Apartment owners are increasingly choosing panoramic glazing of a balcony or loggia. It looks impressive both from the facade of the building and from the inside. Floor-to-ceiling windows allow you to admire the beautiful landscape of the courtyard or overlook the open spaces if the apartment is on the upper floors of a high-rise building. They allow more light into the interior, especially if the loggia is combined with a room. This solution also has a downside - large heat losses. Therefore, it is important to know how to insulate a panoramic balcony in order to enjoy a comfortable temperature in this room all year round.

How to insulate a balcony or loggia with panoramic glazing

It will be difficult to insulate a panoramic balcony if the glass part is mounted without a balcony parapet. It is better to carry out installation work on insulating the balcony slab before glazing. Otherwise, the repairman will have to look for insulation whose width corresponds to the width of the metal window profile.

When preparing for insulation work, the homeowner should consider:

- Double-chamber window profiles are too heavy for standard balcony slabs. Many owners decide to install single-chamber double-glazed windows; first they need to insulate the floor on the balcony and the ceiling.

- Insulation of a loggia with panoramic glazing can be done using crossbars and racks. The result will be a structure of vertical valves separated by horizontal jumpers. Glass without profiles is attached here. A specialized polymer substance is used as a sealant.

- When glazing a balcony facade using a mullion-transom design, double-glazed windows or individual glasses are combined into a continuous panel with light transmission properties. A specialized material or ordinary sealant is used as a sealant. All elements are attached to a metal internal or external base.

Post-transom panoramic glazing system

- The result of continuous glazing is a transparent wall without profiles or connecting bridges. There are two ways to glaze a balcony with glass without profiles - monolithic and strip. In the first case, one glass or a single double-glazed window is used. It is almost impossible to protect such a balcony or loggia from frost. In the second case, glazing is carried out according to the principle of coupe systems. This method implies the ability to open the balcony window sashes.

Stages of insulation of facade structures

Insulation begins with obtaining permission to interfere with the balcony structure. If you take the risk of insulating a loggia without permission from the Housing Inspectorate, you will have problems when reselling the apartment. For permission, you will need a project for reconstruction and glazing of the external structure, as well as a copy of the certificate of ownership of the apartment. The project is certified by the Housing Inspectorate, then the apartment owner needs to organize the following stages of insulating the balcony:

- Dismantling the old structure - handymen remove the glazing, cut off the parapet, strengthen the slab by pouring a rough screed.

- Installation of sidewalls - if they are solid (without glazing), then they are assembled from sandwich panels or foam blocks. The sandwiches are attached to a frame made of profiled pipes, which is assembled in place of the cut parapet.

- Installation of a window sill block under panoramic windows - it is laid out from foam blocks or mounted on the basis of a new parapet, to which sandwich panels are attached.

- Installation of panoramic glazing - the frames are inserted into the sidewalls and secured between the window sill block and the upper balcony slab. If the glazing design allows the window to be disassembled, the frames are installed without double-glazed windows. They will be installed later.

- Insulation of the upper balcony slab - sheets of expanded polystyrene are glued to it.

- Insulation of the bottom slab of the balcony - extruded polystyrene foam is glued to the base, onto which a screed of 2 centimeters thick is poured.

- Completion of window installation - double-glazed windows are inserted into the openings, the cracks are filled with foam. After this, the insulation of the structure is considered complete.

- External floor finishing - centimeter plaster is applied to the insulation boards, which increases the fire resistance of polystyrene.

- Installation of flooring - parquet, laminate, tiles. The choice of coating is determined only by aesthetic considerations.

- Connection to the apartment's electrical network - a separate outlet is provided on the loggia, to which household electrical appliances or heaters are connected. Heating the external structure from apartment radiators is strictly prohibited.

After completing the last stage, the Housing Inspectorate is invited to the house, which accepts the glazing, approving the redevelopment. Having received a visa from the Housing Inspectorate, the homeowner can make changes to the apartment plan, legalizing the installation of a panoramic loggia.

How to insulate a panoramic balcony that is already glazed?

In a particular case, the insulating structure for the floor may consist of the following elements:

- waterproofing material laid directly on a concrete slab;

- a 5-centimeter layer of polystyrene foam (it is laid on a waterproofing material);

- vapor barrier material that protects the insulation from moisture, which, interacting with the cold balcony slab, turns into liquid;

- 10 mm layer of moisture-resistant plywood (serves as support for the outer covering);

- laminated flooring.

Insulation of the floor on the balcony with penoplex (expanded polystyrene)

Tools and consumables for work

The owner of panoramic windows who has decided to carry out insulation must weigh his technical and financial capabilities and choose a specific heating system option. Most often, a home craftsman can independently insulate slopes, install warm baseboards and a “warm floor” system.

To do this, he will need to prepare the following tools and consumables :

Insulation of slopes:- Penoplex insulation;

- glue;

- façade mesh;

- different spatulas;

- knife;

- hammer;

- roulette;

- ruler;

- corner;

- primer;

- putty;

- corner with reinforced mesh.

- Warm baseboard and heated floor:

- heating elements;

- wires;

- connecting box;

- circuit breaker;

- screwdriver;

- tester;

- fasteners;

- protective panels;

- drill, grinder;

- roulette;

- level;

- For a water heating element you will need:

- pipes and fittings, circulation pump;

- soldering iron for welding pipes;

- perforator;

- dowels;

- set of wrenches;

- safety fittings to shut off the heating system in the event of an accident.

Is it possible to replace “cold” glazing with “hot” glazing?

Replacement of glazing can be carried out by taking several steps:

- The maximum weight that the balcony slab can withstand is calculated. Read more in the article “load on a balcony slab“

- The “cold” glass is being dismantled. The mounting foam is cut off, the glass is pulled out, and the fasteners (if any) are dismantled.

- A new structure is being installed. Installation of plastic windows on loggias with double glazing.

If installing new windows is not possible for safety reasons, you can replace them with energy-saving glass installed on “cold” double-glazed windows.

Of course, a person who has no experience in installation work should not take on such work.

Kinds

In the modern world, there are several methods of glazing balconies. All of them have their own individual characteristics, advantages and disadvantages. Let's try to figure out which of the façade glazings for balconies is better, and which one is more suitable for you.

By design

In total, there are 2 methods of glazing a balcony, which differ from each other in design: without extension and with extension.

Thus, glazing without extension is the most traditional method. When implementing it, the frame is installed in the same plane as the parapet of your balcony. In this regard, the main load falls on the parapet.

The second glazing option is with extension (or expansion). If you carry out work according to this method, you can increase the size of the balcony itself. Most often, this type is used if the balcony is initially quite small in area.

Of course, such work is more complicated than standard glazing without extension

This is due to the fact that when installing such a structure, it is important to calculate as accurately as possible the load that will fall on the frame. This load must be distributed between several load-bearing objects: the parapet and the load-bearing slab

Warm and cold

The names of these types of glazing speak for themselves. So, one of the methods involves insulating the loggia, while the other does not.

Cold glazing is a method that has been proven over the years. It was used back in the period when insulation options did not exist. This type of glazing includes the installation of wooden frames with one glass (in rare cases there may be 2). This variety is suitable for you if you do not use the loggia as a living space and do not spend a lot of time there.

The thing is that the difference in temperature on the street and on the balcony, which is glazed using the cold method, will be no more than 5 degrees. In addition, the cold type is the only possible option if the base plate is in poor condition and cannot be replaced. It is also cheaper.

Warm glazing is a more modern and improved option. Thanks to it, you can use your loggia as a full-fledged living space by arranging an additional room in it. In the process of carrying out the work, multi-chamber profiles with a special element - the so-called thermal bridge - are used. This provides thermal insulation for the balcony.

However, in this case, you should keep in mind that, in addition to warm glazing, you will also have to take care of insulating the floor, ceiling and walls. If necessary, heating devices must also be installed. Only in this case will it be possible to stay on the balcony without freezing.

Full and partial

Another classification of types of glazing of balcony windows is the division into full and partial. Thus, partial glazing is also called classic or standard, since it involves installing windows on an existing balcony parapet. This method is the most common.

Full glazing involves installing French windows. Thus, the glazing area is significantly increased, and the windows are located from floor to ceiling. Such glazing is sometimes called lightweight or lightweight, as it turns the balcony into a literally transparent room.

The loggia has panoramic glazing. How to insulate it from the inside?

Insulating a loggia with installed panoramic glazing is possible by performing a series of more or less complex manipulations.

These include:

- closing and insulating seams between double-glazed windows;

- clogging of cracks formed in walls and corner parts of the structure;

- work on insulation of ceiling and floor coverings.

How to insulate seams

First, the seams are cleaned. If panoramic windows on the balcony were installed a long time ago, the window profiles are freed from the remnants of polyurethane foam, plaster and paint applied as part of seasonal cosmetic repairs. This work can be done quickly if you arm yourself with a spatula, the width of which is at least 100 mm.

At the next stage, all voids and gaps are eliminated. To prevent cold air and dampness from penetrating through the balcony into the living space, all detected gaps are filled with polyurethane foam or cemented. The best time for such work is dry, sunny weather.

When the mounting foam dries (this may take about a day), the surface is leveled, and the voids filled with foam are covered with a special construction tape that does not allow moisture to pass through. Sometimes the seams are puttied and sealed with special plastic strips.

How to insulate walls

If the so-called cold glazing of the balcony has already been completed, some of the warm air will escape through the frames. By insulating the walls, the homeowner will achieve partial sealing of the structure.

Work with walls is done as follows:

- Having created a wooden sheathing (for more details, see the article “how to make a sheathing on a balcony”), the master fills each cell with insulation;

- installs the top cladding. Experienced craftsmen prefer to sheathe walls with plasterboard sheets (read more in the article “how to sheathe a balcony with plasterboard”).

Tips for creating a heated floor

A significant portion of cold enters through the uninsulated floor. Therefore, the phrase “warm floor on the balcony” should not be taken with skepticism.

First of all, the balcony slab is leveled. Curvature of balcony slabs is a fairly common occurrence. Floor screed will help correct the situation. The procedure consists of the following steps:

- Construction of a frame from wooden beams. Long pieces of wood are placed lengthwise, short pieces are placed across. The recommended distance between the cross beams is 50–60 cm. Self-tapping screws are used to make wooden sheathing;

- Filling the sheathing cells with insulation. In most cases, foam or mineral wool is used;

- Waterproofing film. This step is not necessary.

- The final stage of creating a warm floor includes covering the floor with plywood (chipboard) followed by lamination. If you wish, you can get by with regular linoleum (for more details, see the article “how to lay linoleum on a concrete floor on a balcony”).

Ceiling insulation

Since warm air flows rise from bottom to top, an uninsulated ceiling will cause heat leakage. The insulation process will not cause any particular complications for the inhabitants of the lower floors. The work will consist of insulating the outer part of the balcony slab located above their heads.

Neighbors living on the top floor will have to arrange an insulated canopy. As a rule, it is attached to a main wall or installed on specially erected columns.

French doors

French doors (another name is a French exit to the balcony) will add brightness and lightness to the living space. Of course, any type of lighting will make the room visually wider, but natural sunlight will do the best job. Actually, this is why French exits are installed in houses.

The advantages of a French exit include:

- High light transmittance. This design not only significantly reduces energy costs, but also allows ultraviolet rays to “work” as filters.

- Elegance and style. The French exit is an original and modern interior solution that will add piquancy and elegance to even the kitchen.

- It is advantageous to install French balconies overlooking open areas, which allows you to admire the beauty of the city without worrying about polluted air and noise.

French balconies are now available for installation in all regions and even small towns. If you want to place an order from a certain master from another location, you will have to pay for delivery

It is important to remember that models presented in specialized stores often copy products, of which there are a huge number in the country. If you are looking for something exclusive for your home, one of a kind, something that cannot be found on the storefront, we recommend going directly to private companies

The balcony (loggia) is glazed with stained glass. How to insulate it?

Many owners, having listened to the opinions of experts, install a temperature compensator. This device protects the structure from deformation and temperature fluctuations during off-season periods. The temperature compensator is installed not on the balcony, but in the adjacent room, in which room temperature is constantly maintained.

Before installing new frames, the craftsman clears the window openings of construction debris and makes sure that the lower edge of the glass unit coincides with the rubber insert, and the upper part of the unit is connected to the H-shaped guide. The correct installation of rubber seals is also checked - it depends on them whether the thermal insulation will be airtight.

Balcony walls are first covered with foil polystyrene foam. Polyurethane glue or special dowels are used as fasteners. All joints are taped with metal tape.

Dense polystyrene foam can be used as the last insulating layer of the load-bearing and side walls. External walls are covered with foil polystyrene foam.

Read more in the article “Do-it-yourself insulation of a balcony with penoplex”

What materials are used for insulation?

When choosing a material for insulation, you need to pay attention not only to its thermal insulation parameters. It is important to calculate the thickness of the finished installed layer, especially if you are planning to insulate a balcony with already installed profiles.

Important! If you incorrectly calculate the thickness of the floor, the window sashes simply will not open.

Let's look at the most common types of insulation and their main characteristics.

Styrofoam

It is easy to install on flat surfaces, relatively cheap, has good thermal insulation properties, and is therefore very popular. Its cellular structure retains heat well and does not allow sound to pass through, since the partitions between the cells dampen heat transfer and sound vibrations. Susceptible to organic solvents such as gasoline, acetone, etc.

Penoplex

Extruded or extruded polystyrene foam can even be used when covering the floor, as it does not deform under strong pressure, levels and supports the surface. In terms of thermal insulation and lightness, extruded polystyrene foam is somewhat superior to conventional polystyrene foam; also one of its advantages is low flammability, but accordingly its price is more expensive. The sheets usually have a special groove for joining, which allows for a uniform coating without cracks and makes installation easier.

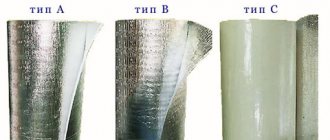

Penofol

Foamed polyethylene is an elastic elastic fabric, available in rolls and sheets. Thin polyethylene foam is usually used as a backing for laminate flooring, and the densest one is used as insulation, alone or in combination with other materials. The most efficient polyethylene foam is covered with foil, which allows heat to be rejected in the desired direction - towards the room. It is important to lay the heat reflector correctly - with the foil side facing the room.

Minvata

Depending on the source material, it is divided into glass, stone and slag, and is produced in various types and forms, in rolls and mats. It is very plastic, convenient and easy to cut with a regular construction knife. It has excellent heat and sound insulation properties and resistance to high temperatures, but is hygroscopic, which can lead to increased humidity, condensation and, as a final touch, the appearance of black mold.

Possible difficulties and errors

The biggest mistakes when insulating panoramic windows are made in the process of calculating the heat balance . If equipment is selected that does not correspond to heat loss through a panoramic window, then there will be no results from such a heating system, and significant funds for its equipment will be wasted.

In order to calculate the design thermal loads of a panoramic window, you need to know all the heat losses and take into account the climatic characteristics of the area. As a rule, thermal calculation of equipment is performed using a special software package, so it is better if it is performed by a heating engineer.

Design

A French balcony is a design that can be decorated in any, most incredible way. Modern designers are sophisticated and come up with the most elaborate variations that will turn an ordinary room into a work of art where you will want to spend all your time, or into a modernized room. It is first necessary to draw up a plan, on the basis of which the masters will work.

Another great solution is wrought-iron balconies. They are ideal for small apartments that suffer from a lack of light and solar heat. Forged products have a variety of shapes, so there will be a large selection.

External thermal insulation

To insulate the room on the outside of the house, a structure of ventilated facades is most often installed. This approach allows not only to retain heat, but also to ensure constant removal of condensate from the insulation body. In the technology of ventilated facades, mineral or stone wool, as well as film waterproofing, are most often used. This technology is perfect for balconies without external enclosing structures.

Another popular option for external insulation is to install a layer of rigid polystyrene foam boards or spray polyurethane foam followed by plastering the surface. This method is more preferable for protecting loggias with a concrete or brick parapet.

When the object is located at a height of more than three meters, thermal insulation must be carried out by specialists who have special permission to work at heights.

Low floor radiators

There is a wide variety of floor radiators: cast iron, tubular steel, aluminum, bimetallic and, as a separate group, floor convectors.

Varieties of convectors are copper-aluminum and steel. They differ in cost - the first ones are much more expensive due to materials and improved heat transfer.

They are a pipe on which ribs are welded. Such convectors are most widely used for heating rooms with glass walls. They create an effective curtain of heat from cold glass, while simultaneously preventing the formation of ice on the window.