Door structures made of polyvinyl chloride (PVC) are quite popular and occupy one of the main positions in terms of sales among all doors. The increased demand for products is explained by the lightness and simplicity of the design, the ability to effectively withstand moisture and temperature changes, combined with significant reliability. High-quality doors made of PVC must necessarily comply with the requirements set out in GOST.

Classification of doors according to GOST

In the process of manufacturing PVC door structures, manufacturers are guided by GOST 30970-2002 adopted and approved in 2002. This document specifies the dimensional grid of the door structure and permissible deviations. In addition, GOST strictly defines the main characteristics of all structural elements, including the profiles used on the PVC door, as well as the devices used. The required product labeling system, as well as guarantees and acceptable packaging, are mandatory.

GOST 30970 was developed specifically for swing PVC door structures with a frame. The requirements do not cover canvases for special purposes, as well as door mechanisms installed on balconies.

According to the derived standard and based on the principle of the main purpose of the leaf, PVC doors are conditionally divided into the following types:

- Entrance, street placement;

- Tambour;

- Interior and inter-apartment, as well as located in the internal parts of common areas.

In addition, door leaves are divided into types according to the filling principle:

- Deaf;

- Decorative;

- Glazed;

- Light.

The door that allows light to pass through is conventionally divided into 2 sectors: transparent upper and opaque lower. Glass used for installation in PVC doors can be multi-layered, reinforced, or made using additional decorative elements in the form of various patterns.

During the manufacture of solid door structures, an opaque fabric is used. Also, based on the structure of the structure, doors are divided into single-leaf and two-leaf. Designs that have one leaf, based on the opening side, can be left or right. Doors with various figured inserts are decorative.

Based on the type of external finishing used, door structures can be:

- White;

- Painted;

- Laminated;

- Covered with a layer of varnish.

When choosing and purchasing PVC products, please note that the sales contract will necessarily indicate the type of material used for the door, the presence of decorative elements, as well as the mandatory designation of the exact parameters of the product.

The manufacturing procedure itself must be carried out in a strictly defined sequence of actions. During assembly, the frame structure is necessarily reinforced with steel elements. During the process of strengthening the structure, the greatest attention should be paid to corner areas. If there is a threshold, metal is used to make it.

GOST 30970-2014 Door blocks made of polyvinyl chloride profiles. General technical conditions

- 91. Building materials and construction

- 91.60. Construction elements

- 91.60.50 Doors and windows *including door units, their components, blinds, shutters *door and window fittings, see 91.190

Document status: valid, put into effect 07/01/2015 Name in English: Door blocks of polyvinylchloride profiles.

Specifications Date of update of information on the standard: 09.17.2019, at 10:28 (less than a year ago) Type of standard: Standards for products (services) Date of validity of GOST: 2015-07-01 Date of the last edition of the document: 2015-02-02 Oil turbine TP-22s: technical characteristics, GOST and cleaning

Document codes GOST 30970-2014:

KGS code: Zh35 Number of pages: 36 Purpose of GOST 30970-2014: This standard applies to door blocks made of polyvinyl chloride profiles with frame structures for buildings and structures for various purposes. The scope of application of specific types of door blocks is established depending on operating conditions in accordance with current building codes and regulations, taking into account the requirements of this standard. This standard does not apply to balcony door blocks, as well as to door blocks for special purposes in terms of additional requirements for fire safety, etc. This standard can be applied for the purposes of product certification. The document was adopted by the body: Interstate Council for Standardization of Metrology and Certification, protocol No. 46-2014 Key words of the document: door blocks made of polyvinyl chloride profiles with frame construction panels, buildings and structures for various purposes, control methods, acceptance rules, reconstruction, repairs, construction, technical requirements

Regulatory references from the text of GOST 30970-2014:

Links to GOSTs: GOST R ISO 10140-1-2012 GOST R ISO 10140-2-2012 GOST R ISO 10140-3-2012 GOST R ISO 10140-4-2012 GOST R ISO 10140-5-2012 GOST R 54162-2010 GOST R 54170-2010 GOST R 54171-2010 GOST 111-2001 GOST 166-89 GOST 427-75 GOST 538-2001 GOST 5088-2005 GOST 5089-2011 GOST 7502-98 GOST 8026-92 GOST 9416-83 GOST 1 0354-82 GOST 15150-69 GOST 22233-2001 GOST 24866-99 GOST 26433.0-85 GOST 26433.1-89 GOST 26602.1-99 GOST 26602.2-99 GOST 26602.3-99 GOST 30673-2013 GOST 30698-2000 GOST 30777-2012 GOST 30778-2001 GOST 30826- 2001 GOST 30971-2012 GOST 31462-2011 GOST 31471-2011

Requirements according to GOST

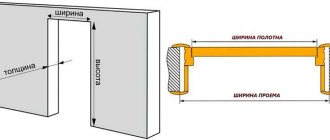

The regulatory document contains a clear description of the structure of the products and the drawings used for their manufacture. In addition, the installation stages are described in detail. So, doors made from PVC panels, according to GOST 30970 of 2002, must have dimensions not exceeding 6 sq.m. Moreover, each opening cannot have an area of more than 2.5 sq.m. The weight of the door structure should not exceed 80 kg. If permissible limits are exceeded, the manufacturer’s design strength calculation must be confirmed by a number of additional laboratory tests.

In the case of a vandal-resistant design, the door, in addition to additional strengthening of the corners, can be equipped with special anti-removal parts, as well as locking and hinge mechanisms, to increase security.

The standard also prescribes the installation method for PVC door blocks. Among other things, one of the very important aspects is the presence of a ventilation hole for the internal cavities of the canvas. Their required quantity was initially determined and specified in the list of standards.

The load on the door structure should also not exceed the norm. The maximum permissible difference in door leaf dimensions is also determined by GOST for a door area of 1.5 sq.m. cannot exceed 2 mm. If the dimensions of the canvas are larger, then the error in length and width should not be more than 3 mm. The dimensions of the grooves are also required to be specified in the regulatory document.

Types: PVC, MDF or veneer

GOST 23747-79 doors made of aluminum alloys.

general technical conditions PVC doors have gained a place in the product market, as they have a number of advantages. They are easy to install, and their low weight contributes to this. A small load on the hinges will allow the structure to avoid sagging in the future. Even pendulum models provide less force than if the canvas were made of a different material.

Structures made from PVC, like MDF, are non-toxic, environmentally friendly and fire-resistant - they are allowed to be installed in medical institutions, where pendulum models are also popular. A PVC film is applied to the surface, which easily turns into a pattern or design. The decor will look the same for many years - bright, clear and pristine. Moreover, this coating is resistant to sunlight.

The benefits don't end there. Despite the economy class, these doors have good sound and thermal insulation qualities, even pendulum models, so they are often used as office doors. Their quality guarantees their original appearance - after 5 years from the date of purchase, the surface does not fade or wear out.

High-quality technical characteristics are successfully combined with low cost, which is several times lower than the pricing policy for coatings that use MDF, veneer or eco-veneer.

Main characteristics of doors

The mandatory level of sound insulation of the product must be 26 dB, and the air flow capacity must be at least 3.5 cubic meters per hour, provided that Dp = 10 Pa. External doors made of PVC, according to GOST, must withstand a minimum number of openings and closings equal to 500,000 times.

Door structures are also divided into groups based on their ability to withstand static loads:

- A) must withstand a drop of a load weighing 20 kg from a distance of 0.8 m;

- B) must maintain the integrity of the canvas when a load of 20 kg falls from a maximum distance of 0.5 m;

- C) withstands a drop of a load of 10 kg from a distance of no more than 0.4 m.

If it is necessary to withstand a blow with a soft object, the indicators will be as follows:

- Group A is capable of withstanding a drop of a load weighing 450 kg from a distance of no more than 1.5 m;

- Group B can withstand the impact of a load of 300 kg falling from a distance of no more than 1 m;

- Group B must withstand a drop of a load weighing 60 kg, but the height cannot exceed 0.5 m.

In addition, the GOST standards specify the requirements for the door regarding the effort applied to open and close the door. Thus, internal doors made of PVC must be opened with a force applied by a person of 75 N. In this case, closing requires an applied force of 120 N.

Differences in color shades on the surface of the structure under normal lighting are unacceptable. In places where welding work is carried out, it is not unusual to observe color differences with the main part of the fabric. The seams of quality products cannot contain cracks.

To increase the protection of technical products, their surface is covered with a special protective film. Each of the elements used in the design must be tested and certified in a special laboratory.

Based on the personal wishes of the customer, it is permissible to use different colors when decorating the outer part of the product. Moreover, each of the structures must be equipped with special protection from exposure to UV rays.

Structural design of the vestibules

Double-floor structures can be closed using an impost or a frame structure. An impost is a plastic partition dividing a door or window in which a groove is installed for closing. The modern hinged design allows both halves of the door to be opened without creating obstacles or disrupting the view.

The frame design is relevant for offices, shops and entrance doors to the house. In this case, one half can be fixed to the latch and opened if necessary to carry furniture or other bulky things. Old interior or balcony doors with two leaves will perfectly replace plastic ones with a hinge that swing wide open outward. In the case of a balcony design, this design allows for more efficient use of the room area.

The hinged design is especially relevant for balcony doors

Gradually, the impost is becoming a thing of the past, giving way to a more rational design - the shulpovoy. In addition to improving the appearance, saving material, increasing the luminous flux, the frame system has increased anti-burglary resistance. Two plastic sashes are connected by snapping and are quite difficult to break open from the outside, unlike an impost structure. The locking mechanism can be attached to one leaf or two, and only a specialist can notice it.

Users also note the good tight fit of door leaves with a latch latch. This is especially true for a balcony door, as it allows you to retain heat in the apartment. Among the mechanisms of the latch design, the simple and economical latch version stands out. There are latches on the passive leaf at the bottom and top, and on the active leaf there is a handle that operates the door opening system.

Internal equipment

All steel structural elements are treated with protective materials to provide high-quality resistance to corrosion. When using aluminum, its nominal strength must correspond to the required parameters of the door block. The liner must be secured with a pair of screws or self-tapping screws. The fastening step cannot exceed 40 cm. When using colored profiles, this distance is reduced to 30 cm. The installation of amplifiers does not require the use of special tools. Installation of liners is done manually.

When producing blocks without transparent inserts, a three-layer PVC foam filling is used. It is permissible to use various finishing materials.

If the structure is supplemented with glass inserts, an anti-fragmentation coating must be applied. The glass itself is made by bonding it in several layers.

PVC or eco-veneer, which is better?

Another comparison with PVC is eco-veneer. It has the fancy name CPL, it is a synthetic product of modern industry. Veneer is often compared with it - there is a lot of information on the Internet about high quality and long service life. But in fact, this is not entirely true. Eco-veneer, of course, demonstrates many advantages, but among the disadvantages of this class of materials are a low level of sound insulation, the lack of possibility of repair and restoration in the event of strong shocks or direct impacts - the use of doors such as pendulum ones is clearly not recommended. And, of course, the material itself is synthetic. So you can easily understand where eco-veneer is inferior and why PVC is better.

When choosing doors, you need to pay attention to the manufacturer and company. To make a successful purchase, the first rule is “price-quality”, the second is personal experience, and finally, a large amount of necessary information

Door to the balcony

Balcony doors made of PVC, according to GOST requirements, may contain irreplaceable elements. However, this option is permissible only if they are of sufficient durability; the service life must be no less than the designated warranty period.

The internal filling of the balcony block must provide high-quality vapor barrier.

During installation work, the gap between the balcony window and the opening must be closed with a window sill. It is also permissible to use a layer of plaster or slopes. The approved fasteners are dowels, self-tapping screws or special adjustable supports.

The gaps between the doorway and the structural elements should not exceed 1 - 1.2 cm. The vertical posts are fastened in at least 3 places, and the distance between the fasteners should be no more than 0.7 m.

Operational advantages

All those who ask what PVC doors are and whether they are worth purchasing often do not imagine all the advantages that such doors have. But in fact, the technical parameters of these solutions are at a fairly high level. In terms of technical characteristics, door leaves, which are finished with polyvinyl chloride film, are significantly superior to their direct competitors - laminated doors.

So, thanks to the PVC coating, the door leaf has a high level of strength - the film copes well with any mechanical stress.

In addition to strength, the coating gives the canvas high moisture resistance. Such door leaves can be installed not only in all rooms, but also in bathrooms and toilets. This way you can make the interior more interesting and unique.

A polyvinyl chloride surface can withstand high temperatures and direct sunlight, while a regular laminated surface simply fades. A PVC door will delight its owner with rich colors and shades. In addition, polyvinyl chloride does not change its geometric characteristics in any way even at high temperatures.

In addition to the fact that the doors are not afraid of moisture, they also have high antibacterial resistance. They can even be installed in the bathroom - fungus or mold will not grow here. Also, the construction material will not dry out due to periodic temperature fluctuations and changes in humidity levels - the door will maintain its integrity under any unfavorable factors.

Polyvinyl chloride coating, as already noted, is not afraid of high temperatures - in the event of a fire, the film will not catch fire.

Accessories

The finished product kit includes: profiles, double-glazed windows, gaskets for sealing, door fittings.

PVC profiles are made from rigid weather-resistant polyvinyl chloride, they are durable, moisture-resistant and geometrically unchanged. The double-glazed window must be mounted from durable and anti-nuclear glass that meets all requirements. Sealing gaskets run along the entire perimeter of the box and fit tightly to avoid drafts and distortions of the structure.

A wide selection of fittings can give doors an elegant and aesthetic appearance. As with balcony doors, products according to this standard are equipped with similar hinges and locking mechanisms.