Window sealant has become quite popular today, and it is used mainly as a sealant for window frames and glass.

Sealant, according to its properties and characteristics, is divided into several varieties, but the most commonly used is considered to be silicone based. It owes its popularity to its almost impeccable characteristics and relatively low price, since only one component is used for its manufacture - silicone rubber.

No. 1. Where does the insulation of wooden windows begin?

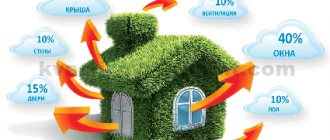

Insulation of old wooden windows begins with examining the structure to detect cold bridges , i.e. the main routes of cold air entering the apartment. It is important to find all the weak points in order to carry out comprehensive insulation . The main cold bridges in wooden windows include:

- the junction of the window frame and sash;

- wood from which the frame is made;

- glass;

- slopes, window sills and ebb.

It is better to insulate the slopes, ebb and window sill from the outside, the remaining elements require insulation from the inside, so you will have to work hard to turn an old wooden window into an airtight one that meets current comfort requirements.

If the window inspection and its insulation are carried out efficiently, you can count on an increase in the temperature in the apartment by 3-40C if you are connected to centralized heating, or on significant cost savings if individual heating is used. In addition, it will be possible to get rid of drafts. The other side of the coin is the cessation of natural air circulation. This problem is also typical for sealed plastic windows. Its solution is periodic ventilation or installation of special valves that allow you to regulate the amount of fresh air entering the apartment.

Be prepared for the fact that for effective insulation you will have to use several of the methods described below. Let's start with the technologies that are used for internal insulation.

No. 2. Insulation of windows with paper

The most ancient, simple and inexpensive way . Today it is rarely used, but it is suitable if the budget is very limited. There are several variations of this insulation method:

- newspapers, wallpaper, paper are torn into pieces, twisted into ropes, which clog the cracks between the sash and the window; to simplify the task, use a ruler, knife, screwdriver or other sharp tools. Some people advise pre-wetting the flagella in water;

- paper waste is shredded, soaked in water and wrung out. To the resulting mass add 1 part clay or 2 parts crushed chalk. The result is a plastic putty that penetrates well even into the smallest cracks.

The classic old-fashioned recipe involves sealing paper insulation with strips of fabric or paper . In order for them to stick well, they were moistened with a solution of laundry soap or a homemade paste was used. The latter can be obtained by mixing water and flour in equal proportions, stirring well and bringing the resulting mixture to a boil.

A more modern option is to use masking tape or special window tape . In this case, the task is simplified, but costs still remain. Windows insulated with paper cannot be opened for ventilation if it suddenly gets warmer in the middle of winter. In the spring you will have to remove the strips of paper/fabric/adhesive tape and take out the insulation. Visible marks remain on the window frames, sometimes even some of the paint is removed, so, unfortunately, you cannot do without updating the decorative coating. However, fabric and self-adhesive paper are the easiest to remove and leave minimal marks.

No. 5. Insulation of a wooden window with foam rubber and sealant

A much more modern, reliable and effective method of insulation is the use of foam tape and sealing cords.

Foam tape is inexpensive, but its service life is only about 2 years. This method of insulation is optimal when sufficiently large gaps have formed between the sashes and the frame. The installation process itself is simple, but labor-intensive, since everything needs to be accurately measured and carefully glued so that the window is well insulated, but at the same time does not stop closing normally. The main advantage of this method is the ability to open the window.

The process of insulation with foam tape comes down to the following:

- measuring the required length and width of the tape. The length should correspond to the perimeter of the valves, and the compressed width should correspond to the width of the voids;

- the places on the doors where the tape will be glued must first be cleaned of dust and degreased with alcohol or acetone;

- foam rubber tapes are produced, as a rule, with a self-adhesive base, so the task is simplified and comes down to only removing the protective layer and carefully gluing the foam rubber to the designated places;

- Some experts advise additionally sealing the window with paper tape, but this loses the main advantage of the method - the ability to open the window whenever you want. An alternative solution is to glue foam rubber in several rows.

Insulation made using sealing cords . They are made from different materials:

- rubber;

- polyvinyl chloride;

- polyethylene foam;

- polyurethane.

The main advantage of a rubber seal is its price, but when the temperature drops, it can harden and break. In addition, rubber is highly wear-resistant, so it is best chosen for windows that constantly open and close. Although other types of cords are more expensive, they perform much better in terms of operation.

Sealing cords are made in different shapes - the choice depends on the size of the cracks in the window structure:

- a seal whose profile resembles the letter P is suitable for windows with medium-sized cracks;

- seal with a D-shaped profile - for sealing fairly large gaps;

- seal type E - for windows with small gaps.

Tubular seals allow you to achieve a fairly high level of sealing, do not interfere with the free opening of the window, can be left in the summer and serve for several seasons in a row. The seal may have a self-adhesive base and then its installation will be identical to the installation of foam rubber tapes described above. If you take such a seal, pay attention to the shelf life of the glue: if it comes to an end, the cord may either not stick at all or quickly peel off.

The safest thing to do is to take a separate sealant and separate glue for it, which can be used as silicone sealant. In this case, the durability of the insulation reaches 5 years.

There is one more nuance. All work with tubular profiles is carried out at temperatures above +100C, so it is better not to delay it until cold weather. The seal must be glued very carefully so as not to disrupt the opening system of the sashes.

Which one to buy

There is a huge assortment. They are divided into acetate and neutral mixtures. Purpose of the first: increasing the tightness of glass. Second: sealing the seams between the smooth surface and the frame.

- Acrylic. It prevents air from penetrating through window joints, which means it perfectly retains heat in the house. When working with it, no special equipment is required. protection. The paint holds firmly on it and hardens quickly. If necessary, you can plaster. But there is one drawback - it is not resistant to humidity and begins to turn yellow over time.

- Polyurethane. Don’t know what sealant to use to seal cracks in plastic windows? Choose him! It is resistant to staining, temperature fluctuations and is practically unaffected by chemicals.

- Butyl. Used for PVC when connecting glass in double-glazed windows. It acts as a barrier to the penetration of water vapor between the glasses.

- Silicone. He is easy to work with. The consistency of the paste penetrates deep into cracks and joints, hardens quickly and creates excellent protection against air. Silicone putty for windows, suitable for outdoor use. You should also be prepared for the shortcomings: it comes off as a strip, just as it was applied, leaving behind an impressive gap. It will not be possible to paint over such sealant.

When choosing, pay attention to the composition of the putty, since each substance has its own advantages and disadvantages.

How to choose the right one

When buying sealant for window frames made of wood or plastic, you must be guided by the following qualities:

- Compatibility with other materials.

- Resist chemicals, temperature fluctuations, ultraviolet radiation.

- Stay not only on the frame, but also on a smooth surface.

- Long service life.

- Elasticity, strength, safety.

In addition, adhere to the following rules:

- Firstly: silicone for window frames cannot be painted over. Therefore, to seal a white plastic window, choose one with the same color. For any other shades - transparent.

- Secondly: if it is difficult to choose or to seal knocks of plastic and wooden structures at low temperatures, you should give preference to universal ones.

- Thirdly: new silicone synthetic pastes shrink after drying.

Important! Silicone protects better from mold and mildew.

No. 6. Insulation of wooden windows using Swedish technology

This is the most progressive, modern and effective way . Windows insulated using Swedish technology are actually equivalent in terms of tightness to modern plastic windows. This method also involves the use of a seal, only for it special grooves are prepared in the window sashes.

Swedish insulation technology involves the following procedure:

- dismantling the sashes;

- cutting thin grooves around the perimeter of the valves, which is carried out with a special cutter; the size of the groove must correspond to the size of the selected seal;

- installation in the grooves of the seal (polyurethane, PVC, polyethylene foam, less often foam rubber is used). No glue is used in this case - the seal holds well due to the thickenings existing in its design;

- applying silicone sealant to the junction of the sash and glass;

- if necessary, fittings and glass are replaced;

- installation of the sashes in place.

The durability of such insulation is 15-20 years , so the labor intensity and high price of the method are fully justified. It’s worth doing such work yourself only if you have at least a little experience in carpentry, otherwise you can only make things worse. The easiest way, of course, is to entrust all the work to specialists.

Windows insulated using Swedish technology can be opened at any time of the year, their appearance does not deteriorate, and sound insulation can be considered an additional bonus.

Best lists

We decided not to stop and compiled a small list of models:

Acrylic

Among acrylics, the best is Macroflex FA131 . And for good reason - it is frost-resistant, which is an excellent plus in winter. Perfectly hides all the cracks and voids.

Price tag: 128 rubles.

Liquid plastic

Liquid plastic is ideal for working with windows. We advise you to pay attention to Weiss Chemie Cosmofen 345. German quality and incredible adhesion will provide you with long and reliable service.

Cost: 619 rub.

Silicone

There are quite a lot of silicone sealants on the market. PENOSIL HIGH Temp is of good quality It is heat-resistant and perfectly covers all errors.

Price: 403 rubles.

No. 7. Insulating a wooden window with sealant

This method is aimed at thermal insulation of the junction of glass and sash . It can be done with your own hands, but will require a high degree of care and precision. The procedure is as follows :

- removing glazing beads, thin slats that hold the glass around the perimeter. During dismantling, almost all glazing beads break, so it is better to buy new ones in advance, and with a reserve. Removal begins with the lower bead, then the side ones are removed, and only then the top one; for this it is convenient to use a small knife or screwdriver;

- the seat inside the sash is thoroughly cleaned of dirt and dust;

- applying silicone sealant and installing the glass in place. All work on dismantling and installing glass is carried out wearing thick gloves;

- installation of new glazing beads.

Instead of caulk, you can use window putty . The procedure remains the same, only after installing the glass, excess putty must be immediately removed with a knife. In terms of aesthetics, this method is no worse, since subsequently the joint will still be covered with a new bead.

Rules of application

Do-it-yourself insulation of wooden windows using sealant is carried out using the following technology:

- remove irregularities, peeling paint and treat the work area with fine sandpaper;

- degrease the surface with a solvent;

- unpack the cylinder, insert it into the gun (it is possible to carry out work without this tool);

- squeeze out the composition so that it covers the surface to be treated with a thin line (the gap must be completely closed);

- remove excess substance, cover with cling film;

- wait until the composition dries (this takes about 5 hours);

- Remove the film and trim off the excess with a utility knife.

Compliance with the instructions will ensure quality work. The tightness of the structure depends on this.

No. 8. Insulating a wooden window with polyurethane foam

Polyurethane foam is used for internal and external insulation ; it fills large cracks well and is used to seal the joints between the frame and the slope, between the slope and the window sill, under the window sill, and between the frame and the top beam.

Working with polyurethane foam is not difficult, but you should know some nuances:

- filling is best done from the bottom up;

- As the foam hardens, it increases in volume, so filling the cracks costs about 1/3;

- work is carried out at air temperatures not lower than +5 and not higher than +300C;

- Polyurethane foam is destroyed under the influence of sunlight, so it must be covered with a layer of finishing material. However, it is unlikely that anyone will leave this material unfinished - it does not look very good.

Instead of polyurethane foam, you can use homemade putty . It is prepared from chalk and gypsum, which are mixed in a 1:2 ratio, and then water is added until a solution of a viscous consistency is obtained. This mixture easily fills all the cracks, and outwardly it looks much more aesthetically pleasing than polyurethane foam.

For indoor use

Representatives of this category of putties are not resistant to high humidity, are destroyed by heat and quickly lose their performance properties. Most of them are used as a temporary solution in emergency situations when no more effective means are available.

- Flour with sand. Regular food flour is used, which is found in most kitchens. Sand is added as a filler. Both materials are taken in equal quantities and diluted with water to a paste. In fact, the result is dough reinforced with sand. It is advisable to use fine river sand or similar materials, crushed to a state close to dust.

- Talc with vegetable oil. Instead of talc, you can use white or decorative cement. Vegetable oil (usually sunflower) should not be refined. This is necessary for the formation of sediment in it, which is used as one of the ingredients. The oily sediment is mixed with talc to a paste. The putty cannot be stored and must be completely used up within half an hour.

Putty application process:

No. 9. Heat-saving film for wooden windows

This method is aimed at increasing the thermal insulation qualities of glass , but today heat-saving film is also glued to a wooden frame. It works like energy-saving double-glazed windows, i.e. allows daylight into the apartment, but does not release heat. This film is made on the basis of polyester, and it receives unique properties to reflect thermal radiation thanks to metal coating. This is a transparent material that does not violate the optical properties of window glass, withstands the effects of detergents, is highly durable and makes the window safe, because if the glass is damaged, all the pieces will remain on the film.

The process of installing the film is simple, but it requires care, because it is important to stick it evenly, without bubbles, with the metallized side facing out. It is best to work with gloves so as not to leave greasy marks on the surface.

Thermal insulation film can make a window “warmer”, but cannot be used as an independent insulation material.

No. 10. We eliminate gaps in the sashes and frames

It is not enough to seal the gaps between the frame and the sashes, and between the sashes and the glass - the window will still let in cold air if there are cracks in the wooden elements . They certainly appear on wood as a result of temperature changes. It is not difficult to eliminate them; the following materials are used for this:

- paraffin. It is heated in a water bath to a temperature of about 700C, drawn up with a syringe without a needle and filled into all the cracks. Within an hour it will harden and turn into a serious barrier to drafts;

- special wood putty;

- sealant, and you can choose the material to match the color of the wood;

- homemade putty made from plaster and chalk, the recipe for which was described above.

Naturally, such thermal insulation measures will be most effective if you first remove the old decorative coating, then fill the cracks, and after that apply a new layer of finishing. Keep in mind that paint adheres worse to paraffin and sealant, so it is better to carefully remove their excess.

Rating of the top 7 best sealants for windows: which one to choose, pros and cons, reviews, price

If you need to glue something to a glossy surface or seal seams after repairs or voids on a window sill, then you will not find anything better than sealant. A viscous paste-like, sometimes tape-like, material made from polymers or oligomers is an indispensable thing for repairs, so we suggest you take a look at the TOP 7 rating of the best sealants for windows. Which one to choose, pros and cons, reviews, price and other useful information are collected in our material.

No. 11. How to insulate wooden windows from the outside?

Internal insulation is sometimes not enough. Slopes often need additional thermal insulation . Work on their insulation begins with the dismantling of the old finish, after which the surface is primed. The cracks can be filled with polyurethane foam; another option is to cover the slopes with polystyrene foam. After hardening, excess foam is cut off and the surface is treated with plaster. A polymer mesh is attached to the foam on top, perforated tape is placed in the corners, after which plaster is performed. All that remains is to prime and paint the slopes.

The window sill area is also sealed with polyurethane foam. A mandatory requirement is the installation of a special strip for drainage of rainwater. It should be inclined and have rolled edges so that moisture does not get on the walls or through the window. It is advisable to seal the joints between the plank and frame or slope with sealant.

It is better to insulate the area under the window sill with polystyrene foam from the outside, because in a third of cases the most heat flows away through this area.

The final touch of external thermal insulation is updating the paintwork. The old peeling layer of paint can be removed using a spatula and a hair dryer, and fresh paint or varnish can be applied instead.

No. 12. Insulation of wooden windows in a wooden house

A wooden house places increased demands on the aesthetics of all work carried out. In principle, you can use any insulation technology, but be extremely careful. It is best to use a transparent sealant for thermal insulation of the junction of glass and frame, heat-saving films, fill large cracks with polyurethane foam and then seal them with casing. An excellent way to additionally insulate windows in a wooden house is to install shutters .