Windows made from PVC profiles have long been firmly established in the lives of most modern people living both in large cities and in private country houses. They are indispensable protection from dust, noise, and most importantly - from cold. There is no breeze through the plastic windows. We can talk about their advantages for a long time; they have long been appreciated by everyone who has risked repairing and replacing traditional inconvenient wooden frames.

Only one drawback can be attributed to the plastic window - the uniformity of color. Basically, previously versions were produced in white or another boring shade. There was no diversity in this regard. A solution was found when lamination with a special film .

What is plastic window lamination?

Lamination is the process of covering a plastic profile with a special decorative film. Occurs under the influence of special equipment, pressure and high temperatures. All this ensures tight adhesion of the lamination film to the profile, turning the product into a single whole.

Lamination film allows you to give the window profile the structure and appearance of wood of any species. A high-quality profile system and functional double-glazed windows provide good thermal insulation and effective noise insulation.

When ordering laminated windows, you need to keep in mind that you will have to pay more for it than for regular windows. Also, when installing windows, the color of the handles and fittings will differ from the decor of the frame, since the manufacturer does not laminate such small parts.

Features of window profile lamination:

Laminated window profiles can be brown on the inside and white on the outside

White profile - standard, intended for outdoor use

Window sills, as a rule, are matched to the tone of the internal profile

Installation features

Choose the right installation specialists, otherwise even a high-quality plastic window profile is unlikely to serve you for long. Professionals should take measurements of the window opening, both inside and outside.

It is important to correctly dismantle the old window profile. All spaces between the wall and the frame must be filled with special foam

Otherwise, there will be drafts in the room. At the end of the work, specialists install the window sill. It is advisable that the installation work be carried out by the same company from which you purchased the plastic windows (if any misunderstandings arise, it will be easier for you to protect your interests).

Non-standard windows are made to order

Advantages and disadvantages of window lamination

The main advantage that window lamination provides is the ability to create a reliable imitation of products made from natural wood. Since the film can be applied to profiles on both the street or room side, or simultaneously on both surfaces, buyers optimize their costs and easily choose the most suitable design option for sashes and frames.

An important advantage is the ability to adapt windows to any facade decoration and individual interior style. The laminated profile looks incredibly impressive together with colored slope systems.

pros

The film is insensitive to temperature changes and ultraviolet radiation, and the profile surface is completely protected from external damage

A large selection of colors and shades, which are complemented by an appropriate texture that imitates various types of wood (for example, oak window lamination)

If you need lamination of windows to look like wood, then know: they are much more profitable than wooden ones

Window cladding allows it to fit into any apartment interior, as it is a full-fledged decorative element

Without deviating from the design principles of the exterior and interior of the building, you can order lamination on only one side, which will significantly reduce the cost of the product

The windows fully comply with GOST and environmental safety requirements

Minuses

The color range is so varied that you will have to spend a lot of time to make the right choice.

The beauty of such windows so shocks those present that you will be asked endless questions about where to place an order.

Of course, the cost of such windows will be higher than ordinary white ones, but not so much as to deny yourself the pleasure of enjoying the beauty for many years

Coverage Requirements

Film for PVC windows is subject to a number of strict technological and design requirements , the fulfillment of which ensures high quality products:

Increased resistance to environmental influences - the film should not fade in the sun or be destroyed by temperature changes.- Wear resistance of materials - over time, the material is exposed to gusts of wind with solid impurities in the air, which negatively affects its structure.

- Mechanical strength of the product - the lamination should not be damaged by accidental scratches or impacts with hard objects.

- Adhesive resistance - the adhesive composition must ensure a tight fit of the material throughout its entire service life.

- Environmentally friendly - when heated, the material should not release toxins, the effects of which negatively affect human health.

- The material should be easy to clean from dirt and have increased resistance to exposure to weak chemicals contained in detergents.

According to the listed requirements, each material must have appropriate certificates issued by government agencies after a series of tests, which guarantees reliability, durability and safety during operation.

How does the lamination process work?

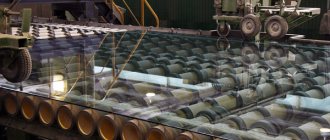

The order of production of a window profile from A to Z:

1. First of all, all excess particles, dust, and dirt are removed from the surface of the plastic. This is done chemically - using alkaline detergents

2. Then the material is thoroughly dried

3. The next step is to apply a layer of primer to the plastic. It is a mixture of glue and solvent and is designed to improve the adhesion of the film to the material

4. In no less than 24 hours, the frame is ready for film application. This happens in a special chamber with precisely controlled temperature (+130°C), air humidity and pressure

5. The squeegee unit evenly distributes the glue over the surface of the film. In this case, the material is heated to a certain temperature (no more than 45°C) in order to improve the application to the plastic and at the same time prevent air bubbles from appearing under the film

6. Simultaneously with the application of glue and heating of materials, special rollers operate in the chamber, pressing the film to the frame and removing air from under it

7. If the edges of the film extend beyond the edges of the frame, the excess parts are cut off with a disk-shaped cutter or a starting knife

8. After applying the film to the window frame, you need to wait at least two weeks until the material shrinks completely. This is necessary so that the window profile does not deteriorate during transportation and installation due to an insufficiently “grabbed” surface

9. Then the product is checked for peeling of the film, presence of defects, etc.

10. When the frame is completely ready, a protective film is glued on top of it to prevent mechanical damage during transportation and installation

11. The finished profile cannot be put into operation immediately. Before welding or cutting the material, you need to wait three days, and before installing arches or otherwise curved frames - 28 days. But the difficulties do not end there - to store such products, it is important to maintain optimal humidity and air temperature. Only after this are laminated window profiles delivered to warehouses and stores, where we see them perfectly covered.

PVC profile processing goes through several stages. First, it is coated with a special primer to enhance adhesion to the film. After this, using equipment, the film is glued to the profile. For this purpose, special adhesive solutions are used, brought to a certain state. As a result of processing on industrial professional equipment, the laminating film adheres tightly to the surface of the profile . This is enhanced by the last stage of processing - rolling with several types of rollers.

After treatment, the laminated surface becomes tear-resistant and can serve for a long time, pleasing to the eye. It is impossible to carry out such a process on your own, since you need special factory equipment, so you can only purchase a ready-made version.

Video: PVC profile lamination process

Expert commentary

Vladislav Dobronravov

Leading technical specialist at Okna-Media company

When cutting a laminated profile, white stripes appear at the corner joints of frames and sashes; special markers are used to disguise them. This phenomenon can be avoided by using a profile painted in the mass that is as close in color as possible. However, this method leads to a significant increase in the cost of products. In addition, the limited number of colors of such profiles still forces the use of markers when combined with many films.

Applying laminating film to glass

Among other things, it is worth noting that both plastic frames and the glass itself can be laminated. This can be used for many purposes besides making windows look aesthetically pleasing.

For example, there are types of films that, when processed, increase the resistance of glass to impacts - there are films that even protect against bullets. Films are also produced that are designed to conserve heat in winter and reflect heat in summer. They can significantly reduce savings on heating in the cold season and on air conditioning in the warm season.

Blitz survey: When choosing a plastic window, what is important to pay attention to? From the articles you can learn how to choose plastic windows depending on the design and heat and sound insulation characteristics.

Another type is lamination with sun protection function . They do not allow harmful ultraviolet radiation into the room, and in addition, they protect against eavesdropping, which is especially important for maintaining trade secrets.

And the last option for glass is mirror glass . When using it, nothing is visible from the outside, while everything is visible from the inside. This is very convenient for residents of apartment buildings.

Features of double-glazed windows

At its core, this product is a combination of two (possibly more) bonded glasses, between which cameras are located. These spaces can be filled with air or an inert gas. There may also be a vacuum space between the sheets of glass.

Thanks to this device, the room will always be warm, and the space between the glasses will remain clean. It is preferable to choose double-glazed windows filled with inert gas, since they retain heat better and protect owners well from extraneous sounds. The glasses are separated by a special frame that contains a moisture-absorbing substance.

Windows with different turning mechanisms

Window frame lamination technologies

The lamination process is rolling out the film using machine rollers.

There are four methods for laminating windows, which differ significantly in the way the film is applied to the surface of the PVC profile:

Internal one-sided

With internal lamination, the film covers only that part of the window that faces the room. This type of decoration allows you to combine the profile with any, even the most extravagant, interior. For example, with the now fashionable eco-style, where light green shades dominate. Sometimes white color cannot fit favorably into the existing style of the room, and therefore, windows laminated only on the inside will organically emphasize the direction of the created style, without standing out and without disturbing the external harmony of the façade of the building.

Places for lamination:

1. One-sided lamination - the film is applied only from the inside

2. Double-sided lamination - the film is applied both from the inside and from the outside

3. Lamination in the mass - changing the color of the structure of the profile itself (black in section)

External one-sided

External window lamination is used extremely rarely - after all, not every owner decides to decorate a light-transmitting structure in such a way as to emphasize the appearance of the building from the outside. It is used mainly for external improvement of window openings of country houses, dachas and cottages, that is, private buildings.

On both sides

Double-sided lamination involves applying a colored film directly to the inside and outside of the window. Moreover, it is not necessary that the film should be the same color - depending on the course of the design idea, you can combine the color of the window frame with both the interior and exterior of the building. The consumption of an additional amount of material, as well as time to control the correctness of its application, makes the production process of this type of laminated plastic windows more labor-intensive, and their cost is higher in comparison with similar PVC structures made without the use of lamination technology.

In bulk

Lamination in bulk is an almost complete imitation of a wooden structure and texture with a plastic window. The use of this method of manufacturing a plastic window profile involves obtaining materials that do not differ in color and texture from natural wood - in cross-section, the profile has a color similar to its outer surfaces. Currently, the color palette for mass lamination is small, but it allows you to obtain a window profile of the most popular range. The production of such colored profiles for plastic windows is carried out only at manufacturing plants.

Expert commentary

Vladislav Dobronravov

Leading technical specialist at Okna-Media company

Lamination can exactly replicate not only the color, but also the structure of various materials, such as wood. This technology is called “coextrusion”. Thanks to it, plastic windows made using this lamination method cannot be distinguished from natural wood even at close range, which opens up new opportunities for decorating rooms, taking into account the slightest nuances in design.

We decide on a shade based on the functionality of the room

The purpose of the room also plays an important role when choosing individual window colors. Let's discuss in more detail.

- Green and blue window colors are suitable for living rooms. It helps you calm down, relax, and enjoy spending time indoors. These calming shades will encourage the owner of the house to enjoy family leisure time in a calm environment.

- Red, burgundy and scarlet can inspire appetite, so it is ideal to use it in the kitchen and dining room. The same window structures are often installed in small cafes.

- Orange and yellow tones, regardless of saturation, are ideal for children's and playrooms. They provoke the development of joy and fun. Judging by this, the room will not be boring.

- Dark: brown, black, charcoal tones of window frames create an intimate atmosphere and evoke sleep, therefore ideally suited for installation in adult bedrooms.

In addition to the color of the windows, it is also necessary to take into account what the shade of the seal will be. It helps create a unique aesthetic in the room and enhances the façade of the house. Brown seals will look ideal with the lamination of PVC window frames to look like wood. For blue ones, the most typical use is gray or black sealants.

Important! Along with choosing the shade of the PVC profile, it is important to decide on the color of the fittings (handles). You can leave them the same or order them in a contrasting tone. For example, for yellow and blue frames, handles painted in a metallic color are ideal.

Dark brown window frames for glazing a loggia Source lorel-spb.ru

PVC windows in black

New trends in modern design include decorating windows with black frames. The exclusivity of the colors allowed us to create a whole trend in interior solutions. For many years now, black windows have been gaining increasing interest from customers. This option became possible thanks to the development of technology for manufacturing profile coatings that imitate any structure, with the ability to create a glossy, metallized or matte surface.

Any fantasy can now be realized thanks to special coating equipment and the creation of a high-strength film. Thanks to the dark shade, such frames will retain their rich, deep color for a long time, and a reliable coating will provide protection from fading and destruction of the product.

From a design point of view, it is preferable to place black elements vertically, so the design of window frames in black fits well into the list of requirements for the aesthetics of the room and stylistic compliance.

Expert commentary

Vladislav Dobronravov

Leading technical specialist at Okna-Media company

A black profile looks impressive next to concrete or brick, against a background of wood or stone surface.

In addition, in some cases, the use of black frames is the only acceptable option that blends seamlessly with the surrounding environment. We should not forget about the fittings; they are selected taking into account the specific color of the frame. As a rule, additional decorative elements and accents are not required for this window design. Depending on the circumstances and design features, it is possible to include fittings in noble silver or golden shades.

Laminated windows with layout

To make a window spectacular, all you need to do is purchase and install a layout. It is most often used on large windows in country houses or offices. Decorative layouts are special various materials in the form of profiles of different widths, which are installed in double-glazed windows and divide them into separate fragments.

The width of the elements can be varied and ranges from ten to forty millimeters. The color range is represented by all colors of the spectrum. The type of layout depends on the wishes of the owner and the style of the building.

Instructions for lamination after DIY installation

To successfully stick PVC film onto the surface of a plastic window profile, you must adhere to the following flow chart :

- The profile must be freed from double-glazed windows and fittings.

- The surface is measured with a ruler, the results obtained are recorded on paper, and then recorded on film.

- The material is carefully cut, taking into account the formation of an overlap of at least 2 mm, if necessary, joining along the length or width.

- The surface of the profile is cleaned and degreased, coated with an antistatic agent, and dried with a hairdryer.

- The profile and film are heated with a hair dryer.

- The sticker starts from the main surface, in one go.

- The material is smoothed from the middle to the edges of the profile.

- To fix the film onto the folds, it is necessary to preheat all edges to at least 60 °C, and then tuck the material into the grooves with spatulas.

- After installing the film, it is necessary to check the formation of bubbles. If air accumulates in certain areas, it is recommended to carefully pierce it with a needle and smooth the film with a roller.

It should be noted that at home, in the absence of special equipment - pressure rollers or a conductor, it is almost impossible to achieve ideal quality.

Additional elements to match the windows

Window sills

When installing windows to match the color of wood, window sills made of wood, plastic, natural and artificial stone, as well as wood-plastic composite can be installed on the inside of the opening. The final choice of material depends on the type of profile and interior design. The dimensions of the window sills and the number of decors will allow you to implement any design project.

Slopes

Slopes are part of the window opening on top and on the sides of the window. After installing or replacing a window unit, finishing the slopes is a mandatory stage of work, which gives the window a finished and neat appearance. That is why you should choose slopes in accordance with the window itself - from the same material and the same color.

Nashchelnik

The flashing (also known as the cover strip) is another additional element that is installed at the installation seam of the window. The use of a flashing allows not only to protect the seam from destruction and give the entire structure an aesthetic appearance, but also to improve the thermal insulation of the window.

Using a laminated strip allows you to make the element almost invisible on a colored window and give it a finished appearance.

Low tide

Window sill is an element whose main purpose is to remove moisture from window glass and prevent water from entering the frame and window sill.

The use of flashings helps prevent the destruction of both the window structure itself and the building materials used to decorate the house. Related articles:

◾Colored windows in the interior

◾Plastic wood-look windows

◾Brown PVC windows

Peculiarities

Laminated windows first appeared on the market of construction and finishing materials in 1982 thanks to the Rehau company. It was this company that first used film for laminating plastic, thus turning a white frame into a colored one. After this, this trick began to be a success, as it made it possible to select the shades of window frames to suit any interior design.

Previously, it was possible to laminate a window only in one way - on both sides, which created problems in apartment buildings. After all, SNiPs have requirements for the facade, including its appearance - it must be uniform, and the windows must look approximately the same.

Now it is possible to cover the frame with film only on the inside, leaving the outside white. This eliminates many problems for homeowners in apartment buildings, while giving the opportunity to decorate the frame and window from the inside as desired. As for the happy owners of private houses, this does not concern them; they can give the windows in their home the shape and color at their discretion.

Thanks to lamination, plastic windows receive additional protection from damage. In addition, the possibilities for decoration are significantly expanded with the use of frames covered with laminate film. For example, an interior decorated in eco-style will only benefit from “wooden” frames, because in this way the artificial material – plastic – is eliminated.

If cached film is used for lamination, the frame will withstand temperature changes from -80 to +1300C.

What you need to know before installing laminate systems

If you decide to install laminated frames and you are not afraid of their high cost and the need to wait longer for their production than conventional plastic windows, you need to remember and follow a number of recommendations:

- Window fittings are not laminated; they are produced in several shades at once (usually, of course, white). Therefore, you need to be prepared for the fact that it will differ in color from the frames. Before paying for your order, you need to consult whether lamination is possible on the selected profile and what the final color will be. This is especially important if the profile that you plan to cover with film is not white.

- In a cottage you can install windows of absolutely any color; in an apartment it is better to stick only to internal lamination so as not to disturb the overall appearance of the facade.

- The film is easily damaged, so handle the laminated frame with care. It is better to immediately purchase a special marker in the same shade to mask such annoying scratches and marks from mechanical damage.

- The optimal shade for the film is slightly darker than what is required. After a short time (up to six months) after installation, it will fade a little and acquire the desired tone.

- Since the film is the most vulnerable part of the frame, the impact on it during installation should be minimized. It is better to seal the surface with masking tape.

- If the laminated frame is covered with protective tape, then it must be removed immediately after all the dirty work is completed. Otherwise, the glue may dry to the film and either leave damage on it or come off along with the film.

- For wood-look windows you will need the same window sills and other fittings. Ordinary handles and fasteners can look alien and give away the unnaturalness of the material.

- In order to correctly mount the colored profile and avoid temperature deformations, you need to make the pitch of the anchors more frequent with an interval of 45-50 cm. Then the fastening will be more rigid.

- Laminated windows are very good to install on loggias, especially large ones. Sub-zero temperatures are not dangerous for film, nor is heat.

Reviews from consumers and those who decided to install such windows are usually positive. Most emphasize that if the lamination process is not disrupted, the film holds tightly and for a long time, no air bubbles arise. The joints are invisible, as they are painted after the installation process is completed.

Some customers note that the same profile color looks different outside and inside the room. If it looks good on the facade, then in the room it may seem too dark. This must be taken into account when choosing a shade.

Almost everyone stops at the low-budget nature of such windows, highlighting, however, the expensive appearance and attractiveness of the design.

Kinds

At its core, lamination is a process in which a colored decorative film is rolled at low speed onto a PVC base under pressure at high temperature.

The following types of lamination are distinguished:

- external;

- internal;

- two-sided;

- in bulk.

In the first option, the frame remains white inside the room, but on the facade it becomes colored. In the second case, the frame remains white on the outside and at the ends.

With double lamination, the color outside and inside can be different or the same, depending on the customer’s wishes.

Bulk-painted windows are usually beige, caramel or brown. They look very natural - like wood, from all sides, including the end. Metal-plastic, covered with wood, is the most beautiful (there are no white marks or bald spots on it), but it is also more expensive than others.

If the apartment is located in a new building, there is no need to laminate the outer side of the frame, but if the house is old, one of the architectural monuments, or simply a restored Stalin building, the colored frame will organically fit into the facade.

Original double-glazed windows or unusual fittings on the windows will add additional chic.

The process of lamination, that is, covering a window frame with a special film, is quite complex and includes several stages. First, a primer is applied to the surface of the plastic. This is necessary in order to increase adhesion, i.e. the adhesion of the plastic to the film. The primer dries within 24 hours, after which the profile of the future frame is placed in an installation in which it is heated to 1300 degrees, after which a film is applied to it. Since a special adhesive is used to secure the film, it cannot be removed once it has been applied and “set.”

After gluing, the profile is placed in another apparatus, where it is processed with different rollers so that all air bubbles are removed from under the film. After this, the coating becomes absolutely smooth and adheres 100% to the profile.

If you violate the requirements for carrying out actions, the film will either simply not stick to the plastic, or it will stick, but unevenly.

After the profile is processed with rollers, it is placed for storage in a room with a specially set temperature and humidity, where it remains for about 2 weeks. After this, a window frame is made from the profile and glass is inserted into it. In this case, it is possible to avoid deformation of the coating and minimal shrinkage of the film. Therefore, having decided that colored windows will be installed in your apartment, you need to take into account that their production will take more time.

In addition, such windows are more expensive than regular white ones. On average, their price is 20 percent higher than traditional ones.

As for the film, it is a polyvinyl chloride coating consisting of many layers. Despite the multi-layer property, it is very thin - 0.2 mm. It is based on acrylic in the color chosen by the customer. When considering coating options for a window facing the sunny side, you need to remember that colored, especially black, film heats up much faster than white plastic.

Laminate film includes several layers. The top layer is transparent, it consists of polymethylacrylate and polyvinylidene chloride. It is these components that make the film glossy and give it shine. They also help the material resist the destructive effects of environmental factors. After all processing stages have been completed, the layout is different - the layers are combined into one whole.

Beware of counterfeits

When windows are laminated, the colors and textures of the films can be very different. Today, manufacturers most actively use wood-like coatings with embossing. Also, for profile finishing, films are sometimes chosen in unicolor or with fancy decors. In addition, there are quite a lot of price offers on the market at the moment. There are cheap decor and expensive ones, and such products have fundamental differences.

Blitz survey: Which plastic windows are better: German or Russian? From the article you can learn about the advantages of German plastic windows.

Some manufacturers save on special stabilizing additives that allow the film to:

- maintain elasticity at low temperatures;

- reflect UF rays;

- do not melt in the sun;

- maintain the structure of the material and rich color.

These stabilizers are quite expensive, and the average buyer will only be able to detect their absence during operation, when problems arise with the decorative layer.

As a result, unscrupulous manufacturers are always tempted to skimp on quality when purchasing materials. It is due to this that they manage to attract customers at a lower cost compared to the price at which most responsible companies perform high-quality lamination of plastic windows. Related articles:

◾How windows are made

◾Windows with layout

◾Glazing of balconies with plastic windows

Caring for laminated windows

Since the basis of decorative films is the same polyvinyl chloride that is used in the manufacture of white profiles, laminated windows are cared for according to the same rules as standard models:

- cleaning is done with soft flannel cloths soaked in warm soapy water;

- do not use abrasive powders or aggressive chemical compounds (solvents) under any circumstances;

- use a polish for plastic surfaces with an antistatic effect - it will not only clean the surface and prevent the accumulation of dust, but also give the profile a spectacular shine.

When using laminated models, it is recommended to always have a marker on hand to match the film. It is necessary to periodically “refresh” the camouflage at the joints. If all technologies are followed when applying high-quality film, the service life of such windows does not differ from the durability of basic white models and, depending on the type of profile, is 30-50 years.

The most important thing for last

Lamination of a PVC window will allow it to “fit” into almost any interior and will extend the service life of the frame. But do not forget that it is much more important to choose the ideal plastic window for your requirements. A beautiful and cool double-glazed window will please only the eyes, but you should enjoy it entirely, in a warm and beautiful apartment.

Therefore, do not forget to first select the optimal PVC window according to chambers, profiles and types of opening (we wrote material about this here) and decorate it to your liking. It's safe and very beautiful!