The roof is a complex building structure, each detail of which requires a responsible approach in terms of construction and finishing. It happens that, being carried away by the main elements, masters neglect the little things that are not so important, in their opinion.

However, even perfectly constructed slopes and impeccably laid covering can ruin crooked windows on the roof gable. In addition, if the rules of arrangement are violated, they can cause a decrease in performance characteristics and premature destruction of the structure.

Options for installing gable roof gables

A well-designed and constructed roof becomes not only reliable protection for a frame house, but also its decoration. Here every detail is of great importance, be it the pediment, cladding or decorative elements. It would seem that with skillful actions, an ordinary structure can turn into a masterpiece of construction art, but before making the gables of gable roofs, developers carefully think through every detail of the installation process, we invite you to familiarize yourself with the basics of this art.

What types of attics with balconies are there, photo examples

If there is a need to expand your living space, then using an attic is an excellent solution. You have an entire floor at your disposal, which can be turned into a cozy room (relaxation room, bedroom, nursery, office). The arrangement of the attic floor is carried out in the same way as in the whole house, but there are still some nuances - this is a balcony in the attic.

The photos in our gallery will clearly demonstrate what attic balconies are, and you will learn the features of these architectural elements from this article.

Pediment functions

The pediment is the upper part of the wall, which is limited on the sides by slopes and below by a cornice. In most cases, a gable roof is made in the shape of a triangle or pentagon. You can also find another description of the pediment: the pitched part of the wall, which has solid masonry with a load-bearing structure. In the case of a timber or frame house, this element is more often referred to as a gable wall, although both terms mean the same thing and apply to all areas of the attic floor constructed from brickwork, timber or block material.

The pediment is assigned several missions at the same time, and it copes with them perfectly:

Exterior works

Exterior work includes installation of waterproofing tape, drainage and waterproofing. But first we need to remove the swing door again so that nothing bothers us. We manipulate the clamps and remove them easily. To perform work outdoors, you need to take care of safety, so there must be a flat and wide enough surface under your feet, for example, a table. By climbing onto it and leaning out of the opening, you will get excellent access to all parts of the installed object without the risk of “diving” with health consequences at the most inopportune moment.

Follow safety rules when working outdoors

Architectural forms

Most of us are more familiar with triangular or pentagonal pediments, but these are not all the forms inherent in the under-roof part of the wall. Architects also create structures of the following type:

Design Features

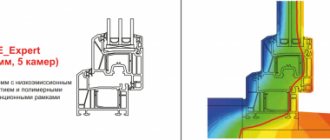

All dormer windows supplied for free sale are distinguished by the following features:

The installation of such window structures is carried out between the rafter beams, which significantly limits their width.- Increased strength of profiles and glass - enclosing structures must withstand snow loads, taking into account the formation of bags with double the mass.

- Dormer window blocks have a special profile of the outer frame, which ensures a tight fit to the roofing, regardless of its material.

- Seals must maintain the dew point throughout the entire winter period, without hardening the structure or destroying the material.

- The fittings of the rotor sashes are made with a lock, which allows you to hold them in the open position.

- The clamping pins ensure reliable sealing of the joint, without causing distortions.

- Most roof trusses are made from wood, and many manufacturers of such window structures also strive to use only natural materials for frame profiles.

- Many windows installed in a pitched roof have an additional galvanized trim, powder-coated in RAL, which eliminates the destruction and warping of wood under the influence of ultraviolet radiation.

- For sashes, fittings are used that are designed to last at least 60 thousand complete opening and closing cycles, without the need for replacement.

Thus, when manufacturing dormer windows, the manufacturer pays increased attention to quality, reliability and durability , which, in turn, affects the retail price of the product.

Calculation and installation

Any competent work begins with engineering calculations, which allows you to maintain the proportions and geometry of the roof, as well as determine the amount of building materials that will need to be used to cover the pediment. To begin with, the height of the gable wall is determined, and if there is already a roof, then the calculation is carried out taking into account the height of the ridge. Otherwise, the duration of the pediment is determined, and, guided by the obtained parameters, the geometry of the gable structure is built. The height of the structure is planned taking into account its functional purpose. For a non-residential attic, a height of up to 1 m is sufficient, while a residential attic requires 1.5 m. If you want to get a comfortable living space, install the ridge at a height of 2 to 2.5 m.

Pediment height for attic

The gable wall of a frame or any other house is built using two technologies, which differ in the order of work:

Before installing the roof. If only the box of the building has been erected, you can build the pediment first, then the slopes will not complicate the process, because they do not take up space. Having chosen this method, install the mast in the center of the gable wall, and its length should correspond to the height of the pediment itself. You need to pull a cord from the mast to the corners of the box, which will outline the contour of the gable space.

If the roof installation is completed. In this case, the pediment is laid out from inside the attic. This method is not so convenient, because access to the object is limited by slopes, but the geometry of the roof has already been formed, and you will not disturb it with your actions.

Installing the pediment of a frame house cannot be called very difficult, because the vast majority of people with certain skills can do it. The sequence of work here is determined by the choice of building materials, and most often they turn to the help of raw wood or brick. If you decide to cover the pediment with wood, then first build a frame, and then cover it with boards at least 30 mm thick.

Experts do not recommend using plywood for such purposes, even if it is moisture resistant, because such material does not have sufficient strength and the structure will not be absolutely reliable. As external cladding, you can use siding or lining, which will give the facade a beautiful appearance and enhance moisture and thermal insulation. The brick structure is created by laying half a brick, with an average material consumption of 40 pcs/1m2, taking into account the fit. It is best to carry out installation with hollow bricks to reduce the load on the foundation of a frame house.

Facing or giving an attractive appearance

This process requires extreme caution, but the essence of it is quite simple - you need to resort to creating a frame, and then start attaching the decorative panels (panels).

It is important to choose the right materials for cladding the pediment so that they match or at least harmonize with the overall cladding of the building. But builders do not always adhere to this rule. So in some cases, different materials look quite good, but the combination of some elements can lead to disastrous consequences.

For example, metal gable cladding on a wooden roof will inevitably lead to rotting of the latter and the need to replace it in the near future. Therefore, pay close attention to the choice of material.

What materials can you choose for cladding?

- Decorative panels made of PVC, asbestos cement and PVC are used for cladding. The materials are durable, resistant to temperature changes, rotting or deformation.

- For lining it is better to use the same material. The main advantages are, of course, naturalness, pleasant shade, rich texture.

Insulation

As mentioned earlier, thermal insulation work is carried out where the attic will be used as a living space, but even if the attic is non-residential, and funds allow, it is better to insulate the gable, because this will have a positive effect on the microclimate inside the frame house and will save on heating.

Following the advice of professionals, it is better to choose basalt wool, and only as a last resort, polystyrene foam.

The installation process begins with the construction of a frame made of boards, the width of which is equal to the thickness of the insulating material. It is necessary to stretch a vapor barrier membrane under the outer cladding of the gable of a frame house. From the inside, such a “pie” must be covered with shields or boards.

Facing the gable with siding

Do not compact the insulation under any circumstances, as it will lose its beneficial properties. Also, do not forget to leave a technological gap between the mineral wool and the internal lining. To ensure that wooden cladding elements last a long time, they are treated with special antiseptic agents. It is recommended to inspect the roof at least once a year and, if necessary, carry out timely repairs. If you know how to make a roof gable, then you will definitely not have any questions with the repair.

Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

Source

Interior work

Internal work includes additional insulation of slopes. We recommend using a relatively new, but already proven material: “sandwich”. Although, of course, there are many options for insulating slopes. It all depends on preference. Some people like to use high density foam, others like mineral wool and line it with plastic. Whatever material you use, the main thing is that everything turns out warm, reliable and beautiful. And handwork itself brings satisfaction.

Sandwich panel

As a logical conclusion, it would not be amiss to share important details with readers. First of all, let's mention permissions. During installation, the side gaps should be at least 20-30 mm on each side, and the height should be about 45 mm for the length of the window. By the way, the length of the structure is chosen based on the angle of inclination of the roof (this is the opinion of experts). We described the width, based on the size of the beam step, above. However, it is possible to install a translucent structure on two spans. This will require additional time and effort, but will allow you to use a much larger window and, therefore, have more light and air in the room. Of course, we will return to the topic of translucent structures, and next time we will tell you in detail how to assemble the façade glazing of an attic with your own hands. In the meantime, feel free to drill holes in the roof and install windows to the delight of yourself and your family.

How to install windows on the roof gable: the specifics of window construction and the technology of their framing

The roof is a complex building structure, each detail of which requires a responsible approach in terms of construction and finishing. It happens that, being carried away by the main elements, masters neglect the little things that are not so important, in their opinion.

However, even perfectly constructed slopes and impeccably laid covering can ruin crooked windows on the roof gable. In addition, if the rules of arrangement are violated, they can cause a decrease in performance characteristics and premature destruction of the structure.

Covering the gable opening

The construction of gable walls is carried out using different materials, the main thing is that they exert as little pressure as possible on the load-bearing walls. Typically, hollow bricks, foam blocks, boards or any sheet material are used. In order for the cladding to blend harmoniously with the house, as shown in the photo, it is better to make it from the same material that was used for cladding the facade.

Covering the pediment of a wooden house

The front opening of a wooden house is covered with siding, corrugated board, wooden boards or any other similar material. Calculate material consumption using the following formulas:

- for a triangular shape, the calculation is made by multiplying the height by half the width of the base;

- a complex shape is divided into regular geometric shapes, for example, a square or a triangle, and their area is calculated.

The boards are nailed to the end wall. If the sheathing is made with siding or other similar material, a sheathing is made for them, taking into account the installation of insulation.

Brick lining

In houses with brick walls, the gable opening is filled with similar material, only the masonry is not made in two rows, but in one row. At the junction of each row with the roof slope, the corners of the brick are cut off to reduce the gap. If the wall is erected before the rafters are installed, then a contour is made from a cord under it, which is gradually laid with brick.

When sewing up an opening with any material, it is necessary to provide openings for windows, of course, if they are necessary. Large pediments are reinforced on the inside with pilasters.

Facing and insulation of the pediment

When calculating the facing material for the facade of the house, you need to make a certain reserve. But before its installation, the façade opening must be insulated. If the attic will be equipped as a living space, the thermal insulation must be separated by hydro- and vapor barrier. All this work is carried out simultaneously with laying the roofing pie. A brick wall can be insulated from the outside with polystyrene foam under the plaster, so as not to take away the internal usable space. After all the work is completed, all that remains is to arrange the overhang by making it with your own hands from the side of the gable. You can see how to sheathe a pediment in the following video.

What else to read on the topic?

Purpose and types of windows on the pediment

The installation of windows on gables is not at all a “fad” of aesthetes, but a well-founded technical necessity. When colliding with the wall of a house, the air flow tends to go around it tangentially. Having encountered an insurmountable obstacle, it breaks into two peculiar channels, one of which rushes towards the foundation, and the second soars forcefully under the cornice.

The part of the air flow rushing under the eaves strives to overturn the roof or simply tear it off and carry it away. The described aerodynamic phenomenon lifts airplanes. What can we say about relatively lightweight structures that protect low-rise buildings from precipitation and wind.

True, the wind only blows the roof away, and excess pressure in the attic space contributes to overturning and collapse. Just to reduce the pressure on the pediment, dormer windows are installed. If a hipped roof is being constructed, then they are placed on slopes parallel to the pitched planes or in the form of small protruding structures with a single- or double-pitched roof.

The name “dormer” windows on the roof is not at all in honor of the secret methods of surveillance, which received the prefix “audio” much later. At the beginning of the 19th century. During the construction of the Moscow Manege, an extremely negative reaction of the roof structure to sudden gusts of strong wind was noticed. Master Slukhov’s “rational proposal” for arranging openings in the form of many windows with blinds eliminated the problem, and the name of the inventor formed the basis of the term.

Windows on gables, as well as windows on slopes, simultaneously perform a number of significant functions:

In heated buildings with a cold, unused roof, dormer windows in winter equalize the difference between the temperature within the attic and outside it. The thermometer readings outside and inside should differ by a maximum of 5 - 6º C, which is ensured by the windows on the roof.

If the attic is expected to be actively used, functional dormer windows become larger in size and acquire the significance of attic analogues. These are traditional companions of sloping roofs, Danish half-hip, half-mansard roofing structures. Structurally, these are ordinary double-glazed windows mounted in the gable wall.

Windows on the pediment should provide adequate ventilation of the space. If one large window is enough to ventilate the attic, then two dormer windows are needed in opposite gable walls.

The placement location is an arbitrary characteristic, depending on the architecture of the house and the taste preferences of the owners. However, there are technical recommendations that are worth listening to in the name of normal roof operation:

To service a 50 m2 roof attic without ventilation vents, at least one window must be installed. If the attic is divided by fire partitions or firewalls, each compartment should be provided with its own window.

The windows on the pediment are made primarily in the form of single-pane glass or a blind sash with blinds. The first option is recommended to be supplemented with ventilation grilles for free circulation of air flow. The second option was originally intended for continuous ventilation without involving the owners of the house in regular opening/closing.

With regard to roof windows, everything is not so strict. The form has the right to be anything as long as it is combined with the architecture. The size is chosen based on the climatic conditions of the construction area. In the southern regions, a dormer window is allowed to occupy ¾ or more of the gable area.

According to the method of installation in the pediment, window openings are divided into:

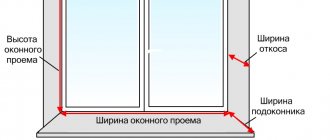

With the first ones everything is very clear. In the end walls of the house under construction, it is necessary to create openings for the installation of double-glazed windows or structures with blinds, either factory-made or home-made. The opening is formed 2-3 cm larger than the outline of the window frame in the vertical and horizontal dimensions.

A window frame is first installed in the opening of a foam concrete or brick pediment, which is fixed with anchor bolts directly into the wall or into an antiseptic-treated plug placed during laying. After placing the window frame in the box, it is attached to the box. And the installation gaps are foamed after laying an oiled or bitumen-impregnated rope in them.

If the end walls of mansard and gable roofs are made using frame technology, the work on installing windows involves embedding a support frame into the frame. This is the most accessible operation for independent execution, the implementation of which is devoted to the article.

What is needed for installation

To carry out the work, you will need fastening steel studs, ridge boards, plywood, rafters, screws, level, insulation, glue, sealants and insulating materials.

The rafters must be the same size. If the shape of the slope is rectangular, then we use the Pythagorean formula to find the area of the pediment. If the form is different, we look for the corresponding formula.

Before installing the gable, your roof and walls must be connected to the drainage system. In addition, the floors must be completed and all other elements must be installed.

The platform built after this must be strong in order to become the basis of the future pediment.

How to make a window on the pediment

Both the attic and dormer windows do not experience loads equal in value to their ordinary counterparts. From above, only a small part of the pediment, the roofing pie and snow press on them. If the roof slope is less than 45º, the snow mass is taken into account; if less, it is neglected. When constructing roof windows, this characteristic is always included in the calculations.

The pediment belongs to the category of load-bearing walls, because obliged to support the load, albeit less than ordinary floor windows. In order for the opening not to weaken the structure, it must be strengthened and part of the vertically directed load must be redistributed to nearby vertical posts.

Window box device

Redistribution is carried out in the simplest way, which consists in installing horizontal jumpers at the level of the top and bottom of the opening. It, as already mentioned, should be 2 - 3 cm wider and higher than the window frame if it is made of laminated wood or plastic. For a homemade wooden frame, you will need to leave 5 cm in height and 2 - 3 cm in width for the linear expansion of the binding.

After fixing the frame in the opening, the voids around the perimeter are filled with polyurethane foam. The specified technological gaps between the window frame and the opening frame should be approximately the same. If, of course, the opening was constructed without significant deviations. Only on the top trim of a homemade window you need to leave a larger margin, about 3 cm. It is insulated and covered with a platband on the outside and inside.

The simplest way to install a window opening in a frame is to simply attach two horizontal ties to adjacent posts. The upper horizontal connection is duplicated by a jumper. The size of the lintel is determined according to the table, based on the standard snow load corresponding to the construction region.

If there is not enough thickness of the pediment frame posts to support the lintel with the cross section determined from the table, they will need to be strengthened by installing a paired element. Simply put, if the lintel turns out to be wider than the rack, it will need to be hemmed with timber or a board of a similar size.

Usually there is one dormer window in the center on the pediment, but there can be two or more attic windows. To form an opening for the first, as a rule, it is necessary to cut the central support post of the layered rafter system.

Sawing is carried out after the installation of the row posts of the pediment, which take on the weight of the outer truss. The central support then no longer has such a decisive importance, and one can safely assign its responsibilities to the ordinary posts of the gable wall frame.

It is much easier to arrange window openings if the roof is constructed using hanging technology. In this case, the pitch between the posts of the pediment frame can be chosen equal to the width of the window frame with centimeters allowed for expansion. If for some reason it is significantly larger than the frame, then additional drains are installed on the sides of the window being constructed.

Openings on the gables of the attic are made according to the described rules, but in a complex: i.e. with cutting the frame posts, strengthening them and then installing jumpers corresponding to the load.

Jumpers are most often made from 48×198 mm or 48×148 mm boards sewn in pairs. The double parts are connected with nails. The prefabricated element is installed on the edge, because the support area of the stitched element cannot be less than 90 mm. Instead of a paired board, you can use a beam of a suitable size.

The jumper is installed above the upper horizontal connection. Between these elements it is necessary to leave a gap of 1.0 - 1.5 cm, required for the permissible deflection of this part. The lintel is placed flush with the gable wall, the boundaries of which are determined by the frame at the construction stage. To do this, grooves are selected in the drain (or racks).

Installation and fastening of the window unit

We will assume that we have successfully completed the construction of the window frame intended for fastening the window frame in the opening. Now it needs to be equipped with the required design, either factory-made or home-made.

The window structure is mounted in the opening provided for it:

Both options must be accompanied by a low tide fixed outside the window. There is no need to install window sill boards and slopes for the first case; in the second they are mandatory.

In most cases, window units are installed in boxes with the sashes removed. However, according to the rules for fixing a number of plastic structures, the sashes are not initially removed, but fitting is carried out to install the frame together with them.

Mounting wedges in the amount of two or three pieces are placed at the bottom of the window frame. In the middle part, the thickness of the wedge should be approximately equal to the width of the gap. The same wedges should be placed around the entire perimeter of the window. A frame for fitting with sashes, if any, is placed on the lower ones, and the side and upper wedges are gradually inserted into the gap.

Having aligned the position of the plastic frame in two traditional directions, it is removed, freed from the sashes and returned to its place for final installation. There is much less manipulation with homemade wooden frames and blind bindings. After alignment in the opening, it is simply fixed with nails or screws, and the gap between the frame and the box is foamed.

Opening framing options

There are a lot of different methods for framing a window structure, which are performed both before, during or after wall cladding. In use are shaped lumber, window casings, and regular timber.

A dormer and dormer window, when covering the pediment with planks, wood or cement-fiber siding, can be simply sheathed using four pieces of timber with a thickness equal to the height of the relief protrusion of the cladding.

The bottom trim is installed first with a segment equal in length to the width of the window block. Then the side frame parts are installed, which should cover the ends of the lower trim. Finally, the top trim is fixed, covering both side bars. Its width for cutting is found by adding the same size window and two ribs of the beam.

It is recommended to protect the top trim with a tin ebb strip, which will remove atmospheric water from the wooden parts of the cladding and will not let it into the body of the frame structure. Structures both with and without insulation suffer from moisture. In addition, when wet, thermal insulation retains heat less well.

The work of those who decide to use vinyl siding for gable cladding will be greatly facilitated by additional elements produced for all types of this material. It is important to remember that you should buy extensions of the same brand as the facing panels. To frame windows on the gable, you will need platbands or J-profiles of increased size.

If the window frame is flush with the gable wall, the sheathing is done using only the J-profile. If the frame is recessed into the opening of an insulated structure, then in addition to the J profiles, you will also need a vinyl shelf to arrange the slope.

To prevent the wood from “steaming” and getting wet under the polymer coating, it is necessary to lay an insulating material between it and the vinyl parts. Standard bitumen waterproofing in rolls or aluminum foil produced in tape format are suitable.

Before work, it is necessary to cut out the platband blanks, because All vinyl cladding extensions are supplied in the form of profiled and perforated strips 3050 mm long, for example. From these you need to cut two vertical and horizontal parts of the window trim.

The size of the elements should take into account their overlap. This is calculated by adding the length or height of the opening with the two heights of the profiles selected for arrangement.

Algorithm for arranging an opening when covering it with siding:

At the end, the assembled platband must be pressed against the pediment. In roof window cladding without insulation, the tongues are bent inside the trim parts or cut off.

A slightly different method of finishing the opening involves making cuts at 45º. It looks more interesting, but requires precise measurements and care in making blanks. The sequence of work is similar.

The arrangement of windows on insulated facades is carried out using a near-window profile - a modernized J-version. It allows you to veneer the slopes of the opening simultaneously with the installation of platbands. To do this, the wide shelves of the near-window profile must be trimmed according to the actual dimensions of the slopes being constructed.

Before installing them, regular vinyl siding finishing profiles are installed around the perimeter of the window opening. Then the system of near-window platbands is inserted into the niche, and secured along the outer edges with a finishing profile. The same method is used to cover doorways if they are on the pediment.

The platband profiles are fastened to the wall in increments of approximately 20–30 cm through the holes provided on the mounting side. Screws with wide heads are screwed in the middle of the hole so that when the polymer profile linearly expands/contracts, it has the ability to move without destroying the structure.

After fixing the trim, vinyl panels for the gable cladding are installed. They must be inserted into the corresponding grooves of ordinary trim or finishing strips used when installing window trim installed in a niche. If necessary, panels are cut to actual dimensions.

Standards

When sitting down to think about the design and starting to draw up a drawing of the future dormer window, it will be useful to familiarize yourself with the requirements of sanitary standards and regulations, better known as SNiPs.

If the project involves the arrangement of several auditory openings in a row, the distance between their outer edges must be at least 80 cm. Compliance with this requirement will allow you to freely arrange preventive inspections of the roof, clean it from snow or leaves, and replace roofing material. On some roofs you can see dormer openings in two rows, one above the other. In this case, it is recommended to comply with the same standards: the step from the bottom edge to the floor and between the openings themselves is from 0.8 m.

Gable roof gable, including its types, as well as how to correctly calculate and make

The upper part of the building's facade between the last crown and the ridge of the roof is called the pediment. It is of particular importance because it completes the façade of the building and gives the house a complete look. Therefore, the finishing of the pediment requires close attention, and for the final work it is necessary to choose a durable, strong and beautiful material. In the case of a residential attic space, you need to think about insulating the gables with environmentally friendly material, installing windows with ebbs and interior decoration of the habitable space. We will tell you how to make a gable roof gable with your own hands.

Dimensions

First of all, you need to decide on the size and location of the future window. The translucent structure is installed in the opening between the beams of the pitched roof. The average distance between them is usually about 600 mm, but can be greater. The height of the window, as a rule, is chosen arbitrarily, but its upper cut must be at least two meters from the floor. A finished window of the required size can easily be purchased at any construction market or ordered to be manufactured from a company that produces such structures. Having delivered the window boxes and fittings to your home, you can safely begin decorating the window opening with your own hands.

1. Distance between beams;

2. Distance between the top edge of the window and the floor

Types of gable roof gables with description and characteristics

The shape of the pediment is laid out at the design stage and follows the shape of the rafter group of the house. For gable roofs, the upper part of the facade is limited by the ridge part, rafters and horizontal tie beam. Depending on the preferences of the owner, gable roof gables come in the following types:

The symmetrical pediment of a gable roof is the most popular in suburban construction

The broken gable of the gable mansard roof allows you to maximize the living space

Decorative elements of a gable roof with a stepped pediment give the building an individual look, but require separate protection from environmental influences

The trapezoidal gables of the gable semi-hipped roof are protected from precipitation by roof overhangs

According to the order of construction, the gables can be arranged as a continuation of the walls of the house or sewn up after installing rafters, sheathing and installation of roofing material. When the pediment is a continuation of the walls of the building, it needs finishing and insulation only at the junction of the walls with the rafter system, in the area of the gable overhang of the roof. If the gable is closed last, the complexity of the cladding depends on the habitability of the attic space. A residential attic requires a responsible approach not only to finishing materials, but also to insulation of the upper part of the facade. A layer of waterproofing film, insulation and vapor barrier is laid between the external and internal finishing; it is also worth taking care of the removal of condensate that occurs between the diffusion membrane and the finishing materials.

It is important to pay attention to the fact that the installation of roof windows requires strengthening of the rafter frame, additional measures to insulate the structure, as well as the installation of drip linings.

Design diversity

It seems that the variety of design solutions knows no bounds; Each craftsman strives to give the dormer window individual features. However, all this splendor can be reduced to a small number of typical window designs, which include the following models:

- With a pitched (flat) roof. A window with side walls and a flat roof, the slope of which is less than the slope of the main roof. In this design there is enough space under the ceiling (unlike a gable one).

- With a gable . A classic and much-loved cuckoo, the structure of the rafter system repeats the traditional gable roof.

Forms for every taste Source pinterest.ca

- Triangular dormer . It is a simplified version of the previous version and gives the building a romantic, fairy-tale look. The difference is the absence of side walls, which makes the superstructure simple to implement. The main drawback is that there is not much light coming in.

- Dormer under a hip roof . The hip roof with dormer windows attracts the eye, and the building acquires a respectable and elegant appearance. To achieve harmony, the angle of the hip above the dormer follows the angle of the main roof.

Dormers under the hip Source proroofer.ru

- Arched dormer . Attractive in appearance, but troublesome to arrange and therefore a rare option. Such window openings are sometimes placed vertically, one above the other.

Arched dormers Source pinterest.com

- Bat . The window opening is elongated and pointed at the corners (in medieval architecture it was called a “bull’s eye”). A plastic form, the construction of which requires professional skills from the performer.

Bat Source makemone.ru

- Anti-aircraft lamp . The design, which gives the building an airy effect, can be in the shape of a pyramid, sphere, rectangle, or oval.

How to correctly calculate the gable roof gable

To calculate the pediment of a gable roof, it is necessary to determine its type and, if the design of the facade and roof is not specified in the project, reflect it on the drawing. There are several ways to attach gables to the roof of a house:

Methods for joining gables and roofs, as well as the materials necessary for this, are regulated by standard СО 002–02495342–2005 “Roofs of buildings and structures. Design and construction”, in particular, Appendix 9. Based on these recommendations, materials and the procedure for performing work are selected. The calculation of the pediment is influenced by the presence of an attic space, which requires additional insulation measures, as well as installation of external and internal cladding. The calculation procedure must begin with calculating the geometric dimensions of the pediment, which will allow you to find out the required amount of material.

Gable roof gable height

The height of the pediment is set at the design stage of the building and is based on the choice of the comfortable volume of the attic floor. The height of a pitched roof is affected by wind load, so the designer needs to choose a middle ground between the convenience of living in the roof space and resistance to wind influences.

The height of the gable is chosen based on a compromise between the largest volume of living space and resistance to wind loads

If there are no design data, the width of the building is used, and the slope angle is selected experimentally using a beacon, a measuring cord with a tape measure and an inclinometer. In this case, a drawing is drawn up with which you can calculate the height. If the width of the facade and the angle of inclination of the pitched roof are known, then the height of the pediment is calculated by the formula H = L ∙ tg α, where H is the height of the pediment, L is half the width of the building facade, α is the angle of inclination of the slope.

When calculating the height of a brick pediment, it is important to understand that the ridge girder will rest on its upper part, so in order to avoid errors, this circumstance must be taken into account.

How to calculate the gable area of a gable roof

The area of the pediment is of great importance for calculating the required amount of insulation and finishing material. The upper part of the facade, as a rule, is a triangle. If it has a more complex shape, then it is divided into several simple geometric shapes.

If the pediment has a triangular shape, then its area is equal to the product of half the width of the building times the height to the ridge

In the general case, a sloping roof may have asymmetrical slopes, then it needs to be divided into four figures - two trapezoids and two triangles - and apply the indicated formulas to each of them

It is important to remember that to obtain the true area of the gables, you need to subtract the area of the windows located on the gable parts of the building from the result obtained using the above formulas.

Calculation of material for the gable roof gable

The procedure for calculating the material required for the gable of a gable roof depends on the method of constructing the facade.

If the pediment is a continuation of the wall, then there is no additional frame and insulation. Soffits (bottom) and wind strips (sides) will be required as finishing materials for finishing gable overhangs. They are calculated as follows:

If the pediment is installed after completion of the roofing work and its material differs from the facade wall of the building, then its manufacture will require a frame for attaching the finishing material and laying a layer of insulation. Due to the presence of a pediment overhang, a canopy is often installed at the boundary between the wall and the pediment, which serves to additionally protect the facade of the house from precipitation.

Before finishing the pediment, which is mounted as part of the roof, it is necessary to calculate and mount the frame, and also prepare the gable overhang for lining

Calculation of material for finishing the pediment is carried out as follows:

To create a pediment frame, a beam with a cross-section of 100x50 mm is required, which is installed in increments of just under 600 mm

The amount of required steam, hydro and heat insulation materials is calculated based on the total area of the gable

The sizes of insulation, finishing materials and insulating films may differ from one manufacturer to another, so for an accurate calculation it is necessary to find out the true parameters of the product from the supplier. To ventilate the gable and overhangs between the waterproofing film and the finishing material, it is necessary to leave gaps for free air circulation using mesh at the bottom and perforated soffits or other materials at the top.

It is very important to ensure the outflow of condensing moisture from the space between the membrane and the finishing material, especially for metal finishing parts.

Video: gable frame

Types of finishing materials for the pediment

The pediment can be finished in different ways. For example, you can arrange the finishing material vertically or horizontally, use shades that match the color and structure of the walls, or build a gable trim that contrasts with the main design of the house. Facade cladding can be made from:

Covering the pediment with a block house gives it an appearance stylized as a log

Plastic sheathing is not subject to temperature deformation and does not change color in the sun

Facing the pediment with painted corrugated board is a good budget option for finishing an outbuilding or garage

Comfortable conditions in the residential under-roof space largely depend on the choice of insulation method, which can be external and carried out simultaneously with the insulation of the walls of the house, and internal on an already assembled pediment. Unpressed polystyrene foam is chosen as external insulation, followed by plastering and painting the surface of the building walls.

Internal insulation of the pediment is made with glass wool, basalt wool or extruded polystyrene foam.

Internal insulation of the gable is most often done with mineral wool using a waterproofing membrane and vapor barrier film

The thermal insulation properties of these materials are at a high level and are calculated on the basis of the technical characteristics specified in the supplier's accompanying documents. The standard dimensions of insulation are 1200x600x50 mm, but the range includes double-thickness mats and slabs 1200 and 1500 mm long, so you need to choose sizes that are convenient for installation in each specific case. You should pay attention to the thermal conductivity coefficient, volumetric weight, water absorption and environmental friendliness of the insulation. Using the table below, you can evaluate the properties of insulation in various designs with flammability class NG.

Table: properties of insulation in different types of execution

| Product type | Density, kg/m 3 | Thermal conductivity, W/m o C | Limit temperature, o C |

| Mats | 50–85 | 0,046 | 700 |

| Light slabs | 30–40 | 0,036 | 400 |

| Soft slabs | 50–75 | 0,036 | 400 |

| Semi-rigid slabs | 75–125 | 0,033 | 400 |

| Rigid slabs | 175–225 | 0,043 | 100 |

Foamed polystyrene foam, used for external insulation of walls, is highly flammable because there is air in the pores of the heat insulator, and the ignition temperature of the material is quite low. Therefore, during installation, you cannot work near open fire, and then you need to plaster and paint the walls of the building.

Construction Basics

When starting to build a gable, you should consider the following points:

- What construction technology will you choose? The pediment can be a completely separate part of the house, which is mounted to the walls, or a continuation of the walls.

- Is your foundation strong enough? Even during planning, it is necessary to take into account the fact that the front walls give additional load to the foundation of the house.

- Climatic conditions of the area. If you live in a windy place, you need to take a number of measures to eliminate wind loads. This part of the building must be securely reinforced.

Be sure to consult a specialist before starting construction. This will help identify the features of the pediment that is suitable for your frame.

How to build a gable roof gable

The arrangement of the pediment should begin after calculations and preparation of the required amount of building materials. First, a frame is constructed, supported by rafter legs and tie rods. Attention should be paid to the strength of the structure, so the insertion points of the windows need to be reinforced with additional elements. After installing the windows, a waterproofing membrane, counter-lattice and finishing material are attached to the frame. Then the eaves overhang is hemmed and decorative corners and wind strips are installed.

It is easier to install insulation from the attic side, because from there the contours of the insulated room and the joints of the gables with the roof are better visible. This procedure allows us to minimize the presence of cold bridges between the external environment and the attic space. The final stage is the installation of the vapor barrier film and the internal cladding of the gable.

The insulation material must be placed in the cells of the frame with a noticeable tension to prevent the formation of gaps between it and the racks

You can make a gable roof gable yourself; it is important to follow a strict sequence of operations and, in difficult cases, follow the recommendations of specialists.

DIY gable roof gable

Self-installation of a gable roof gable requires construction skills, proper tools, and consistent execution of the technological cycle. First you need to mount reliable scaffolding, prepare materials and fasteners. Wooden parts must be pre-treated with antiseptic compounds and dried. During the work you will need the following tools:

After the preparatory process, scaffolding and decking are assembled at a height that provides convenient access to the work site. Then installation is carried out in the following sequence:

When installing the frame, window openings are reinforced with additional racks

After sewing the waterproofing film, a counter-lattice is installed to provide the necessary ventilation gap.

After installing the facing material, strips are installed on the overhangs for attaching the spotlights

The insulation is fixed with a string, and then a vapor barrier film and finishing material for the residential part of the pediment are attached

It is important to follow the sequence of installation operations, then a properly mounted and insulated pediment will last at least thirty years without any need for repairs.

Video: installation of siding and windshield on the gable

Some thoughts

If air exchange is poorly functioning in summer, the temperature can rise to too high values. Some of this heat will penetrate into the rooms below, which will significantly worsen living conditions. In this situation, you will have to purchase an air conditioner, and this will require additional costs for the device itself and its operation.

The result of poor ventilation is shown.

In addition, temperature changes lead to the formation of condensation on the internal elements of the rafter system. Wooden surfaces are exposed to water and then begin to rot.

The service life of load-bearing elements is significantly reduced. Even if a metal beam system is used, exposure to water will cause rust to form over time.

A short excursion into history

For the first time, dormer windows began to be used in the architecture of medieval Europe, becoming especially widespread during the Renaissance (XV-XVI centuries). In Gothic buildings they were traditionally decorated with rich stucco or carvings, turrets, side pilasters and false columns. Structurally, they were a continuation of the wall of the building’s facade, and were located parallel to it. Visible from afar, such structures in an exquisite decorative frame became a real calling card of the entire building.

The construction term “dormer window” is used only in Russian, having no analogues in other countries. Thus, in Europe, windows in the roofs of buildings, since the Middle Ages, have traditionally been called “lucarnes” in the French manner.

Dormer windows - lucarnes

In England and the USA, the name dormer or skylight is more common - attic, skylight. Where did this rather strange name come from in our language? There are two versions of the origin of this name. One is given in V. Dahl’s Russian language dictionary, and the other is associated with the legend about the construction of the Moscow Manege.

The great Russian ethnographer Dal in his dictionary gives the following interpretation of this architectural term. “A hearing window made in the roof.” The word “rumor” previously in colloquial Russian also had the meaning of “vent”, “ventilation hole”. Dahl is inclined towards this interpretation, because “there is nothing to listen to in the attic through this window.” The legendary version associated with the construction of an arena in Moscow is also widespread. This building, now located on Manezhnaya Square of the same name, was erected in honor of the five-year anniversary of the expulsion of Napoleonic hordes from Russia.

As you can see, the playpen has many dormers

Initially, the Manege was called Exertsirgauz, and was intended for drill training of troops, as well as for reviews and parades during bad weather. The construction was initiated by the victorious Emperor Alexander I personally. The construction of the building was completed in a year, and the autocrat had to personally accept the building. But by the time Alexander visited the Manege, a big problem had occurred: the suspended ceilings, richly decorated with plaster stucco, were noticeably deformed for some reason. This did not escape the meticulous gaze of the emperor, who ordered the cause of the defect to be identified and eliminated.

The reason turned out to be simple: deformation of the rafters made of larch. The metal roof of the Manege heated up in the summer sun, and after it, the attic space, made without vents, also heated up. The civil engineer Slukhov was entrusted with correcting the situation, who found a way out in the device along the entire roof of two rows of ventilation windows. Since then, roof windows have become an integral part of the structures of all large buildings, especially those roofed with metal. And in Russian architecture, they are named after the engineer Slukhov, and the name “auditory” is supposedly assigned to them.

More information about the history of dormer windows:

Ventilation system in a warm attic

Currently, natural circulation is not used in heating systems. To live conveniently and comfortably in a warm attic, you cannot do without ventilation. When the attic is converted into an attic, the roof is made ventilated.

When the roof is covered with sheet metal or flexible tiles, a counter batten is sewn onto the rafters. A metal roof requires a windproof film. A slate roof does not require a counter batten. The attic is ventilated along with other rooms. Through the VTK valves located in the windows, air enters the room and must exit through the ventilation openings. If there are none in the walls, then there should be fungal aerators on the roof.