Penofol is an insulation material defined as a heat-noise-moisture-insulating material. It is made from environmentally friendly substances, and is thin and light in weight. In industrial and civil construction it is used for:

- basement insulation;

- wall insulation;

- attic insulation;

- ceiling insulation;

- roof insulation;

- floor insulation;

- hydrothermal insulation of pipes;

- thermal insulation of air conditioner;

- hydrothermal insulation of external walls;

- strengthening waterproofing and massive insulation;

- dust protection;

- repair of ceiling covering;

- strengthening walls;

- door insulation;

- insulation of water heating elements.

In the automotive industry, Penofol is used as a material for sound insulation and insulation of vehicle interiors.

Specifications

Material classification

The following types of foil Penofol insulation are available:

- Type A - material based on polyethylene foam with foil on one side;

- Type B - material based on polyethylene foam with foil on both sides;

- Type C (self-adhesive) - a material based on polyethylene foam with foil on one side. It refers to self-adhesive insulation, due to the fact that a layer of glue is applied to the other side, which is protected by an adhesive coating.

There are also varieties of Penofol. Depending on the additional coating, they are divided into: A, B, C-LL - with lamination with polyethylene terephthalate film; A, B, C-LP - with lamination with polyethylene film; A, B, S-M - embossed with foil on one side; A, B, CR – embossed with foil on one side;

Perforated

Recently, the production of Penofol with perforation has been launched, i.e. the ability to remove moisture from the material. This type of insulation is used mainly on the external facades of a building. Walls where Penofol was used as insulation acquire the ability to “breathe”.

Penofol is made from polyethylene foam onto which aluminum foil is fixed by pressing on one or both sides. It is acceptable to use polyethylene foam of several brands, and not just PPE, in the absence of deterioration in the quality and properties of the insulation. The adhesive layer must be protected by an adhesive material.

Roof insulation with penofol - convenient, effective, affordable

Roof insulation with penofol. If you are looking for high-quality and inexpensive insulation for arranging a roof, attic, attic or ceiling, then our company will be happy to offer you foil Penofol - a new universal thermal insulation product that has a lot of obvious advantages.

By purchasing Penofol for a roof, you will simultaneously solve several issues at once, because it is not only an insulating material, but also a product that is widely used in waterproofing, soundproofing and vapor barrier of modern buildings.

Thus, by correctly installing reflective foil and polyethylene foam, you have the opportunity to create a high-quality and energy-efficient attic and at the same time receive significant savings in time, effort and money.

The main modern insulation materials are in many ways inferior in characteristics to Penofol, so our store’s assortment includes different types of material based on foamed polyethylene, but for roofing work there is no alternative to Penofol A-05, and for finishing the ceiling surface indoors, type C can be used .

Roof insulation with Penofol will allow you to achieve excellent results with minimal time and financial costs. When building a summer house, cottage, laying in the roof and on wooden floors will provide you with a comfortable temperature inside the room at any time of the year. Insulation with Penofol is carried out in attics, installed in attics, verandas, gazebos, summer kitchens, etc., and Penofol is also installed on the ceiling, thereby ensuring reliable thermal insulation of the structure of a house or garage.

- You don’t know how to attach Penofol?

- How to glue Penofol to penoplex?

- Is Penofol harmful to health?

- How to fix Penofol to the ceiling?

- Which side should I lay it on?

- Penofol or Tepofol, which is better?

Our production specialists will be happy to advise you on any questions, tell you about roof insulation with penofol, installation and technical characteristics of our products. Reflective insulation is suitable for construction work on any residential, commercial or industrial site. Heat, hydro, noise and vapor insulation for roofing using reflective insulation in accordance with GOST is in great consumer demand today, since this unique insulating material is characterized by such important consumer qualities as:

- strength – resistant to mild mechanical stress;

- reliability - firmly attached to the false ceiling in flat roofs;

- practicality - performs several functions at low cost;

- multifunctionality - has the effect of insulation and vapor barrier;

- versatility - can be used in any rafter structures and roofs;

- resistance to temperature changes, ultraviolet radiation and other negative factors

- ease of installation - just nail the penofol with a stapler and glue it with tape;

- Penofol insulation is very economical and does not require large installation costs;

- durability – Penofol service life is up to 50 years;

- environmental friendliness - absolutely environmentally friendly material.

Insulating a private building, country house, or any other type of premises with Penofol does not require special training, complex tools or additional installation elements and specific tools. The main thing is to provide a ventilated gap on the foil side of at least one centimeter and seal the joints with aluminum tape LAMS.

Insulation thickness and length

The cost of insulation directly depends on its thickness. The larger it is, the higher the price. Also, the cost increases depending on the number of foil sides and coating layers.

Manufactured in thicknesses: 3mm, 4mm, 5mm, 6mm, 8mm, 10mm (up to 40mm thick on request in rare cases). Penofol 1 centimeter thick has the highest noise protection and retains heat best. The material with a thickness of 5 mm remains in first place in popularity, due to the optimal ratio of quality and price. Available in rolls. Standard roll length (depending on thickness): 5m, 10m, 15m, 30m, 50m.

Foiled polystyrene foam

Izospan is foil-coated polystyrene foam produced in Russia. Its thickness is minimal when compared with mineral wool. However, thanks to the technical characteristics of the material, it can be easily used in a fairly wide temperature range - from -170 to +170 degrees. Such fluctuations occur quite rarely, so the material serves without any complaints for decades.

Izospan is the most popular insulation material on the domestic market, which is chosen when creating warm floors and thermal insulation of attic spaces. Izospan has the most effective heat reflection.

The ability of insulation to absorb water

The ability of any product to absorb and retain moisture is called water absorption. When this value is high, the thermal conductivity and specific gravity increase and the strength of the material decreases significantly.

Penofol's water absorption depends on its type: Type C - 3.5%; Type B - 0.6%; Type A - 0.7%.

Vapor permeability is understood as the ability to transmit and retain vapors, therefore, with a large coefficient of this value, the thermal conductivity indicator is also higher. When using Penofol there is no need to lay additional film.

To compare the vapor permeability of different building materials:

- plywood - 0.02 mg/(m*h*Pa),

- polystyrene foam - 0.023 mg/(m*h*Pa),

- concrete - 0.03 mg/(m*h*Pa),

- DSP - 0.12 mg/(m*h*Pa).

- Penofol has a vapor permeability of less than 0.001 mg/(m*h*Pa).

What to glue it with?

A correctly selected adhesive solution for foil material does not yet guarantee a successful installation. For a quality connection of materials, it is necessary that the surface to be glued be carefully prepared. All defects, irregularities, and various debris must be eliminated.

Concrete floors and walls are leveled, cracks are sealed, and metal products are treated with an anti-corrosion agent.

Adhesive for foil insulation can be either specialized or universal. You can also use liquid nails, double-sided tape, or a thin layer of foam. The choice of glue depends entirely on the purpose of the surface and its further use.

The adhesive composition must correspond to the performance indicators of the insulating material:

- permission for indoor use;

- the toxicity of the solution should be 0;

- high resistance to adhesion;

- the glue must withstand temperatures in the range of -60 to +100 degrees.

In order for penofol to be reliably glued to the surface, the glue must be applied to the side that does not have a foil layer. The adhesive solution is applied evenly, without gaps. The edges of the panel are carefully coated with glue so that the foil material does not come off during operation.

Before you start fixing the penofol, you need to wait 5-60 seconds for the glue to dry slightly. This ensures better adhesion to the products. Penofol is pressed to the surface, holding it, and smoothed out with special care.

Penofol's ability to conduct heat

The thickness of the aluminum foil used to cover the layer of foamed polyethylene is from 12 to 30 microns. The percentage of pure substance is more than 99%. During Dewar's research, it was found that a number of materials are capable of almost completely reflecting thermal energy, however, due to this, the material can heat up and it becomes necessary to supplement the structure with a thermal barrier. In Penofol, the function of a barrier is performed by foamed polyethylene.

The level of thermal reflection of polished foil is at least 97%.

Important! Resistance depends on the thickness and type of insulation. For type B with double foil and a thickness of 4 mm, this figure is 1.20 m2*C/W; 5 mm thick - 1.23 m2*S/W, 10 mm thick - 1.355 m2*S/W. For comparison, the mineral wool layer for such resistance should be more than 85mm. The data calculation was adopted in accordance with SNiP.

Soundproofing

A unique property of Penofol is its ability to provide good sound insulation with a small insulation thickness. This property is actively used in the automotive industry and, if desired, can reduce noise from extraneous factors at home.

Considering that this material can be used both indoors and outdoors, and with a thickness of only 4-5 mm it can significantly reduce the noise of the apartment, this is undoubtedly a useful quality of insulation.

Penofol has sound absorption above 32 dB.

Explosiveness and toxicity

Temperature limits for use are from +100 to -60 degrees Celsius. At such temperatures, Penofol is an absolutely environmentally friendly material and is completely non-toxic. When using it indoors or outdoors, no precautions are required. The sticky adhesive used in the manufacture of Type C insulation is non-toxic. The adhesive used is based on a water-acrylic dispersion. The emulsion used is non-explosive and non-toxic. Hazard class - 4 (low hazardous substances). The material applied to the adhesive base to protect it is a lavsan siliconized film. Non-toxic.

Safety of polyethylene foam

Polyethylene is one of the most stable compounds on the planet. Polyethylene granules, which are used to make thermal insulation, are used to make water cans and bottles, food packaging, and water pipes.

At the household level, if used within the operating temperature range, polyethylene foam is harmless. PPE is dangerous when heated above 110-120 0C.

When burned, it releases acetic acid, formaldehyde, and carbon monoxide.

The decay period of the material is about 200 years. This, on the one hand, makes it one of the most durable materials (which is good). But on the other hand, polyethylene, like plastic, is a real disaster for the earth’s ecology, since a large amount of foamed polyethylene waste accumulates.

Fire safety of penofol

This material belongs to substances that are difficult to burn. Penofol has a corresponding certificate stating that it is not fire hazardous.

When burning Penofol:

- melts upon contact with an open flame;

- does not flare up;

- does not burn.

Important! In terms of flammability, Penofol belongs to group G1 (the material is slightly flammable, does not support combustion, does not spread flame). In terms of flammability, it belongs to group B1 (non-flammable, able to withstand heat flow of more than 500ºC). According to its ability to generate smoke, it belongs to group D2 (moderate ability to generate smoke).

Methods of using Penofol

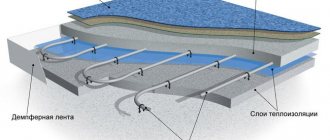

Use on the floor If it is necessary to insulate the floor, Penofol is installed on top of the logs, with the foil side facing up, without tearing. In general, type A with a thickness of 4 or 3 mm is sufficient. It is necessary to provide an air gap of 20 mm. Apply sealing insulation along the entire joint using aluminum adhesive tape.

When laying Penofol on a concrete base, it should be taken into account that concrete is an aggressive environment, therefore, when using Penofol, the floor is covered with plastic film or insulation coated with a protective film is used. Laying is done with the foil side up, butt joint. Sealing is done using mounting tape. A heating system is laid on top and filled with screed. Decorative flooring is laid on top: laminate, parquet, tiles.

Preserving heat from heating devices To increase the temperature in the room, it is reasonable to install Penofol type C or A on the wall behind the radiator. In practice, the effectiveness of increasing heat transfer from the battery by 20% has been proven. Using insulation 5-3 mm thick, you can increase the temperature in the room by 4 degrees.

Insulation of walls If in winter the room is damp and the temperature drops below 20C, insulation of the walls is necessary. It is possible to insulate the outside and inside of the house. The efficiency of insulation indoors is much higher. The use of insulation type A, B with a thickness of 5 mm is justified.

Type C application

In places where it is difficult to use Penofol type A and B, type C is used. It is actively used in the insulation of water heating boilers, sound insulation of air ducts, and thermal insulation of pipelines, which also eliminates the appearance of condensation.

Installation features

Laying penofol is carried out with the foil side always towards the heat, so that it could be reflected into the room. To eliminate the risk of condensation, a ventilation gap of at least 10-20 mm wide is formed on this side. The edges of adjacent workpieces are joined closely without overlap. To ensure the integrity of the protective layer, the seams are additionally sealed with aluminum vapor barrier tape.

sealing seams with aluminum tape Source neoenerg.ru

For walls, it is recommended to choose samples up to 5 mm thick with one foil side. If such a fabric is insufficiently effective, you should first insulate the room with penoplex. It is better not to use mineral wool boards in order to avoid assembling additional sheathing.

Penofol can be attached to walls by gluing it to a clean primed surface or using a construction stapler (with staples). A counter-lattice made of slats or plywood pieces is mounted on top of the insulator. Drywall, chipboard or other rigid sheet materials are sewn onto the finished frame.

Glue used for Penofol

Using glue to attach insulation has several advantages:

- low time and cost;

- does not require special skills;

- technologically simple;

- no need to use a professional tool.

But the load-bearing capacity of fastening with glue is not high and depends on the weight of the material. The advantage of Penofol is its weight. It's light. Gluing depends on the adhesive properties of the adhesive base, i.e. ability to penetrate into the pores of the surface for gluing.

Glue containing an organic solvent is the most effective. Also an important indicator for fastening strength is resistance to water.

The glue used in residential premises must be non-toxic. The safety of the adhesive can be guaranteed if it has an EMICODE certificate. To increase the effectiveness of the glue, you should clean the surface of dirt, dust, coating and eliminate all irregularities and cracks. When using an adhesive, you must strictly follow the instructions. Then, Penofol will last a long time and stick well.

Using the adhesive fastening method is inferior to other more common and reliable installation options:

- fastening with lags;

- fastening with staples;

- fastening with slats;

- fastening with screws, etc.

It is also important to remember that, regardless of the method of fastening, it is necessary to properly insulate all joints of the Penofol structure, and it is worth giving preference to the “joint to joint” installation method over the “overlapping” method. It is best to use special metallized construction tape as insulation. When insulating baths, saunas and other rooms with high humidity, it is better to give preference to other methods of fastening.

Scope of use

Foil insulators, due to the presence of a shielding layer, have a heat reflection coefficient of 97%. Thanks to this, they are very popular among developers. The most famous include such varieties of materials as Izospan, Rockwool and Izover.

If a house or apartment is located close to a roadway or railroad track, residents often hear the noise of passing traffic. When insulating a home with foil insulation, the effect of not only thermal protection, but also sound protection is created. In addition, moisture does not penetrate through such insulation, which eliminates the appearance of fungus and mold. Air humidity remains at normal levels.

Foil insulation is used quite widely. This mainly involves the construction of private houses and insulation of city apartments. The popularity of such materials is explained by a large number of advantages.

Today, foil insulation is often used in the industrial sector. Typically this application is for thermal insulation of pipelines. They can also be chosen when insulating production lines. Household use is also a fairly popular area of application for such insulators.

The main areas of use of these materials include:

- Thermal insulation of water pipes. Boiler rooms, heating networks and public water supply systems are insulated.

- There is another main option for using insulators with a foil layer - country pipelines. This helps protect them from freezing.

- Protection of production equipment from temperature extremes.

- Thermal insulators with a foil surface are also used for insulating the walls of baths, saunas, and bathrooms.

- When using such insulation, vapor barrier of industrial premises is also performed.

- Insulation with an aluminum layer is also installed in air exhaust systems. They are mounted in chambers, air ducts and channels.

- Often such an insulator is chosen for insulating the walls of residential buildings.

- Thermal insulation of attic spaces.

- Foil insulation is often used to soundproof floors.

Such areas of application of the material make it possible to understand why it is used quite often both in industry and in everyday life.

Analogues of Penofol

It is important to understand that Penofol is not the name of the insulation, but a specific brand. Therefore, there are a number of analog materials with similar properties.

Among the analogues are the following:

- Alufom Insulation made of foamed polyethylene covered with metallized film or polished aluminum foil. The areas of application are identical to Penofol.

- Izofol Insulation material consisting of one or two layers of polished aluminum foil or aluminum spraying on a Mylar film, covering polyethylene foam. Available in roll form. Used as heat, sound, vapor insulation. It is used in the construction of industrial and civil buildings.

- Stizol: Stizol F, Stizol F2, Stizol LM; Foamed polyethylene coated with a laminated metallized film (Stizol LM) or one (Stizol F) or two (Stizol F2) layers of polished aluminum foil. It is used as insulation for walls, floors, roofs, and other structures.

- Energoflex Insulation made of foamed polymer or polyethylene. Available in the form of tubes, plates, rolls. Widely used in heating, air conditioning and enclosing structures. The reflectivity of the rolls is 90%.

How to use

Foil materials are used to insulate floors, walls, doors, and insulate pipelines. With their help, it is easy to increase the heat transfer of batteries. The main installation rule: the foil should be directed inward, since this layer reflects heat back into the room.

Rules for installing self-adhesive Penofol:

- The layers are cut with a sharp knife.

- The layers should be placed strictly end-to-end and not overlapping.

- The wiring must be insulated.

- The installation joints are covered with self-adhesive aluminum tape to ensure complete sealing.

- If installation is carried out outside, then you must wait for dry and warm weather.

- Any surfaces are pre-cleaned of dust and dirt and, if possible, degreased.

- If the floor is covered, then the edges of the roll should extend at least 10 cm onto the walls.

- It is necessary to create a ventilation gap between the wall and the covering, since Penofol does not conduct moisture, and it will accumulate and moisten other structural elements. To do this, special slats are attached to the surface, and Penofol is placed on them.