Stained glass windows have delighted the eyes of our ancestors since ancient times. Their relevance does not decrease today, despite the wide variety of materials and decorations. If previously the production of stained glass was the domain of a few craftsmen, then in the modern world almost anyone can master certain methods of creating them. All necessary materials and tools can be purchased in specialized studios and stores. And the widest variety of manufacturing methods will allow everyone to choose one in accordance with their professional capabilities and desires.

Stained glass windows

It is best to start making stained glass with your own hands with the simplest, but at the same time no less spectacular techniques. Let's consider technologies that do not require any special professional skills, expensive equipment, or complex and dangerous chemicals. These include the techniques for making the following stained glass windows:

- Film;

- Jellied;

- Painted;

- Tiffany.

Beautiful stained glass windows

Features and advantages of stained glass glazing

The design of a stained glass glazing system can be used even where it is practically impossible to install ordinary plastic or wooden windows, for example, in bay windows or bays. The undoubted advantages of panoramic glazing are most clearly manifested when used on the facades of large multi-storey buildings, however, even when used in private country houses, stained glass is quite competitive in comparison with alternative glazing options.

Moreover, since the system is constantly being improved, it is safe to say that in the future the scope of its application will only expand. This is not at all surprising, given the numerous advantages, which will be discussed below.

Rice. 2. Facade panoramic glazing.

Economical

The cost-effectiveness of installing stained glass is ensured by several factors. Firstly, there is no need to use lifting mechanisms. Secondly, the work is completed in a short time, since its labor intensity is low. Thirdly, the cost of glass as the main enclosing material is lower than that of other types of facade. Fourthly, the stained glass facade system does not require special maintenance and care, which is also economically beneficial. Do not forget that thanks to the features of stained glass windows, there are real and quite noticeable savings on lighting the interior of the building.

Durability

Most often, stained glass glazing is performed using an aluminum frame and enclosing structures made of double-glazed windows or triplex. The estimated service life of aluminum structures made using modern technologies is approximately 65-70 years. Triplex, double-glazed windows and other types of glass may well last even longer.

It should also be taken into account that the stained glass system is practically resistant to corrosion and other influences of aggressive factors. As a result, facades made using this technology are significantly superior to all existing analogues in terms of structural durability.

Rice. 3. Stained glass with entrance doors.

Strength

Despite the apparent fragility of stained glass glazing, the system has a sufficient margin of safety. For example, the frequently used triplex can withstand an impact weighing 70-80 kg without any consequences.

In addition, all stained glass systems allow the use of glass with special protective characteristics, for example, armored or vandal-proof. As a result, with a slight increase in the cost of the design, a system can be obtained that is very difficult to damage, much less break. In terms of its strength characteristics, stained glass glazing is not inferior to most facade systems.

Light transmittance

One of the main features of the stained glass system is high light transmittance. Moreover, this applies both to cases of using ordinary glass, which is completely transparent, and when using colored triplex or even stained glass, which also transmit a fairly large amount of light.

Staying in a building with natural light is not only cost-effective, but also extremely beneficial and comfortable. It has long been known that the human eye strains and, as a result, gets tired much more under artificial lighting. At the same time, natural light has an extremely beneficial effect on vision and general psychological comfort.

Rice. 4. Natural lighting with stained glass windows.

Easy to repair

Thanks to the design features and installation technology, stained glass glazing is extremely easy and simple to install. But the advantages are far from being exhausted by this advantage. If it is necessary to replace glass that has become unusable, it is enough to dismantle a separate element. Disassembly of the entire system is not required, which greatly facilitates any repair work.

The ability to replace any of the blocks that form the stained glass system is one of the most important factors in the ease of its operation and maintenance. At the same time, repairs do not require specialized equipment or professional skills; the work can be carried out on one’s own.

Rice. 5. Replacement of double-glazed windows.

Environmental friendliness

One of the most important modern requirements for almost all building materials and structures is compliance with environmental safety requirements. All materials, products or structures used in the manufacture and subsequent installation of panoramic glazing are absolutely safe for humans, animals and plants. They are environmentally friendly and environmentally friendly, containing no allergens or other harmful or irritating substances.

Thanks to this, stained glass glazing can be used everywhere, on any buildings and structures, without any restrictions.

Rice. 6. Original design solution for the facade.

Thermal insulation

Various panoramic glazing systems can be used in any region of Russia. They are highly resistant to low and high temperatures without being deformed at all.

In addition, the use of modern materials, including special seals, sealing tapes and various thermal inserts, allows the system to provide high thermal insulation performance. They guarantee both protection of the interior of a building or structure from external temperature influences, and the maintenance of a comfortable temperature regime inside due to extremely low heat loss.

Rice. 7. Comfortable indoor conditions at low outside temperatures.

Soundproofing

High levels of tightness of stained glass systems provide not only heat but also sound insulation. It is also achieved by correctly assembling the system with all the necessary parts and components, including thermal inserts, sealing tapes and special seals.

All components are supplied with the system, and they are selected in such a way as to correspond to the climatic conditions of operation in a given region. In addition, their installation is as simple as other technological processes for installing stained glass.

Rice. 8. A building with stained glass windows on a busy highway.

The attractiveness of stained glass glazing

No matter what remarkable performance properties and characteristics the façade stained glass system has, it would not have become so widespread without one of its main advantages - an attractive, aesthetic, expensive and modern appearance.

A wide variety of color solutions, the ability to give the facade various, sometimes very bizarre, shapes, the creation of a wide variety of design solutions and design options for the building - all this allows stained glass glazing to be considered not just a structural element, but also often the main decoration of the building.

Rice. 9. Design option using panoramic glazing.

Making painted stained glass at home

The first step is to decide on the dimensions of the glass blank and select the desired pattern for it. When choosing a picture for a stained glass window, you can use several methods.

- If you have certain creative inclinations and imagination, draw it yourself.

- Find a suitable picture on the Internet and print it on A4 sheets, using any program capable of printing in multi-page mode. After this, all you have to do is glue together, using tape, a full-size sketch of the future stained glass window from many sheets.

DIY painted stained glass is a pleasant addition to your interior

Stained glass window for a children's room

In the selected or drawn picture, you must pay close attention to ensure that all fragments are clearly drawn and separated by continuous lines.

Next we proceed to preparing the glass.

Step 1. First of all, thoroughly degrease it (a solution of alcohol or ammonia is suitable for this) and wipe it dry so that the surface is not only free of traces of grease, but also completely dry.

Step 2. We lay the glass evenly and accurately on the prepared sketch of the future stained glass window, made on a sheet of paper.

Step 3. Using special stained glass paint, carefully trace on the glass the contours of all the elements of the sketch located underneath it. Most often in this case, black paint is used, since it gives clarity to the resulting picture and also clearly expresses the boundaries of all fragments.

Stained glass paints

Drawing contours

Step 4. After drawing the lines, let the paint dry thoroughly. Otherwise, all the work done may go down the drain if you then accidentally catch a line that has not dried and smudge it. When making stained glass, you cannot rush; you must understand that this is painstaking and lengthy work.

Step 5 . This stage of creating a painted stained glass window is the most creative and represents the process of painting glass, broken by lines previously applied with black paint into separate fragments. Despite the apparent simplicity of this process, maximum care must be taken here. To complete the job, you will need thin brushes with which you will apply paint to the mosaic pieces. Thanks to the previously applied and already dried contour lines, the colored paint will not spread and will remain within the boundaries of the designated area in the overall stained glass pattern.

Filling the contours with paint

While you are carried away by the technical side of the process, you should not forget about its creative component. The colors of paints for filling stained glass pieces must be selected as follows:

- they must be in harmony with each other, creating a feeling of a single picture;

- try to use bright and pure colors;

- It is advisable to apply lighter or darker shades after the paints of the primary colors have dried. In this case, you will be able to increase the picturesqueness of the work, avoiding the appearance of dirt as a result of mixing colors that are not separated by lines;

- The final stained glass window should look harmonious with the surrounding interior.

Ready stained glass

This stained glass window will be the main advantage of the kitchen or dining room

Stained glass "Flowers", made with stained glass paints

Disadvantages of stained glass glazing

No building material or design is without its drawbacks. They are also available for stained glass windows. The main ones are the following:

- relatively high cost of materials and work. Despite the fact that, thanks to modern developments, the cost of the system has decreased somewhat in recent years, it is still used mainly in commercial facilities and where the customer is willing to invest significant financial resources to achieve convenience, comfort and an attractive appearance. type;

- the impossibility of creating non-flat curved surfaces, for example, spherical ones, due to the insufficient strength of the aluminum profile;

- instability of the stained glass glazing system under high wind loads, as well as in areas with seismic activity. This drawback seriously limits the use of the system in question in high-rise buildings, where it may be subject to increased wind loads. It is also not allowed to use panoramic glazing in seismically active regions, but there are relatively few such places;

- difficulty in cleaning the façade from the outside. Large glasses that act as an enclosing structure for stained glass windows cannot be washed from the inside. Therefore, we have to do it outside, which is quite problematic. The problem is aggravated when there are several floors - in this case, the invitation of industrial climbers or the use of lifting equipment is required.

The listed disadvantages of panoramic glazing are not so significant as to prevent its increasingly widespread use.

Rice. 10. Washing stained glass.

Making home stained glass paints

There are several ways to prepare paints. Each of them is good in its own way, so it's up to you to decide which one to choose. Experts recommend mixing components only in containers made of glass. The ideal option would be a jar in which baby food is sold.

Prices for different types of artistic paints

Artistic paints

Method 1

To prepare the paint you will need: nitro varnish marked NTs-218, oil-based artist paints and a solvent.

Nitrovarnish NTs-218 glossy

Oil-based artist paints

We begin mixing by filling the jar a third with nitro varnish, while gradually adding solvent in an amount of 40% of the volume of nitro varnish. Stirring continues until the jar contains a liquid similar to ordinary water. After this, we begin to introduce oil paint into the mixture drop by drop until the color of the future paint acquires the desired brightness. The amount of artistic paint can be up to ten percent of the amount of varnish used.

Method 2

To prepare the paint we will need: glue marked BF-2, a similar amount of acetone and paint soluble in an alcohol solution.

BF-2

Acetone

Artistic paints

During the preparation process, glue is poured into a glass container, and acetone is added to it in a one-to-one ratio. After active mixing, paint is added to the mixture in an amount that provides the color of the desired saturation.

Method 3

The third method is based on the use of gelatin with dry fabric dyes and water. To prepare the paint you need: dissolve 6 grams of gelatin in 200 grams of warm water.

Gelatin

Aniline dyes for fabrics

Similarly, in another container, dry paints of the desired color are dissolved in warm water. Then, in a clean glass jar, the two liquids are mixed until the desired color saturation is obtained. Unlike paints prepared by other methods, after application to the surface of a stained glass window, this paint requires coating it with nitro varnish.

Materials needed to make stained glass

In order to estimate the possible costs of manufacturing a particular stained glass window, we suggest using the following table. Having studied the list of materials that will be needed during the work, it is easier to decide which method of making stained glass is best for you.

| Stained glass manufacturing technique | Materials that will be needed during the work |

Painted stained glass | Sketch paper, tape, stained glass paints. |

Film stained glass | Sketch paper, tape, squeegee, small roller, knife, scissors, metal ruler, clamp, stained glass film, lead tape. |

| Stained glass Tiffany | Multi-colored glasses, copper foil, glue, soldering acid, solder, detergent, diamond glass cutter, sharpening stone, wire cutters, pliers, small soldering iron, patina. |

Filled stained glass | PVA glue, black ink, silver ink, stained glass paints, nitro varnish, sketch paper, tape. |

Making stained glass is a long process that requires a huge amount of time and effort. Even the simplest manufacturing techniques will not be accessible to everyone. But at the same time, the completed stained glass window will delight you with its beauty and sophistication. And it is possible that after making one stained glass window, you will want to do it on a professional basis.

Types of stained glass glazing

There are many types of stained glass glazing. They can be divided into groups according to several classification criteria, which include design options, the type of enclosing structure used, the scope of application of various panoramic glazing systems, and much more.

But despite all the diversity, the main characteristic by which stained glass systems are grouped is the type of fastening used. For any classification of facade stained glass glazing systems, it is used most often. According to this criterion, all systems are divided into five groups.

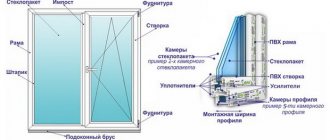

Post-transom stained glass glazing

The most commonly used design option. The main reason for its popularity is its relatively low cost, the lowest among all stained glass systems available. In the mullion-transom version, a profile is used that can be seen through the glass.

Rice. 11. Scheme of post-transom type fastening.

The supporting frame of the structure is formed by vertical posts and horizontal crossbars installed on them. The main components give this type of fastening its name. The enclosing material is installed into the resulting structure using rubber seals and secured with a bead.

Rice. 12. Appearance of ground-beam glazing.

One of the possible options for installing façade glazing is shown in the following video:

Structural stained glass glazing

Structural stained glass glazing is a type of so-called frameless systems. Their main feature is that the supporting profile is not visible from the outside at all. A similar effect is achieved using end fixation, when the glass is mounted on the frame using a point method using a special sealant with increased strength and adhesive ability.

Rice. 13. Scheme of the structural type of fastening of stained glass glazing.

This system is the most expensive, but at the same time visually attractive due to the fact that a continuous glass coating is formed on the outside of the building, ultra-modern and aesthetically pleasing.

Rice. 14. Appearance of structural glazing.

Spider (planar) stained glass glazing

Spider (another name is planar) glazing, like structural glazing, is one of the most expensive and most technologically complex. Due to the extremely high cost of the fastening elements used and the installation work of the system, it is considered elite and is used quite rarely, mainly in the construction of commercial real estate.

Rice. 15. Spider fastening element.

A special feature of the system is the fastening of the enclosing material using “spiders” - special high-strength brackets made of alloy steel, somewhat reminiscent of spiders, the name of which in English gave the name to the entire stained glass glazing system.

Rice. 16. Appearance of the spider system.

Semi-structural stained glass glazing

Semi-structural stained glass glazing is a slightly modified version of structural glazing. Instead of sealant, special glazing beads are used to secure the enclosing material. This reduces the cost of materials used and installation work for the system.

Rice. 17. Mounting unit for semi-structural glazing.

Another advantage of this type of fastening is the possibility of installing opening sashes, which is technologically impossible with structural stained glass glazing. Semi-structural panoramic is more often used than other alternative options for the facades of multi-storey buildings.

Rice. 18. Appearance of semi-structural glazing.

False glazing

False glazing is rightfully considered the most budget option of all used. It is also the easiest to perform technologically. In most cases, the decision to use false glazing is made when it is necessary to hide the shortcomings of an old facade that needs serious repairs.

It should be noted that externally the option is practically in no way inferior to other stained glass glazing options. An additional reserve for savings is that with false glazing, single glass is often used, since there is no need for high levels of thermal and sound insulation.

Rice. 19. Appearance of false glazing.

Division according to the design of stained glass glazing

Depending on the design chosen by the designer, there are:

- transparent stained glass systems;

- colored stained glass systems.

In the second case, instead of transparent ordinary glass, pre-fabricated stained glass windows are installed. They have greater resistance to ultraviolet rays and can also be mounted in large sizes. This is achieved by the strength and reliability of their design.

Most often, colored stained glass systems are used on glass roofs or domes of various buildings. The stained glass windows themselves can be made using a variety of technologies - film, cast, classic typesetting, etc.

Rice. 20. Colored stained glass.

Division by type of stained glass system

Based on the type of system, all types of stained glass glazing can be divided into two groups:

- warm. A warm stained glass system has higher thermal insulation characteristics. They are achieved using special seals, sealing tapes and thermal inserts (the most commonly used additionally installed polyamide insert). Such systems can be used even in regions with extremely cold winters;

- cold. This system is installed in the usual way, which does not involve the use of polyamide inserts. As a result, such glazing has a slightly smaller width and weight of structures.

Rice. 21. Diagram of a warm facade glazing unit.

Division according to other design features of stained glass glazing

In addition to those listed above, there are several more classification criteria, for example:

- According to design features, they are distinguished: deaf;

- opening;

- tinted;

Rice. 22. Triplex glass structure.

- self-cleaning. Does not require constant care;

- armored and high-strength;

- artistic.

Rice. 23. Artistic stained glass glazing of the ceiling.

The variety of different stained glass glazing systems is far from exhausted by the listed examples.

Filled stained glass

Creating a stained glass window begins with choosing a design and transferring it to the glass surface. All further actions are aimed at giving the pattern a convexity, which will prevent paint from leaking beyond the specified space.

Making contour paint

First, let's look at the process of creating a special contour paint. To create it you will need:

- 50 ml PVA glue;

- 30 ml mascara;

- about 40 grams of silver.

Glue and ink in measured volumes are poured into a small container and begin to mix. In the process, silver is gradually added to them. The result should be a lead-colored mass similar in consistency to sour cream. As paint is applied to the surface of the stained glass, its consistency may gradually become more viscous. This can be corrected by adding a small amount of heated water and mascara of the same black color. The paint will return to its original condition.

Rules for applying contour paint

Selecting a sketch

After preparing the contour paint, we begin to apply it along the lines transferred to the glass from the sketch. You must follow the following rules for working with contour paint.

- The contour lines are applied with a thin brush and should be convex enough to contain future paint spills. Therefore, you should not save on it. The resulting homemade paint should adhere confidently to the surface of the glass being decorated, and its color will be close to the color of lead seams inherent in stained glass windows made using classical technologies.

- In the process of applying contour lines, stir the paint periodically, otherwise lighter silver particles will constantly strive to the top. In addition, the color of homemade paint will change over time, so it is advisable to complete the contour application as soon as possible. Otherwise, the uniformity in the framing of the stained glass mosaic elements will be lost.

- After application, you must wait about three hours until the paint dries completely.

Drawing contours

Process of drawing contours

Painting glass elements

When the outline is dry, you can proceed directly to painting the glass elements. We will look at the process of making paint at home below, but for now we will understand the process of applying it.

Step 1 . First of all, you need to make sure that the workplace with glass is located in a strictly horizontal plane. Even a slight tilt in any direction will subsequently lead to the collection of all the paint at one of the edges and a thickening of its layer.

Step 2. Filling the elements must be done with a wide brush. We dip it in the paint and, generously greased, begin to paint over each fragment individually.

You can use a pipette, fill it with paint and paint over the design, as in the photo below.

Manufacturing of contour stained glass

Important! When working, there is one main rule: under no circumstances should you cross the previously applied contour, otherwise the paints will mix and the stained glass window will be hopelessly damaged.

At this stage, you need to show enough perseverance to completely fill in all the fragments of the picture without spoiling anything. After finishing the pouring, we again wait 4 hours until the paint dries, and we can continue.

Manufacturing of stained glass

Pouring paint

Pouring paint

Step 3. This stage consists of re-drawing the contours. This is done with the same brush as the first time and applying the same generous amount of paint. You must be sure that the contours are painted evenly and have no flaws. The black paint should dry within three hours.

Step 4. This stage is to preserve the created stained glass window and protect it from damage. To do this, apply up to four layers of nitro varnish to the entire surface of the stained glass. It can be applied with a brush, but it is best to use a special sprayer. Please note that at least ten minutes should pass between sprays to allow the layers to dry better. Thanks to the measures taken, the stained glass window you created yourself will delight your eye for at least the next ten years. Its production is completed by installing the glass in a specially prepared frame.

Beautiful stained glass window in the interior

Stained glass glazing of balconies and loggias

The expansion of functionality and improvement of basic performance characteristics, which occurred thanks to the use of modern technologies in the production of stained glass systems, made it possible to use them in the glazing of balconies and loggias. This was also facilitated by the fact that the price of stained glass glazing is becoming more and more affordable over time.

The use of stained glass glazing for balconies allows you to achieve a number of advantages:

- the ability to perform glazing work on even the largest openings of almost any shape;

- increasing the level of natural light in rooms adjacent to the balcony or loggia;

- improving the appearance of a building on which stained glass glazing of balconies is used;

- the ability to implement various design solutions for the design of a balcony or loggia;

- high maintainability of the system, which is achieved by the possibility of replacing any of its elements.

The disadvantages of using the design in question include:

- the need for careful adherence to installation technology;

- difficulty in cleaning glass from the outside;

- free view, which is accessible not only to the owner of the apartment, but also from the outside.

The use of modern stained glass systems allows you to get rid of most of the shortcomings or reduce them to a minimum.

Rice. 24. Option for frameless glazing of a balcony.

Carrying out preparatory work

Installation of stained glass windows from aluminum profiles is a rather complex technology and requires preliminary preparation of materials and surfaces. First of all, the necessary measurements are taken and the type of fastening of the stained glass windows is selected.

After this, the openings in which the stained glass windows will be installed are cleared of debris and dust and dirt are removed from there. It is also not recommended to leave moisture, so the surface is thoroughly dried naturally or with a hair dryer. If necessary, you can mark the places where decorative elements will be located.

Stained glass glazing of cottages

The variety of opportunities provided by the use of stained glass glazing has led to the fact that it is increasingly used in private housing construction, in the construction of country houses and cottages.

The systems under consideration are especially popular in cases where construction is not carried out according to a standard design, but using a variety of original architectural and design solutions. It is in such cases that the advantages of stained glass glazing can manifest themselves especially clearly.

Rice. 25. Stained glass glazing of the cottage.

It is most often used:

- when performing stained glass glazing of a cottage facade;

- when decorating a winter garden and similar small rooms or structures. This type of structure also includes various gazebos, pavilions and terraces that are built on the territory of a suburban area. The use of stained glass allows not only to give them an attractive appearance, but also reliably protects them from precipitation and wind;

- to create a single harmonious exterior design that seamlessly includes window and door designs.

Currently, a variety of stained glass glazing systems are increasingly being included by designers and architects in the designs of small country houses and cottages, which indicates that stained glass glazing will be used more and more often.

How are stained glass windows installed and checked?

After the frame is ready, installation of the sashes begins. Afterwards, you can install seals and other parts made of glass. Installation of aluminum stained glass windows, the technology of which has a strict sequence, cannot be carried out in any other order. Additional structural elements, if any, are also installed at this stage of work.

Stained glass design elements

Care should be taken to ensure that the design details are not mixed up and that each one takes its rightful place.

After this installation stage is completed, the room must be thoroughly cleaned.

Requirements for stained glass glazing of facades

The requirements for stained glass glazing of facades, in fact, do not differ from those for other facade systems. There is no single regulatory document that would contain their list and description. However, with some degree of convention, they can be divided into the following groups:

- wishes of customers. The most diverse category of requirements, which is limited only by the imagination and taste preferences of the customer;

- requirements of designers and architects. In most cases, they are reflected in the relevant design and estimate documentation and largely depend on the customer and existing regulatory and technical documents;

- requirements of current standards (all-Russian and regional). At the moment, there is no single document or legal act that would clearly regulate the requirements for facade systems. They are contained in a variety of documents in fragments - somewhere they describe the requirements for thermal insulation characteristics, somewhere - for the lighting of premises, somewhere - for ensuring fire safety, etc.

It should be noted that existing SNiPs for glazing practically do not contain descriptions of modern materials and designs used in stained glass glazing. Until a new SNiP or GOST is developed, special attention should be paid to the compliance of the systems used with the design parameters, as well as to the availability of quality certificates from the company supplying the structures.

Some features when installing units

Aluminum stained glass windows can be installed in two ways; the unit can be located in the upper and lower parts. It is important that only the bottom element is movable. If the installation method is two-post, the rack will be attached to the bottom node, while its edge will be floating. This method of assembling the structure significantly speeds up the work. If spiders are used for fastenings, the gap must be clear and all components must be securely fixed. The upper assembly remains rigid when using this type of fastening.

Aluminum does not compress well, but has the ability to stretch, so it is best to hang structures made from it correctly. You should not fix the racks from below, as this will cause the structures to sag.

Stained glass windows can significantly improve the appearance of your room and make it more interesting. Installation is quite complicated and requires a professional, responsible approach. Having some knowledge of how stained glass is assembled, you can hire a competent team to install it.

History of stained glass windows

It is impossible to establish when the first stained glass samples were made. But it is unlikely that they began to be used immediately after the appearance of glass. Ancient Roman mosaics were also found in temples; they consisted of small plates of colored glass. In early Christian churches, windows were filled with thin transparent stone plates, and ornaments were made from them.

Colored window glazing was first a glass mosaic that was inserted into wood and stone openings and window traceries. Afterwards, mosaics began to be made from colored pieces of glass, which were cut out and assembled into a pattern or ornament in a lead frame. These mosaics were assembled in a metal frame.

The photo shows the design of stained glass windows in ancient buildings:

French balcony with stained glass - style and luxury

You can make ordinary windows with stained glass, or you can have panoramic glazing or a French balcony. Such solutions will emphasize your excellent taste, adding zest to the facade. The photo shows how gorgeous the floor-to-ceiling windows look with stained glass:

Panoramic stained glass windows can contain entire compositions and become real paintings, it all depends on your preferences.

The balcony, glazed from the floor itself, provides more natural light in the adjacent rooms. A stained glass balcony over the entire area with sliding frames will distinguish you from your neighbors from the facade and from the inside, creating the illusion of a larger apartment area than it actually is.

Demonstrate your exclusivity and high level of respectability by ordering windows, glazing or a French balcony with stained glass in.