Izolon

The main purpose of the innovative material - isolon - is high-quality heat, sound, and waterproofing of any products and surfaces. The wide household and industrial use of the material is explained by its excellent efficiency in comparison with existing products for a similar purpose.

Izolon is an elastic foamed polyethylene with a closed-cell structure. With certain features of the technological process, “cross-linked” (PPE) or “non-cross-linked” (NPE) isolon is produced. Cross-linked polyethylene differs from traditional non-cross-linked polyethylene in its structure, which is changed at the level of molecular bonds. In individual molecular chains consisting of carbon and hydrogen atoms, a certain amount of the latter is torn off by a special effect on the material (due to the nature of the effect, polyethylene foam can be “cross-linked” by chemical or physical means). Due to the free bonds formed, the individual chains are connected to each other into a three-dimensional molecular network. The resulting connections are very difficult to break. Therefore, the output is a high-tech material of increased strength.

Specifications

Izolon PPE is produced by foaming polyethylene with gas (propane).

The result of this process is one of the best energy-saving polyethylene foam materials. Hence the labeling of isolon - PPE.

To enhance thermal conductivity, foil or metallized film is attached to its surface. To conveniently fix the material to the desired surface, a layer of glue is applied to one of its sides, and then a protective paper membrane is applied.

The structure of isolon PPE is heterogeneous. Its lightness and low density are due to the presence of air bubbles in its composition. Thermal insulation is sold in most cases in rolls, sometimes in sheets. The price depends on the thickness, density, size of the material, as well as the length and width of the roll, and the manufacturer of the product.

The minimum thickness of isolon is about 2 mm, and the maximum reaches 15 mm.

For construction work and insulation of premises, in most cases, material with a thickness of 5mm and 8mm is used.

The Izhevsk Plastics Plant is a major supplier of isolon, both in Russia and in a number of foreign countries. The excellent price-quality ratio of the products was highly appreciated by consumers.

An enterprise with a half-century history is engaged in the production of colored isolon in accordance with all required GOST standards. The palette of products can be very diverse, but the most popular materials are white and black.

Pros and cons of the material

Izolon has many advantages, for example, this material:

- characterized by high density and tensile strength, making it difficult to tear;

- convenient to cut not only with scissors, but also with a cutter, which allows you to create smooth and clear cut lines;

- is considered an environmentally friendly raw material for the manufacture of anything, and is also anti-allergenic and does not provoke allergic reactions;

- inert to combustion, it melts and is lightweight, and therefore does not weigh down large flower arrangements;

- does not mold, is resistant to water and moisture, and the formation of pathogenic microbes;

- adheres well to each other and other ornamental materials;

- may involve tinting with pastels, due to which life-size flowers can be made more similar to real ones;

- characterized by low vapor permeability, high levels of flexibility and elasticity;

- has no persistent chemical odor, does not emit toxic substances into the air, and therefore does not harm either humans or the environment;

- Can be painted with various dyes (including those based on rubber, as well as acrylic enamel).

The uniqueness of finished products made from isolon is the fact that they can be wiped with a damp cloth (with the exception of tinted fragments). At the same time, the service life of the flowers will be long, because isolon can keep its shape for more than one year in a row. This material has a certificate of quality and compliance with the required standards. However, in addition to the advantages, ornamental raw materials for life-size flowers have several disadvantages, for example:

- despite the assurances of manufacturers, sometimes suffers from transportation;

- not every type of material is suitable for creating large flowers, and therefore the choice must take into account the thickness of the raw material;

- Isolon attracts dust and becomes electrified, which is why it needs to be stored in plastic bags, and the crafts themselves should be treated with a special compound;

- is not a universal raw material for flowers of different sizes (the larger the flowers, the greater the thickness of the isolon should be).

As for the disadvantages of working with the material, to achieve a better result during the work you have to use a hair dryer. It is more powerful and allows you to give blanks cut according to templates the required shape. Another disadvantage of working with isolon is the need to strengthen the base in complex structures.

Despite the fact that the material itself weighs little, sometimes the finished composition tends to fall, which has to be resolved by selecting appropriate supports, playing up the aesthetics of their appearance.

Is it necessary to lay underlay under the IR floor?

- Creates a flat plane. Basically, a substrate made of extruded polystyrene foam is used for this purpose. Thanks to a special locking system, it is possible to create a completely level base.

- Does not allow heat loss. Infrared radiation is strictly directed in one direction, which avoids increased energy costs.

- Helps with installation of finishing floor coverings. The base for an infrared heated floor may vary depending on what kind of material will be laid on top.

What does a layered “pie” look like under a film floor?

Base. The plane is checked; if serious defects are found: drops, cracks, holes, the plane will need to be leveled. A layer of waterproofing is pre-laid. The beacons are placed and the screed is poured. Small unevenness can be smoothed out using leveling mixtures. In this case, a layer of waterproofing is not needed. Aluminium foil. Placed directly on the screed

Covering the base with foil is important to create a shielded surface that reflects radiation. Fiberboard sheets, magnesite plate. Placed on a concrete surface. Insulation is placed directly under the warm film floor

The joints of rolled materials are glued with bitumen film or special tape. IR floor film. An additional layer of underlay is laid on top of the mats, depending on the selected floor covering. So, cork material is suitable for laminate. The underlay in this case will eliminate the likelihood of extraneous noise when walking on the board. The minimum thickness of the underlay is selected depending on how well the floors are leveled. For tiles, you will need to lay a reinforcing mesh.

Insulation is placed directly under the warm film floor. The joints of rolled materials are glued with bitumen film or special tape. IR floor film. An additional layer of underlay is laid on top of the mats, depending on the selected floor covering. So, cork material is suitable for laminate. The underlay in this case will eliminate the likelihood of extraneous noise when walking on the board. The minimum thickness of the underlay is selected depending on how well the floors are leveled. For tiles, you will need to lay a reinforcing mesh.

What causes a chimney to deteriorate?

Leor plastic

It is important to understand the reasons why you need to insulate a chimney, because then you can direct your efforts specifically to combating the causes of destruction. Knowledge is power

There are 2 factors that directly affect the integrity of the chimney pipe.

- Dew point. If the chimney is not insulated, the dew point (or moisture condensation point) moves inward. Warm air that rises from the heating source reaches this point and settles on the walls in the form of droplets of moisture. If the chimney is made of brick, this moisture is absorbed and destroys the fireproof brick from the inside when freezing and turning into ice.

- Aggressive environment of exhaust gases. When burning, chemicals are released that can cause destruction of the chimney system. This is especially true for weak solutions of acids formed in the chimney - nitric or sulfuric. Such an environment can destroy even a stainless steel pipe with prolonged exposure. Again, this mainly happens when the dew point is shifted deeper into the chimney and the moisture does not completely evaporate from the chimney.

It seems that these 2 reasons convincingly show why insulating the chimney. It is worth considering the fact that an insulated chimney works 50 - 60% better than usual. Therefore, when creating a heating system project, be sure to take into account the costs of insulating the gas outlet pipe in the estimate.

Areas of application

Due to its properties, the polymer has found wide application in various fields:

- construction;

- mechanical engineering;

- automotive industry;

- medicine.

It is most common in the construction industry, where it serves as an excellent heat and waterproofing agent for structures and pipelines. For comparison, 1 centimeter of polyethylene foam thickness is similar in properties to 4.5 centimeters of natural wood and 15 centimeters of brick. It is one and a half times more effective than mineral wool and 20% more effective in terms of thermal insulation and noise-absorbing properties.

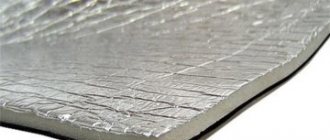

Aluminum foil glued on one side to a sheet or roll of foamed polyethylene helps to enhance the insulating properties. Concrete walls are lined with such mats, and they play the role of heat shields, reflecting infrared radiation into the room, saving heat several times more effectively than similar heat-insulating materials.

In the field of mechanical engineering, the material is widely used as a heat insulator for refrigeration equipment and air conditioning systems; noise insulation and vibration damping elements are made from it. The polymer is also the basis for double-sided tape, sealing and mounting tapes, as well as all kinds of gaskets.

In the automotive industry, it is impossible to imagine modern interior sound insulation or vibration insulation in wheel arches without polyethylene foam. The technical characteristics of the material also make it possible to make various seals and gaskets from it, which are used in almost any components and assemblies of modern cars. In heavy-duty refrigerated trucks, sheets of polyethylene foam are used to insulate luggage compartments.

In the field of medicine, the main property that has led to the widespread use of the polymer is its flexibility and ductility, as well as deformation under static loads and the ability to restore its structure after their removal. Foamed polyethylene is used for the manufacture of specialized products in the field of orthopedics - shoe insoles, corsets.

Foamed polyethylene is also widely used in the industry of goods for outdoor recreation and tourism, where it is used to make mats and various mats that allow you to sleep on the ground or snow without the threat of hypothermia.

The list of industries where this polymer is widely used is far from complete and is constantly updated. Regularly, regardless of industry, the material is widely used as packaging. Thanks to its flexible and elastic structure, it is used to wrap fragile household items - dishes, crystal, glass and porcelain, household appliances, plastic and wood products when transporting them over long distances.

Harmlessness and hygienic safety

ISOLON® has the following permitted areas of application according to the sanitary-epidemiological conclusion: “As a heat- and sound-insulating, floating material, for use in construction, transport, industry, in household goods, as packaging and cushioning material, including for contact with liquor, vodka and soft drinks, perfumes and cosmetics, products for children.” NPE polyethylene foam has a much narrower range of applications according to the sanitary and epidemiological conclusion: “As packaging and cushioning material for food products and consumer goods”

How to install reflective insulation on a concrete wall

How or with what can you glue or attach reflective insulation to a concrete wall? Thank you.

Reflective insulation is a lightweight, flexible material with a thickness of 4 mm or more, consisting of a layer of foamed polyethylene or other polymer, onto which aluminum foil or metallized film is glued on one or both sides. Foil thermal insulation materials are environmentally friendly, easy to install and significantly reduce heat loss.

Manufacturers of reflective thermal insulation materials do not exclude the use of glue during installation, but draw the attention of consumers that they are most effective if an air gap of 2 to 10 mm is created between the wall and the thermal insulation. After all, air is also an additional thermal insulation layer. The method of attaching reflective thermal insulation to a concrete wall is chosen depending on the type of material, capabilities, location and purpose of the room

In any case, the concrete wall must first be cleaned of dust and treated with an antiseptic, and if necessary, dried

The method of attaching reflective thermal insulation to a concrete wall is chosen depending on the type of material, capabilities, location and purpose of the room. In any case, the concrete wall must first be cleaned of dust and treated with an antiseptic, and if necessary, dried.

When insulating balconies or cold external walls with a heat insulator with a double-sided foil coating, it is necessary to fill the concrete with a lathing of slats 5-7 mm thick and attach the material to it with a construction stapler or glue. A second sheathing is mounted on top of the heat-insulating material for laying the finishing coating with an air gap.

When installing on reflective materials with a one-sided metallized coating, it is allowed to use rubber or acrylic-based adhesives such as 88-NP, Akrol Contact, Neoprene 2136 spray, etc. You can also use polyurethane foam, sealing sealant and double-sided reinforced construction tape . The adhesive composition is applied to the back side of the material pointwise in a checkerboard pattern or randomly, so that after gluing to the concrete the required air gap of about 2 mm remains.

Reflective insulation sheets are glued end to end and the seams must be taped with aluminum tape. As a result, an airtight coating is created on the wall, reminiscent of a thermos, onto which a lath of slats can be mounted to secure the finishing material.

Finally, if increasing the thickness of the walls is undesirable or impossible, self-adhesive foil thermal insulation material can be used for insulation. To install it, you only need to prepare the concrete surface and remove the protective film from the underside of the canvas, and after gluing, seal the joints with foil tape. But when fastened to the sheathing, the efficiency of self-adhesive metallized insulation is higher.

How to install reflective insulation on a concrete wall?

Tips on the method of fastening reflective thermal insulation to a concrete wall, depending on the type of material, purpose and capabilities of the room

How to choose isolon for insulation

The choice of material depends on the purpose. For sound insulation of interfloor ceilings and floor insulation, isolon with a thickness of 0.8 mm to 1 cm is most often used. When installing heated floors - from 2 to 4 mm, for laying laminate - from 2 to 3 mm.

Important! When installing a floor with a dry screed, one-sided foil-coated isolon is best suited. If the floor is made with a “wet” cement-sand screed, it is better to choose a double-sided one.

Depending on the purpose, different types of insulating material are used:

- Isolon “Tape” or isolon in tape is used to insulate ceilings and cracks. This is an excellent sealant for insulating window niches and loggias;

- Isolon “Block” is a sheet material used for internal thermal insulation of premises, external thermal insulation of seasonal auxiliary buildings, interfloor ceilings, flat and pitched roofs, foundations;

- For insulation of heating mains and other pipelines, foil-coated isolon is preferred, the performance characteristics of which are an order of magnitude higher due to the reflective layer.

Types of designs

Above is a description of the manufacture of two types of lamps: bedside and floor lamp. It should be noted that this manual can be adapted to other designs. Floor tall and bedside night lights can be installed not only on a stand, but also in a flower pot. To do this, take a pipe along the height of the lamp, a piece of pipe along the radius of the pot bottom and a corner.

Next, connect them and make a hole in the wall of the pot near the bottom along the diameter of the pipe. Insert the structure into the pot so that the end of the short tube looks out of the hole. Fill the space of the pot with a heavy solution for stability and allow it to harden. Now you can install the wiring.

A wall lamp can be made by taking a shorter pipe and bending it more compactly. What shape to give - your imagination will tell you. One of the options is a round or square spiral; it will turn out compact and original. After this, you need to insert the wire into the pipe. The finished lamp is hung on the wall, having first screwed in a screw and drilled a hole in the tube. Not only isolon can be used as a material for the lampshade. It can be made from corrugated paper and foamiran.

If desired, the stem can be decorated by wrapping it with adhesive tape of a matching color. Leaves are cut out of foamiran and modeled using glue and a hairdryer (the procedure of applying glue along the lines of the veins gives a natural effect). Then they are glued to a wire decorated with colored tape and inserted into the holes drilled in the pipe.

In addition to pink lamp buds, you can make voluminous chrysanthemums, peonies, asters, dahlias, as well as poppies, daisies and much more. Since izolon does not abound in shades, you can paint the finished product to your taste with acrylic paints or spray, or decorate it with an oriental slant. The many shapes of lamps and a wide selection of materials give room for imagination. Determine which ones will look best in your interior, stock up on materials and tools and create your masterpiece!

For a detailed master class on making a lamp from isolon, watch the following video.

Specifications

Izolon PPE is produced by foaming polyethylene with gas (propane).

The result of this process is one of the best energy-saving polyethylene foam materials. Hence the labeling of isolon - PPE.

To enhance thermal conductivity, foil or metallized film is attached to its surface. To conveniently fix the material to the desired surface, a layer of glue is applied to one of its sides, and then a protective paper membrane is applied.

The structure of isolon PPE is heterogeneous. Its lightness and low density are due to the presence of air bubbles in its composition. Thermal insulation is sold in most cases in rolls, sometimes in sheets. The price depends on the thickness, density, size of the material, as well as the length and width of the roll, and the manufacturer of the product.

The minimum thickness of isolon is about 2 mm, and the maximum reaches 15 mm.

For construction work and insulation of premises, in most cases, material with a thickness of 5mm and 8mm is used.

The Izhevsk Plastics Plant is a major supplier of isolon, both in Russia and in a number of foreign countries. The excellent price-quality ratio of the products was highly appreciated by consumers.

An enterprise with a half-century history is engaged in the production of colored isolon in accordance with all required GOST standards. The palette of products can be very diverse, but the most popular materials are white and black.

Color options and cost

Department of Forestry for the Siberian Federal District

Unlike its construction counterpart, isolon for handicrafts has several basic shades. For example, you can purchase roll products from suppliers in the following colors:

- white and black;

- turquoise and sky blue;

- emerald and mint;

- orange and yellow;

- coral and red;

- warm pink;

- peach and powdery;

- muted blue and deep blue;

- cold turquoise and silver-gray;

- olive-gray and rich green;

- lilac and purple;

- chocolate and cocoa tint.

However, the price of each shade of PPE material may differ. For example, white isolon is considered a bestseller: the cost per square meter of such material is 89 rubles for a thickness of 2 mm and 99 rubles for a thickness of 3 mm. Options with an adhesive layer are more expensive: say, a meter of white roll material 2 mm thick today costs 143 rubles, with a thickness of 3 mm the cost is 175 rubles.

As for the price for material of 8 mm thickness, today it is 255 rubles per 1 m2. A meter of isolon for making flowers 10 mm thick in white costs 349 rubles. The price of non-ferrous material averages from 115 to 147 rubles per 1 m2. In this case, as a rule, the thicker the raw material, the larger it is.

Two options for polyethylene foam, material characteristics

For production and construction purposes, two types of foam are produced - cross-linked - "SPE", "PPE", and non-cross-linked, most often designated as "NPE". The main difference lies in the production technology, as a result, there is a slight difference in technical characteristics. The characteristics of foamed polyethylene depending on the production method are given below:

- The density of XLPE is 33 kg/m3, for NPE the standard is 25 kg/m3;

- Vapor permeability for XPE is within 0.0012 mg/m*h*Pa, for non-crosslinked this value is at least 0.0003 mg/m*h*Pa;

- The static distributed compressive strength is 0.035 MPa and 0.011 MPa, for cross-linked and non-cross-linked material, respectively.

In addition, XLPE has a higher dielectric constant and a 40% greater operating temperature range. Cross-linked polyethylene can easily withstand the temperature of boiling water, while non-cross-linked polyethylene melts at 85°C.

The differences are noticeable even to an inexperienced builder. Non-crosslinked brands of polyethylene foam are two to three times better at transmitting water vapor, which is why food packaging is made from this type of material. Light crushability provides excellent shock and shock absorption, approximately on par with polyurethane foam. Even if you try to deliberately tear a thin NPE, it will be extremely difficult to do this; the material will stretch like a rubber layer.

Last changes

21.07.2020

New government procurement as a customer, contract No. 3229710125366390117, counterparty: Ks-2 LLC

14.07.2020

The consideration of court case No. A60-32247/2020 dated June 30, 2020 in the first instance has been completed. Organization as a defendant, the amount of claims is 1,518,262,363 rubles.

30.06.2020

New court case No. A60-32247/2020 dated June 30, 2020 as a defendant, the amount of claims is RUB 1,518,262,363.

12.03.2020

New government procurement as a customer, contract No. 1592124046366390117, counterparty: EMUP "Spetsavtobaza"

11.03.2020

New enforcement proceedings No. 68096/20/66019-IP dated March 11, 2020, amount of claims: RUB 213,405.

05.03.2020

New government procurement as a customer, contract No. 7027307763663901174, counterparty: MUP Heat Supply BGO

11.02.2020

A new person who has the right to act without a power of attorney: Acting Director Koshkareva Alla Minshagitovna

Oksana Ivanovna Isakova is no longer a person entitled to act without a power of attorney

Advantages and disadvantages

There are many advantages of this thermal insulation material:

- Low thermal conductivity coefficient;

- High thermal insulation characteristics;

- Isolon protects well from steam and moisture;

- Thanks to the closed cells, this material has a high degree of waterproofing;

- Although the protective layer of isolon is small, it has high shock and sound protection;

- The big advantage is the light weight of the material and elasticity;

- The material also has high dynamic strength;

- Due to its high chemical activity, this material is not used in some areas;

- Izolon resists gasoline, oil and other chemical compounds well. And also does not react with flammable substances;

- The service life of such thermal insulation material can reach 100 years. This is a big advantage of isolon. And also such material can be reused;

- Izolon is an environmentally friendly and safe material that does not pose any harm to human health and life.

There are several disadvantages of isolon:

- High cost of material;

- During transportation, isolon can be damaged;

- Thermal insulation using isolon must be carried out according to technology. If this is not done, damage to the structure may occur and, therefore, the material will not perform its function;

- It is necessary to adhere to the rules for storing izolon.

Despite the minor shortcomings of isolon, it meets many modern requirements and is a high-quality material for thermal insulation.

Types and markings

- Ordinary.

- Foiled. It has a coating of lavsan metallized film or aluminum foil on the front or both sides - the letter A in the marking means one layer, the letter B two.

- Izolon tape - with an adhesive layer on the reverse side for easier installation. It is produced not only in rolls and sheets, but also in the form of tape.

- Izolon tape foil.

- Izolon-block. Blocks measuring 1x1 m and 10 cm thick are made from Isolon scraps of any type by welding and pressing.

There are two methods of crosslinking: physical and chemical. The labeling indicates PPE NR or PPE NX, respectively. There is no big difference in quality between them.

The density of isolon and its associated characteristics depend on the frequency of foaming. This is an indicator of the degree to which the volume of a material increases after foaming compared to its original volume. The smaller it is, the denser the finished product, the higher the strength and moisture resistance, but the lower the heat-insulating properties. In the marking, foaming is indicated by the first two numbers, for example: 3005 - coefficient 30.

| Foaming ratio | 5 | 10 | 15 | 20 | 30 | 35 | 40 |

| Density, kg/m3 | 200 | 100 | 66 | 50 | 33 | 29 | 25 |

The last two numbers in the marking indicate the thickness of the roll or sheet. For example: 4008 - foaming coefficient 40, thickness 8 mm. Another version of the code contains a letter designation of the material and a numerical thickness: PPE-L-10 - polyethylene foam on a lavsan base, 10 mm thick.

Advantages and disadvantages

3. high level of thermal insulation - 1 cm is equivalent to 15 cm of brickwork, 1.5 cm of mineral wool or 1.2 cm of polystyrene foam;

4. good sound insulation;

6. low vapor permeability;

7. ease of installation, almost complete absence of waste;

8. resistance to ultraviolet radiation, weathering - suitability for external thermal insulation work;

9. ease of cutting with a regular sharp knife;

10. chemical resistance - not afraid of contact with petroleum products, oils, etc.;

11. compatibility with all types of building materials;

12. safety for health - izolon does not emit harmful substances and allergens;

13. no odor;

14. environmentally friendly production - freon and other harmful components are not used in production;

16. is not a favorable environment for rotting and the development of harmful bacteria;

17. possibility of reuse;

18. service life up to 90 years.

- high price;

- When transporting and installing foil insulation, care is required;

- when insulating walls, Isolon can only be painted; wallpaper or plaster cannot be applied due to the risk of breakage;

- If the laying technology is violated, its rapid destruction may occur.

According to reviews from builders, it is slightly inferior to expanded polystyrene in terms of insulating characteristics, but is very good for hydro- and vapor barrier.

Polyethylene foam insulation Izolon

Polyethylene foam or PPE is one of the types of foamed polymer materials. As the name suggests, the base for it is polyethylene. Izolon PPE is a thermal insulation that is sold under the brand name of the same name and is a product of the largest Izhevsk Plastics Plant in the CIS countries.

Let's consider the main technical characteristics of Izolon brand PPE:

- Thermal conductivity coefficient – from 0.031 to 0.037 W/m*°C.

- Density – from 25 to 200 kg/m. cube

- Foaming ratio – from 5 to 35.

- The vapor permeability coefficient is less than 0.001 mg/(m*h*Pa).

- Water absorption during 96 hours of exposure to water is less than 1% by volume.

- Compressive strength depending on density – from 0.031 to 0.33 MPa.

- Elongation at break: longitudinal – 250%, transverse – 210%.

- Flammability group according to GOST 30244 – from G2 to G4.

- Color: standard – white and gray. Coloring in other colors on request is acceptable, which does not affect the properties of PPE, however, under the influence of ultraviolet radiation, the color may change slightly.

- Release form: rolls and sheets.

The characteristics of the material are at a fairly high level in comparison with other polymer insulators. Let's review Izolon products.

It is marked as follows: the first 2 digits indicate the foaming ratio, the second two indicate its thickness. For example, PPE 0502 will mean that the last parameter is only 2 mm. Accordingly, its foaming capacity is 5 times.

- Rolled PPE. It is produced in rolls, its thickness is from 2 to 10 mm, width – from 0.8 to 1.5 m, length – from 50 to 200.

- Sheet. Available in slabs with dimensions 1 x 1, 1 x 2 and 2 x 1.4. Thickness ranges from 15 to 100 mm.

- Foil Izolon (folgoizolon). It can be produced both in rolls and in sheet form. It is distinguished by the presence of a foil coating on one or both sides, connected to the base material by lamination. As a result, the letter “L” is added to the marking, for example, PPE L 3005. Width – 1.2 m, length – from 80 to 300 m.

- Izolon Tape. Insulation made with one- or two-sided adhesive coating. Dimensions: width – 1 m, length – 10, 20 and 30 m.

As mentioned above, the marking contains the foaming ratio. Few people will know anything about this characteristic; density parameters will be much more telling. To make your choice easier, here is a table:

| Density, kg/m3 | 200 | 100 | 66 | 50 | 33 | 29 | 25 |

| Foaming ratio | 5 | 10 | 15 | 20 | 30 | 35 | 40 |

So, if you need to purchase insulation with a specific gravity of 25 kg/m. cube, it immediately becomes clear that the marking should first contain the number 40, for example, PPE-4008

The next thing people pay attention to is the area of its application; depending on it, you can choose foil or self-adhesive material

Areas of application of Isolon for thermal insulation:

- It is used for heat and sound insulation of the under-roof space in the presence of structures supporting the insulation.

- Used as thermal insulation for various floor coverings.

- Serves as an insulating substrate under a warm floor.

- Well suited for insulating facade surfaces with low vapor permeability.

Manufacturers and prices

Having figured out what Izolon PPE is, it becomes clear - this is ordinary polyethylene foam, produced under the brand name, the name of which has now become a household name due to the popularity of the Izhevsk Plastics Plant. Unfortunately, of the products of five large Russian enterprises, only two have received mass distribution.

| Manufacturer | Company and release form | Dimensions | Price, rub./m. kv | ||

| Thickness, mm | Length, m | Width, m | |||

| Plant Lit | Penofol rolls | 3 | 30 | 0,6 | 110 |

| 4 | 30 | 0,6 | 120 | ||

| 5 | 30 | 0,6 | 140 | ||

| 10 | 15 | 0,6 | 200 | ||

| 20 | 10 | 0,6 | 500 | ||

| 30 | 10 | 0,6 | 600 | ||

| 40 | 2 | 1,1 | 750 | ||

| 50 | 2 | 1,1 | 1 000 | ||

| Izhevsk Plastics Plant | Izolon rolls | 4 | 100 | 1,5 | 110 |

| 8 | 60 | 1,5 | 240 | ||

| Izolon mats | 20 | 1 | 2 | 315 | |

| 30 | 1 | 2 | 465 | ||

| 40 | 1 | 2 | 775 | ||

| 50 | 1 | 2 | 1 015 |

Please note that the cost in the table is indicated for products with a specific weight of 50-60 kg/m. cubic, and, for example, the price of Izolon PPE 3010, whose density is half as much, is not indicated here

More detailed information about the range can be obtained on the manufacturer’s website or in retail chains.

Review of insulating materials like Isolon PPE

Izolon (cross-linked polyethylene foam) is a universal soft porous material made of polyethylene foam with closed cells, designed for heat, steam, hydro, vibration and noise insulation.

Resistant to any adverse influences, durable provided the technology is followed. The only drawback is the relatively high price. They are sold in rolls 1 or 1.5 m wide, less often in sheets. Rolled Isolon longer than 50 m may have joints. Their number, depending on the size, reaches 6. Description of the main technical parameters:

- thermal conductivity coefficient - from 0.031 to 0.037 W/m*C;

- vapor permeability coefficient - 0.001 mg/m*h*Pa;

- compressive strength - from 0.031 to 0.033 MPa;

- noise insulation - up to 68%;

- density - from 25 to 200 kg/m3;

- water absorption - up to 1%;

- operating temperature range - from -60 to + 75°C;

- degree of reflection - from 95 to 97%.

| Fire hazard class | without flame retardants | with fire retardants |

| by flammability | G2 (moderately flammable) | G1 (non-flammable) |

| according to smoke-forming ability | D3 (high) | D3 (high) |

| by flammability | B2 (moderately flammable) | B1(hard to ignite) |

Installation technology of thermal insulation material

Self-installation of isolon does not require a lot of knowledge, however, a certain algorithm of actions still needs to be followed. In order for the material to perform its intended function, the installation of heat-insulating material must be carried out in the following sequence:

- The surface of the walls is being prepared. Removes old coating. Primed. Polystyrene boards of sufficient thickness are installed.

- Sheets of isolon of suitable thickness are cut to size and attached to the wall. To fix them, an adhesive composition or a stapler is used. To avoid damaging the insulating layer, the sheets are laid end-to-end during installation.

- The joints are glued with mounting tape 50 mm thick. Aluminum tape is used to seal the seams.

- A frame is mounted for fastening plasterboard sheets. The profile depth should be 20 – 50 mm.

- Plasterboard sheets are installed. The final finishing of the walls is in progress.

When insulating balcony structures, it is important to prevent the occurrence of condensation. That is why it is necessary to leave ventilation gaps

Izoplen is a paper-based isolon

Isoplen is a polyvinyl chloride finishing and insulating material made on a paper base. On sale it can be monochromatic and colored, containing such a diverse palette of colors. It is also divided into products with a smooth and embossed surface, which in turn can be glossy or matte. The material is produced in the form of rolls, which have a length of 10, 12 and 18 meters. Their width varies between 50, 60 and 75 cm. The thickness is 0.3 mm.

Isofilm is usually glued to smooth concrete, painted or plastered wood, or other surfaces.

It is customary to use the following as an adhesive:

- Bustilat;

- Decon;

- Gumilax;

- PVA.

During operation, isofilms can be washed with water, with the addition of a synthetic detergent or soap.

Tips and tricks

When choosing isolon, you should adhere to the following recommendations:

The cost of thermal insulation products does not always determine its quality, so you should pay attention to the manufacturer of the product, as well as its technical characteristics, in order to choose a product that is ideal for insulating a particular surface. Installation and fixation of seams cannot be performed with ordinary tape; for such purposes there are specialized adhesive aluminum tapes

- During the installation process, do not forget about the ventilation layer, which must be formed near the walls.

- Products, especially products with a foil layer, require compliance with the specified storage conditions, as well as care during transportation of the goods.

- Violations made during the installation of heat-insulating material can damage the integrity and structure of the isolon, as a result - the product will lose its properties.

A very important parameter of isolon is the thickness of the products. It is this indicator that determines the scope of product operation.

To help make the right choice, manufacturers classify products based on thickness and area of installation.

- To carry out work on thermal insulation of pipes located directly underground, it is necessary to use PPE with a thickness of 15 to 45 mm with a foil layer for work.

- Sound insulation in multi-storey buildings between floors will have a high level of quality if you use isolon of 8-10 mm thickness. Such material will be enough to reduce noise from the movement of people living above, as well as to eliminate the audibility of low-volume music from neighbors. But for buildings where the top floor, for example, will be used as a gym, you need to purchase products with greater thickness.

- Floor coverings, for example, laminate, can be insulated with high-quality 3-5 mm products. For a “warm floor” system, preference should be given to products with a minimum thickness. Based on the type of floor screed, it is recommended to use different types of isolon: for a dry screed - foil material, for a wet screed - you need to lay products with a metallized layer.

- Thermal insulation of wood and concrete bases is carried out with products with a product thickness of up to 10 mm.

Recommendations for selection

To solve different problems it is necessary to use different types of insulation. To increase the thermal insulation properties of parquet flooring, you should choose a solution with a thickness of 25 mm. Isolon is often used for thermal insulation of wooden and concrete floors. For high-quality work, insulation with a thickness of 80 mm should be used.

It is also used for insulating pipes located underground. In such cases, work should be carried out using cross-linked polyethylene foam with a thickness of 15-45 mm.

To carry out measures to create high-quality sound insulation between floors, it is best to use 80 mm material. Such a layer will be quite enough to prevent you from hearing soft music and speech coming from your neighbors. In case of severe acoustic discomfort, to eliminate it, it is necessary to install a more powerful layer.

Izolon is a fairly effective solution for high-quality thermal insulation. With its help you can well insulate any room. Certain types of material provide protection from steam and temperature changes. Proper execution of the work allows you to count on a long service life of the installed layer. If violations were made during the procedure, the process of destruction of the thermal insulation layer will begin quite quickly. In this case, the installation of the isolon will have to be done again.

Subtleties of using foil-coated isolon

If we take an internal wall, then for insulation the foil insulation must be between the wall and the finishing material and so that there is an air gap between the wall and the insulator. In this case, it would be more correct to fill thin wooden slats and then fasten the isolon on them with small nails, having previously prepared the material of the required size. All joints are taped with special aluminum tape. For such work, a material coated with foil on both sides is best suited.

When insulating concrete floors, it is best to first use another insulation and place it between the floor joists, and then lay down the insulation material. After insulation, you need to lay the main floor covering. Izolon is often used as a substrate for laminate flooring.

When insulating balconies, experts recommend multi-layer installation. One-sided isolon with external reflection is laid first, after which you can lay, for example, polystyrene foam, and then again isolon, applied according to the principle of the first layer. Next, you need to make the sheathing, which is necessary for finishing work.

Such modern material as isolon allows you to perform different types of work. Its lightness and elasticity and other unique properties have made it indispensable in construction. A thin layer of isolon does not reduce the area of the room, creating a comfortable indoor microclimate, and for little money.

https://youtube.com/watch?v=dmxolnXC4_U

Advantages

Advantages of isolon:

- Thermal insulation. Indispensable in the construction field.

- Steam and moisture protection. Allows use in wet objects such as baths, swimming pools, saunas.

- Soundproofing isolon.

- UV resistance, which allows its use for external coatings;

- Fire safety.

- Light weight. Does not create additional load.

- Elasticity, which gives isolon its “flexible character”. It can easily take the shape of any object to which it is attached.

- Elasticity. Restores original shape. There is an opportunity to use it again.

- Rot resistant.

- Damping the force of blows.

- Easy installation.

- Safety for people. There are no releases of toxic materials.

- Environmentally friendly material.

- A thin layer of insulation does not reduce the internal dimensions of the insulated object.

The disadvantage of isolon is usually its cost. But if you consider that the service life is 90-100 years, then the investment in its purchase may not seem that big.

Izolon - what is it?

Izolon is an artificially foamed polyethylene consisting of tiny cells or pores. Due to its porous structure, it has increased thermal insulation properties and is used for insulation and waterproofing of surfaces and structures.

The main purpose of the innovative material is high-quality heat, sound, and waterproofing of any products and surfaces.

The wide household and industrial use of the material is explained by its excellent efficiency in comparison with existing products for a similar purpose.

Thanks to its special structure, it has increased strength and high wear-resistant characteristics.

Izolon can be used in conjunction with other materials, for example, for thermal insulation it can be combined with foam plastic, expanded polystyrene for insulating walls and floors, as well as balconies.

In addition, isolon is indispensable for use as an insulating coating for floor screed. In the automotive industry, the material is used to insulate the body and protect metal parts from corrosion.

Material in demand for:

- performing thermal insulation work. It allows you to insulate various bases. Due to its shape, it is widely used for thermal insulation of utility lines;

- creation of thermally reflective screens. The good reflective ability of the foil film with low thermal conductivity allows it to be placed behind heating radiators or behind heating appliances;

- organization of sound insulation. Allows you to protect interior spaces from external noise and vibrations. During construction, it is used as damping gaskets between connected parts;

- hydro-, vapor barrier device. For some premises this is the only option;

- thermal and noise insulation of vehicles;

- manufacturing of freezers, refrigerators, air conditioners and a number of other climate control equipment;

- production of sports, tourist clothing and footwear, manufacturing of toys, interior items.

Basic properties

Many consumers are wondering what isolon is. If you are also one of them, you should know that the material does not perceive temperature changes and does not change parameters when they fluctuate sharply. The structure is characterized by high noise insulation qualities, while the thickness is relatively small.

Izolon is quite often used by motorists for interior decoration. It is impervious to moisture and is able to protect metal from corrosion. For the hood, you should purchase a foil version that is laid on mastic. In order to avoid installation difficulties, it is better to purchase insulation with an adhesive surface; it can even be laid on a base with complex geometry.

If you are wondering what isolon is, then you should also know that this material is durable and reliable. It does not require additional maintenance during operation, is fireproof, does not support combustion, but evaporates. At the same time, it decomposes into carbon dioxide and water.

The main purpose is repair work inside buildings. When creating self-leveling floors, a thin layer of thermal insulation is laid to prevent the solution from leaking to the lower floors. The layer acts as thermal protection and a water barrier, which is important when renovating multi-story buildings.

Among the main properties, ease of installation should be highlighted. The canvas will need to be laid out and secured. In the case of walls, ventilation must be provided. When insulation is carried out from the inside, in the absence of an air layer, the materials will collapse. This is due to the fact that they are hygroscopic and should be protected from moisture or provided with drying and ventilation.

When answering your question about what isolon is, you should know that it can also be used externally. This is due to the fact that the material is resistant to ultraviolet radiation. Due to the fact that isolon has high sound insulation properties, it can be used as insulation for a balcony; it will not decompose under the influence of ultraviolet radiation and will not attract insects, rodents and birds.

Characteristics of PPE and NPE tapes

Important: the main disadvantage of isolon PPE is its high price, otherwise it is an excellent material for insulation. Stages of work:

The company has existed for more than 50 years and produces isolon PPE and NPE in rolls and mats in accordance with GOST standards. The company's products have an excellent price-quality ratio.

In conclusion, we can say that izolon easily tolerates temperature fluctuations, is not afraid of heat and cold, while maintaining its flexibility and elasticity. It takes up a small volume and saves space, the material is environmentally friendly and easy to process. Izolon PPE is a new type of material for insulating residential and non-residential premises. Modern manufacturers present a wide range of thermal insulation materials that are practical and reliable.

Izolon PPE is a universal material that is used for insulation of industrial and residential premises. The material has ideal performance characteristics.

How Instructural

Izolon sealing soundproofing tape consists of closed cells. The first type is polyethylene foam, the second is non-crosslinked polyethylene foam. For comparison, 1 centimeter of thickness of polyethylene foam is similar in properties to 4.

Aluminum foil glued on one side to a sheet or roll of foamed polyethylene helps to enhance the insulating properties. Concrete walls are lined with such mats, and they play the role of heat shields, reflecting infrared radiation into the room, saving heat several times more effectively than similar heat-insulating materials. In the field of mechanical engineering, the material is widely used as a heat insulator for refrigeration equipment and air conditioning systems; noise insulation and vibration damping elements are made from it.

The polymer is also the basis for double-sided tape, sealing and mounting tapes, as well as all kinds of gaskets. In the automotive industry, it is impossible to imagine modern interior sound insulation or vibration insulation in wheel arches without polyethylene foam.

The technical characteristics of the material also make it possible to make various seals and gaskets from it, which are used in almost any components and assemblies of modern cars. In heavy-duty refrigerated trucks, sheets of polyethylene foam are used to insulate luggage compartments. The surface is smooth. On the one hand, price, on the other hand, quality is in the balance.

To understand everything, just look at the numbers and data. All about the advantages in the comparison table. Now we know all the data and differences. It is also possible to produce PPE tapes according to the customer’s required dimensions. Any questions?

NPE - what is it: material features

The building materials market is equipped with three types of polyethylene foam. Two types are cross-linked isolon (PPE), the latter is non-cross-linked (NPE). All types are called foamed. To make the right purchase, you need to understand the characteristics of insulation materials.

Non-crosslinked polyethylene foam has an unstable molecular environment because the molecules do not have a strong bond with each other.

The composition of NPE includes large bubble cells, and the foaming of the material occurs due to gases: freon and propane-butane. The material does not have a cross-linked molecular “network”, so large loads can lead to rupture of the material. NPE usually does not meet the requirements for insulation materials, so it is more often used for packaging.

NPE features:

- The use of the material is not as widespread as the use of PPE.

- In most cases, the properties of NPE do not allow it to be used as insulation.

- NPE is used for packaging furniture, household appliances and shoes.

- Izolon NPE does not withstand heavy loads, so it often breaks.

- The air gradually leaves the cells, so the material is prone to deformation.

Over time, NPE becomes an ordinary film, unsuitable for use. Therefore, you should not use this type of isolon as a material for insulation. Also, it cannot be used for vibration-damping floor screed.

Floor insulation

Quite often, this heat insulator is used for floor insulation work. When carrying out floor insulation work, there are some nuances that you should be aware of. Only in this case can the quality of the procedure be ensured.

An event using this insulation can be carried out in one of two ways. The first option involves using during work, in addition to the main material, an additional heat insulator. Often the choice is made in favor of mineral wool. The process itself begins with surface preparation. Next, the slats are fixed to the base. Dowels are used to securely fix them. A distance of 50 cm must be maintained between the bars.

For high-quality installation of insulation, you need to scrupulously study the nuances of this matter.

Then mineral wool is laid between them, and foil insulation is laid on top of the slabs. It is secured to the slats using dowels. An important point when performing this operation is that the joints of the sheets must be located on the slats. They must be glued using metallized tape. With its help, maximum tightness of the sheets is ensured. After this, a second row of slats is mounted on the isolon, located perpendicular to the first. Next, the plywood sheets are laid. To secure them, ordinary self-tapping screws are used. Upon completion of the work, installation of the floor covering is carried out.

The second option excludes the use of additional thermal insulation material. Izolon is laid on wooden slats. It is placed in one layer end-to-end. To eliminate seams, you must use metallized tape. Then plywood should be laid on the insulation layer, and then secured with self-tapping screws. Flooring material is laid on top of them. Usually laminate or parquet boards are used. To improve the performance of a “warm floor” system, isolon PPE-L is usually laid on the base.

general information

The PPE marking present in the name of this material stands for polyethylene foam. It is used to designate sheets of polymer products cross-linked by physical or chemical means. They are first subjected to an extrusion procedure.

One of the important points in the manufacturing process of isolon is foaming.

During this operation, the insulation increases in volume. It acquires a cellular structure, including several layers. To increase the strength characteristics of the final product, it is reinforced with polypropylene fiber. Certain types of material are covered with a metallized layer of aluminum foil. This significantly increases its thermal insulation properties. Read more: about the properties of isolon insulation.

In this video you will learn how to choose real Izolon: