It is impossible to completely eliminate the possibility of a fire occurring and its spread, even if all necessary measures are taken. Since flames rise not only up stairwells, but also through windows, these areas also require additional fireproof protection. In order to contain the rate of fire spread and the penetration of substances released during combustion into another room, fire-resistant windows are installed, the production technology of which uses special non-combustible materials.

PVC windows and fire safety.

Since fires have been and will always be inevitable, building structures and products made from PVC are also exposed to fire.

How does polyvinyl chloride behave during fires? A huge amount of research has been carried out on the behavior of PVC materials in fire. As a result of these studies, the main characteristics of PVC during combustion were obtained:

PVC is difficult to ignite and does not support combustion in the absence of a fire source. This property of PVC determines its higher place in all national and international fire safety standards in relation to wood.

The amount of heat released when PVC burns is significantly less than that of many other materials, such as wood. Consequently, the use of PVC reduces the likelihood of a fire and reduces the rate of fire spread if a fire does start.

The chlorine content in PVC prevents the spread of fire. This is an important reason for the widespread use of plastic in the construction industry.

Gases released when PVC burns: carbon monoxide and dioxide, hydrogen chloride and water vapor. Due to its pungent odor, hydrogen chloride is easily detected even at low concentrations. Carbon monoxide - the infamous carbon monoxide - on the other hand, is completely odorless. It is well known as a major factor in many fire deaths. However, it is released when absolutely all organic materials, such as wood, burn.

Hydrogen chloride, released when PVC burns, reacts with water vapor and forms hydrochloric acid, which has a corrosive effect on metal structures of buildings. However, the concentration of acid is so insignificant that it does not pose a danger to either the building structure or human health.

Due to the above properties of PVC, insurance companies in Europe consider this material to be no different from other materials in terms of the degree of additional risk it creates during accidents, fires and natural disasters.

was the first in the industry to carry out certification tests of PVC profiles for their fire-fighting qualities. According to the certification test protocols (Test State Enterprise "TsNIISK named after Kucherenko") PVC profiles of the "KBE" system are classified as low-flammability, combustible materials with low smoke-generating ability.

Fire safety requirements in construction are regulated by SNIP 21-01-97 “Fire safety of buildings and structures”. Article 5.18 stipulates that “Fire resistance limits for filling openings (doors, gates, windows and hatches) are not standardized, except in specially specified cases and filling openings in fire barriers.” Article 5.19 states: “The fire hazard of filling openings in the enclosing structures of buildings (doors, gates, windows and hatches) is not standardized, except in specially specified cases.” “Specially specified cases” usually mean fire barriers, which are divided into types according to Table 1, and the requirements for the fire resistance limit for windows in fire barriers are given in Table. 2 of the above document.

A special case is the use of products made from PVC profiles as partitions and internal doors located on evacuation routes in case of fires. Here, depending on the specific situation, different requirements may be presented, the analysis and control over the implementation of which is the responsibility of the architect and fire inspector.

However, in such situations, it must be borne in mind that the fire-fighting qualities of such products (in particular, the fire resistance limit), to a greater extent than from PVC profiles, depend on the filling of the frame elements, which is on average 60-80% of the area of the products, and which can be made from different materials: from different types of glass (regular, reinforced, triplex), from sandwiches lined with plastic or aluminum, from products such as lining, from sheet material - different types of finishing slabs.

Fireproof glass production

To produce custom-made fire-resistant glass, we use monolithic glass sheets of the Pyropane brand, which are distinguished by their high quality and excellent optical properties. In the production of glass, heat-resistant compounds are used that have high fire-retardant properties and do not impair the light transmission of the material. Thanks to modern functional equipment, fire-resistant glass does not change its properties during the manufacturing process, remaining absolutely transparent.

An important characteristic of Pyropane glass is its environmental friendliness. To produce multilayer glass sheets of this brand, resins that are safe for humans are used. Such glass can be used in rooms with increased environmental requirements, since they do not emit dangerous volatile substances and are absolutely harmless to human health.

Fire resistance classes of glass are assigned depending on its properties:

- the integrity of the canvas, guaranteeing protection against flame penetration through cracks and holes (E);

- thermal insulation ability of the fabric (I);

- the ability to limit the flow of heat into the room (W).

Fire resistance requirements for windows and doors

Fire resistance requirements can be regulated in the design documentation for the construction of a structure, or during its arrangement and, in particular, when planning internal partitions.

In cases where there is a high probability of fire in the room, requirements for the degree of fire resistance may be imposed on the glazing.

In explosive premises, easily resettable windows are installed (see GOST R 56288-2014. “Window structures with double-glazed windows, easily resettable for buildings. Technical conditions.”

Fireproof plastic windows in the office must meet the following requirements:

- SNiP 21–01–97 Fire safety of buildings and structures

- GOST 53308-2009

- GOST 30247-94 “Building structures. Test methods for fire resistance."

- Federal Law-123 “Technical regulations on fire safety requirements”

The fire resistance limit of a building structure is indicated by a letter and a number.

R is the time limit for loss of bearing capacity, E is the time limit for loss of integrity, I is the time limit for thermal insulation capacity.

Marking R 120/EI 60 means a limit for loss of load-bearing capacity of 120 minutes, and for loss of integrity and thermal insulation capacity - 60 minutes.

Fire resistance class of fireproof windows (OP)

To assess the fire resistance of windows, only the E indicator (structural integrity) is used. Depending on the requirements, fire windows (OP) can have a protection class of 1-3, corresponding to integrity. The indicator is calculated in minutes: from the maximum E60 - 60 minutes of stability, to the minimum E15 - 15 minutes of stability. How to read the symbols of fire windows in the technical specifications:

It should be borne in mind that combustion itself is a very dangerous process. In the event of a fire, none of the structures (neither PVC windows nor wooden ones) can withstand fire for a long time, and in the event of destruction, they release harmful substances from which they should be protected in the first place. An article on the topic of environmental safety of plastic windows: Environmental friendliness of plastic windows.

Fire resistance limits

The fire resistance limit is of great importance. The indicator makes it clear how long the device as a whole will resist fire. The fire resistance value can be set after checking the profile for fire resistance during testing. The indicator is measured in minutes.

There are three indicators.

- Integrity is lost when holes and cracks appear through which flames and combustion products penetrate.

- The load-bearing capacity is lost when the building structure collapses, bends to the limit, and the rate of formation of the ultimate deformation increases.

- Thermal insulating ability is lost when the temperature rises to the limit and the limiting value of the density of the heat flow at a specific distance from the surface that should not be heated is reached.

The indicator is in the range of 0-90 minutes. It is related to the size of the glass and the floor where it is located. The purpose of the device is to give time to evacuate people before the fire spreads to the entire building.

The safe period of time is 60 minutes. It is better not to install them with less fire resistance.

This is interesting: Fire-resistant stained glass windows: types, requirements, installation rules

Life or wallet (window fire resistance)

It is difficult to calculate how many accidents and deaths could have been avoided if building materials and technologies fully complied with existing building regulations and safety requirements. In pursuit of profit, many manufacturers ignore these requirements, buy false certificates of conformity from corrupt officials, and construction organizations are very willing to buy their products, due to the significant difference in the cost of truly high-quality analogues.

For example, we can take the same doors and windows, which, when installed in a certain list of objects, must comply with fire safety rules. With free access to the Internet, it is quite easy to see for yourself that all manufacturers of doors and windows unanimously claim in the characteristics of their products that their products are made only from the safest materials that do not emit harmful substances and comply with ALL fire safety rules. Moreover, some even indicate certain indicators (EI 15, EI 30, EI 60, etc.) characterizing their compliance with certain legal requirements.

But what does “complies with all fire safety regulations” mean? Let's leave alone those “entrepreneurs” who do not provide any specific indicators in product characteristics and only promise “full compliance.” A demanding consumer who values his time and money immediately loses interest in such unfortunate businessmen, since such products do not inspire confidence and, most likely, in other parameters the products are either not certified at all, or have passed the necessary tests in the form of evergreen, but not at all Christmas trees.

The modern consumer is fundamentally different from the consumer of the early 90s, for whom everything that was at least somewhat reminiscent of European or American goods automatically evoked an association with the highest quality and boundless trust, confirmed only by a set of words. People are gradually learning to separate the wheat from the chaff and, before purchasing anything, they begin to take an active interest in the “what and how” in terms of product quality and safety.

In the fire resistance characteristics, manufacturers give two letters “E” and “I”, next to which a certain numerical value is indicated, for example, “EI 30”. What exactly does this product characteristic mean?

In Ukraine, all building materials must comply with the current DSTU, and in the case of fire safety - DSTU B V.1.1-4-98. According to this official document, “E” is the loss of structural integrity, and “I” is the loss of thermal insulation properties. The number indicated next to it means the time after which the samples tested in the fire furnace lose their integrity (they begin to melt, deform, burn out) and their ability to insulate. This characteristic is called fire resistance limit.

This means that if a window has a fire resistance rating of “EI 30”, then it must withstand the test in a fire oven for 30 minutes at a constantly increasing temperature, which by this point in time will reach 842 C. The higher the EI index, the correspondingly higher the temperature in the oven: EI 15 – 739 C; ЕI 30 – 842 С; EI 60 – 945 C; EI 90–1006 C, etc.

Current building codes and regulations (SNiP) clearly regulate the requirements for installing fire barriers, including windows, doors and partitions, in clearly designated areas.

These include: – places with large crowds of people (schools, kindergartens, hospitals, museums, libraries, shopping centers, hotels, cinemas, etc.); – technical rooms and rooms in which explosive equipment is installed (electrical, gas and other installations); – places designated as evacuation routes in emergency situations (fire and emergency exits, exits from elevator halls; exits to stairs). What do we really have? You don't need to be a fire safety expert to see that these standards are being violated at every turn. Plastic windows and doors are being installed en masse in schools, kindergartens and other institutions where the lives of many people depend on compliance with fire safety rules. It’s funny for an intelligent person to even hear that PVC structures have at least some limit of fire resistance, especially since the combustion products of polyvinyl chloride are very harmful to health and greatly reduce the chances of survival in a fire.

Some might say that wood, aluminum, and even steel also burn. Right. The laws of physics have not yet been repealed. But wooden enclosing structures, thanks to special impregnation, still have a minimum fire resistance limit and do not emit chemicals when burning.

Aluminum structures are best suited to such requirements. And although the melting point of aluminum is 620 C°-660 C°, due to the presence of a special liner in heat-resistant profiles, aluminum structures have different fire resistance limits, the indicator of which depends on the number of thermal liners. When heated, the thermal insert changes from a solid to a gaseous state and absorbs thermal energy up to a certain point. Only after the thermal insert (or several inserts) “boils away” does the profile itself begin to collapse. At the same time, the cost of aluminum windows and doors is approximately the same as that of wooden ones.

It is encouraging that recently the government has begun to take at least some measures in an effort to bring domestic standards closer to European ones. But still, imagine this picture: there is a fire in the apartment, it is impossible to go out into the corridor, the only way is to the balcony. Do you think 30 or 60 minutes will help you wait for rescuers, provided that the window unit meets the fire resistance limit? So what is more valuable – life or wallet?

gost white sugar

Download GOST for fireproof windows txt

Fire windows are a type of fire barrier that combines the functions of a regular window: transmission of natural light, visual visibility, noise and heat insulation, and a fire protection structure to prevent the spread of fire to the facade and roof of the building.

Although in the professional environment it is often customary among suppliers to divide fire-rated windows into so-called external and internal ones, from the point of view of Rospozhnadzor there is no such thing as internal fire-rated windows.

Only translucent fire partitions can be installed inside a building, and even if this partition looks like a set of windows, then regulations must still apply to it as partitions, and not as windows. In particular, different limit states are used for windows and partitions according to clause. The list of regulatory documents on fire-resistant windows includes the following laws and rules: Fire resistance test method - in terms of preparing and testing fire-resistant windows during their certification.

SNiP, also regulating that fire windows should not be openable. Fire protection systems - regulating the rules for installing fire windows of a certain fire resistance in those parts of the building that may be subject to thermal heating due to radiation.

Classification of fire barriers Division of windows into 1, 2 or 3 types; Requirements for limiting the spread of fire in buildings, structures, structures, fire compartments. Windows in fire barriers must be non-opening. In other words, fire-resistant windows are subject to integrity requirements only. Fire windows are designed to prevent fire from spreading outward to the façade and roof.

Thermal radiation emanating from the fire towards the street is dissipated in the atmosphere and does not pose a threat of the fire spreading to other floors of the building. The use of drives for automatic closing of fire-resistant windows is not covered by this document. The scope of application of fire-resistant windows of a certain type is regulated in the Code of Practice SP 4.

In accordance with this document, in the following places fire-resistant windows with a fire resistance limit of at least E must be installed. Such a wall must be a fire-resistant wall of the 1st type, the windows must have a fire resistance limit of E60 p. For fire-resistant windows in these places, the fire resistance limit must correspond to E60 according to P.

Separately, it should be noted that fire-resistant windows are not explicitly subject to regulatory requirements for light transmission, sealing of installation joints from moisture and others related to the daily operation of windows and their contact with precipitation.

The standard task of any window is to provide free access to sunlight into the room and protect its inhabitants from cold and humidity. However, modern high-quality designs have moved far beyond this limited functionality and can now offer much more. Fire windows save you not only from cold, heat and any vagaries of weather, but also from open fire. Innovative technologies make it possible to create models that can withstand prolonged and intense exposure to high temperatures during fire, which in force majeure circumstances can save more than one life.

International and Russian standards have been developed for fire-resistant structures, which make the manufacture of fire-resistant windows a technologically accurate and verified process.

Fire windows: features and design requirements

To increase the safety level of a facility, reduce possible losses and even save someone’s life, it is recommended to install fireproof windows. Today they are found mainly in industrial or administrative buildings and much less often in residential buildings. This selective use is explained by the peculiarities of operation and evacuation from different objects. For the manufacture of fire-resistant windows, special profiles and double-glazed windows are used. There are a number of models that are called fire resistant, but their characteristics do not meet some regulatory requirements.

This review material will tell you about the types of fireproof windows, the principles of their classification, scope of application and installation features.

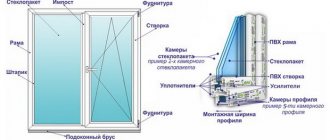

Main design elements

The components of the classic design of the product - without opening doors, are:

- frame - usually steel or with an overlay aluminum profile;

- fire-resistant double-glazed window;

- heat-resistant profile fillers, active inserts;

- fire-resistant compounds - foams, sealants used during the assembly or installation process.

Each element is characterized by a set of material requirements. All structural units must have a fire safety certificate. There are no classic window fittings in fireproof structures.

Frame

The range of offers on the market of fire-resistant products, along with metal fire-resistant windows, includes products made of wood and PVC. Such a product can have an exclusively steel base.

Even class 3 fire resistance of fireproof windows requires special fire-resistant glass. The specific gravity of the light-transmitting material can reach 50 kg per square meter. The total weight of the glazing of one window is estimated at 200 – 300 kg. Therefore, a high-quality fire protection product must have a steel base. In fact, all fire-resistant aluminum windows can only be made of non-ferrous metal profiles.

Naturally, wooden and plastic fire-resistant windows are incompatible with fire safety standards. Regarding the first option: a steel frame made to look like wood is allowed. Installing a fire-resistant PVC window is a direct violation of fire safety rules. Almost all plastics release toxic volatile compounds when exposed to high temperatures for long periods of time.

Glass

There is a simple rule: the higher the fire resistance of the material, the greater its thickness. This affects the weight and cost of the product. There are two basic technologies for manufacturing fire-resistant double-glazed windows:

- a single-layer product using a special chemical composition and a hardening procedure at a certain temperature;

- laminated glass bonded using fire-resistant film or gel-like adhesive.

The advantage of a single-layer fireproof window is lower material thicknesses. Typically, this parameter for materials E30 - E60 is in the range from 6 to 10 mm. The result is a reduction in the weight of the entire structure.

The disadvantage is a complex manufacturing procedure that requires a long time. Also, single-layer glass often has size restrictions.

Multilayer material can reach thicknesses of over 20 mm. The advantage of triplex is due to the fact that the adhesive structure between the layers - film or gel - prevents the material from bursting and scattering into fragments. Additionally, manufacturing laminated glass does not require much time, and there are no size restrictions.

Cold and warm double-glazed windows

An additional characteristic of the material is the possibility of thermal insulation. Based on this criterion, the following types of fire windows are distinguished:

- warm – facing the street;

- cold - used in interior walls.

It is worth noting that the second type of double-glazed window is rarely used. Typically, fire partitions are used indoors, while windows primarily face the street.

What are fire windows: purpose and scope of application

The components from which fire-resistant structures are assembled can effectively retard the spread of flame. The frames of such models do not burn or melt for a certain time, and the double-glazed windows do not crack and remain sealed. Thanks to this, it is possible to localize the source of the fire. In fact, installing fireproof windows is necessary to prevent fire from spreading quickly. Installing such structures at the right time will “give” precious minutes until the firefighters arrive.

Fire-resistant structures are needed wherever it is necessary to ensure the safety of people and the safety of property. Their presence is especially important in places where there is a significant concentration of personnel and visitors. As a result, the list of places where fire windows are most often installed includes the following objects:

- archives and libraries;

- logistics centers and warehouses;

- oil depots and gas stations;

- municipal institutions;

- industrial premises;

- educational, children's and medical institutions;

- laboratories;

- luxury residential complexes.

The rules for installing such structures are determined by clear instructions from SP 4.13130 “Fire protection systems”. This document contains all the necessary requirements regarding the layout of facilities where fire-resistant windows are installed, as well as regulating other important features of building structures.

What about bars?

If software is an unaffordable luxury for you, but fire safety issues are not an empty phrase, you might want to think about how well your window bars comply with existing regulations. I will talk about them in this section.

Fire safety requirements for window bars come down to the following points:

Window bars must also meet certain criteria

- The room must have at least one opening grille. Usually they are made either completely hinged or with only one opening leaf. To protect the house from penetration, swing grilles are equipped with a padlock or built-in lock. In this case, it is necessary to ensure that every family member in the house or employee in the office knows about the location of the key, and the key itself must be stored in an easily accessible place.

- The distance between the grating bars is also strictly regulated. For vertical stripes it should be at least 15, but not more than 18 cm.

- No less important is the material from which the bars on the first floor windows are made. Vertical rods of square or round shape must have a cross-section of at least 1.2 cm. It is this type of rods that is more difficult to bend.

Even the cross-section of the grille rods must comply with certain standards

- The installation of the grille also deserves special attention. The sheathing frame must be secured around the entire perimeter with metal embedded parts or anchors embedded in the wall of the house at least 8 cm.

Advantages of fireproof windows

Since fire can quickly rise not only up stairs, but also through window openings, these areas must also be well protected.

If you ignore this recommendation, then even if there are fire doors, partitions and other utilities, safety cannot be guaranteed. The fire will then find a weak point in the building and continue to spread throughout the facility. Windows become an additional barrier and insurance. They contain the flames from the external walls. Moreover, increasing the level of security of a facility is not the only advantage of fire windows. These designs have quite a few other advantages that are common to all modern windows:

- aesthetic and modern appearance;

- good ability to retain heat;

- high level of noise absorption;

- excellent resistance to wind loads;

- high class of tightness;

- long service life - at least 15 years.

Advantages and properties

The main advantage of fire-resistant windows is the possibility of their installation in buildings that meet the architectural requirements of class I and II.

However, such designs are characterized by standard operational advantages:

- They have a decent aesthetic appearance;

- They have a resource of increased strength;

- Prevents the penetration of noise from outside;

- Inert to agents of a humid environment, having a zero coefficient of water absorption;

- They are resistant to precipitation;

- Do not deform at high and low temperatures.

When a fire occurs in a room, fire-resistant products isolate the spaces not engulfed in flames for a long time; their tightness ensures that smoke cannot penetrate.

Windows do not require labor-intensive efforts during installation and are easy to maintain during operation. At the same time, they serve as an excellent thermal insulation barrier at low outside temperatures in winter, protect against strong gusts of wind, maintaining stable characteristics of the indoor microclimate.

The disadvantages that each technology and any type of double-glazed windows have include a higher price than conventional models and increased weight of the structure.

Fireproof plastic (PVC) windows

When manufacturers or sellers call models made from plastic profiles fire-resistant, they are lying. PVC is a moderately flammable material with a fire safety class (G3). That is, it is vulnerable to flame, which is reflected in the classification of the material. PVC fire-resistant windows, even if equipped with special double-glazed windows, are not able to withstand the effects of fire for a long time. When heated, the plastic quickly softens and the structure loses its load-bearing capacity. As a result, such models cannot become a serious obstacle for fire.

Installation Features

To install these types of window units, you need to go through six steps.

- Unpack the structure and prepare it for installation.

- Install the fireproof side into the room.

- Set up and secure the structure.

- Foam the installation seams with foam that has a fire-resistant function.

- Check the glass unit for damage, then install it in the frame using suction cups.

- Install the retaining beads, first horizontally, then vertically.

Not every installer has the right to install fire-resistant devices. He must have a license issued by the Ministry of Emergency Situations.

The difference in installation is the materials used. The master must not only have a license from the Ministry of Emergency Situations, but also understand what a fire-resistant window is. It is important to remember that the glass is coated on one side with fire-resistant material.

Fireproof aluminum windows

The most effective way to preserve the load-bearing capacity of sashes and frames at high temperatures is to assemble them from metal elements. Previously, steel was used for these purposes, which was eventually replaced by aluminum. It is a lighter metal with a melting point of 660°C. It takes some time for the structures to heat up to this state and soften. At a stable ambient temperature of 1000°C, it takes at least 15 minutes to heat up (in reality you need to wait longer), and then the softening process just begins.

Fire-rated aluminum windows are assembled from warm and cold profiles. You can read more about the difference between types of aluminum structures on OknaTrade. Warm profiles with special thermal inserts are used in the manufacture of structures that are intended for installation in openings of external walls. They prevent industrial, commercial or office premises from cooling down during the autumn-winter season. For use inside buildings and equipping unheated objects, structures assembled from cold profiles are suitable.

Double-glazed windows for fire-resistant windows

Fire doors with windows are structurally different from conventional non-fire resistant models. In the manufacture of these products, a multi-layer filling of a durable frame is used, which is able to withstand open fire and high pressure differences. To complete fire-resistant windows, special double-glazed windows are needed. They are assembled from several glasses, between which there is a special gel that glues adjacent layers when heated. In its normal state, this composition is absolutely transparent and does not reduce the light transmittance of windows.

The fire resistance of windows depends on the number of layers in a double-glazed window. The more of them, the longer the structures can withstand the effects of fire and maintain their linear dimensions. Therefore, fire-rated windows EI 30 and 60 are equipped with different double-glazed windows, which have different weights. The weight of some glass structures can reach up to 300 kg. This must be taken into account not only when manufacturing the frame, but also when preparing for installation in openings. It is also important to use fire-resistant sealants to secure glass units in windows.

Places and nuances of installation

In addition to the three main types of software, which differ in fire resistance limits, windows can be divided into two more types - with a cold and warm profile. They differ in their installation location:

The installation location largely depends on the type of profile

- cold profile is used for interior display cases;

- warm - for open areas.

Where is software most often installed?

- In production workshops with an increased risk of fire.

- In laboratories, scientific and technological complex and research institutes.

- In large office buildings.

- At industrial enterprises.

The high cost of products and the complexity of their installation make the scope of the software quite limited. By the way, about the cost - the price of fireproof windows will, as I wrote above, depend on their size, quality and quantity of special glass.

Fire protection structures are usually installed in enterprises

Eg:

- for windows with an E 30 index it will range from 8,000 to 88,000 rubles. per sq.m.;

- for structures of type E 60 - from 17,000 to 100,000 rubles. per sq.m.

Installation

In general, the software installation instructions consist of several important steps:

- unpacking the structure and preparing it for installation;

- installation of a partition with a fire resistance limit inside the room into the opening;

- fixing the product;

- treating installation seams with special fire-resistant foam;

- checking glass units for any damage;

- frame installation;

- mounting retaining beads.

Software installation is carried out by certified companies

Let me make a reservation right away: you cannot do this with your own hands. Moreover, not every company producing and selling windows has the right to engage in such work. Only companies that have received a special license from the Ministry of Emergency Situations are allowed to carry out installation.

Types of fire windows: type 1 and 2, differences

Type 1

Type 1 fire windows can withstand at least 60 minutes of fire exposure. They are equipped with 6-layer double-glazed windows with at least 5 chambers with fire-retardant gel filling. Such models are designed for use in high-traffic areas, industrial buildings, warehouses, research laboratories and high-rise shopping or business centers.

Type 2

Structures that can withstand fire for about 15 minutes are classified as type 3 and are suitable for use only in residential premises. The feasibility of their installation is questionable, since a flame delay of just a quarter of an hour is often not enough to effectively solve problems.

Areas of application of heat-resistant glass

Heat-resistant glass is widely used in residential premises, industrial, administrative and other facilities. The glass we produce, which meets all standards, can be used in construction without restrictions.

Quite often, heat-resistant glass is used for the construction of fire-resistant partitions in offices, shops, shopping centers, business centers and other similar facilities. Also popular:

- fireproof glass for fireplaces;

- fireproof glass for a gas stove (in the oven);

- fireproof glass for furnace.

The use of heat-resistant glass in the interior allows you to protect the room from sparks when using open fire. Such glass will prevent fire from entering the building if a fire occurs outside until it is completely extinguished.

Requirements for fireproof windows

The production of fireproof windows cannot be carried out the way the customer or manufacturer wants. Requirements for fire-resistant structures are regulated by standards contained in various documents:

- GOST R53308-2009;

- Federal Law No. 123;

- SNiP 21-01-97.

In addition, the regulatory framework from SP 4.13130 is used, which defines the scope of application of fire-resistant windows, and a document regulating the characteristics of the glass with which fire-rated windows are equipped - GOST 32539-2013. To avoid problems with regulatory authorities and ensure the necessary degree of protection, you should strictly comply with all the requirements listed in the documents.

Since the installation of fire windows is carried out in accordance with strict regulations, property owners are further protected from the installation of counterfeit structures.

To avoid unpleasant situations when inspectors from the Ministry of Emergency Situations check the authenticity of products, it is recommended to pay close attention to studying the certificates presented by window manufacturers. Related article: How to hang flowers on a plastic window

Safety glass according to GOST. Armored windows

For the manufacture of armored windows, depending on the requirements, different types of glass are used. Which have different strength indicators. The use of such windows is quite wide, and is used in various areas: banking institutions, secret facilities, in buildings where there is a need to improve security, as well as in cars.

Multilayer protective glasses are produced in different compositions. Plates of silicate glass glued together with polymer materials, or in combination with silicate glass and organic glass, and an option with polycarbonate or reinforcing films is also possible. It is a multilayer block with protective properties. The result is a strong, heavy and thick structure. Armored windows, depending on the composition of the structure and strength, are divided into classes in accordance with GOST R 51136-98:

Impact-resistant glass is a protective glass that can withstand repeated impacts from a freely falling body with standardized parameters. It has increased strength, unlike ordinary glass. It is able to withstand repeated impacts and mechanical stress, which became the basis for the manufacture of door panels widely used in residential buildings and apartments. Depending on the characteristics, they are divided into protection classes A1, A2 or A3.

Impact-resistant glass, depending on temperature, is divided into two types:

— used at temperatures above 0 °C, which is used indoors;

— used at temperatures below 0 °C, which has been tested for frost resistance, and can be installed outside the building;

Break -resistant glass is a protective glass that can withstand a certain number of blows from the butt and the blade of an ax, applied with standardized indicators. Glass with such properties is used in those rooms that may be subject to penetration by intruders. Depending on the strength, it is divided into protection classes B1, B2, B3. There are also frost-resistant and frost-resistant glasses.

Bullet-resistant glass (armored glass) is a type of protective glass that can withstand the impact of firearms and create an obstacle to the through penetration of the striking element. It is the strongest armored glass. Widely used for high security facilities. Bullet-resistant glass, depending on its strength and ability to withstand fire from a certain type of weapon with certain ammunition, is divided into protection classes 1, 2, 2a, 3, 4, 5, 5a, 6, 6a. Just like all safety glasses, armored glass can be: used at temperatures above 0 ° C; and at temperatures below 0 °C.

All armored windows are equipped with triplex technology glass. Thanks to this technology, windows are so durable. And depending on the number of layers, the resistance class is determined.