The most popular material for doors that are installed on the balcony is metal-plastic. And this is not surprising, since it is one of the most practical and affordable materials.

Metal-plastic doors protect very reliably from drafts, do not dry out and are resistant to mechanical stress. But, unfortunately, over time, some defects arise in the normal operation of these products, in particular, they begin to sag or creaking appears. In this case, you should not panic, but take timely troubleshooting measures. Many of them can be fixed on your own.

Why do hinges squeak?

Door hinges begin to creak for various reasons. It is important to monitor their condition to avoid wear and tear in the future. The main problems that cause squeaking are as follows.

- Insufficient lubrication. Over time, the lubricant expires. It thickens, spreads or dries out, blocking the normal movement of the door, which has a destructive effect on the mechanism.

- Corrosion. The most common cause of squeaking hinges on outdoor doors. This is due to high humidity, which not all metal elements of the door structure can tolerate. If measures against rust are not taken, the movement of the blade is gradually hampered and the iron is destroyed.

- Wear of parts. Long-term or improper use of the door structure and its fittings leads to wear and tear of the mechanism and its breakdown.

- Pollution. Dust and small debris often accumulate in the loop space. If nothing is done, dirt accumulates in the lubricant, gets on the hinge hinges and begins to gradually grind down the metal like an abrasive.

- Door warp. If the door leaf is massive or an error was made during installation of the structure, it may become warped. This is not only detrimental to the fittings, but also leads to even greater loosening of the box itself and a change in the contours of the canvas. Usually, the consequences of unprofessional installation make themselves felt in the very first days of operation of the door structure.

The most common flaws during installation, leading to unpleasant consequences: misalignment of the mounted structure, incorrect or fragile installation of hinges, friction of the canvas against the sheathing, frame or platband. The conclusion suggests itself: the creaking of the door indicates that you need to urgently deal with the cause of its appearance.

What causes whistling and buzzing sounds?

People often encounter the problem of whistling from windows during strong winds. From gusts of strong wind, a thin whistle can be heard, sometimes the window buzzes so much as if it is about to fall out onto the street. A whistling sound may indicate the following problems in the window system:

- improper installation work;

- violation of assembly and manufacturing technology;

- not adjusted fastenings, moving elements;

- long service life and material wear.

Incorrect assembly technology

One of the first reasons for whistling from the window may be poor-quality assembly of the system. To exclude this factor, you need to invite specialists for diagnosis. Employees must carefully check the hinges, seam tightness, seals and identify the cause. If it is a manufacturing defect, then the manufacturer must replace the window or repair the defects on site.

Violations of the installation technology include a loose fit of the seal, lack of a sealed seam, large gaps, and cracks. The presence of such defects provokes drafts and whistling sounds. Installation specialists and a representative of the manufacturer should come and try to correct the defects. Work defects can come in two common forms:

- Incorrectly formed seam, which is held only by polyurethane foam. Wind, heavy rains, snow, and sun gradually erode the layer of polyurethane foam, making it thinner. It is logical that air from the street will begin to seep through the cracks. If the tightness is not corrected in time, flooding of the slopes, dampness, and mold will begin.

- Violation of the technology of adhesion of polyurethane foam and window opening. Insufficient cleaning of the window opening from dust and small debris leads to a lack of strong adhesion to the polyurethane foam. Small cracks form and the cavities into which the street wind blows, irritating everyone in the apartment with whistling noises.

The installation of plastic structures should be carried out by qualified installers from a trusted company. Independent installation work or failure to comply with GOST standards will lead to defects. Compliance with the rules, experience and practical skills will help you do everything quickly, without violating the prescribed technologies. You need to entrust complex and painstaking work to those who give a guarantee for the long service life of all parts and components, and in the event of a breakdown, are ready to eliminate the defect.

Out-of-adjustment and wear

Windows and all small components must undergo maintenance. How long the system will protect from bad weather and noise depends on regular lubrication of the seal and adjustment of fittings.

Every three years, the silicone sealant that is used to generously lubricate all joints begins to deteriorate. Cavities and cracks appear through which air whistles through. The solution to the problem is obvious: invite a specialist to replace the sealant. Even if you know how to do it, it's worth inviting an installer the first time. He will show you what to do and how to do it, how much silicone is needed, and explain step-by-step actions.

Possible problems

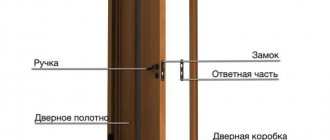

There are many problems with PVC doors related to creaking, and this does not depend on the quality of the door and its installation. Over time, this design requires adjustment. In case of serious problems - the canvas has fallen off its hinges or the locking mechanism has broken - you cannot do without inviting a professional. A simple creaking or jamming can be repaired yourself.

Any door can creak, because the hinges of the plastic leaf are designed using an identical mechanism.

Here are the reasons why metal-plastic doors squeak:

- The sash is sagging and catches the threshold. This is due to the hinges not working properly. This defect must be eliminated, since over time it will lead to the formation of gaps between the frame and the canvas, and therefore to a violation of the heat and sound insulating properties.

- The doors begin to creak, clinging to the frame. This indicates displacement of the sash. To fix this problem, you will need to adjust the fittings.

- The handle doesn't work well. It can either close poorly or hang loose, while it does not fulfill its main task, that is, the opening/closing mechanism does not work. This is a consequence of improper installation of the locking mechanism.

- The door creaks or makes other unusual sounds when opening or closing. In this case, you will need to adjust it correctly in all respects.

Door adjustment

- Creaking sound when there is no lubrication. For normal operation of the hinges, a means to facilitate their movement is lubricant, it is absolutely necessary.

- Problems with the quality of hinges on plastic doors. They may be incorrectly manufactured or installed incorrectly. In this case, no means or adjustments will help; they need to be replaced. It is recommended to do the same if the loops have exhausted their service life.

- Creaking sounds from plastic doors due to rust on the hinges. Oil and lubricant will help eliminate this.

- Lack of bearings in hinges. The problem can be solved by replacing the hinges with the missing element.

- Creaking occurs when the skin rubs against the fabric itself. To do this, you need to conduct a thorough examination of the door leaf, and if you find a protruding part of the trim, you just need to cut it off.

- Deformation of the canvas or improper installation also leads to an unpleasant squeak. It occurs when the door is opened, resulting in friction between it and the door frame. You can solve the problem yourself, but it is better to invite a specialist.

Sequencing

Having prepared or purchased lubricant, you need to slightly lift the door, the hinges of which are creaking. Apply a small amount of lubricant to the gaps between the two halves of the door hinge and lower the door. Close and open it several times so that the lubricant is evenly distributed over the metal surface and penetrates into the hinge cavity. If the squeak is eliminated, you're in luck. You won't have to do anything else.

It is much more difficult to eliminate squeaking if the door hinges are installed incorrectly. In this case, it is not enough to lubricate the hinges. Complete removal of the door panel and reinstallation of the door awnings will be required.

Finding out whether the door is installed correctly is easy. It is enough to open it 1/3 and, in the complete absence of a draft, see if the door changes its position. If the hinges are installed incorrectly, the door will either close or, on the contrary, continue to move and open.

In this case, you need to do the following: use a screwdriver to loosen the screws that secure the hinges to the door frame and fix them in a position of 90° relative to the door frame. Unscrew all the screws, leaving 1 in each of the hinges so that the hinges take the correct position. Mark the new position of the door hinge with a pencil. Use hardwood plugs to fill in the old holes and use a thin drill to drill new ones through the holes in the door hinge. Re-tighten the screws into the newly drilled holes. Try closing and opening the doors. The squeak should disappear.

Various types of lubricant

Lubricating door hinges is the first thing you can do against annoying squeaking noises.

You can use both industrially produced lubricants and improvised home remedies. But it should be remembered that only properly selected lubricant will have a long-term and effective effect.

Universal means

Well-known and affordable products that are easy to buy in a store or find in your garage:

- WD 40 - comes in a can with a convenient dispenser, allowing you to easily reach hard-to-reach places. A very effective product that cleans the surface and improves the sliding of parts. It works instantly, but not for long. You must use oil afterwards.

- Litol - due to its pronounced water resistance and frost resistance, it is widely used for lubricating entrance doors and gates. Not afraid of adverse weather conditions.

- Solidol is a popular inexpensive product, the effect of which will last for a long time. The reason for this is the thick and viscous consistency of the lubricant.

Machine oil

Ordinary machine oil is a good lubricant for door hinges.

Almost every household has a bottle of this technical liquid. Car owners always have waste - oil left after replacing it in the car with a new one. Oil for engine or car parts is also suitable. It is better to choose one whose viscosity is higher.

Sewing machine oil

Handicraft workers will most likely have oil for sewing machines on their households. A small plastic container with a thin spout will allow you to place a drop of oil exactly where you need it. Sewing machine oil is usually light in color and does not leave a dirty residue.

Vegetable oil

As a last resort, you can take vegetable oil from the kitchen. A short-term effect will be achieved, but some negative consequences are also possible.

Vegetable oil is too liquid, it spreads a lot and dries out quickly. Also, a lot of dust and dirt sticks to it, which leads to wear of the mechanisms. Over time, such oil can darken and thicken, which leads to damage to the fittings.

Pencil lead

An alternative to oil is dry graphite lubricant. The door is lifted and small pieces of pencil lead are placed in the hinges. When opening and closing the door, the stylus crumbles, and the resulting powder prevents squeaking. An easier way to use is to pour crushed stylus into the cracks of the hinges.

Paraffin or wax

Candles made of wax or paraffin are sure to be found in every home. A piece of the substance is heated to a liquid state and buried inside the creaking mechanism. When cooled, the wax hardens and forms a smooth sliding surface.

Silicone Grease

An affordable analogue of graphite lubricant, characterized by long-lasting action for several years. Suitable for outdoor entrance doors, as the lubricant is resistant to frost and temperature changes.

What types of lubricants should you avoid?

Even if a squeaky door is very annoying, there is no need to try to lubricate it with the first grease you come across.

It is highly undesirable to use organic substances - lard, butter and vegetable oil. They contain a large amount of water, which will interact with the metal and cause its slow corrosion. Over time, this will only make the squeak louder. Also, animal fats quickly decompose, they can even become moldy.

The popular product WD 40 should also be used with caution. It is not so much a lubricant as a washing composition. It cleans the mechanism of dirt, but at the same time washes away the old lubricant. The quick effect of the first application will be replaced by worsening problems. Therefore, after using WD 40, it is recommended to lubricate the hinges with a thicker lubricant.

The enemy of iron

We looked at a lot of ways to lubricate the door to prevent it from squeaking. But what is better not to lubricate? This is vegetable or olive oil, also Vaseline, these products will help, but only until they dry out. And they dry very quickly. This lubricant also quickly becomes dirty and also contributes to the development of metal corrosion. It is better not to use it so as not to harm the metal. How to get rid of a squeaking metal front door.

The metal sheet is heavy, it is quite possible that it simply sagged. If this is not the case, it seems, then first you just need to lubricate the hinges with new grease, as I have already told you how to do this. Most often, these structures are welded together, that is, during installation, the hinges are already welded to the box and the canvas. If the lubricant does not help, the creaking does not disappear, your only option is to call the specialist who installed this low-quality door for you. If it is possible to return it to the store or exchange it, it is better to do so. If both options disappear, you will have to digest the loops, and whether you will do this yourself or a specialist, of course, is up to you.

Recommendations for applying lubricant to door hinges

Before lubricating the hinges on the door, check their surface for dirt, which can be removed with a dry cloth slightly moistened with solvent. If the hinges are rusty, you will need to first remove the rust with a suitable product. An anti-corrosion agent in the form of a spray allows you to clean the hinges without removing the fabric from them. If the rust solvent is in liquid or oil form, soak a viscose cloth and apply it to the canopy like a compress. Typically, rust dissolves within 2-6 hours, depending on the thickness of the plaque and the characteristics of the product, after which it is removed with a dry cloth.

Please note that you cannot knock off rusted hinges with a hammer or crowbar, as after such handling the mechanism will be damaged and will not be suitable for normal operation.

For ease of use, you will need a small container and a medical syringe without a needle. A small amount of lubricant will be poured into the first, and the second allows you to dose the lubricant into the gap between the hinge components.

Recommendations: how to lubricate the hinges of a plastic door

To prevent the hinges from creaking, they need to be coated with a special lubricant. Moreover, sometimes this needs to be done without removing the door leaf from the hinges.

In the case of a plastic door it looks like this:

- A syringe is taken, which is filled with oil for lubrication and the substance is applied to the fittings;

- If pencil lead is used instead of lubricant, then the door needs to be lifted slightly so that the cracks into which the product is poured are visible.

If the plastic door leads to the balcony, then you need to start lubrication from its side. The door must be open.

Lubricating a plastic door: step-by-step instructions

Plastic doors have their own characteristics. They differ from ordinary steel and even interior wooden doors. The loops of such products also have their own specifics. Before starting work, it is worth choosing the time of year.

It is better to lubricate plastic doors in the fall. In winter, silicone grease can harden, but in summer it can easily be washed off by rain. The spring period is unfavorable due to changeable weather. Autumn is the ideal time to care for plastic structures. Many people start lubricating the plastic door hinges directly, ignoring other parts of the product. This is a big mistake, and it is not surprising that many owners experience door squeaking and other problems. When cleaning, you need to pay attention to the plastic pads that are on the hinges. The composition is also used to lubricate the fittings.

First you need to remove dirt and dust from under the pads. There will certainly be enough of it there.

After the hinges are cleaned, you should thoroughly spray the silicone compound. When the composition is applied, it is recommended to open and close the doors several times so that the product penetrates inside the hinges.

The fittings can be lubricated with simple products such as machine oil. But this composition will be absolutely useless for plastic linings and rubber.

If the creaking of the doors has not stopped or the structure still jams in the opening, then the problem may be due to improper installation or distortions. In this case, the door is either reinstalled or replaced.

The need to lay PSUL

In addition to the vapor barrier membrane, PSUL, a pre-compressed seal, plays an important role in sealing the joints between the door opening and the frame. It is located around the perimeter of the doorway on a protrusion called a quarter.

This is interesting

A quarter is a special protrusion in a wall opening from the outer edge of the opening. It covers the entire perimeter of the hole, except for the base.

As already described above, the plastic door is mounted in the wall opening using polyurethane foam. The seal plays a major role in ensuring the reliability of installation and protecting the polyurethane foam from exposure to moisture. PSUL performs the function of such a seal - it is a barrier that protects the polyurethane foam from water. Without such a barrier, the foam assembly seam will deteriorate over time. This usually does not happen all at once, but over a certain period of time. The destroyed foam is no longer able to hold the balcony block; the wind from the street penetrates into the room through the resulting cracks.

Another thing worth remembering is this. Polyurethane foam plays the role of a kind of damper, a shock absorber that suppresses noise from the street. In its absence, the PVC door is held in place only by mounting anchor plates. It turns into a diffuser of a large loudspeaker, vibrating from every noise, be it a car passing under the windows, the scream of children or the noise of a thunderstorm. A vibrating door greatly increases the noise, and the wind entering the room will only emphasize it.

How to lubricate double-sided hinges

The principle of lubrication is similar to the previous method.

- Open the door leaf.

- Fill the lubricant into a syringe or a special oiler with a narrow long spout and pour it inside the mechanism. For this purpose there is a specially provided hole in the hinge rod.

- Switch the door leaf to the open/close state several times, thereby evenly distributing the lubricant throughout the mechanism.

Two-way loop

Lubricating a plastic sliding door

Such doors are installed between rooms; they allow you to fit harmoniously into the interior and save useful space in the room. And everything would be fine if it weren’t for the creaking that occurs when the canvas moves.

The design of the sliding model is simple and clear, with guide bars along which the door moves, equipped with wheels. This means that the reason is one of two: either the guides are creaking, or the wheels themselves.

In the first case, the problem is insignificant, most likely something has gotten into the groove and a characteristic sound occurs when the blade moves. It is enough to carefully examine the movement mechanism and eliminate the cause of the unpleasant sound.

Door adjustment

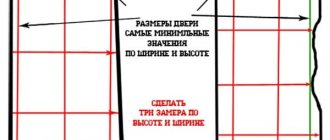

Those who have plastic doors installed in their home need to know the mechanism for adjusting the position of the door leaf. This will help get rid of squeaks, distortions, rubbing, etc. The sequence for adjusting the hinges is as follows:

- The door leaf is closed.

- Outline its positions with a washable marker or other means that will help determine the position of the canvas relative to the frame.

- Already at this stage it is possible to determine what happened to the door. The correct outline of the canvas is parallel to the frame with equal distances on all sides. If the geometry is broken, adjustment will be required.

How noise (whistle, hum) occurs in a balcony block

The balcony door whistles. What to do?

Briefly, the pattern for the occurrence of extraneous noise (hum, whistle) from the door is as follows:

1. On windy days, bulk air masses bend around the building. Modern multi-storey buildings are exposed to significant air pressure on the leeward side; a zone of low pressure is formed on the opposite side of the building.

2. Air tends from an area of high pressure to an area of low pressure, finding all possible paths for this, including through the premises of the building.

3. There are obstacles in the way of air - a plastic door, its frame, glass and finishing elements, insulation and sealants, which lose their properties over time.

4. Poorly secured elements of a balcony door vibrate at high frequencies in the wind, producing sounds of varying strength and height.

What is most unpleasant is that it is not so easy to get rid of the resulting noise or whistle. As in the case of illness, noise (whistle, hum) from a balcony door is easier to prevent than to eliminate. Sick doors are not easy to cure, but by making efforts when choosing them, for example, by checking products for compliance with standards, you can protect yourself from possible troubles.

Door sagging

The sagging of the doors will be indicated by a greater distance from the edge of the frame to the marker line at the bottom than at the top. The upper hinge mechanism will have to be adjusted. To adjust, you will need a spanner, which is inserted into the adjusting screw, and several turns are made clockwise.

This way the canvas is pulled towards the jamb, thereby eliminating sagging. If such manipulations do not help, and creaking, sagging and other defects are not eliminated, you need to do the same with the lower hinge.

Adjusting the top hinge

However, remember that the adjustment of the bottom hinge is somewhat different, because it contains two adjustment screws.

- One is located at the top end, and when you turn it, the door will lift up.

- The second one is on the hinge on the side; it will help center the sash relative to the jamb and horizontally.

Such comprehensive measures will help eliminate creaking and incorrect position of the canvas relative to the box. Adjustment should become an annual rule for caring for plastic doors.

Adjusting the bottom sash

Methods

There are various methods for eliminating squeaking, which you need to familiarize yourself with in advance.

Without dismantling the door

A squeaky hinge can be lubricated without removing the door leaf. The lubrication procedure consists of the following sequential steps:

- opening the door;

- raising the canvas by 1-2 centimeters;

- removing old grease and debris from fittings;

- applying oil liquid;

- lowering the door.

With the canvas removed

Sometimes lifting the canvas is not enough and you have to remove it completely. To do this, the door is opened slightly and a metal lever is placed under it. Then, with its help, the canvas is lifted and removed from the hinges. Having got rid of the door, the hinges are treated with a lubricant.

Rules for performing work

You need to remove the plastic balcony door if one of the hinges is broken, or the door leaf requires repair. You also need to remove the door to lubricate the fastenings with oil. You can replace faulty fasteners without any problems, since the design is of high quality and mobility. It is enough to lubricate the door mechanism once a year. Thanks to this, the durability of the product increases.

It is necessary to remove the PVC entrance door leaf according to the rules. The entrance structure, unlike the balcony structure, is equipped with reinforced fastenings and a mechanism that protects against burglary. It has a lot of weight, so in such cases it is better to work with an assistant. The metal-plastic product is equipped with 3 fasteners.

We draw conclusions: why does the creak appear?

Problems with metal-plastic doors are not uncommon. The popularity of the brand or the high price of the design will not protect against this. The appearance of an unpleasant creaking does not indicate the low quality of the fittings - this is its natural wear and tear, which will appear sooner or later. To determine what exactly the squeaking problem is, it is recommended to place a piece of graphite under the hinge. If this does not help, then the reason is rust or worn-out fittings.

To eliminate the unpleasant sound, you only need to lubricate the hinges with oil and adjust the sash; replacing the entire set of fittings is not necessary. And you can do it yourself.

Remember that timely adjustment and lubrication of hinges will help extend the life of hinges and locking mechanisms.

<textarea name=”ak_hp_textarea” cols=”45″ rows=”8″ maxlength=”100″ style=”display: none !important;”>