To protect rooms from the sun, until recently, darkening window tint films were mainly used. This coating did not allow light to pass through, but it did not prevent overheating, since it itself accumulated energy. Over time, manufacturers have eliminated this drawback and today offer fundamentally new sun protection. This article will tell you about the types of new tint films, the main differences between them, the installation method, and will also help you choose the appropriate polymer coating.

Types of darkening tint films and their main differences

Depending on the type, film for double-glazed windows helps solve different problems. It can darken rooms, keep rooms warm, increase the level of safety of double-glazed windows, protect against overheating and ensure privacy. Thanks to this material, it is possible to quickly adapt windows to current needs. The properties of films are determined by the composition of the layer that is applied to them during the production process. The metallized coating is capable of reflecting different waves from the spectrum of sunlight, so it largely determines the properties of the films. Multifunctional coatings are increasingly found on sale, which are able to simultaneously solve several problems - reflect the sun's rays, retain heat, provide privacy and decorate windows.

Sun protection film

This type is designed to protect interior spaces from overheating and reduce the intensity of natural light.

Most buyers associate solar control film for windows with a colored coating that darkens rooms. However, in reality, dyed polyester is intended for other purposes. It is used to decorate windows. Other films are produced today for sun protection:

- reflective

- have a mirror surface and darken the room; - athermal

- do not allow ultraviolet and infrared rays to pass through, but do not darken the room; - multifunctional

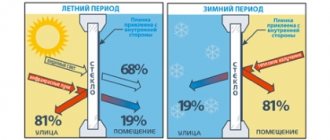

- protect from overheating in summer, and help retain heat in winter.

Window tinting with inexpensive solar control film with a mirror effect is obsolete. This method is used mainly only in cases where it is necessary to darken rooms at minimal cost. Nowadays, athermal and multifunctional coatings are popular, since they almost do not reduce the light transmittance of double-glazed windows. This reflective film is applied to windows, doors, as well as balcony and roof glazing.

Mirror film

This mirror film does not impair visibility from the premises. Tinting plastic windows and aluminum or wooden structures using this coating allows you to simultaneously protect from the sun and provide privacy. There are also mirror films with heat-saving and protective properties. This type of polymer coating can imitate a regular or bronze mirror and colored reflective surfaces with a gloss effect.

At night, when the lamps inside the rooms are turned on, mirror coatings lose their effectiveness and cease to provide one-way visibility. This factor should be taken into account by owners of premises on the ground floors.

Impact resistant film

All polymer coatings that are glued over glass make the windows impact resistant. The difference between them is their ability to withstand different forces. In addition, a protective film is glued to the double-glazed windows to prevent fragments from scattering. That is, the polymer coating may have low impact resistance, but in any case it will help protect against injury. However, such one-sided window film cannot serve as primary protection. To ensure a higher level of security, it is necessary to use a material with a thickness of multilayer polyester from 110 microns. This film is also called anti-vandal or anti-burglary, since it can provide protection from the street.

Decorative film

Such tinting film is glued to windows to decorate openings, shop windows and is often used for facade glazing. It is a dyed polyester, so it accumulates heat and reduces the light transmittance of double-glazed windows. When choosing a color, you need to take into account that decorative films have different transparency.

| Color | Light transmittance of the film |

| Bronze | 20-35% |

| Dark green | 15% |

| Gold | 15-35% |

| Silver | 15-50% |

| Violet | 15% |

| Blue | 15-35% |

| Grey | 15-35% |

| Red | 13-20% |

New generation decorative films are multifunctional. Thanks to additional spraying, they reflect heat rays and eliminate heating of the windows. Such a protective film is applied to double-glazed windows in cases where it is necessary to decorate the windows and prevent the temperature from rising in the interior. This polymer coating can have a glossy surface with a glare suppression function.

Film gluing technology

The canvas for gluing to glass is cut 5-10 mm larger than the size of the glass, measured from bead to bead vertically and horizontally. You need to work with an assistant.

Most reflective films are applied using the “wet” method. To do this, the glass surface is moistened with a solution of liquid detergent (colorless shampoo, dishwashing liquid) in distilled (purified) water in a ratio of 1:200. It is desirable that the solution does not foam.

Apply the solution to the glass surface using a spray bottle.

The film is applied from the top edge of the window. First, remove a strip of film 30-50 mm wide from the protective backing and apply it to the upper edge of the glass. An assistant aligns the canvas vertically so that the excess film evenly extends onto the side beads.

After this, using a rubber spatula 100-150 mm wide, using vertical movements from top to bottom, squeeze out excess soap solution from under the film, trying to avoid the formation of air bubbles.

An assistant evenly releases the film from the protective backing, and you keep the top edge from sliding while simultaneously smoothing the film with a spatula.

Never remove the backing from the entire film! After this it will be almost impossible to stick it evenly.

After gluing is completed, use a sharp retractable knife (with replaceable blades) to cut off the excess film along the glazing beads. Remember to break off the edge of the blade after each cut on the glass to keep the blade sharp at all times.

More on the topic:

- Decorative films for windows. Features of choice and installation subtleties

- Energy saving film. An effective way to keep your apartment warm

- Is the use of heat-saving film on windows justified?

- What to stock up on and what to be careful of when trying to remove the film from a plastic window?

Tools for work

To apply the sun protection film you will need the following tools:

- a scraper designed for washing windows;

- spray;

- stationery knife;

- scissors;

- rubber spatula;

- ruler;

- detergent,

- lint-free fabric.

The water used is ordinary, purified.

General rules for gluing film

It is advisable that the weather be sunny during installation; at this time the glass is warm, which has a positive effect on gluing. Before gluing the solar control film to the apartment window, you need to do a wet cleaning.

Cleaned glass should be free of lint. When cutting, you need to leave a margin of 3 mm on each side. At the end of gluing, you can trim off the excess with a sharp knife.

Where to glue

Sunscreen window film is used for covering residential windows, offices, industrial buildings, and shop windows. There are models that are glued to the outside or inside of the room. Using mirror self-adhesive film, furniture and store windows for advertising are decorated.

Glass gluing technology

It is advisable to install solar control film on glass that is pulled out of the frame. But this is not always possible, so installation usually takes place directly on the windows.

When gluing, the air temperature should be between +4 and +40. If the room is colder, the glue will take a long time to dry, but in hot weather it will dry quickly. Recommended air humidity is from 20 to 80%.

Stages of preparing a window for pasting:

- Wash the glass with baby shampoo.

- If there is dried dirt, use a scraper to clean the glass.

- Remove glazing beads, if any, and wash them.

- Before pasting, wipe with a clean, lint-free cloth.

Film gluing process:

- Measure the glass.

- Check the quality of the material, make sure there are no gaps, unroll the roll and turn it towards the light.

- Using a ruler and pencil, make markings and cut out carefully so as not to tear the film.

- Wet the glass with soapy water using a spray bottle.

- Remove the protective layer from the film and moisten the window with water to neutralize the action of the glue.

- We attach the upper edge to the glass with the adhesive side and smooth it smoothly, removing all the bubbles.

- Using a spatula, we expel all the air; if it still remains, you can lift the film a little and get rid of the bubbles. Just do this quickly so that the glue does not dry out.

- To control, you need to go through the spatula again, especially along the edges.

- Trim off the excess with a knife.

You can look at your work from the outside and once again check the quality of the pasting.

Architectural and facade films

Architectural and facade films for windows are no different from polymer coatings known under other names. They also serve to provide sun protection and decorate buildings. It’s just that these two terms are sometimes used as generalizations for all types of films - shockproof, decorative, sun protection and athermal. In some cases, a film with a one-way visibility effect can be called a façade film. This is due to the fact that such polymer coatings are used in fully or partially glazed business centers and shopping complexes to ensure privacy. Such films limit the view only from the street. In addition, outer film can be called façade film.

Determination of the properties of reflective film

Most consumers who independently choose film in a store expect to do the work themselves, saving significantly on the services of specialists. This is partly justified, since the average price for gluing 1 m2 of “pro” reflective film can vary from 600 to 900 rubles.

But, without having the skills to work with films, you shouldn’t hope that you will get the perfect result the first time.

Never stick the film completely onto the entire glass!

Before starting work, unroll the film from the roll and visually (against the light) evaluate its quality - the degree and uniformity of application of the protective layer.

After this, cut a narrow (100-150 mm) strip from the film and stick it on the window in a place that, in case of failure, is least noticeable from the room - at the edge of the window covered by curtains.

After this, let the film dry for the time specified in the instructions. Visually evaluate the color, degree of light absorption, and comfort for the eyes. Only after this make a decision about gluing the film to all windows.

Remember that in accordance with paragraph 1 of Art. 18 of the Law of the Russian Federation dated 02/07/1992 N 2300-1 (as amended on 07/03/2016) “On the Protection of Consumer Rights”, you have the right to a refund or replacement of the product with another of comparable quality.

Films for Eurowindows

Euro-windows include structures assembled from aluminum, plastic and wooden profiles. An additional feature of these models is the presence of double-glazed windows, sealing contours and modern fittings. The film is applied to Euro-windows in exactly the same way as on old-style carpentry structures. In all cases, it is glued to the glass. That is, there is no fundamental difference between polymer coatings for different types of windows.

To avoid confusion when purchasing, it is recommended to use the names correctly. It is advisable to tell the seller the main characteristics that the protection should have. Only in this case will the tinted glass unit perform all the necessary functions.

Tips for choosing

Considering the wide range of products in this category on the Russian market, making the right choice can be difficult. Before purchasing a product at a retail outlet, it is recommended to take into account a number of important nuances :

- Film thickness - experts do not recommend purchasing products with this parameter less than 80 microns, as it is easily damaged by any mechanical impact.

- Uniformity of composition - before purchasing, it is recommended to check the product against light - if stains or non-uniform areas are detected, you should refuse the purchase.

- No traces of defects - dents, foreign inclusions.

- The film should be smooth to the touch, the metallized coating should not peel off and remain on your hands.

- Each product must be accompanied by a quality passport indicating the state certificate number.

- When studying the chemical composition, the polymer should not contain formaldehyde and other toxins hazardous to health.

The most important selection criterion is brand recognition, the year the company was founded, marketing policy, as well as the presence of positive reviews from satisfied customers online.

External window film – how is it different from internal film?

If the windows are equipped with tinted double-glazed windows, for the manufacture of which glass was colored in the mass, the internal films are not suitable for providing effective sun protection.

With this configuration, there is a high probability of overheating. By the time the heat waves reach the reflective surface, they will already have time to heat up the colored glass. On the way back, after the waves are reflected, the heat transfer process will repeat. That is, the use of internal films in such cases makes little sense. After all, the windows still heat up. To prevent overheating of glass painted in the mixture, you need to use a different technology. In such situations, you need a solar control film for windows, which must be glued from the outside. It immediately reflects the sun's rays and prevents their accumulation by glass colored in the mass. To stick it on the upper floors, you don’t need to hire a tower or industrial climbers. For these purposes, it is enough to remove the double-glazed windows from the light openings, apply a polymer coating to them and insert them back into the windows.

External tinting is also recommended for windows with conventional double-glazed windows. After all, the sun's rays, by the time they reach the inner film, have time to heat the spacer frame and glass. In addition, its use prevents premature depressurization of double-glazed windows.

After all, when using windows, an imperceptible process occurs:

- During daylight hours, the sun's rays heat the glass. Even high-quality, well-polished material contains impurities of substances that accumulate heat waves. As a result, the heated glass expands slightly.

- At night, the windows cool down, which leads to a minimal reduction in the size of the glass.

- Due to everyday expansion and contraction, the layers of sealant on both sides of the spacer are gradually destroyed.

- Accelerated depressurization of double-glazed windows occurs.

- Windows retain heat much worse.

Exterior window tint film has an additional completely transparent layer that protects it from damage. Thanks to it, the coating withstands snow, rain, wind and dust well. The level of wear resistance of this layer largely determines the effectiveness of the film. After all, without it, the polymer coating located on the street side will very quickly lose its properties.

Technical characteristics of sun protection material

All athermal (sun protection) films for windows, widely available for sale, have the following technical characteristics :

The thickness of the material ranges from 50 to 350 microns, which entails different mechanical strength.- Roll width is usually from 500 to 1500 mm. If it is necessary to protect wide openings, the products must be joined together.

- The length of the material in a roll is from 3 to 30 m.

- Color and type of surface – mirror, monochrome, blue, burgundy, with a green tint.

- Light transmittance – from 95% to 15%.

- Reflective ability – from 7% to 50%.

- Light absorption – from 10% to 30%.

- Light delay coefficient – 0.4 – 0.8.

- The ability to provide protection from intense ultraviolet radiation is from 60% to 99%.

- Thermal energy retention – from 40% to 90%.

The above characteristics are assigned to materials based on full-scale tests after the production of a pilot batch of products at the plant. The indicators are recorded in a quality passport, a copy of which must be attached to each product.

Manufacturers of tint films

In Russia, window tint film is mainly represented by products from American, Chinese, Indian and South Korean manufacturers. Moreover, the range of most brands includes polymer coatings of economy, standard and premium classes. Thus, when choosing a brand, it is not advisable to focus solely on cost. Thanks to supplies from India and South Korea, high-quality window tint film has appeared on our market, which can now be purchased at an affordable price. For comparison, it is better to study the characteristics of films with the same functionality and cost. When evaluating, the quality of polyester, uniform color, degree of protection of the reflective layer, absence of harmful components and service life are important.

| Brand | Manufacturer country | pros | Minuses |

| Sun Control | The brand is owned by the UK and the factory is located in India. | The quality of the products of this brand is practically not inferior to popular American coatings - Indian films perfectly filter UV rays, retain heat and protect against overheating | The disadvantage falls into the category of reputational ones, since the coating is produced in India. In addition, counterfeit products labeled with this brand often began to appear in the Russian Federation. |

| LLumar (Eastman Chemical) | USA | A highly durable coating that adheres well to glass and retains reflectivity for a long time. Has a high degree of protection against infrared and thermal radiation | The base used is polyester from a Chinese manufacturer, which slightly harms the reputation of premium products. There are also many counterfeits of this popular brand sold on the market. |

| Professional Window Film | South Korea is a direct analogue of the Ultra Vision coating produced in America | The products of this brand are cheaper than the original film, but have similar characteristics - absorbs almost all ultraviolet radiation and reflects more than half of the heat rays | Inferior to the original film in terms of durability |

| Armolan | USA | Excellent UV protection, high levels of anti-glare and natural color rendering | Limited assortment, since the brand is not promoted |

| Ultra Vision | USA | Metallized coatings do not have a characteristic shine and do not create glare; the film is easily removed and does not leave behind adhesive stains | Mostly products based on Chinese polyester are sold in Russia. |

Chinese window tint film, which can be purchased several times cheaper than premium American coatings, cannot compete with the listed brands. With the same technical characteristics, it transmits light worse and retains heat worse. After about 2 seasons of using cheap films, tinted plastic windows have to be re-glued, since the coating not only does not fulfill its functions, but also begins to peel off from the glass.

Choosing a reflective film for a window

When you decide to improve your home, don’t be lazy when you come to a building and finishing materials store and ask the sales consultant about the properties of one or another film presented in the assortment. Additionally, duplicate the information received by reading the instructions (annotations) located on the film label.

Why is it important?

The vast majority of finishing materials are products of Chinese origin. A well-known brand that appears on the packaging of the film is not a guarantee of the quality of the product.

The marking of the reflective film must include the following information about its properties:

- light reflectance coefficient (from 5 to 90%);

- light transmission coefficient (density) – usually from 5 to 50%);

- UV absorption coefficient;

- IR transmittance;

- film thickness (in microns, for example, 30 µm ± 1-30%);

- metal used for spraying (Au, Ag, Ti) – gold, silver, titanium;

- temperature range in which the film can be used (from -30°C to + 50°C) or others.

Also on the packaging there should be detailed instructions for gluing it onto glass with your own hands.

Light transmittance of tinted windows

Tinting film on windows must be applied taking into account construction and sanitary standards.

All basic requirements contain SNiP 23-05-9 and SanPiN 2.2.1/2.1.1.1076-01. These documents regulate the daily amount of natural light that should enter the interior through window openings. Scientifically, this process is called insolation - irradiation of vertical and horizontal surfaces in rooms with sunlight. Since window tinting film blocks the sun's rays, the insolation of the premises may not be sufficient. It is better to avoid this, since a lack of natural light negatively affects the development of plants and human health. After all, direct sunlight kills microorganisms. To prevent bacteria and viruses from developing in rooms, glass tint film should be selected taking into account its light transmittance.

The required level of insolation of living and working premises is determined using special tables and graphs. They contain all the necessary information that will help you find out the required time (+/-10 minutes) of exposure to direct sunlight. To the extent that tinted glass for windows reduces the intensity of the luminous flux, the actual insolation value should be greater than the permissible minimum.

Scope of application of reflective films

Reflective films for windows are most widely used in the field of industrial design and in the design of commercial or office buildings. In houses, the installation of reflective films is either an urgent need to protect the interior from indiscreet views from the street, or the unfortunate location of the apartment, the windows of which are oriented strictly to the south.

The most suitable film for home use is one that has a low light reflectance of 5-15%. Denser ones absorb and reflect such an amount of light that makes the room uncomfortable for use (if it is not a bedroom). A thick film can create twilight in the room, which has a detrimental effect on the organs of vision, causes tension in the eye muscles, and inhibits the growth of indoor plants.

Reflective films are widely used in the interior - for decorating glass doors in bathrooms and toilets. In this case, the density of the film can be quite high; it does not affect color perception, since in these rooms lighting is provided mainly by artificial light sources - electric lamps.

But when choosing film as an element of interior decor, you should remember: the reflective effect will only work if the lighting outside the room is turned on. If you are taking a shower and the light in the hallway is off, you will be an excellent subject for filming a video from the “behind the glass” series.

Where to buy and how to stick tint film on windows

Window tinting film is sold in online stores, construction supermarkets, markets and window manufacturers.

It is important not to purchase a fake, the real characteristics of which do not coincide with the parameters stated in the instructions. To buy window tinting film from trusted manufacturers, you need to do this on the official websites of well-known companies or from distributors of these products. Tinting of double-glazed windows with film can be done either with the help of specialists or on your own. To cover windows with external coating, you definitely need to invite craftsmen. After all, this procedure requires removing double-glazed windows from the light openings. To avoid mistakes when installing them back, it is better to entrust the entire process to professionals. But you can do the gluing of windows from inside the rooms yourself.

How to stick the film yourself?

Tinting film can be applied to windows only after the glass is cleaned of dust, grease and other contaminants. It is recommended to wash glass with a weak soap solution, for the preparation of which it is better to use a neutral shampoo. To apply the polymer coating, you will need the following kit:

- stationery knife with additional blades;

- spray;

- squeegee with rubber tip;

- scraper for removing stubborn stains from glass;

- scissors.

You will also need glass remover since the shampoo solution along with the dissolved dirt must be completely removed from the surface. After complete cleaning, the windows and tinted glass film are ready for the pasting procedure. The process consists of several stages:

- Spray the film from a spray bottle on both sides with the remaining shampoo solution to protect the adhesive base from dust.

- Remove the pre-moistened lavsan (protection of the adhesive layer) from the back of the film.

- Carefully apply the polymer coating to the glass and carefully align it in the light opening. If protective films for window glass are too large, it is advisable to moisten them again with a shampoo solution on the outside before applying.

- After preliminary fixation and smoothing of the coating, it is necessary to expel all water and air with a squeegee. This should be done with uniform movements from the center to the edges.

- Make sure that the film is securely stuck, and then trim off the excess polyester with a utility knife.

- If the tinting of double-glazed windows is swollen in different places, bubbles with water and air must be immediately removed using a squeegee. Do not let the glue harden. Sometimes the procedure needs to be repeated up to 4 times.

Window tinting with film is completed by cleaning the surface. Moreover, you can wash double-glazed windows only 5 days after the pasting procedure. If you do this too soon, the coating may wrinkle or peel off the glass. You can remove dirt and dust from the surface of the films only with soft microfiber.

Tinting on plastic windows can be applied under glazing beads. In this case, the edges of the polymer coating will not curl over time. To apply the sticker in this way, you need to be able to remove the glazing beads and put them back in place.

Structure of reflective film

The modern chemical industry offers a wide range of films that have a reflective effect. The basis for the production of most of them is polyethylene terephthalate, a material that is chemically and physically resistant to damage and exposure to atmospheric air and precipitation, the service life of which for open spaces (placing the film on the outer surface of a window) can be 5-10 years, and when gluing to the inner surface - exceed 10 years.

Most films have a multilayer structure - they consist of several layers of film having different physical and optical properties and contain pigments that give the film a tint (neutral gray, bluish, pinkish, yellowish), as well as sputtering of rare earth metal oxides with unique reflective properties for UV rays (gold, silver, titanium).

The painted layer is usually placed inside and covered on the outside with protective layers that have increased hardness: resistance to mechanical damage - scratches, or high viscosity - such films have “vandal-proof” properties, i.e. resistant to mechanical damage - shocks and prevents the formation and scattering of broken glass fragments.

Installation sequence

The installation technology is simple. But following it will lead to a positive result.

Sequencing:

Prepare the glass. Wash with soapy water (1 tablespoon of liquid product per half liter of water) and wipe dry. Pay special attention to keeping corners and edges clean.

Prepare the film and cut it.

Moisten the glass surface.

Remove the protective layer from the film and moisten its surface.

Fix the film on the window.

Displace water droplets using a spatula. To make the spatula glide better, it should be moistened. Don’t forget to carefully straighten and press it in the corners.

The film can dry for more than ten days. As excess water evaporates, the coating will become lighter. There will be no air bubbles, streaks or clouding. This is the self-leveling property of this material.

After installing this miracle film on one window sash in the summer, test it. Touch the window sill of the part of the window where the film has already been applied with one hand, and with the other where there is no film yet. You will immediately feel a significant difference in temperature!

Installation tools

To make the window tinting job faster and better, you need to prepare the tools.

You can't do without:

- stationery knife;

- water spray;

- spatula of maximum width;

- paper towel;

- non-aggressive detergent.

It is better to use liquid soap or baby shampoo. And the paper towel should be thick so that it does not leave lint on the glass.

To avoid damage and scratches to the surface of the film, you need to purchase a rubber or plastic spatula.

Color variety

Tinting a balcony, loggia, or other room in the house can be done using different variations of the material. When resolving this issue, you can choose a film that meets the necessary color requirements. A wide palette of colors allows you to achieve the desired result without any problems.

| Film color | Transparency level in percentage |

| Purple | 15 |

| Golden | 15-35 |

| Bronze | 15 |

| Smoky | 20 |

| Green | 15 |

| Gray | 15-35 |

| Blue | 15-35 |

| Solar | 20-35 |

| Silver | 15-50 |

The good transparency of silver film (50%) makes it the most popular among consumers.

Features of the inner surface of light boxes for covering with translucent film?

The light-scattering ability of translucent film makes it indispensable for gluing light boxes illuminated from the inside. However, errors in calculating the required luminous flux or the depth of the light box can cause uneven illumination of the working surface. The brightness of the light box directly depends on the quality and color of the internal surfaces of the light box. The pinpointness of illumination or its unevenness can be corrected by simple steps:

- It is enough to treat the inner surface of the box with fine sandpaper;

- you can cover the inner surface of the box with a white matte film;

- It is necessary to ensure that the inner surface of the box is white.

It is worth noting that the working illuminated image can be illuminated with “warm” light if the inner surface of the box is painted in a yellowish shade of white.

General pros and cons of use

The use of athermal films for protecting rooms from the sun is growing every year, due to the presence of many advantages :

Effective protection of the room from excessive ultraviolet radiation.- Preservation of the visual characteristics of the translucent structure.

- Easy installation - installation of the material does not require contacting professionals, since all work can be done with your own hands.

- Allows you to preserve the original color of curtains, carpets, furniture, and decorative elements.

At the same time, despite the advantages, such products have several minor disadvantages :

- Subject to mechanical damage.

- High cost, in the presence of high-quality metallized coating.

- Reduces the level of insolation of premises.

- May peel off if installed incorrectly.

The above disadvantages are subjective and are often not taken into account by consumers, as a result of which the products always find their buyer.

User reviews

Many property owners leave a lot of positive and negative reviews about sun protection films on forums on the Internet:

- High efficiency of products in a higher price category.

- Any metallized film effectively absorbs light and shades the room.

- Low thermal energy absorption coefficient.

- If you have a glass roof, a film with a light absorption rate of more than 80% will save you from the summer heat.

- High cost of quality products.

You can read real consumer reviews here, here and here.