A private home is always associated with warmth and comfort. Fireplace and large spacious rooms. Everything is natural and environmentally friendly. But in reality, it is not so easy to achieve warmth without high-quality and time-tested materials.

Insulating a house is the most important issue during renovation. The wide range of insulation materials on the building materials market very often confuses people. What to choose, which material is better?

In any case, a choice must be made. To avoid guessing for a long time, you should choose foil-coated isolon. This is a material that is suitable for any type of insulation. It is practical and versatile. And the article will help you draw the right conclusions.

Compound

Foil-coated isolon is the most popular material for insulating private houses. Despite its relatively high cost, its use is only gaining momentum. It is used not only for floors, it is also used to insulate walls and roofs. The versatility of the material makes it possible to use it in absolutely any direction of construction.

The basis of isolon is polyethylene foam, which is recycled several times. Modern technologies make it possible to create a fine-mesh structure, the thickness of which can be adjusted. A thin layer of foil is applied to the outside of this material. This layer serves not only for additional thermal insulation, but also plays the role of protection from environmental influences.

Classification

Izolon is divided into two main types: NPE - non-crosslinked and PPE - crosslinked. The first type is produced using the following technology: polyethylene undergoes three stages of vertical air foaming.

Non-crosslinked isolon is produced using the latest technologies and the most modern equipment. To produce it, a liquid polymer is used, which is preheated and melted, after which it is filled with carbon dioxide. Due to this, closed pores are formed. The canvas turns out uniform.

Isolon is also divided according to the thickness of the main layer (the foil coating is not taken into account here). The minimum thickness of the material is 2 mm, but the maximum often reaches 5 cm. The choice depends on the area of application - industrial, engineering, residential.

Cottage and House - Vapor permeability of materials on the Perm scale

Vapor permeability of materials on the Perm scale

The vapor permeability of building materials in the USA is measured in comparative units Perm (from the term permeability - permeability).

The article was written based on materials from the brochure “Vapor Permeability of Common Building Materials” EEM-00259, University of Alaska, Fairbanks, 2011.

In cold and humid climates, the best vapor barrier is polyethylene film with a thickness of 150 microns or more. In wet rooms (bathrooms), the thickness of the film vapor barrier must be at least 250 microns.

Construction materials are divided into:

Vapor-tight (vapor permeability less than 1 perm): Polyethylene, foil materials up to 0.1 perm Roofing felt 0.4 perm Oil paint, vinyl wallpaper, EPS - up to 1 perm

Conditionally vapor-permeable (vapor permeability 1-10 perm): OSB - 1-2 perm Plywood, foam plastic, glassine, latex paints from 1 to 10 perm Kraft bitumen paper (glassine) 1.5 perm

Vapor permeable (vapor permeability more than 10 perm): Gyprok, ecowool (cellulose insulation), glass wool, thin glassine - more than 10 perm

Vapor barriers according to the International Building Code 2009 (IRC 2009) are divided into three classes: Class I: vapor permeability less than 0.1 perm. II class 0.1 -1 perm. III class 1-10 perm.

Materials such as OSB-3 are “smart vapor barriers.” Thus, at normal humidity, the vapor permeability of OSB is about 2 perm, and when humidity increases to 85%, the vapor permeability of OSB increases to 12 perm.

Rating of vapor permeability of building materials in perm (perm).

Attention! For every doubling of the thickness of a layer of building material, vapor permeability decreases by 50%.

Advantages

Isolon foil insulation has a lot of advantages. Thanks to this, it has a leading position in the market not only for residential applications, but also in industry, the transport sector and even in medicine. Below is a list of the benefits of isolon.

- High thermal insulation performance.

- Almost zero vapor permeability.

- When using isolon, additional waterproofing is not required, since the material does not absorb moisture.

- Has soundproofing properties.

- Installation does not require special knowledge, so it is very easy to carry out insulation yourself.

- The material is elastic and easy to cut.

- Non-toxic during operation.

- Service life is not limited. Izolon is resistant to any climate influences and does not rot. Service life from 100 years.

- Can be reused if necessary.

- Can be used in conjunction with other thermal insulation materials.

- It does not change its chemical composition over a long period of time, which cannot be said about other types of thermal insulation.

- The high thermal conductivity coefficient of foil-coated isolon allows its use in various fields.

Flaws

Having studied the list above, we can assume that foil insulation is the most ideal option for insulating a house. It is so indeed.

Among the disadvantages of this material is only its cost. Due to the fact that the material has a non-destructible structure and is absolutely environmentally friendly, its price may not be affordable for everyone.

The cost is undoubtedly worth it. Long-lasting performance and recyclability are qualities that few materials have. Otherwise, foil isolon has no disadvantages.

Areas of use

Insulation with foil insulation can be done not only on the floor. It has a lot of properties. Therefore, the use of foil isolon is very wide.

- Insulation of residential premises: walls, floors, roof and even foundation.

- Soundproofing and insulation of workshops and utility rooms in production.

- Very often, foil-coated isolon is used for car repairs, it replaces rubber gaskets or is used as an addition to welding.

- The orthopedic direction in medicine uses this environmentally friendly material for the production of insoles, arch supports and anti-deformation inserts. Due to its structure, isolon has good shock-absorbing properties.

- When assembling refrigerators, PPE is used as additional insulation. Used in refrigeration equipment designs.

- For thermal insulation of baths, saunas. Retail premises, warehouses.

- Pipeline production - gas, ventilation.

There are many areas where isolon is used. This is due to its versatility and practicality. The soft and flexible material allows you to give it any shape.

Foiled penofol for frame housing construction

It should be borne in mind that Penofol, due to its small thickness, does not retain heat very well and cannot be used as the only insulation. Penofol is equivalent to stone masonry five centimeters thick.

Penofol - reflective thermal insulation - a new generation of insulation. Unique thermal insulation properties with low thickness.

Penofol is produced in rolls, in an assortment of thicknesses, perforations and self-adhesive layers.

Penofol A consists of polyethylene foam coated with one

sides with aluminum foil 14 microns thick.

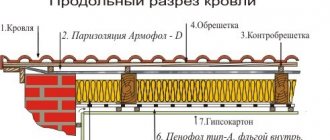

It is used for internal steam, noise and heat insulation of walls, floors, roofs, thermal insulation of air ducts and pipelines indoors.

Thermal conductivity coefficient 0.049 W/mK

Packaging: in rolls.

PENOFOL® - heat, - vapor barrier with a reflective effect. This is a layer of foamed self-extinguishing polyethylene with closed air pores, coated on one or both sides with high quality aluminum, 14 microns thick and 99.4% pure.

By the way! It will be interesting to know: Cold roof - is waterproofing necessary?

PENOFOL® has steam, hydro, wind and sound insulation properties. The material is thin, flexible, lightweight and environmentally friendly.

Main technical characteristics of insulation "PENOFOL" according to the Technical Assessment (FTS Gosstroy of Russia) TO No. 0457-01

Sequence of work

To ensure that the material does not cause any problems during operation, it is worth remembering the general installation rules:

- The thickness of the foil-coated isolon is selected taking into account the characteristics of the surface that is being insulated.

- Using a sharp construction knife, cut the material into pieces according to pre-made dimensions.

- When laying foil self-adhesive isolon, remove the protective film and, lightly pressing, lay the material on the surface. In order to avoid the formation of voids, it is more convenient to do this with a roller or brush in one direction.

- To adhere isolon without an adhesive layer to the surface, you need to use acrylic glue or solutions of type No. 888.

- For greater strength, cover the joints with construction tape or fasten them with a stapler. It is better to use metallized tape. This is the most durable material, and the joints will definitely not come apart.

As you can see, the work is not difficult, and anyone can handle it. You just have to start.

What is penofol?

Penofol is a foamed, foil-coated polyethylene with a closed-cell structure. Today you can buy the following types of this material:

The thickness of the pillow may vary.

Penofol has the following characteristics:

How to make long-burning stoves with your own hands: diagram, necessary materials and tools, useful tips.

About where a long-burning furnace can be useful during mining is written here.

By the way! It will be interesting to know: Vapor barrier - which side to lay it correctly towards the insulation and other features of the use of membranes

Floor insulation process

The key to a cozy home is a warm floor. Izolon will help you create such an atmosphere. You have no doubt about it.

Floor insulation with foil insulation can be done either together with other insulation or without it. It depends on the climate, weather conditions and the desired result.

In the first case, mineral wool is more often used. The main rule here is to ensure that the isolon joints are located on the slats and taped.

Before starting work, it is worth dismantling the old insulation and laying bars on the surface to which we will attach the material. Also, these bars will separate the layers of mineral wool from each other. The foil should be on top. The slats are laid on top of the isolon perpendicular to the first row. Mineral wool is laid, and another layer of isolon is laid on top with the foil layer down. This method of insulation is suitable for northern climates.

Isolon spreads on its own onto a wooden surface. Metallized tape is used to fasten the joints. Izolon is covered with plywood, and then the final floor covering is installed.

Let's sum it up

So, we found out that there are several types of foil insulation:

- polystyrene foam in sheets for flooring;

- mineral wool in sheets and rolls;

- penofol;

- shells for insulating pipes made of foam plastic and mineral wool.

All types of insulation, except shells, with a reflective layer are intended for internal insulation. The foil should be placed in the middle of the room. Such materials are suitable for external insulation, since the concept of reflecting IR radiation is reduced to nothing. Therefore, there is no point in paying for something that will not bring results.

Foam and mineral wool slabs must be glued using a special plaster-adhesive mixture from trusted manufacturers. The latter include the same Knauf or Ceresit. Laying on the walls is carried out from the bottom up, the sheets are additionally secured with dowels. And the most important thing is the presence of a ventilated gap in front of the reflective surface. If it is not there, then instead of reflecting heat you will get even more heat leakage and, in addition, mold on the finish.

Materials used in the construction of roofs and arrangement of premises with non-standard temperature and humidity operating conditions are endowed by manufacturers with special properties. They not only easily resist the attacks of steam-saturated hot air, but also create a “thermos” effect, due to which energy consumption for heating is greatly reduced.

These specific products include foil vapor barrier, the installation of which allows you to solve a lot of important problems in the construction of building structures.

Wall insulation process

If the process of floor insulation is a common thing, then the insulation of walls with isolon became known relatively recently. There are almost no differences in the process of laying thermal insulation. Therefore, you can handle the work yourself.

Important! It is worth selecting isolon taking into account the characteristics of the surface for insulation.

Insulation of walls is carried out in the following order.

- The walls are prepared: cleaned and, if necessary, leveled.

- The bars are laid at a distance of 50-60 cm. They are fastened with self-tapping screws, the heads of which are puttied.

- Isolon foil is attached to these bars with construction tape inside the room. This is done so that the material reflects heat.

- Slats in two rows are installed on the coating perpendicular to the bars. Next, the main wall covering is installed. It is worth remembering that the slats are laid in two rows for high-quality fastening of the main covering.

Tools for working with isolon

Foil isolon has a very elastic and flexible structure, so it is very easy to work with. You will need few tools. Everything you need is always at hand.

- Construction knife.

- Screwdriver.

- Construction stapler.

- Hammer.

- Metallized tape.

These are the main tools needed to work with foil insulation. Depending on the situation and room, additional materials may be used.

How to choose isolon

To ensure that funds for insulation are not wasted (the material is very expensive), it is worth knowing which type to choose, depending on the room. The characteristics of foil-coated isolon depend on its thickness, so the main selection criterion is based on this.

To cover the floor, a thickness of 2-4 mm is required, and for interfloor ceilings it is worth using a thickness of 20-30 mm. To insulate large pipes, 10-30 mm is also suitable.

To carry out roof insulation work, it is worth selecting isolon with a thickness of at least 15 mm. This will allow you to use the attic space as a storage room. In the case of creating a residential attic, the thickness of the thermal insulation should be from 30 mm. For the equipment of such interiors, isolon is necessarily used as an additional coating of mineral wool.

Isolon with a thickness of 4-20 mm will help reduce vibration and impact noise.

The overall atmosphere in the house depends on what material you choose. Additional sound insulation will not hurt if, for example, there are railway tracks or a busy highway nearby. In any case, isolon, even if it is not thick, will help you make the room more comfortable and warm.

Types of insulation

The material comes in the following types : roll, sheet, foil and isolon tape.

Rolled isolon has a thickness from 2 to 10 mm, width from 80 to 150 cm, length from 50 to 200 m.

is marked as follows: the first 2 digits indicate the foaming ratio, and the second - the thickness of the sheet.

For example, Isolon 3005 has a thickness of 5 mm, a foaming ratio of 30 and a density of 33 kg/m³. Table 1 . Characteristics of rolled isolon

| Izolon PPE | Thickness, mm | Density, kg/m³ | Roll length, m | Sheet width, m |

| 3003 | 3 | 33 | 170 | 1,5 |

| 3005 | 5 | 33 | 100 | 1,5 |

| 3008 | 8 | 33 | 60 | 1,5 |

| 3010 | 10 | 33 | 50 | 1,5 |

Important : Izolon of various thicknesses with a foaming ratio of 30 differs in the number of meters per roll, but has the same density and sheet width per roll.

Indicators of the expansion factor of foaming are poorly understood by the buyer, so you can use the table of the dependence of the expansion factor on the density of the material.

Table 2 . Density and foaming ratio of rolled isolon

| Density, kg/m³ | 200 | 100 | 66 | 50 | 33 | 29 | 25 |

| Foaming ratio | 5 | 10 | 15 | 20 | 30 | 35 | 40 |

Leafy . Available in slabs 1*2 m or 2*1.4 m. Thickness can range from 15 to 100 mm.

Foiled . Available in both rolls and sheets. It is distinguished by the presence of a foil layer on 1 or 2 sides, attached by lamination. Therefore, the letter “l” appears in the marking. Width - 1.2 m, length - from 80 to 300 m.

Isolon tape . It is distinguished by the presence of an adhesive layer with a protective paper membrane on 1 or 2 sides. The roll width is 1 m, length - 10, 20 or 30 m.