The common term “PVC doors” usually means plastic entrance, interior or balcony blocks. In fact, plastic structures represent two large directions and further, we will talk about the characteristics, advantages and disadvantages of these directions. And practitioners will receive a list of manufacturing companies they can trust.

What are PVC doors and how do they differ from PVC profile structures

In what rooms can plastic doors be installed?

Since developers of metal-plastic doors are guided by regulatory construction documents, the range of their applications is very wide. Such doors satisfy almost any requirement, except fire safety. They are applicable for various premises and purposes. But in some places they are completely irreplaceable. First of all, these are rooms with high humidity:

- bathrooms;

- toilets;

- swimming pools;

- kitchens;

- balconies and loggias;

- winter gardens and terraces;

- basements;

- boiler rooms;

- garages.

Wherever it is necessary to maintain stable temperature and humidity, plastic doors will be appropriate. The hygiene factor of such a doorway is also important. The canvas and frame, coated on the outside with a polymer composition, are immune to the chemical effects of household and industrial substances. They are easy to clean using ordinary detergents.

Photo gallery: where you can use plastic doors

Plastic doors are successfully used for baths and toilets

The front door serves as reliable protection for the home from intrusion.

Sliding plastic doors are used in places with wide passages

High-quality PVC doors are installed with balcony glazing

In addition, the vast majority of doors of this type are made to order according to individual parameters. This means that the manufacturer is able to give the product any shape, color and dimensions. The most daring design solutions are implemented without compromising strength and reliability. Exterior decoration imitates any material - wood, metal, fabric, etc. Inlaying the door leaf has become very popular - giving relief to the surface of the door. Colors are selected to match the wallpaper, floor or other interior elements.

Thanks to the variety of possibilities, plastic doors are increasingly found in government agencies, residential buildings, and enterprises.

Their shape can be classic rectangular or arched, in a medieval style.

An arched plastic door creates an original style in the house

Certification of plastic doors occurs in accordance with GOST 30970–2002. The standard regulates the technical characteristics that the product must have - air permeability (no more than 3.5 m3 per hour per square meter), sound insulation (at least 25 dB), etc. The state standard specifies the service life of a metal-plastic structure - it must be at least 40 years old.

Kinds

By type of construction they are divided into:

- Foldable. They have the shortest service life.

- Sliding.

- Swinging open. The most popular models.

- Depending on the door leaf. Has many options. There are models entirely made of plastic, and some with various inserts.

Also divided into:

- Single leaf.

- Bivalve.

Manufacturing of plastic doors

Making plastic doors is a complex technological process that cannot be repeated at home. Factories for the production of PVC doors and windows are equipped with high-precision equipment, robotic machines and laboratories for product quality control.

The main obstacle to artisanal production is the production of a metal-plastic profile, consisting of an aluminum base and a PVC layer fused on top. But even if you have a ready-made profile, it is not possible to assemble it into a monolithic structure in a garage or home workshop. In addition, the door, if it is not a solid option, includes a double-glazed window or a sandwich panel. Their production requires the presence of sophisticated compressor equipment and a device for extruding polymers.

Equipment for polymer extrusion requires spacious premises and cannot be operated in home workshops

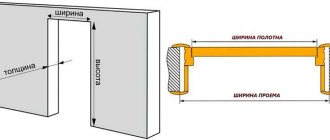

Even large manufacturers of this type of product have restrictions related to the dimensions of doors and windows. Thus, for PVC entrance doors the following maximum and minimum parameters are accepted:

- maximum permissible door leaf dimensions 940x2140 mm;

- minimum permissible sash height 900 mm;

- the minimum permissible door leaf width is 340 mm;

- the minimum permissible height of the door leaf with a five-point lock is 1870 mm (1970 mm in the double-leaf version);

- Products with a non-rectangular configuration are not covered by the manufacturer's warranty;

- in beveled imposts, the minimum permissible cutting angle does not exceed 45 °C;

- the maximum permissible side length of the trapezoid should not exceed 2010 mm.

The list goes on and on; each plant has its own maximum parameters for products. This is due not only to limited production capabilities, but also to the laws of strength and resistance of materials. In order to provide a warranty, design standards must be observed.

Repair and restoration

During operation of doors, breakdowns and failure of individual devices occur. It is not always possible or necessary to turn to specialists. Some defects can be eliminated independently, without outside help. Most often you encounter the following phenomena:

- glass cracks in a double glazing unit;

- door lock failure;

- hardware malfunctions.

Cracks in glass

The cause of cracks in glass is often violations of operating standards. This is either mechanical damage or the result of a large temperature difference. Some unlucky users place heating devices in close proximity to the double-glazed window. As a result, the temperature difference outside the door and inside the room reaches a critical value (about 90 °C) and the glass breaks.

In this situation, you cannot do without replacing the double-glazed window. It is necessary to very carefully remove the damaged glass from the frame, releasing the glazing beads. After this, a new double-glazed window is installed in the reverse order. Fortunately, today you can order any sizes from the factory. The cost of repair will not be so high, and it will take no more than two hours.

A sharp opening of the sash, accompanied by distortion of the canvas, can lead to cracks in the glass elements

Castle repair

You can also repair the lock yourself. The easiest way is to replace it with a new one. To do this, dismantle the rotary handle, remove the plastic decorative trim and unscrew the fixing screws at the end of the door leaf. Then the device is inspected, and if a breakdown is detected, the defect is eliminated. Perhaps the reason for the malfunction was a simple lack of lubrication or clogging.

If you cannot fix the problem on your own, you will have to buy a new lock assembly or spare parts for it. Each company that produces plastic doors has its own configuration features. Some equip their doors with locks of their own making, while others use products from third-party manufacturers. When replacing, you need to select either mother samples or interchangeable ones.

To repair the lock yourself, you need simple tools: a screwdriver, pliers, a file.

Video: installing a lock on a plastic door

Accessories

Fittings include door hinges, rotary or stationary handles, closers and door eyes. The main troubles happen with the hinges on which the sash is suspended. After some time after installation and grinding in under load, the blade may sag.

To restore normal operation of the door, there is no need to change the hinges or call a technician. Using a hex wrench of the appropriate size (it must be included in the hinge kit) and information from the technical documentation, you can independently adjust the operation of the hinges. To do this, you need to free them from the plastic covers, find the adjusting screws and turn left and right to achieve the normal position of the sash.

It is recommended to adjust door hinges not only when the door is already sagging, but also preventatively, at least 2 times a year

Video: adjusting balcony door fittings

Installation features

The installation of a plastic entrance door with glass must be carried out with the utmost precision; this work should be entrusted to professionals.

Installation is carried out in several successive steps:

- The first step is to install the door frame.

- Specialists install vertically located load-bearing elements. After this, horizontal elements are attached to the vertical elements.

- The next step is glazing the canvas. Glazing is carried out only if the canvas is brought to the installation site disassembled - with the double-glazed window removed. The glass unit must be secured to the profile using a sealing compound, and then covered with a horizontal strip in the center of the panel. But, in most cases, the manufacturer delivers ready-to-install entrance doors with built-in double-glazed windows.

- Installation of fasteners. At this stage, the type of parts used matters:

- If there are hinges, the frame is first mounted, and then the sashes are attached to the hinges. The canvas is hung first on the lower hinges, then it is closed and the hinge at the top is secured with a pin;

- in the case of a rail-carriage mechanism, you need to install tracks;

- With a carousel system, it is necessary to install the shaft and install the blades.

- At the final stage, work is carried out to seal the door.

Caring for plastic doors

Sellers often assure buyers that once they spend money on purchasing a plastic door, they don’t have to worry and forget about maintenance. Unfortunately, this is just a myth. Plastic doors, like all others, require maintenance. Of course, plastic is less whimsical and capricious, but it still needs regular “water procedures”.

First of all, attention is paid to the glass, the cleanliness of which determines lighting and visibility. They are cleaned once a month or as needed. Special detergents are used, but in the absence of these, ordinary soapy water can be used.

Inexpensive cleaning products will help keep your door window clean

In addition to glass, drainage channels (entrance and balcony doors) and rubber seals must be cleaned. If dirt and debris accumulate in large quantities in the folds of the seal, very soon it will fail or tear. It is recommended to inspect and clean your gutters twice a year. If damaged parts are found during the inspection, they must be replaced. You need to pay special attention to the sealing rubber located on the threshold. It is most susceptible to the accumulation of debris. It is recommended to clean thresholds with a vacuum cleaner.

It is strictly forbidden to clean glass units using solvents, gasoline or sandpaper. Detergents should not contain abrasive crumbs.

Door fittings also require regular lubrication. Ideally, lubrication is carried out during maintenance of fittings (door handles, hinges and locks), but at least once a year. In this case, oily liquids recommended by the manufacturer are used. WD-40 is used for internal doors, external structures are treated with frost-resistant lubricant.

Universal lubricant will always help keep the door in good condition.

Colors

The style and character of the room determines the color scheme of all furnishings in the rooms or building, this also applies to doors. Since plastic is easy to paint, the possibility of making doors of different colors will not raise any doubts.

Doors in this regard may have the following characteristics:

- The glossy surface of the door can have the desired shade, it all depends on the desired effect.

- A matte finish will add a resemblance to rubber and make the color softer and warmer.

- The ability to add texture and any color can create the effect of wood, stone, metal or other material.