Warmth in the house allows you to achieve the desired comfort and coziness.

If in the summer there are no problems with the temperature, in the winter you have to take additional care of a good indoor environment. To keep your home warm, you should pay attention to window openings, which often become a passage for drafts.

Various insulation products can help solve the problem, the variety of which should be carefully studied to select the appropriate tool.

Preparatory stage

First, you need to assess the situation, that is, find out where the draft is coming from - from the frames or from under the window sill? The reason may be an old seal or defective slopes.

To determine the area from which the cold is blowing, just run your palm over the surface of the window frame. If you cannot identify the cause, you can hold a lighted candle near the window block. The flame of a fire is most sensitive to drafts.

- Possible gaps and cracks can be indicated by moisture after the previous rain, which is concentrated in a certain place. When water accumulates in the corner of a window opening, most likely the reason lies in the joints.

- Drafts can occur due to poor sealing. You can do an experiment. A piece of paper is placed in an open window and the frame is closed. If the sheet is easily pulled out, then the seal is weakly pressed against the window frame.

When choosing a method of insulation, you need to clearly understand the purpose for which this is being done? Sometimes, in pursuit of cheapness, a window loses its attractive appearance and the approach to the window is blocked.

It is important to consider the price of materials. Some of them are quite affordable (the sealant costs no more than 200 rubles per can). More durable methods will cost more, but may be a worthy investment in the future.

No. 11. How to insulate wooden windows from the outside?

Internal insulation is sometimes not enough. Slopes often need additional thermal insulation . Work on their insulation begins with the dismantling of the old finish, after which the surface is primed. The cracks can be filled with polyurethane foam; another option is to cover the slopes with polystyrene foam. After hardening, excess foam is cut off and the surface is treated with plaster. A polymer mesh is attached to the foam on top, perforated tape is placed in the corners, after which plaster is performed. All that remains is to prime and paint the slopes.

The window sill area is also sealed with polyurethane foam. A mandatory requirement is the installation of a special strip for drainage of rainwater. It should be inclined and have rolled edges so that moisture does not get on the walls or through the window. It is advisable to seal the joints between the plank and frame or slope with sealant.

It is better to insulate the area under the window sill with polystyrene foam from the outside, because in a third of cases the most heat flows away through this area.

The final touch of external thermal insulation is updating the paintwork. The old peeling layer of paint can be removed using a spatula and a hair dryer, and fresh paint or varnish can be applied instead.

Do-it-yourself insulation of PVC windows

If you detect a violation of the thermal insulation, you can contact specialists, or you can handle the work yourself.

Insulation of window frames

The most popular materials for sealing frames against drafts include:

- Polyurethane foam;

- mineral wool;

- Silicone sealant;

- Foam rubber.

The listed materials are often used in window insulation technology.

An excellent option for insulating plastic windows is polyurethane foam, which, after application, expands in volume and fills the cracks.

A significant disadvantage of this material is its fragility. After severe frosts it may crack. In addition, polyurethane foam is effective only with minimal cracks.

- Window frames can be insulated using mineral wool, which has high thermal insulation properties. Unlike polyurethane foam, mineral wool is easy to use and resistant to temperature changes.

- Silicone sealants are widely popular for insulating window openings. It is necessary to take care of a special tool for using the material - a lever syringe.

- Silicone sealants can protect the window from moisture and drafts, preventing the formation of mold. When choosing, it is better to give preference to a transparent sealant. Once on the glass, it will not leave marks or unsightly smudges on it.

- Before directly using polyurethane foam or sealant, it is recommended to check the approximate area of expansion and increase in volume. To do this, you need to apply a small drop to the corner of the window opening.

- There is a well-known budget way to insulate windows with your own hands - plug the cracks with ordinary cotton wool, and then stick on masking tape. People of the older generation are familiar with the option of covering openings with strips cut out of paper and glued to welded paste.

You can insulate PVC windows yourself using foam rubber, which is sold in any construction supermarket. The product is characterized by a low price and good quality. Foam rubber is sold in the form of rolls, the adhesive side is protected with a special film. During operation, it is removed and glued to the gaps of window openings.

Insulation of slopes

If you find problems with drafts from the side of the slopes, you can use plasterboard or sandwich panels.

When using polystyrene foam, you must keep in mind its fragile qualities and ability to absorb moisture. It is advisable to carry out external insulation using dry mixtures.

First of all, you need to treat the gaps and cracks: remove dust and remnants of polyurethane foam. Next, proceed step by step:

- Parts of a certain size are cut out of drywall and coated with a moisture-resistant primer. Takes time to dry;

- Insert sheets of plasterboard into the slots;

- The remaining gaps are filled with polyurethane foam;

- When the foam hardens, the surface needs to be leveled by removing excess foam.

External work should be carried out at an outside temperature of at least 5 degrees Celsius. Otherwise, the material may lose its quality properties.

Insulation of window glass

To save heat in your home, it is advisable to purchase window insulation film. It prevents the formation of condensation. In addition, such windows are particularly durable.

- The window block is first prepared - the frames and glass are washed and the material begins to be glued.

- The glass surface must be treated with a degreasing compound and wiped dry with a lint-free cloth.

- The film is glued so that the metallized side is on the outside. The material is glued not only to the surface of the glass, but also to the frames.

- Stores offer adhesive-based films, but there are also options using adhesive tape.

Advice! “To prevent the formation of bubbles and creases on the film, use a hair dryer to style your hair.”

Bubble film can help prevent cold air from entering the room. The most practical material is considered to be one with wide bubbles. It is necessary to cut out the required area of material, taking into account the approach to the window frame.

After this, spray the degreased glass with plain water from a spray bottle and glue the film with the corrugated side to the glass surface. If desired, you can glue an additional layer of film.

A significant disadvantage of using bubble wrap is that it reduces the amount of light in the room.

Replacing the seal

You can replace the sealing rubber yourself by buying a new one at a construction supermarket. When purchasing, it is important to pay attention to the color of the product. The rubber must be black.

Remove old material, clean and degrease the surface. Next, lubricate the surface with glue and carefully glue the rubber.

We bring the third glass to clean water

Manufacturers and sellers of heat-saving film for double-glazed windows claim that it reflects thermal radiation. In fact, this is 100% deception. Now we will prove this to you.

There are high-quality energy-saving films that can reflect part of the IR spectrum. Their cost starts from $15 per linear meter (cheap Chinese manufacturers). European heat-reflecting films cost from $20 per sq.m. depending on the characteristics.

Important

Thermal film third glass can be purchased for $3. Often the kit includes double-sided tape. The difference in cost speaks for itself.

Window insulation with thermal film, which works, occurs by gluing it to the glass. Its task is to reflect infrared radiation. If you stick a third window film on a double-glazed window, there will be no effect.

They sell you a piece of shrink film in the package. You can buy it at a hardware store. The effect will be the same. The cost of such film is from 0.5 dollars per square meter.

Application of Swedish technology

The essence of Swedish window insulation is to glue an additional rubber seal between the sashes. A “glazed window effect” is achieved, which contributes to a significant increase in thermal insulation.

This method is considered the most expensive, as it involves window repairs.

Even the smallest gaps can become the main cause of heat loss. You can carry out window insulation work yourself. If difficult situations arise, when the house is still cold, you need to contact the installers to correct the defects.

What is REAL heat-saving film

Energy-saving films are glued directly to the glass. They have two tasks:

- Reflect infrared radiation emanating from the room back;

- Let infrared radiation into the room from the outside.

Thermal reflective film usually has a color ranging from yellow to blue. It all depends on the type of spraying. The light transmittance and reflectivity of IR rays depend on the composition of the sprayed substance and its quantity.

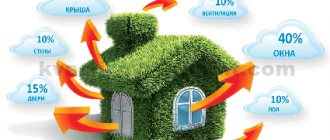

A good heat-saving film can return up to 80% of thermal radiation into the room. This is about 20-30% of the total heat loss of the house. For an apartment this will amount to 30-50% of heat loss, since in a multi-storey building heat does not escape through the floor, roof and walls adjacent to neighbors.

Photo of window insulation

Lifehack

To maximize insulation of a house or apartment, you can use overhead heat shields. They are installed on top of conventional metal-plastic or wooden frames. The surface of such a screen is covered with heat-reflecting film. When installed, it seems to add an additional double-glazed window.

You can cover the glass with energy-saving film and ordinary polyethylene, polypropylene or shrink film. This way you will kill two birds with one stone. At the same time, heat loss due to convection and infrared radiation will be reduced.

Tape installation

The installation of self-adhesive tape must be approached very carefully. The quality of its fastening and the effectiveness of insulation will depend on this. Before you start gluing it, you need to carefully prepare the working surface.

To do this, the frame must be cleaned of old insulation and all contaminants. After this, the place where the tape is attached must be thoroughly washed and degreased. You can use alcohol or acetone to degrease the surface.

More on the topic How to make a heated floor on a balcony with your own hands

Once the surface is ready, you can begin attaching the material. To fix the insulation at the line of contact between the sash and the frame, the protective paper is removed from the back side.

It must be eliminated gradually, as needed. To facilitate the installation process, the tape can be pre-cut into pieces of a certain length.

The material easily sticks to the frame. But, complete hardening of the adhesive composition occurs after some time. During this time, you should refrain from frequently opening and closing the sash.

Choosing the right option

One of the main points that you should pay attention to when choosing a sealant is its shelf life.

Products with an expired or nearing expiration date may peel off from the surface over time, or may not provide proper sealing at all. In order to check the quality, it is enough to bend the material and evaluate how quickly and accurately it restores its original shape.

When choosing a self-adhesive rubber seal, it is best to opt for softer models. If there is sufficient softness, the material will be able to replicate to a greater extent all possible surface irregularities, thereby eliminating any draft.

No. 3. Debugging the clamping mechanism

House shrinkage and weather factors can lead to slight distortion of the window sashes and slight deformation of the sealing rubber. This leads to deterioration of thermal insulation, but in this case, returning the former tightness is a matter of a couple of minutes, however, knowledge of the design of a plastic window and skills in working with tools will be needed.

The clamping mechanism can be adjusted using special eccentrics located along the perimeter of the sashes. To ensure a tighter fit of the sash, the eccentric must be turned clockwise using a 4 mm hex key. Focus on the serif located on each such element. When it is directed towards the street, the pressure is weakened; when it is directed towards the seal, it is strengthened. The video shows everything well.

adjustment of the hinges , which also have their own mechanism responsible for the pressure density, helps to insulate a plastic window Here the regulation is carried out using a hexagon. You should follow a simple rule: if the tongue is pushed out strongly, then the sash fits well. To pull it out, you need to turn the hex counterclockwise if the hinges are on the left, and clockwise if on the right.

Things are even simpler with glazing beads . It is enough to pry off the old, loose glazing bead with a thin spatula, and install a new one in its place, which can be bought from the same company that sold and installed your windows.

After adjustment, check whether the tightness of the structure has improved using your palm or a lighter. If everything is done correctly, but there is still a draft, you will most likely have to change the seal.

Foam rubber

Foam rubber insulation for windows (foam rubber tapes) was used to seal windows for the winter long before the production of insulation was put into production.

The advantages of this material are known to everyone: it is easily compressed (and, as a result, installed), does not injure the surface of the frame, this method is cheap and simple.

There are also disadvantages: foam rubber for insulating windows is not the best choice; even with very good compression, air still leaks through the pores, and it is also not very durable - foam rubber comes off relatively easily.

The second problem can be partly solved by modern rubber-based adhesives. To solve the first part of the cracks (especially in hard-to-reach places), it is advisable to fill them with silicone or acrylic sealant before installing the insulation.

Products in profiles

Among the most common seal profiles are several:

- O-profile for large gaps (from 3 to 7 mm);

- D-profile closes gaps from 3 to 7 mm;

- V-profile for medium-sized cracks from 3 to 5 mm;

- P-profile for gaps from 3 to 5 mm;

- E (K)-profile for gaps from 1 to 3 mm,

- The C(I) profile closes small gaps from 1 to 3 mm.

Seals come in different colors (the most popular are black, dark brown, white); there are also transparent ones.

Ethylene propylene synthetic rubber

EPDM, a compound of ethylene and propylene rubber (soft porous rubber seal), is most often used in the manufacture of self-adhesive seals, because the material is quite ergonomic and does not deteriorate when exposed to constant loads, which is especially important and necessary for windows and doors.

A special advantage is that rubber is a non-toxic coating that is environmentally friendly for people and the environment. It does not form mold, rot, insects, termites and other pests.

Very wear-resistant. Absorbs shocks, maintaining the durability of structures. Adheres to any surface, used for metal doors and even gates, hatches and cabinets, for industrial purposes - on electrical equipment and ventilation systems.

What should I do before installation?

If you want to ensure that when installing a self-adhesive seal on doors and windows there are no problems leading to its subsequent deformation or dismantling, be sure to follow the pre-installation procedure, namely:

- clean the surface from dust and dirt, wipe the surface with alcohol or acetone and dry thoroughly; visually mark the places where the seal will be glued and the places of contact (on the frame, sash, door or door frame);

- prepare the required length of the seal in advance; remove the protective layer gradually and press firmly to the base; after 2 hours, the glue finally sets to the base, drying occurs in temperature conditions from +5-40 degrees Celsius.

Source: vhod.guru/otdelka/uteplenie/samokleyuschiesya-uplotniteli-dlya-dverey-i-okon.html

Reviews of film Third Glass

I have wooden windows and I decided to use thermal film. It's hard to glue alone. It separates along the seam when heated with a hairdryer, and after gluing it reacts to temperature changes - it contracts when heated and comes off. However, the effect is present: after gluing, the temperature rose by 3 degrees, the glass stopped leaking. Like an ambulance.

Alexander, Ukraine

A very curious animal lives in my apartment - a cat, so heat-saving film for windows would definitely attract her attention. To avoid damaging it (the film), I decided to stick it from the street. The apartment became a little warmer, but the condensation, albeit in small quantities, remained. Next year I will stick it on the side of the apartment.

Arthur, RF

In general, everything went according to plan. All that remains is to check how effective this “third glass” is. Therefore, they did not seal the second half and decided to wait until the next day.

The next morning, the other half fogged up, but ours remained clean and transparent:

M., St. Petersburg

The “third glass” turned out to be an ordinary thick, but fairly transparent film of large width. Good double sided tape included. Which need to glue the film to the frame. IMPORTANT: the film should not touch the glass. It turned out to be difficult, because... It is also advisable to glue it without creases and folds, with good tension.

Julia, Kyiv

Types of self-adhesive seals

Among the varieties of self-adhesive seals, it is worth mentioning the most commonly used rubber (low in cost, often purchased specifically for wooden structures), foam rubber (made of foam rubber), polyvinyl chloride, polyethylene foam, and the more recently appeared self-adhesive seal made of closed-cell foam rubber (porous rubber).

It is always more profitable to take a self-adhesive seal for the entire living space, which is why they are usually sold in coils or rolls of 40 meters or more.

And they will prove their practicality during long frosty winters and hot dusty days. They perfectly hide any imperfections in geometry in structures.

Advantages and disadvantages

The solution has a number of advantages:

- minimal thickness, high light transmittance;

- possibility of gluing wooden and plastic double-glazed windows;

- ease and efficiency of installation, no need for specific knowledge and tools;

- affordable price;

- fire safety;

- environmental friendliness.

The only significant drawback is considered to be susceptibility to deformation under intense mechanical stress. The service life of the product is 1-2 years.

If the double glazed window is to blame

Sometimes a window stops holding heat due to depressurization of the glass unit. A sign of loss of seal is condensation on the inner surface of the glass. The reason may be either a manufacturing defect or simple damage to the double-glazed window, for example, when drilling a profile during the installation of sun blinds or roller blinds.

Glass can also crack if there is a sudden change in temperature from temperature shock or from carelessly hitting the glass. Even if the glass has not shattered into fragments, the glass unit will no longer have the required tightness.

In this case, the house owner is faced with the question: how to insulate double-glazed windows in plastic windows? The only solution here is to replace the double-glazed window with a new one. This is a simple operation, however, it is better to entrust it to specialists.