Modern wooden windows with glass blocks are characterized by a long service life of at least 25 years.

However, their individual components wear out much faster than the established warranty period.

Vulnerable components of a window unit include rubber seals. They work in the most stressful conditions, daily exposed to both the negative influence of the external environment and mechanical stress due to the frequent opening of the doors.

Damaged seals become a source of cold and moisture entering the room, leading to the destruction of the wooden frame. Therefore, even with the slightest violations in their integrity, they must be replaced with new ones. The owner of such windows needs to understand what a window seal is and be able to choose and install it correctly.

What it is?

The seal for this modification of windows is a flexible cord or tape made of rubber, synthetic rubber or silicone , made with different profiles. It is glued to the wooden surface of the frame or inserted into pre-prepared grooves in order to create the tightest possible clamping of the sashes to the frame structure.

What is it needed for?

The need to place rubber products on wooden frames is predetermined by the nature of the wood.

It's no secret that wood, under the influence of the external environment, can change its shape : shrink or swell, becoming saturated with moisture.

These phenomena lead to deformation of frames and the appearance of cracks.

Such violations create many problems:

- there are drafts in the house;

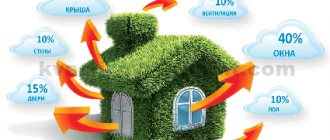

- heat loss and humidity increase, which leads to increased heating costs;

- the room becomes noisy due to street sounds;

- the wooden frame begins to rot, which contributes to its premature failure.

The main functions of the seal on wooden windows:

- insulation of interior spaces from moisture and street noise;

- protection of the wooden frame from atmospheric moisture;

- resistance to the entry of cold and heat from the street into the room;

- ensuring the tightness of the glass unit;

- protection against dust ingress;

- protection against condensation on glass.

Materials for production

It is possible to compensate for the gap in the door structure only with the help of soft and at the same time elastic materials; in addition, the seal for the front door must have a whole range of additional qualities:

- The rubber material must have high contact strength, otherwise the door leaf will simply crush the seal when closing;

- The material should not change its characteristics at low or high temperatures, maintaining elasticity and strength. For example, in severe frosts, the temperature of the seal on the front door can drop to minus 5°C, ordinary rubber materials become hard and brittle;

- The elastic seal coating should not absorb water, release chemicals and have good abrasion resistance.

The requirements for the seal for interior doors are radically different from the conditions for the front door; there are only two of them. The material must have a low elastic modulus and very good crushability. Simply put, when closing a wooden, plastic or cardboard door, the resistance of the sealing tape to the pressure of the door leaf should be minimal, otherwise in a couple of months the door will bend like a “propeller” due to its high elasticity. Therefore, porous rubber, foam rubber or filled silicone tubes are often used as a seal for wooden doors.

Varieties

On the building materials market today there are hundreds of types of insulation for window systems. So that buyers can navigate them and choose the desired modification. they are grouped according to a number of characteristics: by purpose, materials, installation method and profile section shape.

By purpose

All insulation materials for wooden window blocks are classified according to purpose into two large groups: for sealing only glass and only wooden structures.

The thickness of the product and the composition of the material depend on this classification, since they have different operating conditions and mechanical loads.

For fixing glass panes

These seals are placed in contact between the glass and the frame, both inside and outside, and firmly connect both parts of the structure. They belong to the group of glazing bead products (wedge), and their main purpose is to ensure tight contact between the glazing bead and the glass. For this purpose, a thinner cord is purchased, and the color is chosen to match the shade of the wood or paint layer.

The main manufacturers of this type of product:

Semperit.- Schlegel.

- Deventer.

- KBE.

- Standard Prof.

- Stomil Sanok SA

- ASS Lastik.

The cost ranges from 20 to 25 rubles. for 1 m.p.

To fit the sashes to the frame

This modification of the product is responsible for ensuring a tight fit of the sashes to the frame and to each other . Usually they are purchased in two or even three types: for the internal, external and middle contour of the fit.

There are no special requirements for the appearance of these products, but they have their own characteristics in terms of quality, as they must provide. Both the tightness of the vestibule and mechanical strength.

The best manufacturers for this type of company products:

- Rehau.

- Kaleva.

- Veka.

- KVE.

The cost of the product is in the range from 30 to 40 rubles. for 1 m.p.

By material type

| EPDM seal | Thermoplastic seals | Silicone seal |

| High operating temperature range | Large tolerance margins in the gap | Does not support combustion |

| Low sensitivity to rapid cyclic temperature changes | Cheap seal | Resistant to light-thermozone aging |

| Low sensitivity to ozone and ultraviolet radiation | Welding in profile corners | Can be used over a wide temperature range |

| Small radius of curvature of the seal | Inert to most chemicals | |

| Springiness | Very soft material, does not absorb moisture well |

Grouping seals according to this characteristic indicates their strength characteristics, appearance, heat and noise insulation properties. This indicator also has a greater impact on the cost of the product. Most often, cords are used for such windows:

- with filler;

- silicone;

- rubber or caoutchouc;

- synthetic polymers;

- synthetic rubber.

Distinctive features of various sealing products:

| EPDM (elastic rubber) | PVC | Silicone |

| Used in the range from -60 to +120 C | Eco-friendly | Maintains excellent properties at high and low temperatures |

| Resistant to temperature changes and exposure to sunlight | Does not burn, which makes it indispensable in fire hazardous areas | Resistant to high humidity, ultraviolet radiation, aggressive chemical environments |

| Can be used for 10-20 years | Has several color options | Very durable |

| Has good performance characteristics |

With filler

This insulation is made in the form of a hollow tube filled with foam rubber . From the point of view of thermal protection, it has good performance, but in terms of mechanical strength and elasticity it is inferior to solid-cast modifications. Conventional products with filler, due to their low characteristics, are rarely used to protect wooden frames.

Not long ago, retail chains began selling Shlegel Q-Lon foam sealing tape from Germany. It does not have the disadvantages of previous modifications with filler, therefore it is more durable and has a longer service life.

Shlegel Q-Lon has a polyethylene film shell reinforced with fiberglass thread, polyurethane foam is placed inside the hollow structure, and a polypropylene core is installed for rigidity. Such a cord can be purchased at a price of 75 rubles. m.p.

Silicone

A very popular seal, despite its high price. In the European classification, these products are labeled VMQ and are considered the most effective option for sealing wooden windows. They have high strength, elasticity, frost resistance and are able to withstand the aggressive effects of atmospheric moisture.

Even after prolonged compression, they are able to instantly restore their geometry, and therefore can be used for up to 40 years. The only drawback of VMQ is that it is afraid of mechanical and shock loads.

The most popular in domestic markets is the colorless silicone seal for wooden windows “Zubr” at a price of 277 rubles. m.p.

Rubber or caoutchouc

This type of protective tape is made from rubber and vulcanized rubber . They belong to the middle price category, and at the same time have fairly high characteristics that can perform their function for up to 20 years.

Disadvantages include black color and low frost resistance; with large temperature changes they can crack.

The most popular brand of rubber seals is LeroyMerlin; in the retail chain you can purchase a 5.5 m pack for 200 rubles.

Made from synthetic polymers

these sealing tapes are designated TPE from the group of thermoplastic polymers . Their peculiarity is that at normal temperatures they are similar in properties to rubber. But at the same time they can have any color and shape, without loss of physical qualities. Works well in particularly stressed areas, such as the corners of wooden frames.

The advantages of such protective years include::

- excellent degree of sealing;

- high elasticity;

- do not burn, but they can be connected by welding;

- can have any color to match the frame, and are easy to install.

The disadvantages of these options include:

- low temperature range from - 20 C to + 35 C;

- at lower outside temperatures the material hardens, and at higher temperatures it softens.

Most popular brands:

- Trelleborg K5286-15LA, 45 RUR. m.p.

- Stomil Sanok SA, 41 rub. m.p.

- Schlegel, 36 rub. m.p.

- Deventer, 60 rub. m.p.

EPDM

These sealing tapes also belong to the synthetic group, are made from ethylene propylene rubber and are mostly used in the manufacture of wooden frames. In the European classification they are designated EPDM.

The advantages include high protective resistance to ultraviolet radiation and low negative temperatures, permissible operating temperature from - 50 to + 80 C, ability to work in stressful conditions without loss of quality for up to 20 years.

Disadvantages of EPDM products include their black color and the ability to leave marks on the frame. EPDM with D-profile can be purchased in the retail chain for 50 rubles. m.p.

By installation method

According to this indicator, they are divided into two large groups for wooden window blocks - self-adhesive and without an adhesive base. The first type is more preferable because it is easy to install yourself. The second type is used by professionals and for factory installation of protection in the production of wooden windows with double-glazed windows.

Self-adhesive

This popular protective tape for wooden windows can be either single-sided or double-sided . To install the product, you only need to remove the protective strip and press it firmly into the desired location on the frame. This installation option is the easiest and fastest. However, it has a drawback - the adhesive layer quickly loses its qualities.

Self-adhesive seals are produced by almost all leading manufacturers of windows and rubber products for sealing frames; the most popular brands of self-adhesives are:

- ATT Stomil, 16.50 rub. m.p.

- Wellamart, 27 rub. m.p.

- Supretto, 34.50 rub. m.p.

- Stomil Sanok R, 16.70 rub.m.p.

Without adhesive base

Protective tape without an adhesive layer, used on an industrial scale . In order for the product to work well for at least 20 years, it will be necessary to use high-quality glue with the characteristics corresponding to the main material of the tape: frost resistance, moisture resistance, ultraviolet resistance.

The disadvantages of such products are the complexity of installation and the need to additionally purchase glue, which is expensive. But as a result, such a product will last two or even three times longer than self-adhesive ones.

Popular insulation without adhesive base “Anker” can be purchased on the market for 28 rubles.m.p.

Grooved

With fastening into a groove without glue - a less common type of cord, which involves its installation using special mounting rollers . The advantage is that it is not necessary to apply glue for fixation, but the task is complicated by the fact that special grooves must be made in the wood before fastening.

Sealants for wooden windows for a 3 mm groove are produced by the following brands:

- Deventer.

- KBE.

- Rehau.

- Monblanc.

- Proplex.

- Novotex.

- Grain.

- Brusbox.

- Kaleva.

- Exprof.

The cost of such cords is from 35 to 40 rubles.

By section

This is an important characteristic for choosing seals for wooden windows, since the strength of attachment of the sash to the frame depends on this indicator. A very thin cord will not be able to properly seal and press the window elements, while a cord that is too thick will interfere with the operation of the sash. Therefore, for each individual window block design, its own section options are used, according to the size of the cracks and gaps :

- D - up to 1 cm;

- P - from 3 to 6 mm;

- E, V - round section less than 3 mm;

- I, C - flat slots 1 mm.

The most popular products of this modification:

- PRC - “E”, 21.30 rub. m.p.

- Technics, self-adhesive type P, 27.60 rub. m.p.

- Stomil Sanok P 9×5.5 mm, 12.56 rub. m.p.

- Stomil Stomil Sanok E 9×4 mm, 15.98 rub. m.p.

- Stomil Sanok D, 14.90 rub.m.p.

- Deventer SV 125, 70 rub. m.p.

- Remontix - P, 40 rub. m.p.

- Remontix - E, 40 rub. m.p.

- Ultima - D, 40 rub. m.p.

How to choose?

Before choosing the brand and type of product, the user must measure the required length.

To do this, measure the perimeter of the frame and take an additional reserve of at least 20%.

After this, the width of the gap is measured to determine the desired cross-section of the product.

When choosing a brand, they are guided by the following aspects::

- High levels of moisture resistance and frost resistance, data can be found on the original packaging.

- For self-adhesive tape, it is important to check the expiration date and whether there is a protective film on the adhesive base, otherwise the tape may dry out when stored in a warehouse, losing its adhesiveness.

- High elastic and strength characteristics. You can check the product by squeezing or stretching the tape and cord; if the performance is good, they quickly return to their original shape.

- You need to choose a product according to the color of the window frame, which increases its aesthetic component.

- For products without an adhesive base, you will need to choose high-quality nitrocellulose-based glue or silicone sealant.

- Availability of a certificate for the product, the European brand must comply with SS EN ISO 9001 standards.

Which is better: manufacturer ratings

On the Russian construction market today there are quite a lot of offers for insulation for wooden windows, both from domestic and Western manufacturers. In order for window owners to navigate this list of products and choose the most worthy option, experts advise studying product ratings and customer reviews before purchasing .

Ratings of seals are compiled by large trading platforms based on user demand, taking into account the opinions of an authoritative community.

Since they are grouped according to different criteria, the ratings also need to be considered taking into account the classification of products.

Rating of the best thermoplastic products:

- Monblanc, 20 rub. m.p.

- Ultima, 34 rub. m.p.

- Anchor, 28 rub. m.p.

Rating of rubber products:

- KBE, 35 rub. m.p.

- VEKA, 20 rub. m.p.

- Schlegel, 29 rub. m.p.

Rating of silicone products:

- REHAU SIK, 70 rub. m.p.

- TESA, 41 rub. m.p.

- ASRemWindow, 43 rub. m.p.

Principles for selecting sealing products

Armed with the above information about the types of seals, you can safely go to a retail outlet and make a purchase, not forgetting to first measure the dimensions of the cracks and decide on the most suitable profile section.

Having picked up the product you like, the first thing you need to do is pay attention to the information provided on the packaging. No matter how competent the sales consultant is, it is better to make sure for yourself, for example, what material a particular seal is made of and, in the case of a self-adhesive product, whether it has expired by the date limiting its suitability. Then you need to make fun of the insulation a little - try it by touch, squeeze, stretch - the main thing is to evaluate the product for elasticity and softness, and if the seal has these qualities, after manipulation it returns to its original shape, then the product is of high quality - you can take it

If, in an everyday situation, the seller grumbles and swears and does not allow tests to be carried out, this may be a hint of poor quality of the product. If the choice is made and it falls on a seal without an adhesive surface, you need to take care of what to use to attach the product to its proper place. In this case, you need to additionally purchase high-quality glue, for example, silicone sealant.

Tools and accessories

By releasing products for sealing wooden windows, manufacturers made sure that the home craftsman did not need particularly complex or scarce tools to install them . They will be needed to open the frames, remove the glass and thoroughly clean and degrease the surface before gluing the cord or tape.

For the performer, a penknife, a screwdriver, a ruler for measuring the length of the seal, a roller for sealing the cord in the grooves and a construction glue gun will be enough.

To install protective tapes and cords, you also do not need to have special knowledge ; just study the manufacturer’s instructions and purchase the necessary consumables: silicone glue, any degreasing solution and clean rags.

Step-by-step installation instructions

After all the necessary materials to complete the work have been purchased, the workplace is prepared. Replacing the seal is easier when part of the wood frame is horizontal. In this case, the frame is laid on a double-glazed window, on the external profile. Sometimes this requires removing the handle.

The joint of the tape is usually located at the top ; this is where you also need to start dismantling the old seal. After this, the profile is carefully treated to remove contamination.

Important! VMQ and TPE seals vary from corner to corner. This suggests that they need to be cut, not bent. In this case, all joints are glued with “Moment”.

In the sash

This insulation method is called Swedish and is considered the most reliable in the world . Before laying the seal along the entire perimeter of the fresco, prepare a groove at an angle of 45 degrees. Clean it from shavings or sawdust.

The insulation with a fold is placed into the chamfer and pressed with a roller, moving it back and forth, while not allowing the tape or cord to be pulled. The sashes are mounted on a wooden frame, quality control is carried out by opening and closing the sashes

In a double glazed window

The seal around the glass unit is installed after cleaning the placement area. The work is carried out in the following sequence :

- First, remove the glazing beads from the sides.

- The linings are removed and the glass unit is dismantled.

- Wash and degrease the installation site.

- Install the cord first, and then the double-glazed window.

- Fix the glazing beads.

Difficulties and errors in the process

Installing seals in wooden windows with double-glazed windows is a very complex operation; it must be approached responsibly so as not to spoil the entire window structure. If the master has any doubts, it is better to invite specialists.

The main mistakes that home craftsmen make:

- incorrectly selected material;

- use of a low-quality product;

- violations during window disassembly;

- depressurization of the glass unit.

In order to avoid mistakes and damage window fittings, the master must adhere to the following basic rules :

- Remove the sash before installing the seal.

- Do not leave dirt in the grooves.

- Install all seals at the same time.

- Glue the tape at the joint.

Price table for seals for wooden windows

We offer a large selection of different types of seals in a wide range of colors: white, ivory, mahogany, brown, light oak, gray, black.

The cost is indicated per linear meter of sealant, taking into account the visit of the specialist and all installation work.

If you don’t find a similar seal in the table, don’t worry, call, the measuring engineer will definitely select an original or an analogue of the seal.

If a wooden window has been in use for many decades and a draft blows through its cracks, cold penetrates in the winter, and the roar of a motor can be heard from the street, then it is necessary to look for a way out of the situation. Today, this problem can be solved very simply - by installing a seal along the contour of the window structure.

Substitution rules

If the owner of a wooden window has chosen the right insulation and installed it efficiently, and also performs all the necessary periodic maintenance, then the protection will work for at least 5 years.

In practice, there are enough examples where seals last as long as a wooden frame.

If the operating conditions of rubber products are violated, they may fail in a year or two. Every year before and after the heating season, the owner must inspect the window unit for technical condition and know the basic signs of seal failure.

These include:

- the appearance of extraneous increased noise in the house;

- fogging of windows, both inside and outside, and between the panes;

- mold on the walls near the window opening;

- dust on the windowsill;

- drafts in the room;

- upon external inspection, cracks are noticeable on the product, and the material has become hard and inelastic;

- The color of the seal has changed completely or in places.

Attention! If any of the above signs are detected, the window owner should plan to replace the wooden window seal in the near future or contact a specialist.

If he decides to carry out the replacement himself, then he will need to select insulation using the above method and prepare the tools:

- pliers;

- screwdriver;

- compaction rollers;

- glue gun;

- rags.

The main difference from the initial installation of the seal is the need to remove the old product and thoroughly clean the area on the frame for future installation of the protective tape.

Content

Almost every manufacturer of wooden windows strives to improve the quality of their products. The success of the manufacturer depends on how attractive the produced window will look. But despite appearances, the quality and reliability of a window can be deceiving. An important part of every window is the seal. A properly selected seal will provide protection against blowing and good sound insulation.

The design of modern wooden windows has two sealing circuits. One is located on the rebate of the window sash, the second is on the overlap of the sash. The dimensions of the grooves where it is installed will help you choose the right seal for the window structure. The seal must meet the highest requirements. The more high-tech the seal is made, the longer the window in which it is installed will remain a quality product. With a low-quality seal installed, the window may remain beautiful in appearance, but even when closed, the wind will pass through it. As a rule, a draft enters the room through the most unprotected place of the window unit - the corners of the sash. This is due to the fact that the seal, when installed at the corners, does not fit together well. When installing the seal on the corners of the sash, it is very important to use special scissors for cutting, which form a clear angle. In the absence of such scissors, the cut is not clear, and the corner of the window may be blown out.

When choosing seals for a window unit, you need to pay attention to the properties of the material from which it is made. The physical characteristics of the seal depend on the quality of the material. One of these indicators is the ability of a material to recover. The fact is that when the window is closed, the seal performs its direct function - it seals the gap between the sash and the window frame, preventing the occurrence of a draft and the penetration of extraneous sounds from outside into the room. At this moment, the seal is in a compressed, working state. If the window sash is opened, the seal will begin to recover to its original state in which it was before installation. The lower the temperature outside, the slower the recovery process. If the seal does not restore its original shape, then the next time the sash is closed, the seal will no longer perform its functions fully, which means we get a draft and extraneous noise in the apartment.

How to extend service life?

Proper use of insulation in wooden frames increases its service life many times over.

Basic recommendations for the use of window sealing products:

It is necessary to thoroughly wash windows and all their components at least 2 times a year, before and after the heating season.- Use only special solutions for cleaning windows; do not use strong acids, alkalis or other aggressive, flammable liquids.

- The seal is thoroughly cleaned from dust and street dirt from the outside and inside, around the entire perimeter.

- The cleaned and dried seal is lubricated with a special silicone grease that maintains the elasticity of the product.

Important! If there are no special lubricating solutions for insulation in the house, you can use regular glycerin, but in this case the effect of its use will not be so strong.

Average prices in the Russian Federation for installation

In order to correctly install the seal, it will be necessary to disassemble the sashes, which can lead to an imbalance in the operation of the window fittings. Therefore, it is advisable to carry out such work by specialists.

Today there are quite a few companies, both in Moscow and in other regions of Russia, that perform this type of work with high quality and with a guarantee. Prices depend on the glazing area, the number of sashes, the type of seal and the technical condition of the window unit.

Average prices for installation operations by service organizations:

- replacement of rubber seal, 100 rub. m.p.;

- installation of a self-adhesive seal, 50 rubles;

- insulation of wooden windows with rubber seals, 120 RUR per m.p.;

- EPDM installation, 140 rub. m.p.;

- TPE installation, 160 rub. m.p.;

- installation of silicone insulation, 250 rubles. m.p.

Manufacturers

There are many domestic manufacturers producing seals. These are large companies:

- Tekoplast;

- Aviora;

- Lada-Imid;

- Kim Tech;

- Bison;

- Cyclone;

- Ultima.

There are also little-known companies:

- MZEP;

- VZRTI.

When purchasing expensive materials, you should carefully study the packaging, because it contains basic information about the purpose and technical data.

Correctly and efficiently installed insulation prevents cold air and harmful gases from entering the room from the street, creates a feeling of comfort and serves as a good heat insulator.

In conclusion, you can watch a video that gives useful practical tips:

Voted over 388 times, average rating 5

Comments

Unfortunately, there are no comments or reviews yet, but you can leave your...

Add a comment Cancel reply

We recommend reading

Insulation Technology for heating roofs and roof windows: what elements does the system consist of? The window is a source of heat on the roof of the extension, especially ...

Insulation Grilles for window sills - scope of their application, types, quality, cost, installation Ventilation for window sills - quite recently few people could think about this...

Insulation How to properly insulate wooden windows for the winter: stages of work, choice of insulation and photos Windows are an integral part of the house. In addition to providing comfort, they...

Insulation Causes of heat loss from windows: how to reduce them by installing plastic windows More than half of the heat loss of a house or apartment in winter comes from...