The most popular building materials for insulating buildings are polystyrene foam and penoplex. They have many identical characteristics: light weight, ease of processing. But, nevertheless, they have certain differences. Therefore, it is necessary to figure out what is better for insulation: polystyrene foam or penoplex?

Foam plastic or penoplex - which is better?

Until recently, rooms were insulated with polystyrene foam. But over time, a new, more modern penoplex appeared, which has different properties than its predecessor, although the same raw materials are used for their manufacture. This article is aimed at determining the capabilities of these materials, their fundamental differences from each other, and helping to make the right choice.

Production of foam plastic and penoplex

Polystyrene is used to make these insulation materials, but their production itself is different. Thus, during the production of polystyrene foam, polystyrene granules are treated with steam, and therefore their volume increases 50 times. When gluing together, the output is a rather airy raw material, in which there are micropores and voids between the granules. To achieve high density, the granules must be well compressed to improve the quality of the material. Polystyrene foam is often called expanded polystyrene.

Foam production

To create penoplex, the extrusion method is used. Due to the significant temperature conditions and high pressure, a material with a uniform dense structure and excellent consistency is obtained. This product is also commonly called extruded polystyrene foam.

Penoplex production

Characteristics of penoplex and polystyrene foam

Penoplex is denser than polystyrene foam, which is why it weighs more and, therefore, can withstand a greater load. The tightness of the granules in the production of polystyrene foam is not strong, so in terms of its thermal insulation properties it is inferior to penoplex, which is highly compressed.

Penoplex slabs

In order for the protection against cold to be the same, you need to buy 25% less penoplex than polystyrene foam.

Penoplex belongs to the category of moisture-resistant materials. It has a water absorption rate of 0.35%, while for foam plastic this figure reaches 2.0%. Foam plastic has a greater degree of vapor permeability than penoplex, for which this value is almost zero. But it is worth noting that these two insulation materials have a very low degree of vapor permeability.

Foam boards

As for fragility, foam loses here. It is more fragile, easily crumbles and breaks, and is afraid of bends. The strength of penoplex is 6 times greater, and it cannot be broken without much effort. It also bends well, which compares favorably with polystyrene foam.

In terms of operating time, both of these materials will last quite a long time, but penoplex will retain its qualities longer. Over time, the foam will begin to crumble.

Polystyrene foam is more fragile than polystyrene foam

You need to know that both of these insulation materials are afraid of bright sun and negative atmospheric influences.

Polystyrene foam and polystyrene foam can be cut with an ordinary knife, but when working with the first material, great care must be taken, as it may break. Especially when it comes to three-centimeter sheets.

If we take into account the pricing policy, the cost of polystyrene foam is much less, so in the construction of high-rise buildings this insulation is used so that the cost of the project does not increase. It is also chosen by those who have limited financial capabilities.

Gnomes

Let's make some more helpers for grandpa. We have to design holiday gnomes. Prepare:

- small bumps;

- wooden balls (look for materials with a diameter greater than two centimeters);

- felt;

- glue;

- threads;

- felt-tip pens.

Cute creations are made quickly. These DIY pine cone crafts are among the most interesting crafts. Be sure to involve him in this magical creativity.

Making holiday gnomes:

Gnomes (Step 1)

- Let's start the creative process by making a hat. For gnomes it has a triangular shape. You can choose any height for your product; in our case, the cap measures about six centimeters. Roll the material until a cone is formed. We sew the fabric and cut off the excess. Turn the cap inside out.

- We cut out miniature mittens from the same material. Glue them to the bump. The product can be improved. And do as shown in the example. Glue chenille wire to the cone and then mittens to it. You can do it easier and simply replace such handles with plasticine ones.

- Cut out fabric hearts. We'll need them for our legs. We glue the material at the base of the cone. If you notice that the craft is unstable, replace the fabric with plasticine.

- Place a bead on the top of the cone. This is the head. We put a hat on her. To prevent it from falling off, the material can be placed on glue.

We draw eyes and a mouth. DIY children's craft gnome made from a pine cone!

We have already described earlier how to make autumn crafts for school, we propose to supplement the list of crafts with several more products that can be created.

Properties of foam plastic

Polystyrene foam belongs to the category of artificial materials; it is not afraid of corrosion, excessive humidity, and is not afraid of the harmful effects of external factors. In its basic properties it is similar to mineral wool and is practically in no way inferior to it. Its density is slightly lower, and its thermal conductivity is slightly lower.

Walls insulated with foam plastic almost stop breathing. To prevent condensation from forming between the wall and the foam, it is necessary to correctly calculate its thickness so that the dew point is in the insulation itself.

The average thermal conductivity of polystyrene foam is 0.037-0.047 W/m °C. It can be used at temperatures from -40 degrees to +70 degrees. According to the flammability class, it is classified as a fire hazardous material. Such insulation can be safely used for about 30 years.

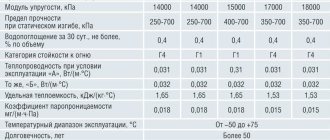

Properties of penoplex

It is widely used for floor insulation, and there is no need for a full-fledged frame. Its thermal conductivity indicators are significant, which makes it possible to use it in small quantities.

If floor insulation with polystyrene foam requires a thickness of 8-11 cm, then with penoplex this figure decreases to 3-4 cm. Moreover, the floor will be warmer than with polystyrene foam. This makes it possible to widely use penoplex in the Far North with its critical sub-zero temperatures.

Floor insulation with penoplex

Penoplex has absorbed the best properties of polystyrene foam, only improving them significantly. This means good strength and low breakability. As for flammability, it is lower compared to polystyrene foam. In terms of cost, it is superior to polystyrene foam, but the price-quality ratio is excellent.

Balcony insulation with penoplex

This material tolerates operating temperatures from -50 degrees to +75 degrees and will last for half a century without losing its capabilities.

What to look for when choosing

Extruded polystyrene foam Penoplex is produced in the form of slabs of various markings - Penoplex 35, 31, 31С, 45С, 45, 75. Moreover, recently the marking of slabs 35, 31, 31С has been replaced by new types:

- 35 (without fire retardants) - Penoplex-Foundation;

- 35 — Penoplex-Roof;

- 31 - Penoplex-Wall;

- 31C - Penoplex-Comfort.

The average consumer is unlikely to be interested in super-dense slabs marked 45C, 45, 75 to solve pressing insulation problems.

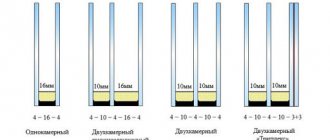

Plates with increased strength are used for thermal insulation of load-bearing structures of buildings and structures, road surfaces, for loaded structures and airfield runways. The thickness of the slabs is 40, 50, 60, 80 and 100 mm, and the size is 600 by 2400 mm.

Therefore, the question of choosing between the materials expanded polystyrene and penoplex 45 or 75 is raised only on an industrial scale.

An ordinary buyer, as a rule, needs to choose one of two options - expanded polystyrene or penoplex 35? Or, in light of the latest innovations from the penoplex manufacturer - Penoplex-Foundation, Penoplex-Roof, Penoplex-Wall and Penoplex-Comfort.

The new labeling of thermal insulation boards speaks for itself here. Extruded polystyrene foam or Penoplex 35 is divided by the manufacturer into two types - without the use of special treatment to reduce flammability for Penoplex-Foundation and with impregnation with fire retardants for Penoplex-Roofing.

Expanded polystyrene Penoplex-Comfort is the most versatile brand of material. The slabs are used for thermal insulation of balconies and loggias, roofs, walls, plinths, foundations and floors, as well as insulation of garages and outbuildings.

The almost complete waterproofness of the slabs makes it possible to use them for thermal insulation of bathhouses, saunas and swimming pools with high levels of humidity. The thickness of the slabs is 20, 30, 40, 50, 60, 80 and 100 mm, and the size is 600 by 1200 mm.

Prices

The production of both expanded polystyrene and penoplex is quite cheap. What is their retail price?

The price of extruded polystyrene foam and penoplex with the most minimal parameters (density, thickness, quantity per package) starts from 1000 rubles, respectively. and 1200 rub. per package. Conclusion - the brand name of various manufacturers also matters when choosing and purchasing insulation.

Penoplex turned out to be the most expensive insulation among all brands of extruded polystyrene foam. And with an increase in the characteristics of heat-insulating boards of different brands, the price correspondingly increases further - up to 3,000 rubles. and 4200 rub.

The cost of expanded polystyrene (foam) also depends on the physical characteristics and manufacturer and is in the range of 1000 - 3000 rubles. per package. The price of penoplex and expanded polystyrene on the building materials market is slightly different in favor of the latter.

The small price difference between expanded polystyrene and penoplex is most likely due to the more complex manufacturing technology of penoplex. or maybe the seller’s trade markup is too high.

Pros and cons of penoplex

Like any other insulation, penoplex has its own positive and negative properties.

| Advantages | Flaws |

| Low vapor permeability, preventing the absorption of moisture, water and condensation | Excessive fire hazard |

| Low thermal conductivity | May be damaged by rodents |

| Excellent durability | Capable of melting and flaming |

| Ability to withstand significant loads | Requires special handling to minimize the possibility of fire |

| Significant service life of the material | |

| Simplicity and speed during installation work | |

| Light weight | |

| Good combination of "Price - Quality" |

Concept of polystyrene thermal insulators

Polystyrene foam, like expanded polystyrene, is made from the same material, but using different technologies, and therefore has a number of differences.

Polystyrene foam is formed as follows: styrene granules are heated with steam for a long time, it expands and takes the shape of a slab. With prolonged exposure to heat, the material hardens, becomes hard, and pores form on the surface, due to which the foam breaks down into individual granules over time.

Expanded polystyrene or, as they also say, extruded polystyrene foam. Its manufacturing technology is slightly different - styrene granules are initially filled with a certain gas, then the whole mass is heated so that it begins to expand. After which it is extruded using an extruder into a special shape, this is necessary in order to obtain a more uniform structure of the material and strengthen the bonds between molecules. When the material fills the entire workpiece (block), it is pressed - this increases the quality characteristics of polystyrene foam. After the material hardens, a block of penoplex is obtained, which is sold in stores.

Pros and cons of foam plastic

When choosing insulation, you must first become familiar with its strengths and weaknesses. So, the main positive and negative aspects of polystyrene foam are the following:

| Advantages | Flaws |

| Affordable price | During the combustion process, toxic substances are released that have a negative impact on the human body. |

| Excellent thermal insulation properties | Possibility of releasing harmful substances even with a slight increase in temperature |

| Light weight | Able to create a vapor barrier |

| Wide range of applications and versatility | Hygroscopic |

| Long service life | Does not tolerate direct sunlight |

| Resistant to fungal growths and various microorganisms | Can be destroyed by rodents |

| Easy to install | Instability to various types of solvents has been revealed |

| Environmentally friendly product | Does not tolerate mechanical damage well |

| Noise insulation is minimal |

Foam plastic or penoplex: which is better for external insulation

If we take into account the fact that penoplex is superior in density to polystyrene foam, nevertheless, residential buildings are insulated from the outside with the latter.

Here are the vapor permeability coefficients of some materials, including polystyrene foam:

| Material | Vapor permeability, mg/(m*h*Pa) |

| Brick | 0,11 |

| Concrete | 0,03 |

| Drywall | 0,075 |

| Pine, spruce | 0,06-0,032 |

| Mineral wool, stone | 0,3-0,37 |

| Mineral wool, glass | 0,5-0,54 |

| Styrofoam | 0,05 |

As we can see, the values of foam plastic are more or less comparable to the vapor permeability of brick, concrete and pine. Although polystyrene foam boards can “breathe,” they nevertheless transmit steam rather poorly. Thus, it is necessary to keep in mind that condensation does not appear in the structure of a building with insulation. Although foam plastic does not get wet, there is nothing good about walls wet from condensation. In other words, before installing insulation (any kind, not just foam plastic), it is necessary to accurately calculate its thickness, taking into account the temperature inside the house, the temperature outside, the level of air humidity, the thickness and material of the walls, etc.

Insulating the outside of the house with polystyrene foam

Penoplex is also used to insulate the external walls of buildings, but a vapor-permeable membrane must be laid between it and the building, which will automatically lead to an increase in the cost of the facility and an extension of construction time. As for non-residential buildings, insulation is carried out with both one and another material.

Insulation of external walls with penoplex

Expanded polystyrene is used, among other things, for insulating ceilings. But it is preferable to use penoplex compared to its competitor. There is one advantage that needs to be taken into account: foam plastic does not need to be covered after it is installed, as it is strong enough to support human weight. With polystyrene foam it is more difficult in this regard. It requires a hard covering, such as covering with boards.

Roof insulation with penoplex

Expanded polystyrene foam can be used to fill frame structures. This makes it possible to build such structures at high speed, but the soundproofing properties there will be minimal. But there are buildings that do not need sound insulation at all.

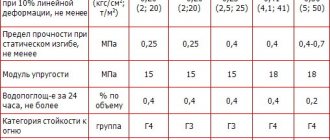

comparison table

Many people find it difficult to decide which material to use for insulation: polystyrene foam or penoplex.

A comparative table of insulation materials will help you decide which is better.

| Properties | Styrofoam | Penoplex |

| Density (kg/m³) | 11-40 | 25-47 |

| Compressive Strength(MPa) | 0,05-0,16 | 0,2 |

| Flexural strength (MPa) | 0,7 | 0,5 |

| Water absorption (%) | 1-2 | 0,5 |

| Thermal conductivity (W/m•°C) | 0,029-0,032 | 0,039 |

| Fire resistance | G3-G4 | G1-G4 |

Indicators vary depending on the type of insulation chosen. Accurate information about the characteristics of the purchased thermal insulation material is indicated in the technical documentation.

Foam plastic or penoplex: which is better for internal insulation

It is preferable to carry out such work using penoplex. If its properties are inferior to foam plastic for external work, then for internal insulation it is several times superior to it. Its positive properties, such as moisture resistance and airtightness, make it possible not to create an additional vapor barrier between the insulating materials and the wall of the building itself.

But insulating premises from the inside is a necessary measure, and from the outside the object remains unprotected from temperature changes and negative atmospheric phenomena. It is also worth remembering the possible release of harmful substances from such building materials into the room.

Floors are insulated with penoplex and foam plastic. In this process, they are almost equal in their characteristics, given their fire resistance and environmental friendliness. These materials are currently widely used when laying heated floors.

Floor insulation with foam plastic

It is worth noting that after installing polystyrene foam boards, they are hidden under various other coatings, so most of their negative qualities are negated.

What material to choose for home insulation

When comparing the described materials, you will notice that they have similar characteristics. But it should be noted that penoplex is more durable and moisture resistant. It has better thermal insulation characteristics, as it is a denser material. But it should be remembered that without special treatment it is more flammable than polystyrene foam. But after all the necessary processing work has been carried out, it is safe and if a flame occurs, it does not contribute to its spread.

When choosing rigid foam, you need to take into account that it has lower sound insulation characteristics. Polystyrene foam retains heat better in a building, as it has a looser structure. But because of this, it can partially absorb moisture. In order for this insulation to last longer, it is necessary to cover it with protective compounds.

When considering the features of polystyrene foam and extruded polystyrene foam, it is important to consider that if installed incorrectly, the effectiveness of the insulation can be greatly reduced. That is why, if you are unsure of your abilities, you should hire professional builders

When purchasing, you should take into account that penoplex has a higher cost and is divided into several types

When purchasing, it is important to choose the best option for your own home. For example, some types of this insulation are intended for foundations or underground structures

Others can be used to insulate facades and floors of country houses.

To decide what exactly is right for your home, polystyrene foam or polystyrene foam, you should take into account the amount of money you are willing to spend on insulating your home, as well as the climate of the region

It is also important to consider the purpose of using the material. If it is necessary for installation on a foundation, preference should be given to polystyrene foam

You should also remember that it is a more modern insulation material and is better protected from the effects of the external environment. Every year, manufacturers add new components that make the material safer.

Areas of application of foam plastic

In addition to the already given examples of insulation of walls, floors and roofs, polystyrene foam is also used in the following cases:

- For insulating the foundation. It is recommended to insulate it to the depth of soil freezing - that is, on average 1 meter. But it is best to completely insulate the surface of the foundation, and then backfill the pit. It is very important that a continuous thermal insulation contour is maintained between the walls of the foundation or basement and the walls of the first floor of the building. This leads to the absence of cold bridges. If it is planned to build a three-layer wall, which consists of a base, insulation and a decorative wall, then the same structural elements must be in the basement so that the thermal insulation layers can be connected. The same principle of insulation is used in relation to the two-layer wall of the foundation and basement. The only drawback is that the rigidity of the slab does not allow it to adhere tightly to an uneven surface. Therefore, dowels with wide heads are used.

- For insulating the attic. To insulate the slopes of a residential attic, foam plastic is placed as follows: on top of the rafters, while they remain open, decorating the room, or between the rafters, then the foam plastic is carefully cut and additionally fastened, which significantly increases the duration of construction and the cost of specialized teams. Polystyrene foam can also be attached to the supporting frame or under the rafters, but this will significantly reduce the overall volume of the room.

- To insulate flat roofs, polystyrene foam with special rigidity is used. The base is mainly concrete, rarely corrugated board or wood. Moisture insulation in the form of roofing material or film is spread on top, and then foam plastic is tightly laid.

Differences in laying technology

*

It is better to install the sheets outside the building. The production technology of extruded polystyrene foam involves the transfer of the “dew point”. External thermal insulation can reduce heat loss by half. The slabs are covered with plaster or siding.

Important! To make effective thermal insulation and improve the quality of sound insulation, the slabs must be placed tightly. Laying work begins from the bottom, otherwise the material on uncured glue will slide down.

Penoplex is attached in 2 ways:

- On glue. For reliability, the fastening of the slabs is reinforced with umbrella dowels;

- Ventilated facade. A sheathing is made from wooden slats or a metal profile, insulation is placed in the cells, and everything is covered with cladding.

When thermally insulating the facade of a house with polystyrene foam, unusual decor is often used. Penoplex is covered with various plaster and mosaics, and other materials are used that distinguish them from other buildings.

Cleaning the wall from old layers of paint

It is better to use slabs with a tongue-and-groove edge. This makes it possible to prevent the appearance of cracks and cold bridges. Penoplex brand PPS 25-RG-B is often used.

Areas of application of penoplex

This thermal insulation material is used in various fields of construction:

- To protect the foundation. This material has a number of positive qualities. If you use such insulation, the depth of soil freezing decreases, therefore there is no need to lay a deep foundation. This makes it possible to reduce the work of digging a pit and arranging a deep concrete foundation, which could lead to additional financial and labor costs. At the same time, moisture will not penetrate into the foundation, which will have a positive effect on the human body due to the provision of a favorable microclimate. Moreover, the presence of penoplex helps to save on heating costs.

- For insulation of basements. Due to the fact that penoplex is a moisture-resistant material, it can be laid on top of gravel, which is used as a rough floor covering. If there is a foam concrete base, it is first covered with waterproofing, and then penoplex is laid. If the floor on the ground floor is supposed to be warm, then the waterproofing layer is increased.

- In order to insulate balconies and roofs. Penoplex is light enough, so it will not unnecessarily load the floor slabs on the balcony. You can install this material yourself, thereby reducing the cost of paying for thermal insulation work. As for the roof, it helps reduce heat loss and the service life of the roof is significantly increased. In this case, penoplex is laid on the outside of the roof in such a way that there remains a cavity for ventilation, which can minimize the evaporation process. Before thermal insulation work is carried out, the roof is cleaned, waterproofing work is carried out, then foam boards are installed.

How to untangle small knots

- This method is suitable in cases where the hair is not severely damaged and there are no complex (large) knots on the hair.

- To begin manipulation, choose a comfortable place with good lighting. The treatment is performed on dry hair, so there is no need to wet the curls.

- Take the tangle in your hand so that it is clearly visible. Start taking out one hair at a time, gradually stretching each of them to its full length. Your movements should be carried out from the tips to the roots, that is, from bottom to top.

- If you don’t have the time or patience for such activities, use a wide-tooth comb. Do not process the knot itself, carry out normal combing from the tips to the root area.

- In this case, with a comb you risk tearing the hairs. To prevent this, use special sprays or gels that make combing easier. They are marked accordingly; the products do not require rinsing.

Date: September 25, 2022