“Management is the art of doing things right.

Leadership is the art of doing the right thing.”

Peter Drucker

In 2022, REHAU celebrated the 15th anniversary of its production in Russia. During this time, the window market experienced various periods of ups and downs, struggles with “clones”, economic crises, changes in the sales system and marketing strategy, but the young and united team successfully completed the tasks. 9 years after the opening of the plant, the REHAU company became No. 1 in the Russian market of window profiles. Read about where and how the most popular profile in Russia is born in the material WINDOWS MEDIA.

REHAU is a modern enterprise in Gzhel

Today Gzhel is not only a famous center of folk crafts, but also the production site of the most purchased window profile in Russia. Over 15 years of operation, the German concern has invested more than 70 million euros in the development of its Russian enterprise.

photo: REHAU plant in Gzhel

Starting in 2005 with the production of 20 thousand tons of window profiles per year, the company's new plant reached a production capacity of more than 70 thousand tons per year. In spacious buildings with an area of more than 50 thousand square meters. m there are extrusion and auxiliary workshops, a laboratory, a logistics center, as well as warehouse and office premises. Today it is the second largest enterprise among all factories in the window division of the REHAU concern. At the existing site there is every opportunity for further growth of capacity through the commissioning, if the market situation develops favorably, of another extrusion workshop.

The emergence of modern production of REHAU profiles brought the best German traditions and rich experience in the field of extrusion to the Russian window market. In 2007, the plant in Gzhel was recognized as the best of 40 REHAU plants in terms of product quality and production safety. In 2011, the Moscow region enterprise became the leader of the international REHAU group in the implementation and development of the “lean production” system.

Rehau is a trusted brand

Over the years of presence of products under the Rehau brand in Russia, they have earned unconditional recognition and trust from customers. Plastic windows produced by Rehau are chosen by those who value the durability and reliability of the product, as well as the absence of any problems during operation.

Scientific research carried out on Rehau double-glazed windows allows us to conclude that their service life under normal load conditions is 60 years! Such figures are truly impressive and allow buyers to understand that they are paying money for real German quality.

Closed warehouses in Gzhel

In Europe, due to the mild climate, storing window profiles in open warehouses is the norm. In Russia, with harsh climatic conditions, such a practice is fraught with the risk of large claims losses. A leader must constantly think about its consumers and their interests, so the REHAU company consciously made additional investments by building closed warehouses for storing profiles with an area of 27 thousand m2.

photo: finished product storage area

Storing raw materials in closed warehouses where a stable temperature is maintained also has a positive effect on the quality of the products.

Are there any differences between Gzhel windows and other windows?

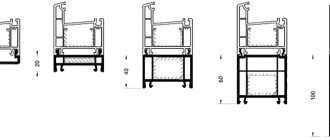

Gzhel windows are no different from good premium class windows. They are available in 60 and 70 depth boxes and are selected depending on customer requirements and operating conditions. Windows can be not only white, but also colored and equipped with all types of glass and double-glazed windows available in the company’s product range. The bags also come with a lifetime warranty.

There is still a small feature that makes them stand out from other windows. This is the presence of rolling bearings at the locking points, which makes the operation of the sashes soft, silent and increases the service life of the window. Today no one can boast of this, since in the pursuit of cheaper products this option is a thing of the past. All other windows that are represented on the market have locking fittings of direct mechanical friction: metal on metal!

Visually, “Gzhel” windows are distinguished by a branded protective film with a blue ornament and the inscription “Gzhel” and branded fittings with a pressed inscription of the same name and the “Moscow Windows” logo.

Independence from suppliers - REHAU strategy

REHAU's policy is maximum independence from supply problems, therefore the company cooperates with several suppliers of PVC-S and additives, which eliminates interruptions in the production process. Careful incoming control of each batch of incoming raw materials with mandatory testing in our own laboratory is aimed at high and stable quality of the produced profile.

photo: laboratory

The preparation of the mixture for extrusion of window profiles is carried out in 3 independent areas, which is part of the production safety policy and contributes to its uninterrupted operation.

High Speed Extrusion and Innovation

On 24 high-precision and high-speed lines, more than 40 main articles of white and body-dyed PVC window profiles are extruded around the clock and all year round, with the exception of New Year's holidays.

All extrusion equipment was supplied from Germany according to the standards adopted by the concern. Impeccable cleanliness and neatness emphasize German pedantry. To maintain order when storing parts of technological equipment at the enterprise, places for each tool are clearly defined, signed and marked.

photo: extrusion equipment

Specialists in Gzhel have developed and implemented an innovative technology that ensures rapid readjustment of lines when changing manufactured articles. As a result, the loss of raw materials and the time required to restart the lines are significantly reduced. If earlier this could take 2-3 hours, now the entire operation is completed in 20-30 minutes.

The introduction of an innovative “smart vacuum” system into the process of creating and maintaining the vacuum required for profile formation made it possible to control the operation of pump motors without idle energy consumption, which led to a reduction in energy consumption and noise levels at the enterprise.

What is the difference between REHAU profile windows and other manufacturers?

1. Durability of windows made from REHAU profile – 60 years

The basis of a quality profile is a patented mixture recipe. Just as delicious bread is made only from high-quality flour, a reliable and durable profile can be made only from high-quality raw materials and additives. Constant investments in R&D allow us to improve the recipe and achieve the best results in the industry. lead-free calcium-zinc additives . The strategy of working only with trusted suppliers and constant quality control of components in our own laboratory allows us to achieve high durability characteristics. This is confirmed by the test results of the REHAU window profile, the durability of which is estimated at 60 conventional years.

Photo: Rehau windows still retain heat in German hotels built in the post-war period. REHAU takes a responsible approach to all its products, regardless of whether it is a standard system or a new generation product. Our own window profile recipe, proven over decades, is the same for all REHAU models, which guarantees the quality of the brand.

2. Windows from REHAU profile - snow-white for 60 years

The snow-white appearance of plastic windows from the REHAU profile, creating a feeling of purity and elegance, is one of the reasons for their popularity. Yellowness or indelible brown spots will not appear on the surface of REHAU profile systems. Neither the scorching sun nor the smog of city streets will change the snow-whiteness of REHAU windows.

Photo: the white color of the Rehau profile has been preserved for 60 years. The reason lies in the use of a patented recipe for the REHAU profile. Work to improve it has been ongoing for 60 years. The use of only expensive and high-quality components and strict adherence to all technological processes ensure the preservation of the original whiteness throughout the entire service life.

3. REHAU window profile - a unique surface

- The glossy surface of the REHAU profile is non-staining and practical to use, despite its snow-white color. Fingerprints, dirt and minor mechanical damage will not be visible on REHAU windows. This is the result of many years of research and development at Rehau.

- The surface of the REHAU profile is not porous, so it does not absorb, but, on the contrary, repels dust and dirt from the window. The ease of washing will please every housewife. After washing, the window regains its unsurpassed appearance.

- The special geometry of the REHAU profile glazing bead made it possible to avoid the accumulation of dust in the most visible place of the window frame - the junction of the glazing bead and the profile. Removing dust from a thin gap has always been difficult. The glazing beads of REHAU profile systems are only a fraction of a millimeter below the surface of the main profile, and this is enough to make it easy to remove dust from the most visible place.

Photo: ease of care for REHAU profile

- It is recommended to wash REHAU windows with water and regular detergent twice a year. This is enough to maintain the original whiteness of the profile throughout its entire service life - sixty years.

4. Fashionable window designs from REHAU profile

The role of windows in the interior design of a building increases every year. Property owners are no longer hiding windows behind curtains and tulle. The window becomes a decoration of a modern interior; it emphasizes individuality and complements the style of the building.

Photo: REHAU windows create comfort and coziness at any time of the year. The developer of REHAU profile systems takes into account the desire of customers to have not only high-tech, but also beautiful, individual windows. Therefore, there is a large selection of window profile models. The rounded, ergonomic or brutally beveled shapes of REHAU windows will fit perfectly into any interior, creating a feeling of warmth and light. The possibility of lamination as one-sided or two-sided or the use of profiles painted in the mass will create a unique image of any room.

5. Wide range to suit any budget

The wide product line of REHAU systems will allow you to choose the optimal solution for objects of any price category and purpose - from luxury residential complexes, penthouses to country houses and summer cottages. Windows from the REHAU profile are ideal for schools and kindergartens, clinics and hospitals.

Photo: the REHAU profile line includes various products. The REHAU assortment will satisfy the most demanding customer and buyer with a limited budget. The highest German quality remains unchanged in any system, giving comfort and warmth for many years.

Own tool shop

The forming dies are manufactured at the REHAU tool factory in Germany. Their finishing and maintenance are carried out in Gzhel. To quickly respond to market needs and quickly master new systems, the company plans to significantly increase the level of autonomy of the tool section of the Moscow region plant, modernizing it as part of the investment project currently being implemented to expand the enterprise. This step will further increase the competitiveness of REHAU in the Russian market.

Increasing the area for picking and loading goods

The new investment of 7 million euros is intended not only to strengthen the tooling area, but also to develop the plant’s logistics infrastructure, in particular to expand the logistics center, order picking and shipping area. Even after a significant expansion of the assortment due to the launch of new profile systems on the market, prompt customer service and speed of delivery of goods will be ensured at the usual high level.

photo: REHAU logistics solutions

The modernization precedes the next increase in capacity and increase in the range of extruded products planned for the coming years. German pragmatism aims to increase production capacity in parallel with increasing the level of customer service.

How to check the manufacturer of window profiles?

Unfortunately, nowadays you can often find fakes on the market that are passed off as products from the popular company Rehau. How to protect yourself from scammers and purchase original products? To do this, you need to learn to decipher the markings. Each product has an individual code on the back. It contains all the information. It looks like this: REHAU G 401 11 32 22-09-14 88 3 RAU - PVC 155 KOMO Art. 554411:

- G - country where the Rehau profile is produced;

- 401 — city code;

- 09/22/14 – date of manufacture;

- RAU - PVC - name of the material;

- 155 KOMO – certificate information.

If the marking is in Russian, then the profile was produced on the territory of the Russian Federation.

The Rehau brand has been a leader for many decades. This is due to the quality of the products, a wide selection of designs and a long service life.