Low density and light weight, excellent thermal characteristics and good sound insulation make polystyrene foam one of the most popular thermal insulation materials. Modern technologies make it possible to produce various types of foam, which differ in characteristics, cost and purpose. Knowing the differences will help you choose the optimal material for various jobs.

Polystyrene foam is, first of all, an excellent heat and sound insulator. A small layer of such a heat insulator can retain heat inside buildings even in the coldest winters. Almost everything can be insulated with this material: external and internal walls, roofs, floors and even pipelines. Due to its low weight, even a thick layer of foam does not exert a significant load on the floors, supporting structures or foundation.

What are the benefits of using polystyrene foam?

• reduction of costs for construction and installation work;

• saving thermal energy for heating buildings;

• reducing the cost of heating equipment (achieved by reducing its quantity);

• reducing the structural thickness of walls, allowing to increase the usable area of buildings;

• creation of increased thermal comfort of buildings;

• environmental safety of the building structure.

FIRE RESISTANCE is one of the most important characteristics that a high-quality building material must meet. Expanded polystyrene does not support combustion, and its flash point is almost twice that of wood. In addition, when burning, foam releases 8 times less energy than wood. This means that the flame temperature when burning polystyrene foam is lower. The foam is flammable only in direct contact with an open fire. When the exposure ceases, self-extinguishing occurs within 4 seconds. Such characteristics make it a fireproof building material.

The only drawback of polystyrene foam is that when burned it releases toxic gases into the atmosphere. Therefore, during the construction of a building, the possibility of contact of insulation with open fire should be prevented.

Polystyrene foam does not have a high density (50 times lower than that of water), but, nevertheless, it shows excellent resistance to uniform mechanical loads, both tensile and compressive.

Polystyrene foam can withstand pressure for years without deforming, collapsing, or changing its physical properties. A clear illustration can be its widespread use in the construction of runways. The strength indicator largely depends on the thickness of the polystyrene foam board and on compliance with the rules for its installation.

The durability of polystyrene foam was revealed during studies, both in laboratory conditions and in natural conditions. Since polystyrene foam is essentially plastic, scientists expected high durability. During the research, their expectations were fully justified.

Thus, expanded polystyrene is able to maintain its original thermophysical properties for several decades without deforming or losing its structure. It was also found that it is able to withstand short-term exposure to low (limit -180ºС) and high (+95ºС) temperatures. This makes expanded polystyrene an ideal insulating material in the Russian climate, and also expands the scope of use of the material - for example, let’s allow its contact with molten bitumen.

Which side to mount

Slab polystyrene foam 25 is installed on the outer surface of walls, foundations, and roofing pie. The material is suitable for insulating balconies, loggias, house facades, and is used on the outer walls of garages, swimming pools, and pitched roofs. Expanded polystyrene is not installed indoors. This is explained not only by the flammability of polystyrene foam, but also by thermal engineering rules: when installing insulation inside, the dew point shifts and the wall begins to freeze. External installation of polystyrene foam heat insulator protects the wall from cold, freezing, dampness, and moisture does not condense in it. After completion of the work, the room becomes warmer, the noise level from the street decreases, and dampness disappears from the walls.

What is foam made from?

Polystyrene foam can be made from any polymers (plastics). The most well-known raw materials are polyurethane, polyvinyl chloride, phenol-formaldehyde, polystyrene and others. But no matter what plastic the material is made of, it contains only 2% of it, the rest is atmospheric air. Domestic building materials are produced in accordance with GOST 15588-2014 and are designated by the general marking PSB, to which are added numbers and letters that indicate additional properties: low density, self-extinguishing, universal and others. The raw material for expanded polystyrene looks like translucent beads with a diameter of 0.2 to 3.7 mm. The material is produced in several stages:

- Foaming.

- Drying.

- Stabilization.

- Cutting.

- Maturation.

- Baking.

One of the methods involves, after stabilization, moving on to baking, bypassing the 2 previous stages. Not so long ago, a modern version of the material appeared on the market - extruded foam. It differs from the classic one in the smaller size of the cells and their complete closure. This material was considered more technologically advanced, but ordinary polystyrene foam is still the most in demand; it can be used as insulation for walls made of any materials: wall blocks, concrete monolith, wood, brick and much more.

Creating a wireframe

The frame is a structure that serves as a hanging base on the walls of the house for installing insulation. It is made from metal profiles or wooden blocks located horizontally and vertically. Then the sheathing is installed on the guide profiles, onto which the slabs in turn are fixed. The frame structure is attached to the wall with anchor dowels and nails. The reliability of the entire insulating structure depends on the strength of the frame fixation.

produces high-quality foam plastic of various densities. If you have any questions, we invite you to contact us by phone +375 (33) 661-98-08 or +375 (44) 78-78-333.

Specifications

| Options | Values | Comments |

| Compressive strength at 10% linear deformation | From 0.05 to 0.16 mPa | Strength indicators directly depend on the polymer from which the foam is made. For example, phenol-formaldehyde has higher strength values. |

| Thermal conductivity | From 0.038 to 0.043 W/mGrad | The parameter also depends on the brand of building material. |

| Frost resistance | Up to 200 cycles – regular Up to 500 cycles – extruded | Characteristic values depend on the brand |

| Water absorption | 1% per day | Tests showed: 3% of the volume for 1 month of complete immersion in water. The parameters are insignificant, however, if moisture gets into the polystyrene foam, it can subsequently freeze when cold weather sets in. |

| Vapor permeability, coefficient | 0.03 mg/mhPa | This building material does not create natural air exchange between indoors and outdoors. |

| Fire resistance | Flammability G3-G4 Flammability B2-B3 Smoke generation D3 | Expanded polystyrene is considered a highly flammable material |

| Cost of foam | On average 3 thousand rubles per 1 m3. | Polystyrene foam is quite affordable, the price depends on the brand and thickness. |

| Soundproofing | Depending on the thickness, it can increase protection up to 32 dB | Expanded polystyrene is characterized by high performance, but is inferior to other materials, for example, mineral wool |

| Environmental friendliness | Safe | It has no radioactivity and is completely recycled, since no toxic raw materials are used in production and a minimum of energy is consumed. |

| Life time | From 13 to 80 years | The value of the indicator depends on the manufacturer, production technology and raw materials. |

| Foam density | From 11 to 40 kg/m3 | The characteristics depend on the brand. |

Standard sizes of polystyrene foam - thickness varies from 20 to 100 mm, length and width: 1000*1000, 1000*1200, 1200*1200. How much foam plastic costs depends on the dimensions.

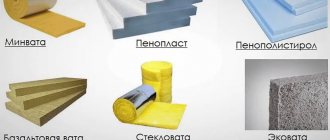

Types of foam

Divided into the following types:

- polystyrene;

- polyethylene;

- polyvinyl chloride;

- polyurethane.

Polystyrene

There are two ways to produce this type of foam:

- Pressless . This variety is familiar to every person. When buying home appliances, you can pay attention to the fact that they are packaged in foam plastic, consisting of small balls fastened together. It is very fragile and can be crushed and broken by hand.

- Press . But this type will be much more difficult to crumble. The granules of such foam are more tightly bonded to each other. The production technology is much more complex and more expensive than that of the non-press type, so it is much less common.

There is such a variety as extruded foam , it is practically no different from non-pressed foam.

Polystyrene types of foam have one significant disadvantage - high hygroscopicity .

We recommend: Linoleum flooring, what it is, types, characteristics. How to choose the right one for your home?

Water vapor enters the cavities that are located between the “balls” and granules.

This material “does not breathe”, so the steam does not escape anywhere and when exposed to sub-zero temperatures it can freeze, destroying the structure.

Even in the absence of exposure to cold, the accumulated steam worsens the thermal insulation properties of the foam and increases the humidity in the room.

Extruded foam plastic does not have such disadvantages, since it is homogeneous in its structure . It is common in the production of disposable cutlery, tableware, and food packaging.

As for the durability of polystyrene foam, we can say that for non-pressed foam it will range from 10 to 35 years . Extrusion will last much longer, about 50-70 years . Of course, the service life directly depends on the manufacturer of the material and the impact of destructive factors at the installation site.

Polyurethane

One example of polyurethane foam is foam rubber . It has a porous structure, good air and steam permeability, and high elasticity. It is used in furniture production, both as upholstery and as a filler.

Based on it, many household items are made. It is highly flammable and releases hazardous substances that are more toxic than polystyrene foams. The reason for this is hydrocyanic acid in the composition. It is extremely short-lived, turns yellow and is destroyed when exposed to external factors such as ultraviolet radiation.

Polyvinyl chloride

Polyvinyl chloride itself is a thermoplastic polymer that contains up to 56.8% bound chlorine , which makes it difficult to burn. It can be produced using both press and non-press methods. Its properties are similar to extruded polyethylene foam.

It contains no toxic substances. When burning, polyvinyl chloride foam extinguishes on its own.

It is highly elastic, but can corrode metal structures next to which it is located.

Polyethylene

It occurs quite often in everyday life. It looks like a translucent film consisting of air pimples.

It is used for wrapping fragile items and easily damaged equipment and does an excellent job of protecting against damage.

Polyethylene foam is very elastic and has different thicknesses, from a few millimeters to several centimeters. It is similar in strength to extruded polystyrene foam, but its distinctive feature is its non-toxicity. It is considered an environmentally friendly material with a long service life. Flammable.

Disadvantages of polystyrene foam

This material is very popular and is used almost everywhere; it occupies a leading position in the demand for thermal insulation materials. Can be used both for domestic purposes and in mass construction . Despite its popularity, many simply do not know all the shortcomings that this product has.

Highly flammable

Despite the many different types of foam, none of them can withstand fire for a long time ; if exposed to high temperatures for a long time, it will ignite and turn into a liquid mass. The smoke released during combustion can paralyze the human respiratory system.

We recommend: What is building reinforcement, what is it used for and where is it used? Production, characteristics, types and selection criteria

It is because of this disadvantage that the material is not suitable for finishing ventilation. There will be a constant flow of oxygen and empty space. In this case, putting out the fire will be very problematic.

Fragility

It is quite difficult to install this material correctly; it crumbles and breaks a lot . Very fragile: for example, if the ceiling is insulated with polystyrene foam, then walking through the attic can damage the insulation.

Hygroscopicity

Hygroscopicity is the property of a material to absorb moisture . It is not recommended to use polystyrene foam in damp, damp areas. It will not be the best choice for finishing a basement or bathroom, but extruded polystyrene foam will stand up to such a test.

High sensitivity to solvents

When gluing foam boards, you must make sure that the materials are compatible. Some adhesives can corrode foam .

Excellent housing for mice

This building material has all the properties to make mice want to settle there: it retains heat well, is easy to “gnaw through” and provides reliable protection.

To avoid this, you need to cover the material with mineral wool, which will repel rodents with its pungent odor. You can cover the foam with metal inserts - this is labor-intensive, but they will become an insurmountable barrier for mice .

Fragility

The material will have to be changed approximately every ten years, and even earlier if it is exposed to destructive factors.

Toxicity

Polystyrene foam is dangerous not only when burning. Due to prolonged exposure to time and lack of timely replacement, it begins to produce a harmful substance - styrene monomer .

When installed in an unventilated room, there will be a specific odor that has a negative impact on human health.

Vapor barrier

During installation, it should be taken into account that foam plastic “ does not breathe ,” therefore, if you install it in a room without artificial ventilation, this will result in increased humidity and constant condensation on the glass.

Difficulty in installation due to the large number of joints

It is very difficult to thermally insulate surfaces of complex shapes . The foam sheets are quite small and it will not be possible to cover the ceiling or floor with one monolithic layer.

You will have to spend a lot of effort to fit the insulation tightly and seal all the joints.

In conclusion, we can say that polystyrene foam has a number of qualities that are not characteristic of other materials, therefore, it is indispensable for some construction work: thermal insulation, design.

Its popularity is widespread, even despite some disadvantages. It's easy to use and fairly cheap, making it a great choice.

Installation of polystyrene foam under plaster

For external thermal insulation work, polystyrene foam is covered with a layer of plaster at least 3 cm thick. This construction technology is called “wet facade”.

First, a frame for slab insulation is attached to the outside of the building along the entire surface of the walls. Then it is hermetically sealed with polystyrene foam, and plaster is applied on top. Sometimes the slabs are immediately glued to the wall, additionally secured with umbrella dowels.

The method allows you to reliably insulate a building and protect fragile foam plastic with a plaster layer from mechanical stress or fire.

In order for the concrete solution to adhere reliably to the PPT slabs, the plaster layer is reinforced with a special mesh that is resistant to an aggressive acid-base environment. After the base base has dried, decorative plaster is applied to it, and the finishing is completed by painting the facade with paint for exterior use.