after the introduction of fire retardants, go into class G1 (self-extinguishing). Most Russian manufacturers are unable to do this, which is most likely due to semi-handicraft production.

Conclusion: basalt wool, unlike polystyrene foam, does not burn. Therefore, if there is a high risk of fire, it is better to avoid polystyrene foam.

Vapor permeability

The vapor permeability indicator is especially important when insulating wooden walls. They actively “breathe”, regulating the water balance inside the log or timber. Blocking the wood's ability to remove excess moisture with vapor-tight insulation provokes rotting processes. During the hot season, the tree does not rot, but rots. To a lesser extent, but the above is also true for brick and concrete - condensation forms on the surface of the wall, followed by the growth of mold or mildew.

Comparing the vapor conductivity of basalt (about 0.3 mg/(m.h.Pa)) and polystyrene foam (0.03 mg/(m.h.Pa)), it should be noted that they have exactly opposite properties: polystyrene foam is practically vapor-proof, while basalt wool allows the walls to breathe.

Conclusion: the vapor-tight properties of polystyrene foam give a huge advantage to cotton wool: it can be used on any type of wall material. The use of polystyrene foam is undesirable when insulating the walls of a wooden house, and when insulating brick and concrete, it is necessary to calculate the dew point so that it does not end up on the surface of the wall. If such calculations are not carried out, then the problem can be solved by increasing the thickness of the thermal insulator layer (you need to bring the dew point inside the insulation, where there will be no harm).

Which is easier to install?

Insulation of a building with polystyrene foam and basalt wool is carried out using similar technologies, which does not provide an advantage to any of the types under consideration.

Conclusion: the technology of thermal insulation by any of the materials being compared does not give any of them any advantage.

Other criteria

When choosing insulation, it is recommended to pay attention to such comparative qualities as:

- polystyrene foam is much lighter than mineral wool;

- expanded polystyrene absorbs moisture less and does not lose its properties when wet;

- basalt mats have greater bending strength, which makes it possible to insulate surfaces with complex configurations;

- the fire protection characteristics of polystyrene foam are significantly lower than those of its competitor;

- Polystyrene has virtually no vapor permeability.

Which material is better in use?

Polystyrenes burn, the house can burst into flames like a match.

In principle, the installation is almost identical, so there is no particular difference whether mineral wool or polystyrene foam is used. What shows itself better during operation is another question. Here we will look at several aspects:

- shrinkage;

- fire safety;

- toxicity;

- mice.

Polystyrene foam and its derivatives do not shrink at all. Low density mineral wool can settle, but at a density above 85 kg/m. a cube and a wall height of up to 3 meters is unlikely. If you select thermal insulation according to manufacturers’ recommendations and adhere to the correct installation technology, then this problem will be completely eliminated.

Polystyrene foam and EPS cannot boast of fire safety. Both materials support combustion and at the same time produce toxic smoke. You need to be extremely careful with this material; if a fire occurs, the insulation will burn out very quickly. Mineral wool does not burn at all; it can withstand temperatures of 750 degrees. It is even used to insulate chimneys. Foam plastics are toxic and full of carcinogens, no matter what marketers say about its environmental friendliness. Many types of mineral wool are also harmful, as they contain phenol formaldehyde, while there are acrylic-based materials that are absolutely safe.

Another problem is mice. They successfully live in both foam plastics and mineral wool, although they prefer polystyrenes. In the book “10 thousand tips and teachings for all occasions” from the 1955 cartoon “The Enchanted Boy,” little Nils read: “To get rid of rats and mice once and for all, it is best to buy a young and healthy cat.” The advice is still relevant today.

What is better to insulate with polystyrene foam?

This material has proven itself very well in places where air humidity is quite high but insulation is required.

- Foam plastic will not do anything when in contact with wet ground, so it can perfectly insulate foundations, as well as various engineering structures located underground. Tens of years will pass, and the insulation will remain the same as at the very beginning. It is often used in the construction of multi-layer foundations as a middle layer. It turns out to be a very reliable and high-quality foundation.

- When building houses without basements, on a monolithic foundation, it is also convenient to use polystyrene foam. Plates of this material are laid on a leveled area, and then a layer of concrete is poured on top of them. The slabs themselves can be either one row or several. After the concrete has hardened, the walls of the house begin to be erected.

- To prevent the foundation of the house from freezing, it is very effective to insulate not only its vertical, but also its horizontal part with polystyrene foam. Expanded polystyrene slabs are laid along the foundation. Then they are backfilled, if necessary, additionally laying a waterproofing layer. This method of insulation reliably protects the foundation from frost.

- The walls of houses (both inside and outside) can also be effectively insulated with polystyrene foam. It is best if these walls are block or brick. A high thermal insulation effect is achieved when using polystyrene foam to insulate interior spaces, and the formation of a dew point is not observed.

- For non-ventilated roofs (warm, flat roofs), the PSBS grade of expanded polystyrene is used. A waterproofing layer must be placed on top. For cold roofs that are ventilated, thermal insulation is carried out differently. The inside of the roof is insulated with polystyrene foam, leaving space for ventilation. This prevents water vapor from condensing.

- It is also good to insulate floors and ceilings between floors with foam boards. A layer of insulating material is placed under them, and concrete is poured on top.

- A variety of packaging is also made from polystyrene foam, and it is also used for thermal insulation of refrigerators, freezers and special isothermal vans.

Installation

Both extruded and regular foam have greater strength and elasticity than insulating wool. It is easy to cut and sanded without problems, but gluing it without joints at which cold bridges form is very difficult. The solution in this case is an L-shaped edge on sheets.

In the case of felt insulation, sufficient elasticity is present only where the mineral wool is produced in the form of mats laid in the frame or on the facade surface. But you don’t have to think about cold bridges here, because the joints between the materials are negligible. And again we can state a draw.

What is better to insulate with mineral wool?

- For wooden houses you don’t have to choose which is better - polystyrene foam or mineral wool. “Breathing” wooden walls cannot be insulated with foam plastic - this will negate their beneficial properties. Therefore, they are insulated with mineral wool. And in buildings built from other materials, partitions, floors, ceilings, and ceilings are sheathed with mineral wool. If external walls are insulated, then a ventilated façade of a suspended type is made. Vapor barrier membranes are an integral part of this design.

- Mineral wool is used to insulate attics, attics and floors of houses, and pitched roofs. At the same time, be sure to leave space for ventilation.

- Brick houses with a small number of floors, in which the middle thermal insulation layer is mineral wool. It is also used for three-layer panels made of concrete, reinforced concrete, as well as sandwich panels in a metal shell.

- They are used in places where it is necessary to provide good protection from very hot objects, since basalt wool can withstand temperatures up to 1000 0C.

- Frame buildings of any type are best insulated with mineral wool. In addition, it is also used for sound insulation. Moreover, this material is well suited for horizontal, vertical, and curved surfaces.

- Mineral fiber wool, produced in the form of soft slabs, can be used to wrap heat, water and gas pipes. It is also used to insulate industrial equipment in enterprises.

Service life

Manufacturers of expanded polystyrene and mineral wool indicate a service life of at least 50 years. To achieve this and extend the period of use, the insulation should be reliably protected from the influence of external factors:

- Penoplex - from ultraviolet radiation, which impairs performance characteristics.

- Mineral wool - from mechanical stress and moisture. Which can lead to deformation and shrinkage.

Users note the average service life of mineral wool is 25-35 years.

As for penoplex, there is no specific data, since insulation has appeared recently.

Video description

How to properly insulate the external walls of a house with penoplex, watch the video:

Therefore, to insulate the walls of a house from the outside, the best choice would be to use pegopolystyrene. Due to the lack of ability to absorb moisture, this material will last a long time without the use of additional construction membranes.

Therefore, when choosing the best way to insulate the walls of a house from the outside, penoplex or mineral wool, the best choice for insulating facades will be the use of PPS. Due to the lack of ability to absorb moisture, this material will last a long time without the use of additional construction membranes.

Mineral wool is used to insulate the facade of a private house or outbuilding in cases where it is possible to install a special sheathing. Often, insulation of this kind is combined with the installation of siding, since sheathing is also needed to prepare the walls. Therefore, when choosing stone wool or polystyrene foam, which is better for insulating the facade, what the exterior decoration will also matter

Application

In various situations, penoplex or mineral wool is used for thermal insulation.

What is better is determined taking into account the nuances of each specific case, climatic conditions, the material from which the structure is constructed, and financial capabilities.

What material to insulate what with?

The best way to carry out thermal insulation is determined by each owner himself, but there are a number of recommendations from professionals that will help make the right choice:

- You can insulate walls from the inside with both materials. But it is better to insulate wooden buildings with mineral wool. Because it has higher vapor permeability.

- It is better to insulate the foundation of a house, blind area, basement, and basement with penoplex foam, since it has higher strength and can withstand significant loads.

- The roof is insulated with both mineral wool and extruded polystyrene foam. Here the choice should be given, taking into account the material of construction. Most often, house floors, attics and attics are insulated with stone wool.

- For rooms with high humidity: car washes, baths, saunas, the use of polystyrene foam insulation is strictly not recommended.

It is impossible to say unequivocally which insulation is better. There are many factors to consider to make the right choice.

What is better to use for foundation insulation?

The construction of the foundation of a house is often associated with the need to insulate it. If the walls of a private house are well insulated, but the foundation and floor of the first floor are cold, then heat leaks are inevitable, as well as a violation of the comfortable atmosphere in the house. A foundation protected from heat loss provides:

reducing home heating costs;

Insulation of the foundation is possible in two options. The first is placing a heat-insulating layer around the perimeter of the house on top of the foundation.

The second is used in the process of making the foundation. If the installation is made of concrete, then at the pouring stage you can add a layer of insulation, thereby ensuring the installation of a warm circuit along all surfaces of the house that are at the temperature limit. Since pouring concrete involves so-called “wet” work, a material that is resistant to moisture absorption will be required. The best solution would be to use polystyrene foam or polystyrene foam. It is this insulation that will be able to retain heat in the house without losing its performance properties when in contact with an aggressive humid environment. Stone wool is not suitable for these purposes: during installation it may lose its shape, which will lead to a decrease in performance properties. In addition, during installation, moisture can get inside, which will lead to damage to the material.

There is another possible option: liquid polyurethane foam. This material is flexible and does not leave cracks or gaps.

Along with insulation, liquid polyurethane foam additionally protects the foundation from moisture. It is enough to apply a layer of 5 cm to ensure reliable protection of the foundation from precipitation. But there are also disadvantages: the high cost of the material, and the need to apply it using special equipment

Hygroscopicity of mineral wool and polystyrene

This is what installation errors lead to.

The second no less significant factor that will help determine whether foam plastic or mineral wool is better for insulation is hygroscopicity (the ability of the material to absorb moisture). Moisture absorption is measured as a percentage of the weight of the material per day. That is, how much moisture, as a percentage of its own mass, is absorbed by the insulation when immersed in water for 24 hours. Stated characteristics:

- polystyrene foam no more than 1%;

- extruded polystyrene foam 0.04%;

- mineral wool 1.5%.

The degree of water absorption of the insulation determines the possible areas of its application. For example, EPS practically does not absorb moisture, which is why it is used for laying in the ground. Polystyrene foam begins to crumble from moisture, and mineral wool, once wet, does not retain heat at all, so it is not of much use either. At the same time, based only on the hygroscopicity of materials, it is impossible to determine what is better to insulate a house with foam plastic or mineral wool

The issue needs to be considered holistically and the following characteristic is important

conclusions

When choosing durable and reliable insulation, many developers pay attention to mineral wool and polystyrene foam. Many inexperienced owners prefer mineral wool to polystyrene foam because it is environmentally friendly and has high vapor permeability.

However, this solution is not always optimal. This insulation is capable of allowing air and water to pass through. Moisture can settle on the inner surface of the facade. This can lead to freezing and destruction of the facade. The decorative layer deforms over time, and the insulation becomes like a sponge that has absorbed moisture.

Foam boards are capable of allowing air to pass through, but not too much. Since the material has no pores, and it itself is quite dense, moisture cannot pass through it. Due to the fact that air passes through the joints, a certain ventilation is created.

Advantages of expanded polystyrene assortment

Almost all the requirements of modern technologies are met by the high-density insulation Penoplex Foundation. The price of this material can rightfully be called moderate.

- The material combines effective heat conservation and a minimum level of loads on the insulated base, as well as moisture and frost resistance and preservation of working properties over a 45-50 year designated service life.

- Simple mastic-adhesive installation allows home craftsmen to partially or completely master the entire scope of work on their own. Assembly of panel cladding and sealing of joints is simplified by tongue-and-groove or step joints.

- Low thermal conductivity makes it possible to use 30 mm Penoplex panels for insulating building structures. Depending on design requirements, this figure can be increased to 50-60 mm.