When windows are replaced, everyone strives to carry out the repair so that not only the window, but the entire system lasts as long as possible. I also want to achieve maximum thermal insulation so that the structure is easy to maintain, and also looks aesthetically pleasing and fits into any interior.

Sandwich panels

Materials from which sandwich panels are made

For the layer of such a sandwich the following materials are used:

- Mineral basalt wool is one of the most popular and widespread materials today. This is a highly effective non-flammable thermal insulation based on a fibrous structure with different types of filler. Effectively retains heat at very high and low temperatures. Does not contain binding elements that negatively affect humans. Has good sound insulation.

Sandwich panels made of polyurethane foam are very convenient for balconies, as they are light in weight and at the same time high in strength. Resistant to rot and mold due to high moisture tolerance. They have good noise and heat insulation. Non-flammable, environmentally friendly material.

Fiberglass has glass strands in its structure, which provides excellent thermal insulation. The material has excellent sound-absorbing properties, but depending on the thickness. Elastic material that can be easily transported because... it does not cake or deform. Non-flammable and resistant to combustion. Non-toxic.

Expanded polystyrene is nothing more than a lot of air bubbles enclosed in thin polystyrene shells. Due to its cellular structure it has excellent thermal insulation properties. Very resistant to moisture and therefore rotting. It does not react to substances such as soda, soap and mineral fertilizers.

The following materials are used to frame the outer layer:

- Galvanized steel, which is very resistant to corrosion. But the protective characteristics largely depend on the thickness of the applied zinc.

- Aluzinc is also a very durable material that reflects sunlight well and is resistant to high and high humidity.

- Polyester is made from polyester using a special technology. It maintains its structure and does not deform, despite the impact of all kinds of negative effects, be it high temperature or high humidity.

Modern options for finishing slopes on windows or why I am against plastic

If you are just planning to replace your windows with new ones. Whether it's plastic windows or modern wooden ones. Then you will encounter a problem - replacing the slopes, because the old ones will be damaged during the dismantling of the old window.

Today we’ll talk about slopes, which slopes look modern, and which ones I don’t recommend and why

So let's go

Why are slopes needed at all?

- makes the window design attractive. Think for yourself, how can a window look good with a broken wall (slope)

- slopes improve sound and thermal insulation

- protects mounting elements and seams from the environment. It not only protects the fasteners from corrosion but also prevents the windows from fogging up and freezing

There are three popular options for finishing slopes.

Plastering

The option is low cost. And for work you only need to have: a finishing mixture, a minimum set of tools and water-based paint. For internal slopes, I recommend using a gypsum mixture. First, we level the base with starting putty and finish with finishing putty.

Important Do not dilute large amounts of solution. It dries out quickly. Apply the solution in several layers. The next one is applied only after the previous one has completely dried.

Disadvantages - for a smooth surface you need to have straight arms and put in a lot of effort and time - a common occurrence is the appearance of cracks on the slope (small layer of plaster, poor quality of sand or changes in humidity) - poor thermal insulation

Plastic sheathing (sandwich panel)

I agree that plastic is in demand due to its quick installation and affordable cost.

It has a number of advantages over competitors: - goes well with the window profile. - long service life - easily withstands temperature changes - there is a protective layer that does not burn or melt - very easy to maintain

Disadvantage : the opening becomes vapor-tight. If the insulation was done poorly, then you cannot avoid a large amount of condensation. - NOT environmentally friendly - fades in the sun over time, turns yellow - becomes electrified when cleaning - does not quite match if the window is wooden or wood-look - looks very cheap in the window opening, especially the corners that cover the end side and everyone is already tired of it

Plasterboard finishing

An excellent material for hiding wall defects. Like no other, it is perfect for finishing slopes.

Among the advantages are: - suitable for any windows (plastic, wood) - you can make a slope of any size from it - low price - quickly installed (again, if you have direct hands) - can be painted in any color - has visual integrity of the structure - the most important thing this is an environmentally friendly and aesthetic material (in its finished form) it looks modern on a window opening, not like plastic))

Disadvantages - the material is not very durable (but depending on how you use it, you can break the wall if you want) - if the humidity is high, it quickly collapses (all depends on the insulation) - additional painting is required

It is important to recommend using moisture-resistant drywall (green), it is not afraid of condensation on the windows

Personally, I chose the option with plaster for myself and recommend it to all my friends and acquaintances. I wrote about its advantages above.

I will be glad to discuss your thoughts on this matter, write comments

Installation of PVC slopes

Attaching the profile to window slopes Installing plastic panels for window slopes is quite simple, following the rules for performing the work:

- Initially, you need to make guides, securing them around the perimeter of the window. For this, a starting profile is used, which is mounted on the slope wall. Fastening is carried out with self-tapping screws; they should go quite deep into the wall.

- If the walls are made of brick, then use a drill to drill holes, and then attach the profile with dowels. To make the panel slope level, a level is constantly used during the work.

- Next, the size of the window is taken and transferred to the finishing material. Measurements must be taken accurately so that everything falls into place and the opening is reliable. It is necessary to saw or cut the panel according to the transferred dimensions.

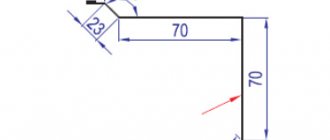

Measuring the window slope

- The cut out elements are tried on in depth. If the opening is deep and the sandwich panel does not fit, then it is trimmed.

- The cracks need to be sealed with polyurethane foam or sealant applied if the internal slope has minimal holes.

- After the material has dried, you can complete the window with special decorative elements. A corner is mounted on the joints, due to which each corner of the window will be of the correct shape. Manufacturers make them from plastic and are used simply to mask seams.

- All dirt and dust are removed, foam or sealant is cut off. If the joints are not perfectly smooth, then white sealant is used to seal the imperfections.

- Next, the panel is mounted into the starting profile at the required length, and the space can be filled with insulation. There is no need to finish the window additionally, except to install corners.

Installation of PVC slopes A slope on a balcony made of plastic panels is carried out by analogy, the facade slope of windows, attic, interior, if we are talking about the front door, is also made. You can put a platband on the door, choosing it by color or finishing it with other materials.

Photos on the Internet will allow you to get acquainted with the finishing and composite. Each stove has different technical characteristics, depending on the country of manufacture. It has a good reputation, which produces panels, the reviews about it are only positive, and there is a large selection, you can even buy matte material. Finally, you can watch a video tutorial on how to assemble a plastic window assembly:

Frequently asked questions |

What is PVC?

Polyvinyl chloride (PVC) is a material belonging to the group of thermoplastics. Thermoplastics are plastics that, once molded into a product, remain recyclable. Pure PVC consists of 43% of a petrochemical product - ethylene and 57% of chlorine, which in turn is obtained from table salt. PVC is obtained in the form of a powder mass. To create a window profile, stabilizers, modifiers, pigments that color the profile in a given color, and auxiliary additives are added to powdered PVC. Thanks to these components, such properties of PVC windows as light resistance, resistance to harmful atmospheric influences, the color and shade required by the customer, the specified surface quality, weldability, etc. are obtained.

Which profile to choose for windows?

The choice of profile depends on the size and configuration of the windows you want to order. For example, if the window is blind or has a small sash, then you can make a window from any lightweight window profile with a wall thickness of 2.5 mm or 3-chamber or 5-chamber PVC profile. And even if you insert any double-glazed window into it, the plastic window will successfully fulfill its duties for a very long time! But if the window is large, with a sash width greater than 750mm and a height, for example, greater than 1500mm, and even somewhere on a floor exposed to wind loads, then you should be wary of ordering and buying a plastic window made of a lightweight profile! The likelihood that a thin-walled PVC profile in such a plastic window will turn with a “screw” or bend in an arc over time increases sharply. This primarily applies to balcony and terrace doors! The gradations of window prices are as follows: economy class, mid-price category and premium class. The cost of PVC windows also depends on their configuration: sills and window sills, type of double-glazed window, number of double-glazed windows and window profiles, type and brand of fittings, frame lamination, glass tinting, availability of energy-saving glass. We can choose the option that suits you both in price and quality.

What are windows made of?

1. Frame - a structure that is located along the entire contour of the window system; it is fixed motionless in the window opening using anchor plates or dowels. The frame supports the entire window structure. 2. Impost - serves to divide the window frame into contours in which a sash, etc. can be made. 3. A sash is an opening element of a window that is equipped with fittings to perform its functions - opening, different ventilation modes. 4. Beading - a longitudinal element used to hold a double-glazed window or sandwich panel in the frame. 5. Sash impost (binding) - serves to divide the sash into separate closed contours.

6. Double-glazed window - the transparent part of the window, an airtight glass structure assembled into one package. 7. Sandwich plate is an opaque part of the window, which is superior in thermal insulation to double-glazed windows and is installed in the lower part of the doors.

Are PVC windows hazardous to health?

Very important are the issues of safety of PVC windows for the health and well-being of people and the issue of environmental friendliness of windows in the global sense of environmental protection. The main substance for the manufacture of PVC is sodium chloride (table salt). In the production of PVC, oil and gas are used - also natural raw materials, from which ethylene gas is obtained by cracking, distillation and separation of different phases. As a result, as a result of several chemical reactions, PVC is formed - a stable chemical polymer compound that is not toxic to human health. The production of PVC is a closed process and proceeds in accordance with all standards and in compliance with the necessary safety and labor protection measures. One of the uses of PVC is the manufacture of vessels for storing donor blood and blood plasma.

5.How many glasses are there in single-chamber and double-glazed windows?

A single-chamber double-glazed window structurally consists of two glasses fastened together by a spacer frame, and therefore there is one chamber between them. In a two-chamber double-glazed window there are three glasses separated by spacer frames, between which there are, respectively, two chambers.

What is better to put at the bottom of the door to the balcony: sandwich or glass?

Basically, a plastic sandwich panel is placed in the lower part of the metal-plastic balcony door. This is done for practical and safety reasons, so as not to break the glass, especially if there are small children in the house. Of course, glass looks more beautiful, but in terms of thermal insulation, a 24 mm sandwich panel is slightly warmer than a single-chamber double-glazed window (4-16-4). Another advantage of the sandwich panel is that the weight of the door is less than with a double-glazed window, so the load on the bottom hinge will be less.

How to avoid fogging of PVC windows?

Modern plastic windows in Kyiv are used in housing with the expectation of creating comfort without “increased stress on the thermoregulation mechanisms.” According to GOST, during the heating period of the year in living rooms, the optimal temperature is 20-22 degrees, and the optimal humidity is 30-45%. If the air humidity in the room is more than 45% and the temperature is +22 degrees. Without additional ventilation, condensation will settle on the window. To avoid the formation of condensation, you should ventilate the room more often (at least once a day), use micro-slot ventilation or step-by-step opening provided by the fittings.

What is better to install - a double-glazed window or an energy-saving one? What are the differences?

Even a single-chamber double-glazed window with 4-16-4i energy-saving glass retains 25% more heat compared to a double-glazed window 4-10-4-10-4 with conventional glass. You also need to remember that a double-chamber double-glazed window is one and a half times heavier, and this will create a greater load on the double-glazed window fittings, which means that over time, a sash with a double-chamber double-glazed window, all other things being equal, will sag faster and will not close tightly. A window that closes poorly and is not tightly closed means a lot of heat loss. But also a double-glazed window with different distances between the glasses is the best sound insulation, so by installing a double-glazed window with energy-saving glass you can achieve the best sound insulation and thermal insulation.

Finishing process

Before you begin directly fixing the sandwich panels, you need to prepare the sheathing for them. In some cases, it is possible to install sandwich panels directly on the wall, but this is only possible if it is perfectly level and can support the weight of one or more panels. This applies to a greater extent to loggias, so you will have to construct a sheathing for the balcony. The latter can be made from a special metal profile, which is also used when installing siding on building facades. The use of wooden blocks is also suitable. The size of the elements for installation is indicated by the manufacturer himself.

On the balcony it is easier to create a metal frame that will withstand wind and other loads well. It is necessary to place vertical elements in increments of up to 50 cm. If other parameters are required for a particular type of sandwich panels, the manufacturer indicates them in the product data sheet. The metal frame on the balcony is fixed to the main slab, as well as to the one that acts as a roof, if present. Additionally, the elements are fixed to the load-bearing walls of the building to give them the required rigidity. When choosing this installation option, you can enlarge the balcony along the window sill. When fixing each slats under the sandwich panels, it is necessary to constantly monitor the vertical level.

The first step before installation is to install a starting strip, which can be the edge of the slab itself or a specially installed metal element. The sandwich panel is inspected for damage. After this, the protective film, which is located on the inside, is removed from it. In accordance with the manufacturer's instructions, holes are drilled through which the sandwich panels will be attached to the sheathing. When everything is ready, a sealing tape is glued around the perimeter of the sandwich panel, which will ensure a better fit to the metal sheathing. The panel is placed closely against the sheathing and fixed to the racks with self-tapping screws. The next element is installed in the locking part of the previous one until complete joining, after which the sandwich panels are fixed. The method of internal cladding with sandwich panels is shown in the video below.

Features of plasterboard slopes for window openings

Many people prefer plasterboard slopes. The method is based on gluing or screwing sheets of material of the required size to the side niches, followed by priming, puttying and painting. This option attracts with its simple and quick installation, which even a novice master can handle. The material is also characterized by an acceptable cost.

Installation of plasterboard slopes - a quick and easy finishing option

Using strips of plasterboard, you can create perfectly smooth sides of the window. The space between the drywall and the wall is filled with mounting foam, which serves as a seal for the window. This surface is suitable for numerous paintings.

However, this method is not without drawbacks. The material is susceptible to moisture, so it can be used exclusively for finishing internal slopes. Condensation forms on the surface, which will soon lead to swelling and destruction of the structure. Such defects can be eliminated by completely redoing the slopes.

Drywall, like plaster slopes, is not able to interact firmly with the plastic frame. This contributes to the formation of cracks at the joints. The material is quite fragile, which does not exclude the possibility of it being pressed through and bending during installation.

After installing drywall, you will need to prime, putty and paint the surface to give it a finished appearance, which is not required when using sandwich panels for window slopes. It will take a few more days to complete all the work.

The installation of such slopes is carried out in two ways: frameless and framed.

Helpful advice! To avoid finishing, you can use laminated drywall, which is mounted using special corners covering the ends of the sheet.

Sequence of installation of plasterboard slopes

Installation of plasterboard slopes can be carried out in two ways: framed and frameless. With the frame installation method, at the initial stage you should screw the starting profile using self-tapping screws, as in the case of using sandwich panels for window slopes. It is fixed on the line of joining of the plasterboard sheet and the window frame in the groove. The original frame is ready, after which you can begin installation.

A feature of plasterboard slopes is that the strips of material do not fit tightly to the window frame. A gap is formed, which negatively affects the thermal insulation properties of the opening. This space should be filled with mounting foam or mineral wool.

Important! Filling the gap with polyurethane foam is done very carefully, since the material increases in volume, which can lead to damage to the drywall.

Fastening drywall can be done using liquid nails

At the junction of plasterboard panels, perforated corners are installed. The finished surface is primed and puttied. After the composition has completely dried, the coating is rubbed with sandpaper to obtain a smooth base, which can be painted in any color with water-based paint.

The frameless method involves installing plasterboard panels to the window opening using liquid nails or other suitable composition. The surface is first thoroughly cleaned and primed. Each slope element with applied glue is pressed tightly against the niche. To fix the elements, you can either use a wooden beam, which will give the structure evenness, or install spacers to the window sill. After complete drying, the slopes are puttied and then painted.

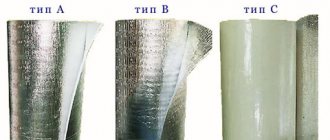

Types of sandwich panels

Expanded polystyrene, polystyrene foam, and mineral wool can be used as insulation in sandwich panels for balconies. Mineral wool has excellent fire-fighting properties and absorbs moisture well. Expanded polystyrene is resistant to moisture and water and has excellent thermal insulation characteristics. Polystyrene foam crumbles and retains heat worse than polystyrene foam.

Plastic based on polyvinyl chloride, chipboard, OSB, magnesite board, metal can be used as the outer layer. The metal coating is the most durable, resistant to mechanical loads, but is significantly heavier in weight than plastic.

Sandwich material is used for finishing, insulating walls and for installing warm roofing.

Panels are produced in widths of 1000 and 1200 mm, thicknesses from 10 to 25 mm, and lengths up to 12 meters. Long panels are inconvenient to install and transport, but this disadvantage is compensated for by the fact that fewer joints will prevent moisture from penetrating into the structure.

Features of slopes for gypsum fiber windows

Gypsum fiber is often used to finish slopes. The technology for installing the material is similar to the principle of finishing niches with plasterboard. However, gypsum fiber has distinctive advantages over its analogue. The material has good strength and rigidity. There is a variety of products that are characterized by excellent moisture-proof properties. This feature makes it possible to use the material for finishing the external slopes of windows.

Slopes made of gypsum fiber are characterized by ease of installation and high speed of work. The material has excellent technical and performance qualities. It withstands mechanical stress and adverse environmental factors. Due to the presence of fibers in the structure of the material, it is an additional insulation for the window, which increases its thermal insulation properties, which makes it similar to PVC sandwich panels for slopes.

Drywall is characterized by high strength and rigidity

Due to the good strength and rigidity of the material, it is possible to obtain an ideal design geometry that will have a long period of operation. Such slopes are characterized by maintainability. The damaged area can be puttied and tinted.

The disadvantages of the material include its higher cost compared to conventional drywall. However, it is lower than the price of sandwich panels for slopes. Cutting such material is also much more difficult. The surface needs finishing, which is carried out by priming, puttying and painting.

Helpful advice! When painting gypsum fiber slopes with high-quality latex paint, it is possible to obtain a durable, moisture-resistant surface that can be washed.

Video

You can watch video instructions on how to properly cover a loggia with sandwich panels.

Proper insulation of a balcony or loggia expands the interior space of the apartment, adding several square meters. Creating comfortable conditions on the balcony depends on the thickness of the insulation layer and the quality of the finishing material.

Traditionally, balconies and loggias are insulated with mineral wool roll materials, followed by cladding with clapboard or plastic boards. This option is quite convenient, but requires a lot of time. It’s easier and faster to install a ready-made slab, which serves both as insulation and as a facing panel.

A balcony made of sandwich panels does not require additional insulation. It does not need to be additionally lined with clapboard or other finishing material. You can always choose the right shade from a variety of colors. The time spent on insulation, repairs and finishing of the premises is half as much as with the traditional approach.

To get a warm, cozy balcony, you need to understand the types of sandwich panels, as well as how to install them.

Preparatory work

Before thinking about how to make slopes from sandwich panels, it is advisable to prepare the tools necessary for the job. For this event you will need:

- Miter box – for cutting material at the required angle. This device significantly reduces work time and also allows you to create a more beautiful coating.

- Set of spatulas. Although the process itself will only require a medium and small option.

- Metal hacksaw or electric jigsaw.

- Screwdriver or set of screwdrivers.

- Level and roulette.

- A special construction gun that is used to apply “liquid nails”.

- Stapler. A more professional option is needed, which belongs to the middle price category. Such a tool will be useful in the household, so the cost of purchasing it will be justified.

Tools required for installing slopes made of sandwich panels

To install slopes made of sandwich panels, a number of preparatory measures are required:

- All areas that will not be involved in installation are covered with plastic film and cardboard. This will prevent damage to the window sill and the window itself.

- The slope areas are well inspected. It is necessary to make sure that the surface is completely dry and there are no traces of mold.

- Excess polyurethane foam is trimmed off. A simple utility knife is perfect for this.

- The condition of the base is immediately checked. If necessary, apply a layer of putty. The presence of crumbling areas indicates that the area needs to be completely replaced.

- To prevent the appearance of fungus, use a primer with an antiseptic.

- The installation seams are additionally sealed.

Preparatory work before installing slopes

Thus, you should get a clean surface, without any defects. It must be taken into account that after applying the primer, the work area must dry thoroughly.

Balcony finishing with sandwich panels

To decorate a balcony with sandwich panels, a straight, flat surface is required. If the fencing of a loggia or balcony has no flaws and is located strictly vertically, sandwiches are attached without preliminary preparation. In other cases, installation will require the construction of a frame made of metal profiles or wooden blocks.

Before starting work, purchase materials and prepare tools.

Preparation of tools and materials

To cover a balcony with sandwich slabs, you will need the following materials:

- sandwiches. When choosing a specific model, the dimensions of a single element are taken into account. If it is possible to order slabs to a specific size, it is better to use it. In this case, tedious adjustment of the material on site can be avoided;

- wooden block, cross-section 40x40 mm for assembling the frame;

- a metal corner with a 40 mm shelf, if the frame is assembled from metal;

- self-tapping screws with a blade length exceeding the thickness of the installed plates by 10 mm;

- anchors for attaching the frame to the walls of the facade or loggia;

- mounting foam to eliminate gaps between the base and the frame;

- silicone sealant to eliminate gaps between individual plates;

- plastic strips for masking the joints of individual plates;

- corner plastic strips for masking corner joints.

Additional materials may be required to install panels from different manufacturers. You can find a more complete list in the instructions for a specific product.

During the work you will need the following tools:

- building level;

- plumb line;

- yardstick;

- electric drill;

- screwdriver;

- perforator;

- angle grinder with cutting wheels;

- hammer;

- welding machine, if the frame is assembled from a metal corner.

Step-by-step installation

When starting to work with sandwich slabs, carefully study the manufacturer’s recommendations for their installation. Each model is manufactured using certain technologies, so it is better to follow the instructions. It will not be possible to install sandwiches outside the balcony with your own hands, without the involvement of installers. Work at heights is carried out only by trained finishers.

To assemble a frame for fastening slabs on a balcony, use:

- wooden block, section 40x40 mm;

- metal corner or profile;

- polyvinyl chloride strips.

The metal frame is welded. Polyvinyl chloride strips and wooden blocks are fastened together with self-tapping screws. When assembling the frame on the balcony, the position of each plank is checked by level and plumb. The distance between adjacent planks should not exceed 500 mm. Wooden and metal surfaces are treated with agents that protect against corrosion and rotting.

Instructions for installing sandwiches on the balcony

Preparing the base for fastening the slabs. If the surface does not have vertical deviations, no preparation is required. If the surface is not level, install a frame. The installation step of the stiffeners must take into account the length and width of the slab so that the joining of individual elements is supported.

The lower sandwiches are installed along the entire length of the balcony, secured with metal screws. A hole is first prepared in the slab using an electric drill. The hole is drilled with a cone drill so that the lock washer is slightly recessed into the base. The screws are tightened with a screwdriver until the washer is firmly fixed. Excessive force can damage the protective lining, so when tightening the self-tapping screw, you need to control the force. Before installing the sandwich, a sealant is glued to the base or frame, and the protective film is removed from the plate itself.

Balcony window prices

In order for the loggia to have a complete look, in addition to balcony glazing, it is important to choose windows for the room adjacent to the landing. Our calculator will help you choose the appropriate profile, double-glazed windows, fittings, accessories and additional services. The parameters selected in the configurator can be automatically generated into an application. After sending, a manager from the nearest company office will calculate the price and contact you.

Installing a new unit

When replacing an old double-glazed window with a new one, the manipulations are performed in the reverse order

When dismantling, it is important to remember the location of the plastic spacers that create a deformation gap for the tight fit of the glass and frame

Having installed and adjusted the gaskets, you can immediately begin installing the glazing beads. The tool that helps the process is a rubber hammer with a rounded head. The rubber glides gently over the glass, maintaining its integrity. Hammer blows should be of medium strength.

Uniform advancement around the perimeter ensures the correct positioning of the glass block in the door frame slot. Having finished installing the double-glazed window into the balcony door, you need to check how well the block “fits” into the seat, ensuring sufficient tightness. The inspection will help prevent moisture penetration and condensation collection.

How to insert a window into a sandwich panel

The location of window openings is determined at the design stage of the building. When erecting walls, a fastening frame is installed in parallel.

Before cutting out an additional window opening in an already finished building, you need to study in detail:

- Dimensions of the finished window block.

- The side the window opens to.

- Ventilation properties.

Hasty decision making is unacceptable. Once the work is completed, the building owner may be in for an unpleasant surprise. For example, the window sashes will not open completely or there will be drafts throughout the room, even when opened for ventilation.

Installation of a window block in a pre-prepared frame:

- The window unit is placed in a slot limited by the frame guides.

- Using wedges and a level, it is leveled to the correct position.

- Attached to the frame with self-tapping screws or similar.

- The seams and gaps between the block and the wall are filled with sealed material.

Comparison of sandwich panels and double-glazed windows: which is better

The design of a balcony or loggia is often accompanied by the joint installation of metal-plastic glazing and plastic sandwich panels. The latter are often used for covering blind sections, which can be located at the bottom of the balcony door frame that reaches the floor, or for finishing side sections. This is done to limit light transmission in specific areas. In addition, due to their good strength properties, sandwich panels are considered the best option in comparison with double-glazed windows in terms of safety.

Installing sandwich panels instead of double-glazed windows allows you to make the side sections of a balcony or loggia blank, which is necessary for installing cabinets or other items that should not be visible from the outside. This design can subsequently be used as a ventilation outlet, since a number of holes can be made in it.

Sandwich panels, unlike double-glazed windows, are resistant to moisture, ultraviolet radiation and mechanical stress

However, using panels instead of double-glazed windows has other advantages. The material is resistant to various negative influences. It is impervious to ultraviolet radiation, moisture, chemicals, and tolerates mechanical and shock loads. The panels are strong, reliable and durable. They do not require special care, which cannot be said about traditional glazing. You can also choose different colors of the material, which is clearly shown in the photo of sandwich panels.

Since the plastic sandwich panel is represented by a multilayer material, inside of which there is a layer of insulation, such cladding is characterized by good heat-insulating and sound-absorbing properties.

Installation of plastic slopes

In terms of installation, installation of slopes for PVC windows is the simplest. In addition, plastic, unlike other materials, can tolerate deformation to a critical point. If a wooden slope cannot withstand seasonal temperature changes and becomes deformed without varnish protection, then plastic calmly tolerates both moisture and temperature changes. From a decorative point of view, slopes can resemble the texture of finishing options such as metal and wood. This is achieved by lamination with a special film that imitates these materials. Find out about a new method of installing slopes, which will be very interesting.

– Type of premises (residential, commercial, special purpose). So, in a room subject to large temperature changes and high humidity, drywall should not be installed.1. The main disadvantage of the material is that if the surface of the panel is damaged, the defect (pothole, deep scratch) cannot be quietly eliminated. As a result, the entire panel will have to be replaced.

Another important advantage is their “strength”. What do I mean here? Imagine that your door is open. The wind picked up on the street, it suddenly opened to its fullest extent, and it (sometimes directly with its handle) flies straight into the corner of the slope.

If the slopes are plaster or drywall, you will get a chip or dent. In the case of sandwiches, nothing will happen, the sash will simply spring back. Until recently I hated them. They look too creepy and cheap.

But over time, my opinion changed. Look, for starters, most modern windows are now plastic. At the same time, they do not seem like a collective farm to anyone. What a window, what slopes, everything is logical here. Finishing the slopes gives the window completeness.

Many people prefer classic finishing with plaster and drywall. Today, slopes are often made using plastic panels. To determine which window slopes are better, you need to take into account a number of features.

The most advanced type is sandwich panels. This is a more expensive material, but is well worth the price. The sandwich panel consists of 2 sheets of hard plastic, providing a decent and aesthetic appearance. The material has a hard surface and good impact resistance.

Thermal insulation layer

Materials that play the role of insulation:

- Mineral wool. The most common insulation used today. Fibrous in structure, it is based on silicate melts and all sorts of combinations of various slags and rocks. Advantages: good sound and thermal insulation. In addition, mineral wool is not a highly flammable substance, and withstands both temperature changes and the negative effects of most chemicals.

- PPU (polyurethane foam). The distinctive features are light weight combined with a large margin of safety. Polyurethane foam tolerates a high percentage of humidity in the surrounding space, is not susceptible to rotting, and maintains high levels of thermal and waterproofing. Polyurethane foam is not classified as flammable.

- Expanded polystyrene. It is distinguished by its cellular structure and high environmental safety indicators.

- Fiberglass. The composition contains thin glass threads. Decorative wall panels containing this material have a good ability to absorb sound. Fiberglass is not flammable, does not emit any chemicals harmful to the human body into the surrounding atmosphere, and tolerates the negative effects of various chemical compounds well. It is easy to transport and install.

What requirements must the slope material meet?

Regardless of the technology for protective and decorative finishing of a window opening, finished slopes must meet certain requirements. The design must withstand various mechanical impacts without loss of operational and aesthetic characteristics. It is necessary that the slopes are moisture resistant. This especially applies to outdoor structures. The material must be characterized by wear resistance, immunity to ultraviolet rays and high humidity, and temperature changes.

Important! To waterproof the frame, a PVC window ebb is attached to its outer side.

Slopes must be moisture-resistant, wear-resistant, and have low thermal conductivity

The protective structure of the window should not deform over time. It must be distinguished by a long period of operation without loss of original properties. Due to the fact that the slope panel closes the installation gap, this is the main source of heat loss. It is necessary that the material has low thermal conductivity, which will provide a good level of heat and sound insulation in the room.

The chosen finish for the slopes should be aesthetically appealing. High-quality cladding is characterized by a neat appearance. It is necessary that the finish is in harmony with the window profile and fits into the interior design of the room. Maco window fittings have proven themselves to be the best in this regard.

Balcony doors

Types of balcony doors:

- classic option. In the upper part, a double-glazed window is inserted into the frame, at the bottom the door is opaque, the filling is made of a sandwich panel. This is a warm, reliable traditional solution;

- with transparent bottom. A variation on the theme of the classic model, but instead of a sandwich panel a double-glazed window is also installed, the room becomes better illuminated with natural light;

- all-transparent (solid) glazing without partitions. This type of door uses a full-length double-glazed window without partitions. The opening visually expands, allowing maximum daylight to enter the room;

- “French balcony” option. The window and door are made to the floor. This is a very interesting, stylish, ultra-modern option; even more light enters the room, making the room visually larger.

Design Features

PVC profile is a convenient, universal material for a door to a loggia or balcony. Such doors and windows are not afraid of moisture and temperature differences.

At the same time, the structures are very light, which is one of the main advantages. There is no significant load on the frame and hinges, so over time the door will not sag or warp.

PVC doors are made from window profiles. A 60 or 70 mm profile can be used.

The design is also identical to PVC windows, and the advantages are the same:

- excellent heat conservation due to the use of a multi-chamber metal-plastic profile, double-glazed windows and double-circuit seals. High sound insulation of the room;

- resistance to external influences, changing weather conditions, preservation of the original appearance throughout the entire period of operation;

- environmental friendliness;

- durability, trouble-free use can last for decades;

- ease of care and maintenance.

In the classic version, the balcony door is glazed in the upper part, and the lower part consists of a sandwich panel. But at the request of the customer, other options are possible, with glazing at the bottom. Double-glazed windows are single- or double-chamber.

Accessories

Of course, a balcony door weighs more than a window, so it is very important to use high-quality fittings. Our company installs only the most reliable handles and other elements on its products

The use of an additional middle pressure along the height of the entire door makes it possible to increase the tightness and prevent the penetration of cold air or moisture inside.

To avoid heat loss when opening the door to exit to the balcony, there is a balcony latch and a special porch.

If you decide to install a metal-plastic balcony door, you will rejoice at the step you have taken many times over. The design is very easy to maintain and lasts a very long time. It provides reliable protection of your home from cold, dust and external noise. The color of the profile does not change even in direct sunlight.

Don’t think that a PVC balcony door can only be white.

Modern designs can be laminated using a film of almost any shade or with imitation of natural materials. You can also buy a door painted in the paste - such models are very resistant to mechanical damage (scratches) and do not require lamination.

You can install balcony doors made from reliable profiles from well-known brands: Rehau, KBE, Brusbox. Choose high quality!

Algorithm for installing a balcony block in the video:

Replacement of glass unit

Glass is not inferior in compressive and tensile strength to cast iron, but it does not withstand impact loads well, so replacing cracked glass in a double-glazed window is the only thing that can be suggested when it is broken or cracked. Even if a small crack has formed in the very corner of the glass, which, moreover, is not in sight, then in this case you still need to take measures to replace it, because a depressurized double-glazed window becomes a serious bridge of cold. The same is true if the glass unit is depressurized, although the glass remains intact and there are no cracks on its surface.

When else is it necessary to replace the glass unit in a plastic window?

Mechanical damage or depressurization is not the only reason to replace glass. The contractor handing over a completed construction project to the customer usually does not pay attention to the energy efficiency of window structures and installs what is inexpensive, leaving residents with the need to carry out all the improvements.

The 32okna company’s craftsmen not only repair conventional PVC windows, but also install innovative DS double-glazed windows with improved thermal characteristics. Their advantages over conventional double-glazed windows are:

- The presence of a reflective layer on the inner glass that prevents thermal energy from escaping from the room;

- Patented thermal break technology that protects the edges of the glass from freezing;

- Better resistance to condensation in high humidity conditions;

- Greater light transmission coefficient with a high level of sun protection;

- Four standard color variations. The color of the glass is noticeable only from the outside; when viewed from the room, the glass is completely colorless;

- The minimum number of joints in a frame with a low coefficient of thermal expansion.

Replacing a standard glass unit with DS “thermal units” is very important in the cold climate of the Russian north, and to install them you do not need to wait until the old glass breaks. We are talking about saving on heating, so the price of such an upgrade will definitely pay off.

Services for replacing glass in double-glazed windows in St. Petersburg

Our specialists not only replace broken glass units, but also replace standard glass with energy-efficient DS thermal units - one of the most advanced products of recent times. Over the entire operational period, DS heating packages allow you to save up to 1 million rubles on heating, which is tens of times more than their cost.

Revolutionary innovation in the production of double-glazed windows

They retain heat in a house or apartment 2 times better. Protects against condensation formation several times more effectively. They allow 70% of natural light into the apartment, which is 10% more than usual. They significantly keep the rooms cool in the summer.

And the most important thing is that you don’t need to replace your entire windows, we will only replace the glass, after which the room will become much warmer!

Double-glazed window DS is the latest energy-saving window system. The new product has a number of advantages over outdated technologies.

Advantages of STiS DS double-glazed windows

When creating DS heat packages, the developers pursued the goal of creating human comfort, protecting them from harmful influences and reducing energy consumption. The result has a number of advantages over standard double-glazed windows that were installed previously.

Why do you need to replace the glass in a double glazing unit:

- improves the appearance of the window;

- protects health from exposure to ultraviolet radiation;

- will increase the light transmission capacity of the window;

- will get rid of harmful formaldehyde fumes;

- will save money and pay for the replacement of double-glazed glass.

- And if condensation formed on glass previously installed in a PVC profile, then from 2022 this drawback has become history. The benefits are so great that they are worthy of more detailed consideration.

No more condensation

An experiment was conducted to increase the air humidity in an apartment equipped with STiS DS heat packages from 46% to 72% at negative ambient temperatures. The same thing was done in a room with ordinary plastic double-glazed windows.

Humidity 46% Humidity 67% Humidity 72%

In the latter case, evaporation formed at a humidity of 67%, and when it reached 72%, the moisture covered the entire surface of the glass with condensation. Under the same conditions, DS glass units remained transparent, and only a critical humidity of 76% caused fogging to appear in the corners.

Replacing a double-glazed window is a guarantee of energy saving

The next experiment consisted of warming up the rooms, followed by spot temperature measurements of a standard double-glazed window and new generation glass using a thermal imager. The result showed that in the first case the temperature was 1.50C lower than that of the STiS DS thermal package.

DS vs Regular Temperature difference at bead DS vs Regular

Taking into account the glazing area, the result is a twofold reduction in heat loss in the room compared to the period before replacing the glass in a plastic window with STiS DS glass. This leads to a reduction in energy consumption in winter, and as a result, savings on heating costs.

Money is also saved in the summer. STiS DS double-glazed windows keep the room cool 2 times more effectively. This means that less electricity is spent on cooling (operating the air conditioner). Thus, the cost of replacing glass in a plastic window is completely covered, and people’s reviews confirm this.

Double-glazed windows STiS DS and human health

The test results and reviews from those who have already replaced the glass in a plastic window prove that this measure has a beneficial effect on people’s health. Three harmful exposure factors are excluded:

- The amount of ultraviolet solar radiation is reduced by 4 times (by 75%), which has a beneficial effect on the skin and vision.

- The transparency of DS glass allows 10% more light to enter the room. Visual functions improve and fatigue decreases. Again, energy is saved in the morning and evening hours.

- Reducing the amount of solar energy penetrating into the room eliminates the release of formaldehyde from interior items and finishing materials. There are a number of disorders and diseases associated with poisoning by harmful substances.

Over the entire long period of operation, STiS DS double-glazed windows can save up to 1 million. And by ordering a service from our company, you will receive an individual offer with optimal conditions.

replacing a sandwich with a double-glazed window

Replacing sandwich panels with double-glazed windows in an apartment in St. Petersburg

Replacing a sandwich with glass in a door Replacing a sandwich with glass St. Petersburg Replacing a sandwich

Types of balcony doors

A modern balcony door is connected into one block with a window. In this design, there is a transparent window in the upper part, and an opaque one in the lower part. This is a classic option for both wooden and PVC structures.

There are cases when the threshold is not used - for example, when the premises are undergoing renovation or construction work is carried out, which could be difficult due to the installation of a threshold.

Now you can also install a stylish, not quite ordinary option - a balcony door with a transparent part at the bottom. A very interesting, sophisticated version of a plastic door. Such a door will favorably emphasize the decoration of a balcony or loggia; it looks lighter, although in fact its weight is greater due to the double-glazed windows.

With a wide sash, manufacturers install reinforced hinges. To lighten the design - and therefore reduce the load on the fittings - in such structures it is recommended to install single-chamber double-glazed windows with two sheets of glass and one air chamber between them.

Some balcony doors are completely filled with glass. Visually, they seem almost weightless, as if there is nothing in the opening. This option is preferred by owners with a modern new renovation; this solution allows you to give the room individuality and emphasize its style.

Also, a similar solution is recommended in cases where access to the balcony is equipped from a small room. The transparent filling provides a significant visual expansion of the space, solid glass does not create obstacles for viewing, and the balcony looks like a logical extension of a small room.

In “Stalin” houses, balcony blocks are a two-leaf structure. In such apartments, the ceilings are higher than usual, and the balcony door is correspondingly higher. This point must be taken into account as a pricing factor when ordering glazing, since it has a significant impact on the final cost of the structure.

Door leaves can be opening on splint doors or with one fixed half. You can install a classic door with an opaque sandwich at the bottom or with an all-glass filling.

In the upper part of the balcony door in an apartment in a Stalinist building, the frame can be made as a blind part or in the form of an opening transom. To make the design more convenient to use, during the production process a remote opening mechanism is installed on it, which allows you to easily open the sash in ventilation mode without using a stepladder or similar devices.

Technology for installing a plastic window and balcony door in the video:

We are not afraid of frost...

- Shop

- Specialists

- Magazine

- Forum

- All sections

►Redevelopment

- Catalog of houses

Where to start repairs

►

Design and decor

- Apartment

- Bedroom

- Kitchen

- Dining room

- Living room

- Bathroom, toilet

- Hallway

- Children's

- Attic

- Small rooms

- Workplace

- Wardrobe

- Library

- Decoration

- Furniture

- Accessories

- Vacation home

- Landscape

- Storage systems

- Corridor

- Cleaning

►

Construction and repair

- Foundation

- Roof

- Walls

www.ivd.ru

Types of sandwich panels

Expanded polystyrene, polystyrene foam, and mineral wool can be used as insulation in sandwich panels for balconies. Mineral wool has excellent fire-fighting properties and absorbs moisture well. Expanded polystyrene is resistant to moisture and water and has excellent thermal insulation characteristics. Polystyrene foam crumbles and retains heat worse than polystyrene foam.

Plastic based on polyvinyl chloride, chipboard, OSB, magnesite board, metal can be used as the outer layer. The metal coating is the most durable, resistant to mechanical loads, but is significantly heavier in weight than plastic.

Sandwich material is used for finishing, insulating walls and for installing warm roofing.

Panels are produced in widths of 1000 and 1200 mm, thicknesses from 10 to 25 mm, and lengths up to 12 meters. Long panels are inconvenient to install and transport, but this disadvantage is compensated for by the fact that fewer joints will prevent moisture from penetrating into the structure.

Operational Features

Sandwich panels

Despite their lightness and rich color range, window panels are classified:

- according to the level of resistance to ultraviolet radiation;

- according to the degree of moisture absorption;

- resistance to abrasive external substances;

- according to the level of resistance to cyclic loads;

- according to the operating temperature range.

How to choose material

Before you decorate your balcony interior with sandwich panels, you need to know some rules for choosing the material:

- Some manufacturers who do not strive for the quality of materials add a lot of chalk to the composition, after which the plastic panels begin to bend poorly, they are almost inflexible, due to which the panel immediately bursts.

- When choosing, it is better to press the panel with your finger; if a dent appears immediately, but does not disappear from the material, then the plastic is thin and will not be suitable for balconies and loggias. If the material is elastic and hard, then the panels can be purchased and have a long service life.

- The structure of PVC panels is cellular, so there are ribs inside. The relief material must be chosen correctly, the panel material is pressed from the end, if the edge breaks or is pressed through strongly, then it is better to put the panel aside - this is a defect. A high-quality product will be able to withstand pressure; all that should happen to the edge is deformation.

Types of plastic panels

- The price is affected not only by the quality of the plastic, but also by the size, namely the width and length of the slats. In some cases, thin exterior panels may cost more than thick ones. It all depends on the size of the slab.

- When choosing a sandwich panel, you need to look at its surface from different angles. Such material should not allow stiffening ribs to pass through under the light, if they are visible, the product is of poor quality or is defective in the hands. In this case, the manufacturer simply saves on the composition.

- Often white plastic is sold, but it may have a gray tint, in which case the material is made from recycled materials.

When purchasing a large volume of plastic, you need to carefully look at the batch numbers, they must be the same, otherwise at the end of the work different shades of plating are possible.

Below we will talk a little about the disadvantages of drywall and the advantages of plastic

In fairness, I would immediately like to say that plasterboard not only has its disadvantages, but also has its advantages, however, when assessing the totality of the pros and cons, it is significantly inferior to PVC sandwich panels.

Drywall is also called gypsum board; it consists of two sheets of cardboard with gypsum placed between them.

Disadvantages of drywall for window slopes

- Difficult installation. Drywall is more difficult to install than PVC slopes. Here you need to measure everything with great precision, and any minor flaw will have to be carefully hidden with paint, which is difficult to do in the corners. It is easier with sandwich panels, since their installation uses special ready-made profiles for joining sheets, which covers the joint and makes it beautiful.

- Dirty installation. You need to understand that when cardboard and plaster are sawed, everything around is covered with this white dust. Naturally, this installation cannot be called clean, since after installing plasterboard slopes, thorough cleaning is required.

- Not resistant to moisture. This is probably the biggest drawback of drywall. And although manufacturers try to make it moisture-resistant, cardboard and gypsum will never become neutral with respect to water; they are still susceptible to moisture absorption and swelling. Therefore, in rooms where there is moisture and temperature changes, it is strictly forbidden to use slopes for plasterboard windows. And even in simple apartments there are great risks of damaging plasterboard slopes, because everywhere people fry, steam, wash diapers, and this steam can penetrate inside the slopes. When repairing windows in such premises, we strongly recommend that owners replace the slopes with PVC. We visually show the owners any defects that appear and the owners of the premises are convinced that we are right.

- Tendency to fungi and mold. As a result, due to poor resistance to moisture, drywall is susceptible to fungi and mold. After all, this material absorbs moisture and becomes a breeding ground for pathogenic bacteria. Naturally, both the appearance and the healthy atmosphere in the room suffer from this.

- Susceptible to small dents. The structure of cardboard is such that it is easier for traces of small impacts and scratches to remain on it. If the PVC panel springs from a small impact and there is no mark left on its surface, then the drywall will most likely succumb to the pressure and its surface will leave a mark of the impact.

- Requires care. Drywall must be painted and even putty in order for it to have a positive appearance. Moreover, this procedure must be repeated periodically, which naturally takes time and brings material costs.

- The appearance is not ideal. Drywall will never become as smooth and even as plastic, much less give a glossy effect.

Advantages and disadvantages of sandwich panels

- Firstly, they cope with two functions at once: aesthetic finishing and thermal insulation.

- Sheathing sheets are usually large, so the joints are not noticeable.

- The cladding takes up a minimum of the internal space of the balcony, because There is usually no need to install additional structures to the walls.

- They provide maximum protection from noise, dust and cold with their low weight.

- Thanks to their environmentally friendly composition, balcony sandwich panels do not smell or emit harmful substances.

- Simple and convenient to install and dismantle.

- Contaminants are easily removed from them.

- No façade finishing is required.

With all the above advantages of sandwich panels, it is necessary to note some minor disadvantages:

- Due to their lightness, they cannot cope with heavy loads, so you should not attach too heavy structures to such panels.

- Freezing is possible in places where the joints are poorly finished.