Tempering glass

Likes: 4137

5.0

5

1

4137

Tempered glass according to drawings and dimensions, order safety glass for your project. The plant will produce tempered glass on time and deliver it to the site. Glass-Store.ru

- How does the hardening process take place?

- Where is it used?

- Tempered Glass Specifications

- We work and produce 24 hours a day, seven days a week

- How to order tempered glass in Moscow?

Glass is tempered from ordinary sheet glass by heating it to the melting point and sharply cooling the glass. The DomGlass company has installed a special glass tempering production line, the maximum width of tempered glass is 4200 mm. For the production of tempered glass, technical conditions are used, adhering to which, the glass does not break during the tempering process; below, the main values of glass thicknesses and dimensions are presented in more detail.

We accept orders for tempered glass of any complexity and size, and are able to fulfill even the most demanding requests. Our highly qualified employees will always provide you with competent, detailed advice and help you decide on your order.

Submit your application

Tempered glass is absolutely safe and serves as the basis for indoor use!

Broken tempered glass crumbles into small pieces with blunt edges that are not capable of causing injury, and is impact resistant.

The constructed object is not exposed to any temperature influences, weather conditions and retains all its original characteristics. And also this:

- Environmentally friendly material;

- The degree of strength is 7 times more reliable than glass that has not been tempered;

- The interiors have a lot of light, a feeling of lightness, airiness, transparency, and aesthetics.

Advantages of Tempered Glass

Advantages of tempered glass:

- high mechanical strength both against impact and fracture (several times more than that of conventional material);

- vibration resistance;

- permissible operating temperatures - from -150 to +300 °C;

- durability;

- high level of safety - even if tempered glass breaks, it will crumble into many small rounded fragments with blunt edges, which are practically impossible to cut;

- Possibility of use for utilitarian and decorative purposes.

Standards and terms

For tempered glass, the European standard EN 12150 uses the term “thermally toughened glass”, and the American standard ASTM C1048 uses the term “full tempered glass”. The Russian standard GOST R 54162-2010, developed on the basis of EN 12150, uses the abbreviated American name in the English version of the name: “tempered glass”. There is also an interstate standard for tempered glass GOST 30698-2014, which is also developed on the basis of EN 12150, and essentially duplicates GOST R 54162-2010.

The European standard EN 1863 calls thermally strengthened glass “heat strengthened glass,” and the American standard ASTM C1048 calls it “heat-strengthened glass” (with a hyphen). The Russian standard for thermally strengthened glass GOST 33087-2014 was developed on the basis of EN 1863.

Application of Tempered Glass

The use of tempered glass covers a variety of areas. This material is used to make:

- double-glazed windows for doors and windows;

- sheets for glazing facades;

- showcases, partitions;

- staircase steps, railings;

- glass for cars (rear and side);

- parts for furniture and interior items;

- refrigerator shelves, fireplace screens;

- elements of greenhouses, greenhouses, winter gardens;

- external structures (canopies, roofs, bus stops, etc.)

How is stalinite made?

Some of our clients do not know what tempered glass means.

Therefore, it is worth considering the manufacturing process of such products in more detail. These spare parts undergo special hardening. In order to harden them, you need to heat the part to a very high temperature. It can reach 680 degrees. Then, auto glass for foreign and Russian cars is quickly cooled by blowing cold air. During the cooling process, compressive stress is formed on the surface of the spare part. It increases the mechanical strength of the material and its resistance to temperature changes. Some manufacturers tint finished products, but not more than 5% darkening. Therefore, it is quite difficult to determine the shade of tint by eye. If you don't know how to check the color of a part, take a piece of white paper and place it under the glass part. The paper will immediately take on a pale blue or light green tint.

Very high strength is the main difference between tempered glass and regular glass. For this reason, the material is used not only in the automotive industry. It is made from:

- impenetrable windows in psychiatric wards;

- shop windows;

- glass furniture;

- heat-resistant dishes;

- railway structures.

Preparing for work - what tools are needed?

Often, in the hands of beginners, hardened material becomes unusable precisely because of haste and lack of experience. In such cases, the only correct option is a laser, but not everyone can afford to buy such a device. In this regard, you will have to look for another way out. Many experts advise working using the pre-annealing method. This will allow you to cut the glass quite accurately and use it for its intended purpose.

It is necessary to take into account the peculiarity that when cooling the annealed material, its outer side will cool much faster than the inner one. If the surface has completely cooled down, this does not mean that the inside is ready for cutting. Due to the fact that the glass cools slowly, the appearance of a large amount of stress in it is prevented. Because of this, it is possible to obtain a better quality cut. This is worth considering every time you want to cut material.

Glass cutter for working with glass

In order to do the job correctly, you need to prepare the following tools and materials:

- a piece of tempered glass;

- warm clean water;

- bake;

- a thermostat, however, if it is not there, then you can cut the material without it;

- square;

- marker;

- grinding stone;

- glass cutter;

- a wooden rod with a diameter of no more than 6 mm;

- glasses for protection.

Having prepared everything you need, get to work. When slicing, follow safety precautions to avoid damaging the skin of your hands and face.

Glass Tempering Equipment

Tempered glass is always a popular material. It is used in architecture, transport, and the production of consumer goods (household appliances, electronics, lighting and decor). Professional glass tempering furnaces will help automate production and accurately control the quality of finished products.

From the VEGA catalog you can choose equipment from the leading Chinese manufacturer Gangxin. The company's equipment provides a full cycle of automatic production of thin tempered glass with high energy efficiency and productivity. These products can be purchased in all regions of Russia through the nearest VEGA branches. Delivery of orders throughout the CIS is also available.

Principle of operation

Most hardening plants are a single system consisting of a transport conveyor, heating, hardening and cooling sections. The roller conveyor is driven by servo drives with flexible adjustment of frequency and speed. Glass bending machines also have an additional molding section following the heating chamber.

The hardening process is based on heating the glass blank to 650-700 °C. It warms up on both sides followed by cooling. To ensure uniform heating of the loaded sheet, hot air from the heating elements is distributed by blowing fans. The finished product is also cooled by air.

After tempering, glass is approximately 5-10 times stronger than regular glass and, importantly, is injury-proof. Tempered glass breaks into small fragments in the form of granules with smooth edges, it is almost impossible to get injured by them.

For tempering flat glasses

Universal, because suitable for loading products ranging in size from 50×100 mm to 3500×8000 mm. They have impressive productivity, up to 400 m²/h. Depending on the design, convection cooling from fans or blowing with compressed air from a compressor is used. All models of this type can work with low-emissivity (energy efficient glass).

For tempering curved glass

They are used for the manufacture of glass mounted on transport, as well as decorative and façade glass. Depending on the orientation of the bending shafts, there are models of longitudinal and transverse bending. Also, these machines can bend the edges of the sheet asymmetrically (on one side) or symmetrically (on both sides).

The thickness of the workpieces for subsequent bending is limited to 4-12 mm, the area is also smaller than in flat hardening furnaces - no higher than 3000x5000 mm. The average productivity of curved glass tempering furnaces is 50 loads per hour.

Combined

They combine the advantages of the 2 previous types, but are used exclusively for processing thin sheets up to 6 mm in height.

With double heating chamber

They are characterized by maximum productivity. These machines produce 1.6-1.8 times more products than standard flat glass furnaces. Most often used for processing thick sheets.

With double convection

Modification of convection ovens for the production of large volumes of energy-saving glass. Can accommodate workpieces that are equally large in area. Excellent for hardening sheets used in façade glazing, glass canopies and roofs.

Tempered glass manufacturing technology

Glass tempering technology involves two key processes. First, the material is fired in a kiln until softened. Then it is cooled under streams of air, which is supplied evenly from several sides. Let's describe the process in more detail.

- The sheets are cut to obtain blanks of the desired configuration.

- The glass is polished along the edges with an abrasive material.

- Heat in the oven to a temperature of 650–680 degrees.

- Cool on both sides with powerful air currents.

To temper ordinary glass, air coming from an air-jet grille is most often used. There are other methods, for example, ion tempering, when the glass is placed in a special chamber where ion exchange occurs. In this case, temperature does not play any role at all, unlike air hardening.

Tempered glass vs regular glass: main differences

The main differences relate not to appearance, but to the properties of the material. It becomes more resistant to any mechanical stress and temperature changes. At the same time, visually the glass remains the same - the optical properties of the products are preserved by 99%.

Image No. 1: This is what tempered and regular glass looks like when broken.

For this reason, it is almost impossible to distinguish tempered glass from regular glass by external signs. The simplest ways are to look at the surface under a powerful light source (the reflection on the plane will slightly ripple) or break it (the absence of sharp fragments indicates that the material has been hardened).

Image No. 2: how regular and tempered glass behaves in the event of mechanical damage

Material characteristics

- Increased strength. Tempered glass is 5–7 times more difficult to break than regular glass. For example, a 4 mm thick sheet will retain its integrity when a load weighing 45 kg falls on it from a height of 1 meter.

- Heat resistance. The material can withstand temperature changes from -70 to +250 degrees. For this reason, it is often used to make ovens and fireplaces.

- Vibration resistance. According to this indicator, the material is 5 times superior to its non-hardened counterpart.

- Safety. Products subjected to heat treatment are broken into small fragments, which remain on a special film. For this reason, the risk of injury is reduced.

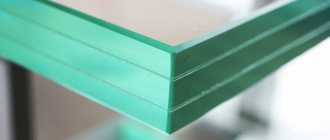

Duplex

Impact-resistant duplex glass is a protective material consisting of only one layer of glass, which is covered with a durable, sometimes decorative, matte or tinted film. Duplex, thanks to its protective film, provides not only anti-vandal properties, but also high safety from injuries, since when its surface is destroyed, the fragments will stick together and will not fly apart and damage people and material assets. Due to its simple design, this safety glass is light weight, high strength, relatively low price and is inferior to triplex only in less noise insulation.

How to temper glass at home

Tempering glass at home, unless, of course, you have a muffle furnace and a powerful ventilation unit, will not work. You can only slightly increase the strength properties of products. There are two ways to do this: using a special film and releasing. Briefly about both methods.

- Using film. A way to protect your phone or tablet screen from scratches and other external influences (not shocks). You can buy film at any store that sells digital gadgets.

- Vacation. A method for relieving excess stress from glass products. Tempering is used to strengthen glasses, jars and other utensils. We'll tell you more about the vacation below.

As you can see, we are not talking about the hardening process. Only about a slight increase in the strength properties of some products.

Required equipment

To make tempered glass at home, you will need powerful industrial equipment: muffle furnaces and fans. Purchasing them for one-time use is irrational, since the finished material will cost less than the cost of its production.

Photo No. 1: muffle furnace for glass tempering

Note! Drilling tempered glass at home or cutting a finished sheet will also not work. All processing is carried out preliminary, before hardening. Otherwise, cracks and chips may form on the sheet.

The production uses powerful installations designed to harden sheets with dimensions up to 6000*3210 mm. Keraglass brand ovens have preheating and convection chambers. In the preheating chamber, the glass temperature is gradually increased to 300 degrees. Then the material enters the main heating chamber, where it reaches 700 degrees. The process ends with forced cooling. The presence of special scanners and IR sensors allows you to evaluate areas of heating.

Photo No. 2: industrial furnace for tempering glass

Material consumption

Tempered glass is made from sheets of ordinary glass. During processing, the volume of the original raw material is preserved. Thus, from 1 sq. meter of glass can be made 1 sq. meter hardened Also, hardening does not affect the optical properties and appearance of the canvas.

Disadvantages of tempered glass

Tempered glass has one significant disadvantage - it cannot be processed after heating and uniform cooling procedures.

Attempts to cut or drill will cause destruction of the sheet structure. In addition, this material is vulnerable to end impact - if the blow falls on the edge, the glass will instantly break.

Designers were able to take advantage of the vulnerability of this material to end impacts - they created multi-layer panels with a reliable effect of broken glass.

Why shouldn't you do the hardening yourself?

The hardening procedure itself looks very complicated. However, before working in production, the material also undergoes preliminary preparation. Ignorance of technological processes can reduce the result of work to nothing. So what happens in production?

- Glass is selected by discarding damaged sheets.

- Sheets are cut according to previously prepared drawings.

- The edges of the product are polished.

- Drill holes for fittings and fasteners.

- The blanks are washed and dried, then assessed for defects.

- The glass is tempered and checked again for defects.

- The material is packaged and sent for sale.

Note! It is also impossible to polish tempered glass that has gone through the entire technological cycle. There is a high risk of damage to the canvas.

As you can see, there are too many nuances and features that cannot be taken into account when working.

Tempering glass at home

Many people wonder how to temper glass at home? This is impossible to do, since the technology requires special equipment. On some sites you can find information that hydrofluoric acid helps a lot, but working with it is extremely undesirable.

Firstly, this is a rather dangerous and toxic substance, which requires a special protective suit when handling. And, secondly, although the glass will become stronger, it will lose its transparency, so it will be unsuitable for further use. Therefore, you can only purchase ready-made material and use it for your needs.

The only option for independent use is film for tempering screen glass. This element can be easily installed at home. The film is sold in a mobile device accessories store and is quite inexpensive. It will protect the screen from scratches and abrasions, but it will not withstand strong mechanical shock.

We work and produce 24 hours a day, seven days a week

The DomGlass plant has firmly established itself as a leader in the glass industry market, continuing to expand its network of business partnerships. We invite B2B segment partners, as well as architects, designers, construction organizations, studios and furniture manufacturing companies, to long-term fruitful cooperation.

They choose us because we:

- We work with small and large enterprises and are aimed at long-term cooperation;

- We prepare individual commercial offers;

- We guarantee prompt optimal production times and product quality;

- We organize our own delivery.

Being a manufacturer and working with large volumes of production, we have the right to set optimal prices per m2.

Areas of use

But glass ceramics or tempered glass are used not only in the automotive industry. The scope of its application is incredibly wide and extends as far as the user’s imagination allows. In principle, this material can be installed anywhere, even instead of conventional window glass. But it will cost much more, which is why people do not often take such a step.

Farmers use tempered glass greenhouses to prevent workers from being accidentally injured while processing plants or harvesting crops. For personal needs, installing such a structure will also be quite expensive, especially since greenhouses often last only one season, and then they are dismantled as unnecessary. Only farmers build monolithic structures that will last for many years, because they regularly grow a certain crop.

The manufacturing technology of protective glass is not a secret. Moreover, no unique methods are used at the acquisition stage. The material is obtained naturally, in the same way as the standard variety. And it receives hardening as a result of additional manipulations with temperature.

Protective tempered glass can be easily found on sale. The material is not scarce, so any user can easily find any quantity he needs for his work. There is also an option to place an individual order for the production of non-standard shapes. The fact is that after hardening the element is more difficult to process, so it will be easier to immediately cut out the desired shapes and then harden them. Cutting glass of this type is possible thanks to modern technologies, but it is a rather complicated procedure, so it will cost accordingly.

In offices you can often find partitions made of tempered glass. They are installed so that employees have personal space and can concentrate on work without distracting other colleagues. And they choose safety glass because it can be accidentally broken, and it is necessary that the worker does not get injured from the fragments. In some companies, glass is painted over with opaque paint so that a person is not distracted by extraneous movements and concentrates on his duties.

Manufacturing technology

So, tempered glass is produced as follows:

- 1. First, a standard type of material is smelted using known technology.

- 2. Then it is cut into the required parts. The thickness and dimensions of tempered glass depend on its brand and purpose. Upon request, the user can receive any parameters that he will need for subsequent work.

- 3. Next, the resulting elements are subjected to heat in special ovens. The processing temperature ranges from 650-680 degrees Celsius.

- 4. After leaving the furnace, the material is instantly cooled with air from all sides. As a result of such manipulations, a protective layer is formed on the surface, which increases impact and thermal resistance, and also makes it possible for the glass not to break randomly, but to crumble into cubes with non-sharp edges to minimize the risk of cutting injuries to a person.

Traces from oven rollers

In a glass tempering furnace, the glass is softened to about 600 ºC. During processing in the furnace, the glass is in constant cyclic reciprocating motion on ceramic rollers. As a result, when passing through the furnace, the glass more or less takes the shape of these rollers, which causes noticeable wavy glass curvatures on most heat-treated glass products, including double-glazed windows (Figure 3).

Figure 3 – Optical distortions from the marks of the hardening furnace rollers on tempered glass of double-glazed windows [2]

Local deviation from straightness of tempered glass without coating over a length of 300 mm should not exceed (Figure 4):

- for glass with a nominal thickness of 3 to 5 mm: 0.5 mm;

- for glass with a nominal thickness from 6 to 25 mm: 0.4 mm.

Glass manufacturers are able to reduce these local deviations from the impact of the tempering furnace rollers to 0.13 mm [1].

The requirements for local deviation from straightness of thermally strengthened uncoated glass over a length of 300 mm are more stringent than for tempered glass: it should not exceed 0.3 mm;

Figure 4 – General and local deflections of glass: 1 – general deflection of a sheet of glass; 2 – width, height or diagonal of the glass sheet; 3 – local deflection (roller trace);

4 – length 300 mm

How to temper glass

The hardening process takes place according to a certain technology. It involves heat treatment of a glass object. First, the glass is heated strongly and then quickly cooled. To increase the intensity of the process, quenching media with special cooling capabilities are usually used. Most often, ordinary air is used as such a medium. In this case, an air-jet blowing grille is used.

A very effective technique is one in which special cooling liquids are used as a quenching medium. They allow you to speed up the heat transfer process. Such liquids can be molten salts, metals, mineral oils and silicone solutions.

When using liquids in a quenching environment, the heat transfer coefficient changes depending on the temperature conditions. A significant disadvantage of this hardening method is the insufficient controllability of the process. So, when hot glass gets into the cooling liquid, boiling occurs. And this dramatically affects the heat transfer coefficient.

Another way to temper glass is using molten metals. The peculiarity of this method is the high heat transfer of the metals used. The main disadvantage of such hardening is the high density of the melts, which significantly complicates the process of immersing glass.

Modern enterprises use automated systems that make it possible to temper glass of any size and thickness.

Thermal treatment of glass and distortion of images

Typically, glass installed in a building structure is subjected to various types of loads, which can cause distortion of the object that we see through the glass or the display of this object from the glass. These distortions are defined as a change in the shape, orientation, or location of the original object. Factors that may cause these distortions include the following:

- the difference in altitude above sea level between the place of manufacture of double-glazed windows and the place of their installation;

- changes in atmospheric pressure;

- change in outside air temperature;

- wind load;

- the pressure of the frame on the edge of the glass or glass unit.

Below we will consider the effect of thermal treatment of glasses on the curvature of optical objects.

About the influence of changes in weather conditions - air temperature and atmospheric pressure - on optical distortions of double-glazed windows, see here.

How to distinguish tempered glass from non-tempered glass.

Since, in appearance, tempered glass is indistinguishable from raw glass

, sometimes you have to think about what kind of glass the customer brought you, tempered or not. Products are often brought to us for trimming, and naturally the customer does not know whether he has it hardened or not. Even though we are not responsible for damage to the customer’s material, it is unpleasant for us if we fail to do our work efficiently, so we will share with you the secret of how to distinguish tempered glass from non-tempered glass.

- If glass with a chip is sent for trimming, then most likely it is unheated, because No one will temper glass with chips.

- When cutting tempered glass, the cut turns out to be torn, the glass cutter cuts in fits and starts, there is no clear, smooth sound.

- Tempered glass is sometimes marked (tempered, tempered)

- If you degrease glass and spray water on it, the water will accumulate in puddles on tempered glass, and spread on damp glass.

- There are special instruments for determining the tension of glass, as well as those that recognize tempered and non-tempered glass.

- It is believed that through polarized glasses, dark spots become visible on tempered glass, but there are no such spots on ordinary glass.

Bottom line.

The phrase of one of the heroes of the cult Russian film “Boomer” - “we’re not like that, life is like that” - fully corresponds to the harsh realities of today’s way of life. Therefore, at present, especially for residents of apartments located on the ground floors, the issue of ensuring the safety of their homes is acute. In addition to installing a video camera on a window and installing a door with video surveillance, you also need to take care of protecting the window opening.

Today, there are several options for equipping a modern window with glass designed to perform various types of tasks. You can choose tempered glass, or you can choose glass with increased anti-burglary characteristics - “Triplex”. In any case, how the window protection will be provided, and how effective it will be, depends entirely on the requirements for organizing the security of the protected premises and the financial capabilities of the owner.

How can you distinguish tempered glass from regular glass?

In what cases can hardening not be done:

Tempering may not be done in cases where there is no expected temperature heating of the glass or physical impact on the glass that could cause it to break; kitchen glass aprons are usually tempered only behind the hob to save money; glass display cases should preferably be tempered, and any dimensional products where possible free fall of glass onto a person must also be tempered or at least protected with a film so that pieces of glass do not fly apart but remain hanging on the film; glass tabletops are not always tempered.

Differences in solar energy transmission spectra

To illustrate the differences in the optical properties of different materials, we have prepared a graph showing the transmission spectra of solar energy. Having studied it, we can come to the conclusion that especially large differences are observed at wavelengths from 190 to 380 nm - the ultraviolet region, as well as in the range from 780 to 2500 nm, which belongs to the infrared region.