Today, different types of glass are used to make high-quality windows. This allows manufacturers to be more flexible when fulfilling orders and responsive to consumer requests. Thanks to this approach, companies have the opportunity not only to produce exactly the product that the client needs, but also not to inflate the price for it. The range of glass available to manufacturers allows them to solve diverse problems - increasing the energy efficiency of windows, retaining and reflecting light waves of different spectrums, ensuring safety and aesthetic appeal.

Types of glass

Sometimes, when studying information, the varieties and types of glass for plastic windows are confused. In order not to make a mistake with your choice, you cannot substitute terms. A grade is actually a brand of glass used to indicate the quality of a product. All the basic requirements that are used to classify products and determine their quality are listed in GOST 111-90:

- optical distortion;

- deviations in sheet thickness;

- the presence of non-destructive defects;

- general deviation from the plane of the sheet.

In total, the state standard identifies 8 categories that determine the quality of glass.

Marking is carried out as follows - from M0 to M7. Moreover, extreme positions are not used in the manufacture of ordinary windows. Modern double-glazed windows are most often assembled using M4 glass, although theoretically M5-6 grades may be suitable. Polished M7 sheets are used to assemble display cases, and M0 class products are intended for the manufacture of optics or measuring instruments. You can also find TS and XC markings. This means that the glass is thermally or chemically resistant. Category XC is needed for the production of laboratory glassware, and with the use of TS, fire-resistant models of profile structures are assembled that can withstand exposure to flame for a long time.

Some impact-resistant glass for windows is also processed at high temperatures, but they should not be confused with products labeled TC - these are completely different products.

Main selection criteria

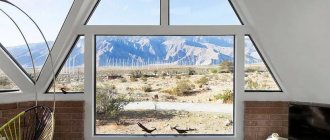

Modern PVC construction is a rather complex technical solution, the composition of which includes several elements. The main components of a modern window are clearly shown in the figure below.

It is worth noting that most buyers, when selecting a model, are guided by the degree of popularity of the manufacturer. However, in addition to this, it is necessary to take into account the fact that the appearance of PVC structures may not always meet the requirements placed on it by an individual buyer. The service life of a plastic window is quite long, the purchase is not cheap, so the appearance of the product plays an important role.

Double-glazed windows for an apartment, in addition to appearance, must be selected taking into account the planned qualities of the window:

- required temperature conditions;

- sound insulation level;

- additional accessories;

- comfort in use.

Before you finally decide which windows to choose, you need to decide what properties they should have. Also important is the fact where their operation is planned. For example, for various warehouses and commercial premises, installing impact-resistant double-glazed windows would be a completely reasonable solution. For ordinary residential premises, such an option will be unnecessary.

Properties of glass

Different types of glass for windows have different properties.

However, their basis has common characteristics. After all, it is necessary to separate the properties of the glass itself and the auxiliary elements that are used in the manufacture of different products. The only exceptions may be tempered or body-dyed glass for window frames and active sashes. These products have different thermal conductivity, fragility and bending strength. Since the composition of window glass is approximately the same between different manufacturers (75-80% SiO2, 10-15% CaO and approximately 15% Na2O), it has generally similar properties:

- thermal conductivity ranges from 0.4 to 0.82 W/(m °C) - this means that the material conducts heat well and has low energy efficiency;

- light transmittance – up to 92%;

- chemical resistance – window glass is inert to household chemicals and substances contained in the air;

- light refraction – from 1.46 to 1.53;

- the impact bending strength is 0.2 MPa, which indicates the fragility of the material;

- electrical conductivity depends on temperature and the presence of impurities, but in general the material is safe to use.

Such properties today cannot be considered ideal for modern windows, so manufacturers use technologies and substances to improve the characteristics. After all, safety, level of energy saving, sun protection and aesthetics largely depend on what window glass is made of. To improve the properties, different methods are used - adding the necessary chemical compounds and substances to the mixture during the glass manufacturing process or applying various coatings to the surface of the finished sheets. The technology of integrating other materials inside the glass (reinforcement) is also sometimes used.

Three-chamber designs

The design of a three-chamber double-glazed window provides for the presence of four glasses and three air chambers located between them.

Advantages:

- increased level of thermal insulation - at low temperatures outside, the figure is 50% higher than that of a two-chamber product;

- excellent noise insulation - up to 50 dB.

Flaws:

- significant weight (from 50 kg), creating an increased load on fittings and window profiles and reducing service life;

- reduced light transmission;

- high price.

Installation of a three-chamber product is quite complicated. In addition, it requires the manufacture of a durable profile of increased strength and large width or dividing the structure into several windows, which makes the final cost of the window even higher. The use of three-chamber structures may be advisable in two cases:

- harsh climate with prevailing low temperatures throughout the year;

- location in an area with high noise levels: near airports, railways, highways.

Some manufacturers claim that the installation of three-chamber structures is justified by a significant reduction in heating costs compared to two-chamber products. In fact, the difference in heat saving levels becomes significant only at an outside temperature of minus 40 degrees, so in regions with a temperate climate there is no point in installing a three-chamber double-glazed window for reasons of better thermal insulation.

Float glass

This most common type of glass today consists of sheets with a thickness of 0.4 to 25 mm, which are formed on molten tin. This technology makes it possible to provide glass with a smooth surface and reduce its cost, since manufacturers no longer need to polish and grind the surface of the sheets. Float glass can be either transparent or tinted in bulk. In the second case, special mineral additives are added to the silicate mass, which give the sheets a blue, green, red or bronze color. Both types are actively used for the manufacture of double-glazed windows, but the most common is transparent float glass 4 mm thick.

The characteristics of float glass can be improved by covering windows with polymer films, which help increase the level of heat and sound insulation.

The difference between the gases found in a modern window

Dried air inside the glass unit is the default.

It is dried under the influence of special drying granules that fill the spacer frames. Air is a good heat insulator that costs nothing. Then why do they pump inert gas into the glass unit? Noble gas: argon (Ar) or krypton (Kr) - has a density and mass greater than air. This property of inert gases allows them to act as the best insulator.

| Gas | Density kg/m3 |

| Air | 1,2 |

| Argon | 1,8 |

| Krypton | 3,7 |

Heat transfer in a dense gas environment slows down, which means that a window in which a double-glazed window with inert gas is installed better protects against temperature changes outside.

The safety of noble gases is determined by the fact that both argon and krypton - used to fill the chambers instead of air - are contained in the atmosphere and air around us.

Argon

It has two unique qualities:

- reduction of heat loss due to the fact that it has a lower thermal conductivity value than air;

- lack of movement inside the double-glazed window, since this gas is heavier than the atmosphere and, therefore, practically does not move inside the window unit.

Since it is a more affordable gas, most PVC window manufacturers offer it as a standard filler. Heat savings when using argon increase to 60% compared to conventional double-glazed windows.

Krypton

The use of krypton as a filler provides higher energy efficiency parameters and allows for the smallest distance between glasses. A narrow glass panel requires a small amount of this gas, which allows you to create denser systems.

Blitz survey: When choosing a plastic window, what is important to pay attention to? Poll Options are limited because JavaScript is disabled in your browser

From the articles you can learn how to choose plastic windows depending on the design and heat and sound insulation characteristics.

We advise you to study - Air humidifier for children - which one is best for your baby

For maximum efficiency and space saving in the production of plastic windows, krypton is used in three- and four-chamber double-glazed windows, and argon is used in double and triple-glazed products. Despite the high density - Krypton is 3 times heavier than air - the improvement in thermal insulating properties (by 5%) is not adequate to the increase in cost (7 times more expensive than argon), therefore Krypton is used less frequently in the production of energy-saving double-glazed windows.

For more information about the advantages of using gas in the inter-glass space, read the article: “Filling a double-glazed window with inert gas. Opportunities and advantages."

Energy efficient glass

Today, glass with a special selective coating is increasingly used to make warm windows. A metallized layer applied to the surface transmits visible rays of sunlight and blocks thermal ones. Thanks to this separation, it was possible to provide windows with high energy efficiency without reducing light transmission. Currently available:

- i-glass

– have a soft coating; - k-glass

– have a hard coating.

A detailed comparison of the characteristics of these two modifications is given in a special article on OknaTrade. Energy-efficient glass for plastic windows allows not only to better retain heat in winter, but also to retain coolness in summer - that is, it fully functions in 2 directions.

Energy-efficient double-glazed windows have approximately the same heat transfer resistance coefficient as conventional two-chamber models. An additional benefit from their use is that they can significantly reduce the weight of windows and prevent interior spaces from quickly warming up in the summer.

Types of low-emission energy-saving glasses

The “magic” coating of energy-saving glass, which selectively transmits light and heat, is a metal film several microns thick, which is applied to the glass in different ways. There are soft and hard coatings of low-emissivity glass.

What are the best window sills?

k-glass

Hard coating, or (k-glass) , is formed when a tiny film of metal is deposited on molten glass during the glass manufacturing process. It transmits light without obstacles and poorly transmits heat (energy saving percentage is up to 70). In addition, this coating is extremely durable. Due to their heat-saving properties and ease of operation, windows with k-glasses are replacing conventional ones in Europe.

i-glass

The soft coating, or (i-glass) , is applied under vacuum without increasing the temperature: a very thin film of silver is sprayed onto plain glass. In terms of technical properties, i-glass surpasses k-glass in terms of energy saving percentage (up to 90). In countries with harsh climates, they mainly use only soft coatings, although in Russia they know practically nothing about it.

Due to the unique heat-saving properties of i-glass, you can significantly save on heating. Without a doubt, the future lies in low-emissivity glass, although the Russian market has yet to develop this niche. The technology for producing such glass is complex, and the price is correspondingly high. Even in the West, only very reputable companies were able to organize such production.

links to materials that complement this article: Windows with self-cleaning glass - always light!

PVC windows with heated glass. How do they work?

Glazing windows with energy-saving glass - making the house warmer!

Triplex glass

Since ordinary float glass easily breaks even as a result of a slight impact, in the production of windows there was a need for an impact-resistant material with good light transmittance and a high level of safety. This is how triplex appeared. It was obtained by combining ordinary glass and a polymer film, which is located between two sheets. This combination made it possible to simultaneously increase both strength and safety. Even if triplex glass manages to break, thanks to the film, the fragments will not scatter throughout the room. At the same time, the number of layers in triplex can be more than three, which makes it possible to further increase the impact resistance of products. Today, technologies make it possible to produce triplex with four layers of polymer film, the total thickness of which is 32 mm.

What types of double-glazed windows are there according to their functional purpose?

The main types of double-glazed windows for plastic windows are standard float glass and air as a filler. The practice of using double-glazed windows shows that this option is the most practical both in terms of performance properties and price. A high-quality one or two-chamber double-glazed window fully satisfies all the requests put forward for plastic windows, and in the temperate climate of mid-latitudes nothing better could be desired.

But progress is inexorable - manufacturers of PVC windows are constantly working to improve designs. Sometimes the differences between a regular double-glazed window and an improved one are clear only to specialists. Some innovations seem, at first glance, completely unnecessary, but upon closer examination, the advantages are quite real and significantly improve the functionality of metal-plastic structures (both windows and doors).

Multifunctional double glazed windows

The first, and one of the most common improvements concerns glass, as the main element of a double-glazed window. In multifunctional double-glazed windows, silver or chromium molecules are sprayed onto ordinary glass. Almost invisible in normal lighting, it does not transmit long-wave radiation (infrared spectrum), which allows you to avoid overheating of the room in hot weather when directly exposed to sunlight. In addition, in cold weather, such double-glazed windows help retain heat, since the applied coating reflects the heat coming from the heating devices into the room.

At the same time, the entire visible spectrum passes through the glass without delays or restrictions - the light transmittance of a double-glazed window does not differ from ordinary glass. Spraying is carried out only on the glass that is inside, in the case of a single-chamber package - on the inner plane. It is very stable and designed for many years of use; practically its durability does not differ from the service life of the entire window structure.

This design of a double-glazed window allows you to retain up to 30% more heat in the house than a conventional double-glazed window, which is reflected in a reduction in coolant consumption. Such double-glazed windows are especially beneficial in houses with an autonomous heating system. Also, the multifunctional double-glazed window has enhanced sound insulation. A slight mirror effect reduces the possibility of viewing the room from the street, and the retention of a significant part of ultraviolet radiation protects indoor plants from overheating.

Self-cleaning double glazed windows

A very practical and convenient invention. The outer side of the glass is coated with a special transparent substance that has the lowest possible level of adhesion to most household and technical contaminants. The coating also has the ability, under the influence of ultraviolet light, to decompose any substances adhering to the glass. The resulting products are easily washed off by rain or crumbled by the wind. Dirty water on such glasses does not leave streaks or stains.

If there is no rain for a long time, you can simply water the glass with water from a hose from a garden pump or water main. Such glass is very convenient in the windows of high-rise buildings, glass facades, shop windows, and it is practical to install them in a cottage or house in the fixed sashes of wide windows. Self-cleaning glass has the same transparency as regular glass. In one set, you can combine self-cleaning glass with energy-saving or tempered glass, increasing the versatility of the double-glazed window.

Soundproof double glazed windows

Comfort in the home depends on several parameters, among which one of the main ones is silence. For cottages or country houses this may not be so relevant, but for apartments (shops, restaurants, offices) facing busy streets or highways, sound insulation is absolutely necessary.

The design of soundproofing double-glazed windows is somewhat different from conventional ones. Thicker glass is used here, up to 6 mm. The outer glass is usually laminated glass. As a rule, three-chamber double-glazed windows filled with argon or krypton are used for soundproofing windows. These gases have lower sound conductivity than air due to their higher density, which determines greater resistance to the propagation of sound waves.

Often, soundproofing double-glazed windows are made with chambers of different widths - this reduces the risk of resonant vibrations and amplification of certain sound frequencies, instead of weakening them. Even a difference of a few millimeters can significantly improve the level of sound insulation.

The quality of installation of the components is very important:

- glass;

- distance frames;

- accessories;

- seals.

It is quite possible to reduce the overall level of external noise reduction in such double-glazed windows by 25 - 30 dB. Even next to a six-lane highway, the noise level in the room will not exceed 55 dB, which is similar to the level of a quiet conversation or office work noise. The same windows facing an ordinary city street will reduce the noise level to a barely audible 30 dB.

Soundproof double-glazed windows cost a little more than regular ones, but an increase in costs by 25 - 30% is quite justified - comfort in the house is more important than money. Moreover, you will need few soundproofing packages - at most one or two windows overlook busy and noisy streets.

Mirror double glazed windows

Double-glazed windows with a mirror coating are appropriate not only on the ground floor - often mirror glass completely changes the exterior of the house and turns a completely ordinary, unprepossessing building into an architectural masterpiece.

In addition to high protective properties (from ultraviolet radiation and immodest glances), they also have an increased level of strength. The thinnest metal film has a high resistance to accidental mechanical impacts and is absolutely not afraid of abrasives - silver or golden metal is sprayed onto the internal surfaces and does not interact with the external environment.

But when installing a mirror glass unit, several factors should be taken into account:

- appropriateness in building design;

- maintaining relative “opacity” only during the daytime;

- higher cost.

When you turn on the interior lighting in the house, everything that happens in the room becomes clearly visible on the street, just as when using ordinary glass. You can save on curtains and blinds only in offices or stores.

Colored double glazed windows

Double-glazed windows with colored glass are usually used as part of façade decoration. But while possessing undeniable design capabilities, they do not lose their purely applied capabilities. Colored glass perfectly protects the house from excess ultraviolet radiation, does not allow the room to be seen from the street, while at the same time letting in enough daylight. Also, with the help of colored glass, you can create original interior lighting that gives a certain flavor.

In most cases, the color of the window is given by special films glued to the glass using the lamination method. But you can also find glasses colored throughout the entire volume, into which various compounds are introduced during manufacturing that change color without losing the main qualities - strength, heat resistance, chemical inertness.

The first version of double-glazed windows is more common - the relatively low cost allows you to produce painted windows industrially in any size. Colored solid glass is quite rare; such double-glazed windows can be ordered individually only from a few manufacturers.

In addition to their attractive appearance, colored glass also has increased strength. The laminating film prevents glass from cracking due to accidental impacts and is not inferior in strength to triplex or tempered glass. But when ordering colored double-glazed windows, you should not get carried away with the color saturation - a light shade that does not reduce transparency too much is sufficient.

A special case of colored double-glazed windows are tinted (darkened) by gluing special films. Such windows are very appropriate in modern interiors, but, in addition to being decorative, they also have excellent performance properties. Especially on the south, south-east side of the building or in a hot climate zone. In the latter case, it is not the thermal insulation properties that come first, but the ability of the window to protect the room from direct sunlight and high outside air temperatures.

Double-glazed windows with smart glass

The word SMART, fashionable in the modern world, is applied to self-regulating systems that respond in a certain way to changes in external conditions. In relation to windows, these are complex double-glazed windows that change the level of transparency and thermal conductivity depending on external conditions. A complex layer is installed between the glasses, powered by an external current source, which responds to changes in light intensity and temperature.

The complexity of the system also determines the fairly high cost of such windows. Most often they are used in “smart home” systems, which are characterized by the complexity and high price of the main components and components. If in such a house the costs of a “smart” window amount to 2–3% of the total cost of equipment, then in an ordinary apartment or cottage they will exceed 20 or even 30 percent of construction costs.

An example of changing the transparency of smart glass:

Energy-saving double-glazed windows with k-glass

The essence of these double-glazed windows is that a thin layer of metal oxides, mainly silver, is sprayed onto ordinary float glass. Waves of electromagnetic radiation are reflected from it.

In practice, this is reflected in an increase in heat reflectivity directed towards the higher temperature. This contributes to the absence of heat in the summer, in a room protected by such windows, and to the minimization of heat losses in winter. A spray thickness of 0.4-0.6 microns does not in any way reduce the transparency of the window, but significantly enhances it mechanically. K-glass is distinguished by its comparative simplicity of technology and does not add much to the cost of the entire structure. If there is a choice between k and i-glass, then you definitely need to choose the K-option. In addition to their lower cost, such double-glazed windows will not bring any surprises throughout their entire service life.

Double-glazed windows with i-glass

The glass manufacturing technology for such bags is much more complex than “K”. Sputtering is carried out in a vacuum and involves a kind of “sandwich” spraying, alternating oxide and metal layers (oxide-metal-oxide). In this case, the thickness of the metal layer (most often silver) is no more than 10-15 nm (10-9 m).

Even such a thin layer of metal reduces the thermal conductivity of the package by 90% without changing light transmittance. But spraying is quite vulnerable to external influences, so it is carried out exclusively on the inner surfaces of glass. At a comparative cost with K-packages, i-options allow you to save 20% more energy spent on heating. In addition, they are also 20 - 40% lighter, which makes it possible to install single-chamber, i-packages of any size in walls with not very high load-bearing capacity and in large-area structures - shop windows, facades, panoramas.

Double-glazed windows of increased strength

The main requirement for double-glazed windows that are installed in windows on lower floors or in industrial premises is strength. Of course, it is almost impossible to protect glass from break-ins, but it is not difficult to protect a window from accidental impacts and wind loads. For these purposes, double-glazed windows use: triplex, tempered or reinforced glass. They have fairly high strength, transparency and an affordable price.

1. Triplex - a multilayer structure made of float glass and polymer film, glued with transparent glue. If damaged, the sheet does not crumble into fragments; pieces of glass remain glued to the film and do not pose a danger to others.

2. Tempered glass is heated to a certain temperature (above the melting temperature) and sharply cooled in air or technical oils. As a result, its strength increases significantly and its physical properties change - strength increases by 3 to 5 times, and bending resistance by at least 2 times. When destroyed, small pieces of a parallelepipedal shape are formed, which are unable to injure a person.

3. Reinforcement is made by gluing a polymer mesh onto the glass or installing it inside the glass during the production process. Sometimes it is not polymer that is used, but a steel mesh structure. This glass has a rather original appearance and somewhat reduced transparency, but its strength is not inferior to metal.

Wired glass

To strengthen the glass, a metal mesh can be used, which is placed into the body of the silicate mass during the casting of sheets. In the production of reinforced glass, 3 types of steel wire can be used:

- chrome plated;

- nickel plated;

- annealed.

The mesh can be twisted or welded with different areas and shapes of cells and is located parallel to the surface of the sheets. It does not make the glass much stronger, but at the same time it does not allow it to crumble when broken and becomes an additional barrier to intruders entering the interior. Reinforced glass is transparent, frosted and colored and has a smooth or textured surface.

Strained glass

If ordinary float glass is subjected to heat treatment at a temperature of 650-680 °C and at the same time rapid two-way cooling is provided, it will become tempered. This means that such sheets will be much more difficult to break. It also increases thermal resistance and improves safety - tempered glass fragments have blunt edges, making it almost impossible to get hurt by them. Such products are most vulnerable to impacts at the end, and this should be taken into account when designing glass structures.

Reflective glass with reflective coating

These glasses are somewhat similar to energy efficient ones, but are designed for different purposes - reflection or segregation of solar rays. The protective metallized coating can also be soft or hard and differs in its degree of resistance to external influences. Some types of reflective glass can protect against overheating while maintaining high light transmittance of windows.

Solar control reflective glasses have a mirror surface, so in some cases they can be used to ensure privacy.

Window fittings

A unified system of components, parts and mechanisms installed on a window structure is called window fittings. Its main purpose is to open and close the window sashes, as well as to ensure a tight fit of the window frame and sashes in the area of the vestibule. The reliability and durability of a window structure depends, first of all, on the quality of the fittings, because they bear the main dynamic and mechanical load during operation.

The quality of the fittings themselves is characterized by parameters such as mechanical strength and corrosion resistance. If the window structure is equipped with low-quality fittings, neither the best profile nor the highest quality glass can save it. It is not surprising that the cost of fittings accounts for up to 30% of the total cost of a finished window.

Some units have rather complex mechanisms, but in general the fitting system is very easy to use. One handle is used for control.

Window fittings are also not picky in maintenance. This requires a minimum set of special tools. For example, one key is suitable for adjusting the degree of compression of the seal and for aligning the position of the sashes vertically and horizontally.

Special fittings

Modern window designs are equipped with specially designed fittings that significantly expand the functionality of the entire system. Today, manufacturers offer a wide selection of special fittings that increase the service life of the window and improve its performance properties.

A common situation: window sashes with a tilt-and-turn mechanism can open simultaneously in two modes: “open” and “tilted.” In the latter case, the sash simply hangs on the lower hinge. To avoid damage to the opening mechanism, an erroneous action safety device is installed on the window, which prevents the handle from turning when the sash is open.

It is best to equip window structures with large and heavy sashes with a special fitting unit - a heel with a thrust bearing and a microlift, since the large weight of the sashes often causes them to sag. The microlift reduces the load on window hinges, which significantly increases their service life.

To give the open sash stability and fix it in one position, thereby preventing it from hitting the slope, you can install a rotation limiter.

The rotation stopper allows you to fix the open window sash at a distance of 5 cm from the frame. The stopper will prevent the sash from swinging open even with a strong gust of wind.

Between the two standard positions of the window handle “open” and “tilted”, positions in the ventilation mode can also be set at different angles of inclination of the sash. For this purpose, a stepwise ventilation mechanism is installed.

There are two-, three- and four-stage mechanisms. They allow you to independently adjust the degree of tilt of the sash from the frame, based on your preferences and weather conditions.

Tinted windows

Tinting allows you to darken rooms, protect them from overheating and, in some cases, reduce heat loss. This type of glass is presented in 4 modifications:

- tinted in bulk;

- with pyrolysis coating;

- covered with polymer films;

- coated with metal oxides applied in a vacuum chamber.

The characteristics of these products and the method of care depend on the type of tinting. Glass tinted in the mass is considered the most resistant to mechanical damage, but they themselves quickly heat up in the sun and begin to transfer heat to the interior. As a result, it is recommended to give preference to glass with pyrolysis or vacuum coating.

White frosted glass for windows does not belong to tinted products, since they are made using other technologies - sandblasting or chemical etching.

Types of polyvinyl chloride windows by opening mechanism

folding swivel

PVC windows open in several ways. The following opening mechanisms are distinguished:

- Hinged, when the sash opens inward relative to the horizontal hinges;

- Turning. The sash also opens inward, but narrower in relation to the vertical hinges;

- Tilt-and-turn. A very popular type of opening today, combining a rotary and a folding one.

Non-standard windows

non-standard-window-1 non-standard-window-2

Innovative technologies make it possible to produce profiles of various shapes, and adding pigment to the raw material allows you to obtain the desired color of the structure.

A high-quality PVC window can fit even into an exceptionally sophisticated interior. For example, round windows are often installed in the bathroom or corridor, triangular or trapezoidal in attics and attics, and bay windows in the veranda and winter garden. Unusual windows are an ideal solution for furnishing country cottages, as they fit perfectly into almost any modern architectural style.

https://youtube.com/watch?v=gPFmk1zURi4%3F