For a long time, there was no alternative in this segment of the construction market: mineral wool, glass wool and foam plastic were usually used as insulation. Nowadays, most buildings are insulated with polymer materials, which are characterized by high heat saving rates, are easy to install, and can last a long time without losing their properties.

One of the popular types of insulation is technoplex. The insulation is suitable for interior and exterior decoration and has a number of undeniable advantages over analogues.

Let's consider the main characteristics of this material.

Technical and physical characteristics of the material

The manufacturer indicates the performance and other properties of the insulation on the packaging. Having carefully studied the instructions, you can understand that the technical characteristics of Technoplex (50 mm) look like this:

- sheet thickness – 50 mm;

- average density of the material – 26-30 kg/m³;

- compression resistance – up to 25 tons/m²;

- material water absorption rate (per day) – 0.2% of the total volume;

- use in the temperature range – from -70 to +75°C;

- flammability class - G4;

- heat capacity indicator – 1.45 kJ;

- vapor permeability coefficient – 0.01 m/h/Pa;

- bending strength – not less than 0.3 MPa.

As you can see, with low weight and minimal thickness, the material has the ability to withstand heavy loads, which significantly expands the scope of its application.

It is also important that this type of insulation is not prone to rotting or infestation by rodents and fungi. During operation, it does not emit harmful substances into the air and remains resistant to most chemical compounds (except gasoline and organic solvents)

TECHNOPLEX – TECHNONICOL

Scope of application TECHNOPLEX extruded polystyrene foam is specially designed for thermal insulation in private housing construction, including “warm floors” in apartments, insulation of balconies and loggias, floors on the ground and foundations of private houses.

Description XPS TECHNOPLEX extruded polystyrene foam is a thermal insulation board that is used to insulate balconies, partitions, and in floor construction and “warm floors.” XPS TECHNOPLEX is one of the best thermal insulation materials for country house and apartment insulation. In the production of XPS TECHNOPLEX, nano-sized graphite particles are used. Nanographite reduces the thermal conductivity of the material and increases its strength. Thanks to the saturation with nanographite, XPS TECHNOPLEX boards acquire a light silver tint. Advantages

- Saves your money due to better thermal insulation properties in terms of m?. in relation to other thermal insulation materials;

- Retains heat 1.5 times more efficiently than conventional foam plastics and 2 times more efficiently than stone and glass wool;

- Not afraid of moisture;

- Does not shrink over time;

- Does not contain formaldehyde;

- Not susceptible to rodents;

- Convenient and easy to use. Provides high installation speed;

- Stable characteristics throughout the entire service life;

- Convenient packaging for transportation.

Characteristics

| Main physical and mechanical characteristics: Name of indicator | Unit change | Criterion | Meaning | Test method |

| Compressive strength at 10% linear deformation: 20 – 39 mm > 40 mm | kPa | no less | 100 150 | GOST 17177—94 |

| Flexural strength | kPa | no less | 100 | GOST 17177—94 |

| Thermal conductivity at (25±5) C*: 80 mm | W/(m•K) | no more | 0,032 0,033 0,037 | GOST 7076—99 |

| Thermal conductivity under operating conditions “A and “B” | W/(m•K) | no more | 0,034 | GOST 7076—99 |

| Water absorption by volume | % | no more | 0,4 | GOST 15588—2014 |

| Vapor permeability coefficient | mg/(m•h•Pa) | – | 0,014 | GOST 25898—2012 |

| Flammability group | – | – | G4 | GOST 30244—94 |

| Flammability group | – | – | AT 2 | GOST 30402—96 |

| Smoke generation group/toxicity | – | – | D3/T2 | GOST 12.1.044—89 |

| Operating temperature | C | within | from -70 to 75 | STO 72746455—3.3.1—2012 |

| Geometric parameters | ||||

| Thickness | mm | within | 10 — 100** | GOST 17177—94 |

| Length | mm | within | 1180, 1200*** | GOST 17177—94 |

| Width | mm | within | 580, 600*** | GOST 17177—94 |

* – thermal conductivity measured within 24 hours from the moment of product release; ** – slabs with a thickness of 80 mm or more can be produced using the ThermoBonding method; *** – upon agreement with the consumer, it is possible to produce slabs of other sizes.

Dimensions of extrusion insulation

In order to correctly determine the required number of slabs, you should study in more detail the characteristics of Technoplex 50 mm. How many slabs are in the package, and what size they are, you can, of course, check with the seller, but it is better to have this information in advance.

So, from information from the manufacturer we know that the described slabs come in two types:

- with dimensions 118 x 58 cm;

- size 120 x 60 cm.

Also, insulation sheets can have different widths (from 20 to 100 mm). But since slabs with a width of 50 mm are considered the most universal, our article is devoted to them. One package contains 6 slabs of the same size.

Video description

A comparison of both insulation materials is clearly shown in the video.

Since both insulation materials have the same source material, they are harmless to the environment and humans, and are not afraid of almost any building mixtures or solutions. Throughout the entire service life, subject to operating conditions, no harmful substances are released. The flammability of both insulation materials is the same: they easily ignite and release asphyxiating substances. It is recommended to pre-treat the sheets with fire-retardant compounds.

Installation of both materials is similar and does not require special knowledge; a novice master can easily handle it.

Despite the strong similarity, most often the choice is made in favor of Penoplex. There are several reasons for this:

- Price . Penoplex is about 10-15% cheaper than Technoplex. For large volumes of work, the difference in cost can be significant.

- Sheet size . Both insulation materials have similar widths (58 and 60 cm) and thickness (from 2 to 15 cm), only the length differs. "Penoplex" is sold in slabs 120 cm long, less often 240 cm (only at maximum density). "Technoplex" is produced in the form of sheets of various lengths: 120, 240, 300, 400, 450 cm.

Insulation from outside Source avrora-sm.ru

Application and types of penoplex

Considering that penoplex has a number of advantages, its scope of application is quite extensive. EPS serves as an excellent insulation material both indoors and outdoors. It is perfect for apartments, houses, cottages and other buildings. Penoplex can be used to insulate roofs, attics, and balconies, in any climatic region without the use of an additional moisture-proof layer. Since the material practically does not absorb water, it is quite possible to use it in an environment with high humidity. At the same time, its thermal conductivity remains almost unchanged. EPS sheets of various thicknesses are available for sale, and depending on the specific requirements, you can always choose the best option.

In addition to a variety of sizes, extruded polystyrene foam is available in several types depending on density and application. Let's look at each type:

Penoplex Wall. The old name is Penoplex 31 with fire retardants. This material has a density of 25-32 kg/m³ and is intended for effective insulation of external and internal walls, partitions, and plinths. These slabs are also used in the construction of buildings when constructing walls using “well masonry”. Compared to traditional brick walls, such walls are much thinner, but are not inferior to them either in reliability or in the ability to retain heat. In case of insulation of external walls with penoplex, a plaster system can be made on top of the insulation using a mesh, or it can be lined with any façade cladding material (siding, tiles, lining).

Penoplex Foundation. The old name is Penoplex 35 without fire retardant. This material has a density of 29-33 kg/m³ and has high thermal insulation characteristics, a minimum coefficient of water absorption and resistance to chemical and biological destructive factors. Its water-repellent ability allows it to be used as a waterproofing coating. Penoplex Foundation is a rigid slab with a stepped edge, used in the construction of basements, foundations, and insulation of septic tanks. The slabs are very durable and can withstand significant loads. Therefore, they can also be used as a basis for garden paths, plinths, and floors.

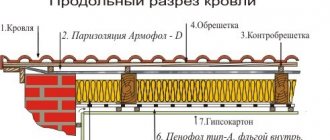

Penoplex Roofing. The old name is Penoplex 35. This material has a density of 28-33 kg/m³ and well insulates the building from cold air, has minimal water absorption, the ability to insulate noise well, and has a long service life. The slabs have a standard size of 600x1200 mm, but if necessary they can be easily cut with any available tool. And the light weight of the slabs allows them to be used without reinforcing roof structures. The stepped edge located along the perimeter acts as an additional guarantee that “cold bridges” will not form at the joints of the slabs. This type of penoplex can be used to insulate any type of roof. However, more often this insulation is used for insulating flat roofs, as well as for insulating the attic space of a ventilated roof.

Penoplex Comfort. The old name is Penoplex 31C. This material has a density of 25-35 kg/m³ and has an extremely low thermal conductivity coefficient, high hydrophobicity, and excellent ability to insulate noise. It does not rot and is not a favorable environment for the settlement of insects, mold and fungi. Penoplex Comfort is produced in the form of slabs measuring 600x1200 mm, which have a step-shaped edge along the perimeter. It serves as an additional guarantee of accurate installation. Being a kind of universal, this insulation is simply ideal for thermal insulation of a private house. They can be used to insulate floors, foundations, basements, roofs and walls.

Penoplex 45. This material has a density of 35-47 kg/m³ and is used as insulation for road surfaces, in particular runways, to prevent them from frost heaving of the soil and destruction of the top layer of the road surface. It is also widely used for insulating roofs in use, on which there are pedestrian areas and various areas, including parking lots.

Description and features of the material

Technoplex insulation is made from polystyrene granules, which, under the influence of high temperature and high pressure, are mixed with a special foaming composition and graphite. The viscous mass is sent into molds of a certain size, where it hardens and is cut into sheets of standard parameters.

The final product is smooth and dense. The structure of the sheet consists of a large number of small closed cells that do not allow air to pass through. Thanks to this, the characteristics of Technoplex (50 mm) are quite high. Graphite additives significantly improve the thermal insulation abilities and increase the strength of the slabs.

Products are sold in rectangular packaging, the size and weight of which depends on the size of the material.

Basic installation rules

TechnoNIKOL xps 35-250 slabs are available in polyethylene film packaging, which is distinguished not only by its heat shrink properties, but also by its UV stabilization.

Whenever you purchase products, they should be stored in a place where there is no direct sunlight. You can keep materials exposed to direct rays only before starting work, but this time should be short. All slabs are manufactured with a width of 580 mm and a length of 1,180 mm, but the thickness can be different: from 40 to 120 mm. Some manufacturers also offer options with lengths of 3,000 mm and even 4,500 mm. Such a wide range allows you to choose the type that suits you perfectly.

Positive features of the material

The technical characteristics of Technoplex (50 mm thick) indicate that this material allows you to significantly save your budget, since it has improved heat-insulating qualities. Compared to conventional polystyrene foam, the capabilities of this product are two times higher, and if you look at the thermal insulation performance of fiberglass slabs, it becomes clear that their capabilities are 1.5 times less.

In addition, a number of positive properties of the material should be noted:

- Increased strength. The extrusion material is more than 5 times stronger than polystyrene foam.

- High density. "Technoplex" is able to withstand heavy loads, which makes it possible to use it when arranging floors.

- Resistant to moisture. The dense and solid structure of the material does not allow moisture to pass through, while polystyrene foam is capable of absorbing liquid, albeit in small quantities.

Despite the fact that the Technoplex material (50 mm) has quite high characteristics, it still has one drawback - poor vapor permeability. This fact must be taken into account when purchasing extrusion plates for certain jobs.

Installation features

The process of installing the material itself is simple and will require the performer to have minimal construction knowledge and tool skills. To carry out installation we will need the following tools and consumables:

- perforator;

- hammer and spatula;

- sharp knife;

- tape measure and level;

- marker;

- directly technoplex of the required brand and thickness;

- special plastic dowels with a wide head;

- adhesive mixture for polystyrene foam;

- metal support profile.

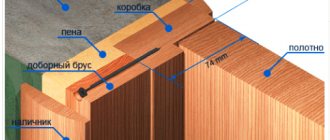

When the materials and tools are ready, you can begin installation. First you need to prepare the surface. Most often, technoplex is used for external insulation of a facade or foundation, so the surface must be fairly flat (there is no need to inject it to the nearest millimeter) and clean. Some professionals recommend additionally priming the wall or foundation for better adhesion of the adhesive. This step will not be superfluous, although it is not mandatory.

After preparing the surface, you can begin installing the technoplex. To begin with, the lower horizontal rail made of a metal profile is leveled and secured. When choosing a batten, it is necessary that its width matches the thickness of the insulation board. Then we attach the top rail.

We begin to lay polystyrene foam boards between the guides. To do this, lubricate the surface with glue and press it against the wall (foundation). We check the correct installation using the level. Considering that the solution hardens for a certain time, it is possible to slowly adjust the location of each slab relative to the level to achieve the desired result.

After the glue has completely dried (usually after 2-3 days depending on the brand of the mixture), we proceed to additional fixation of the slabs. To do this, use a hammer drill to drill holes in the surface through the insulation and insert plastic dowels. Due to their design, they have a hollow body and teeth on the outside of the nail. We hammer a steel rod into a special hole, which deforms the dowel from the inside and forces it to be firmly held in brick or concrete.

As a rule, 5 dowels are driven into one slab - 4 at the edges so that the head fixes the adjacent slabs and 1 in the center. Sometimes, in order to save money, they are content with less.

The installation is complete, now you can begin finishing the exterior surface.

Insulation of external walls

Builders, as a rule, perform insulation from the outside. In this case, the area of the room will remain the same. To perform the work, sheets of technoplex 100 mm thick .

If you take a thinner material, you need to use 2 layers of insulation, due to which heat loss will be reduced by 40–60%. Naturally, it is customary to begin external thermal insulation work using technoplex after surface preparation. To do this, the walls are cleaned and then leveled with plaster. Next, the insulation sheets are glued. To ensure they hold well, dowels can be used. In this case, the fastening is carried out end-to-end. Since the coating of techoplex sheets is smooth, the surface must first be roughened.

The slabs are glued starting from the bottom . Thanks to this, they will not mix while the glue dries. Then a layer of special mastic is applied to the surface and a reinforcing mesh is fixed on it, which will make the protective layer quite rigid. Next, treatment is carried out with a primer and finishing compound. As a result, the facade of the house will have an attractive appearance.

Experts recommend performing thermal insulation work in dry weather. It is also worth paying attention to the air temperature. It must be at least 5˚ C.

Description and features of the material

Technoplex insulation is made from polystyrene granules, which, under the influence of high temperature and high pressure, are mixed with a special foaming composition and graphite. The viscous mass is sent into molds of a certain size, where it hardens and is cut into sheets of standard parameters.

The final product is smooth and dense. The structure of the sheet consists of a large number of small closed cells that do not allow air to pass through. Thanks to this, the characteristics of Technoplex (50 mm) are quite high. Graphite additives significantly improve the thermal insulation abilities and increase the strength of the slabs.

Products are sold in rectangular packaging, the size and weight of which depends on the size of the material.

Technoplex production technology

Extruded polystyrene foam is made from polystyrene foam granules.

Synthetic insulation is made from polystyrene granules. Raw materials are loaded into the hopper. Modifiers are added to it to improve the properties of the final product. Among them are flame retardants to reduce flammability, stabilizers, and antioxidants. TechnoNIKOL's unique additive is tiny carbon particles. They increase the strength and thermal insulation properties of the final product. Foaming of granules occurs using carbon dioxide. At all 7 plants of the company, environmentally friendly, freon-free production technology has been introduced.

Under the influence of high temperature and gas supplied under pressure, the raw material melts and foams. The mass is extruded from the extruder in the form of a tape. After hardening, it is cut into sheets of standard sizes and shapes. The boards are packaged in polyethylene shrink film.

Technical and physical characteristics of the material

The manufacturer indicates the performance and other properties of the insulation on the packaging. Having carefully studied the instructions, you can understand that the technical characteristics of Technoplex (50 mm) look like this:

- sheet thickness – 50 mm;

- average density of the material – 26-30 kg/m³;

- compression resistance – up to 25 tons/m²;

- material water absorption rate (per day) – 0.2% of the total volume;

- use in the temperature range – from -70 to +75°C;

- flammability class - G4;

- heat capacity indicator – 1.45 kJ;

- vapor permeability coefficient – 0.01 m/h/Pa;

- bending strength – not less than 0.3 MPa.

As you can see, with low weight and minimal thickness, the material has the ability to withstand heavy loads, which significantly expands the scope of its application.

It is also important that this type of insulation is not prone to rotting or infestation by rodents and fungi. During operation, it does not emit harmful substances into the air and remains resistant to most chemical compounds (except gasoline and organic solvents)

Penoplex density 35 kg/m3

It makes no sense to talk about the relevance of the problem of reducing the level of heat loss from buildings and structures. Given the increased demand for products in the “insulation” category, the market is literally flooded with various samples. This article is devoted to one of the most popular modern heat insulators Penoplex 35 - its characteristics, properties, specific application.

This insulation is a type of expanded polystyrene, which is produced by extrusion under conditions of high pressure and temperature. This technology provides increased density of samples with low weight, which makes them universal in use.

Main characteristics of slabs

It makes no sense to list everything for the reason that many of them will tell a reader who does not have a specialized education little about anything. But knowing some will help you make a choice, given the large assortment of Penoplex heat insulators (the article What is better to choose - Technoplex or Penoplex insulation can help with this?).

1. Density (kg/m3) - it is indicated in the name of the sheets of the series (35). Although this value is average. Depending on the manufacturer of Penoplex 35, the indicator of this characteristic varies between 29.5 - 36.5.

2. Daily water absorption (in% of the total volume of the sheet) – no more than 0.1.

3. Strength (flexural, in MPa) – 0.4.

4. Standard sheet sizes (cm) – 120 x 60, thickness from 2 to 10.

5. Thermal conductivity (W/m) – 0.030.

6. Pack weight (kg) – from 10 to 15 (depending on the thickness of the samples).

Features of thermal insulation material

1. Several types of insulation are sold under the Penoplex brand. Samples with a density of 35 differ from analogues in that they have a minimal thermal conductivity coefficient in numerical terms.

2. The low level of water absorption of Penoplex in most cases allows you to avoid additional waterproofing of surfaces.

3. Increased resistance to ignition. This is ensured by the introduction of “fire retardant” class substances into the feedstock before molding Penoplex sheets, which sharply reduce the likelihood of flame propagation. In fact, the material is not flammable. With increased thermal exposure, it basically melts, and the release of toxins is minimal.

4. Correct and relatively small sample sizes allow:

- accurately determine the volume of purchase of Penoplex (by number of sheets or by m3);

- significantly simplify the thermal insulation process;

- dramatically reduce the amount of waste during cutting, which to a certain extent affects the final price of insulation;

- organize the transportation of sheets in any convenient way. If we are not talking about m3, then you can deliver the material from the store to your home manually.

5. Sufficient density of Penoplex series 35 slabs allows for external finishing of surfaces without installing a supporting structure. Mainly - with plaster compositions, with additional reinforcement of the layer with reinforcing (plastic) mesh. Another option is wallpapering any type.

6. Since this insulation has a polymer base, Penoplex does not rot or be destroyed by biological pests. The result is a long, maintenance-free service life.

7. The low weight of the samples allows them to insulate any base; moreover, they do not weigh down the structure.

The disadvantage of Penoplex with a density of 35 is perhaps the only one, but it should be taken into account. The density of the structure is reflected in such characteristics as thermal conductivity, sound insulation and vapor permeability. The latter is especially relevant if installation is carried out by gluing sheets to the base. Carrying out additional measures to ensure natural circulation of air flows under the cladding leads to an increase in the cost of work.

Before purchasing Penoplex, it is advisable to determine not only the linear dimensions, but also the optimal thickness of the sheets.

The high technical characteristics of Penoplex of this series, taking into account zero flammability and a large selection of sizes, allow it to be used for insulation of a wide variety of structural parts:

You can buy a variety of products that are used to insulate pipelines. Due to good sound insulation, the noise level during hydraulic shocks in the systems is reduced.

| Thickness, mm (number of sheets per package) | Cost, rubles |

| 20 (18) | 1 290 |

| 50 (8) | 1 470 |

| 100 (4) | 1 360 |

*Approximate prices for the Moscow region.

** Prices for Penoplex with a density of 35 standard sizes, in rubles per package, depending on the thickness. The number of sheets is indicated in parentheses.

Cost per m3 – 4,490 rubles.

When purchasing Penoplex, you should take into account the inevitability of cutting and adjusting individual segments, so the batch volume must be increased by approximately 10% of the calculated one.

Technoplex insulation technical characteristics

Technoplex extrusion has a low thermal conductivity coefficient, is resistant to mechanical loads, does not shrink, is chemically resistant, and is not subject to decomposition and rotting. Technoplex has technical characteristics in comparison with brick such that the thermal conductivity of 30 mm extruded polystyrene foam is comparable to a 400 mm brick wall. Finnish foundations are often insulated with this material.

Technoplex 50 mm characteristics

Technoplex.

Characteristics of slabs with a thickness of 20 to 120 mm The scope of application of extruded polystyrene foam, due to its high strength and resistance to moisture, is very wide. XPS is used today when pouring USP, insulating strip foundations and blind areas of houses. The material does not lose its original characteristics even in water, since the structure of the material consists of closed cells that do not absorb moisture, unlike mineral wool.

Advantages and disadvantages

Any building material has its own strengths and weaknesses, which determine the area of application. Technoplex was no exception. The undeniable advantages of insulation include the following:

- Resistance to wet environments

- Reduced frost resistance coefficient, which eliminates the need to lay a layer of waterproofing

- Resistance to mechanical damage and dynamic loads

- Neutrality to most active substances

- Ease of installation

- Long service life without loss of original qualities

Among the disadvantages are the following:

- Material is burning

- When interacting with complex carbons, a conflict of materials occurs, which leads to destruction of the insulation structure. An unsuccessful example of a combination of components: insulation with Technoplex when facing with siding

- Sensitivity to prolonged exposure to direct sunlight

- Limited range of operating temperatures, which does not allow the material to be used for insulation of baths and saunas

The disadvantages include the high cost, which, however, is justified by the high technical characteristics and almost eternal service life.

Dimensions of extrusion insulation

In order to correctly determine the required number of slabs, you should study in more detail the characteristics of Technoplex 50 mm. How many slabs are in the package, and what size they are, you can, of course, check with the seller, but it is better to have this information in advance.

So, from information from the manufacturer we know that the described slabs come in two types:

- with dimensions 118 x 58 cm;

- size 120 x 60 cm.

Also, insulation sheets can have different widths (from 20 to 100 mm). But since slabs with a width of 50 mm are considered the most universal, our article is devoted to them. One package contains 6 slabs of the same size.

Dimensions

When manufacturing a technoplex, certain standards for finished products are observed. Therefore, regardless of the manufacturer, the insulation has the same size and sheet thickness. It looks like this:

- Length – 1,180 – 1,200 mm .

- Width – 580 – 600 mm .

- Thickness – 20 / 30 / 40 / 50 / 100 mm .

It should be clarified that thick slabs are used only in the construction of industrial buildings and road work. Meanwhile, the characteristic L-edge profile is absent on products with a minimum thickness.

Which is better: technoplex or penoplex

When building any house in Russia, owners ask themselves about its insulation. Today, the insulation market has a large number of items; tiled thermal insulation materials are in particular demand. Among them, technoplex and penoplex have proven themselves. To better understand their properties, you need to make a small comparison of the main characteristics.

Composition of materials and method of their production

Extruded polystyrene foam or penoplex refers to tile heat insulators. It is produced by extrusion from polystyrene.

This method allows you to achieve a uniform structure of the material, consisting of tiny cells with air.

During production, polystyrene granules are mixed at high temperature and pressure, and a foaming agent (light freons with carbon dioxide) is introduced into the mixture. The next stage of production is extrusion. The resulting material has good thermal insulation properties.

Technoplex is also a tile material for thermal insulation. During its production, graphite nanoparticles are added to extruded polystyrene foam; they further reduce the thermal conductivity of the material, while increasing its strength.

Both materials are environmentally friendly, do not support combustion, and do not dissolve in water and soil. They are suitable for private construction, thermal insulation of balconies and the installation of “warm floors”.

Strength of materials

In terms of mechanical compressive strength at 10% deformation, penoplex (type 35) and technoplex XPS30-200 Standard have the same values of 250 kPa. This value depends on the density of the slabs.

The tensile strength during static bending of penoplex is, depending on the type, 0.4-0.7 MPa. The same indicator for technopex is 0.3 MPa. It can be concluded that penoplex is more resistant to static bending, as it can withstand greater loads.

Operating temperatures of materials

Operating temperatures of penoplex are from -50 to +75ºС. The operating temperature range for the technoplex is between -70ºС and +75ºС. Obviously, the temperature range of the technoplex is greater, this is its advantage, but -70ºС is rare even in our country.

Thermal conductivity and water absorption of penoplex and technoplex

The thermal conductivity of penoplex, depending on the type and operating conditions (A or B), is no more than 0.028-0.031 W/mK. This indicator for the technoplex under various operating conditions is 0.031 W/mK. Thus, both materials are effective thermal insulators.

The water absorption of technoplex is no more than 0.2% by volume in 24 hours. The water absorption of penoplex (type 35) is only 0.1%. Penoplex immersed in water for 28 days increases by only 0.2% of its volume. This indicates the negligible water absorption of penoplex.

In addition, this material is able to retain its properties after a large number of defrost-freeze cycles. For example, after 1000 such cycles, penoplex changes the thermal resistance by only 5%.

Price for penoplex and technoplex

Thus, penoplex and technoplex can be called similar materials, with slight differences in some indicators. Their main difference is the price.

TECHNOPLEX35 250

TECHNOPLEX 35-250 slabs are intended for thermal insulation of floors, including load-bearing floors on the ground and floors of refrigeration chambers; thermal insulation in the structures of inversion and exploited roofs, roofs with mechanical fastening; as a thermal insulation layer in a plaster facade system; used for thermal insulation of loggias and balconies.

Dimensions.

Today, TECHNOPLEX 35-250 thermal insulation boards are produced in widths of 580 mm, thicknesses of 20, 30, 40, 50, 60, 80, 100 and 120 mm and lengths of 1180, 2380, 3000, 4000 and 4500 mm. There are two options for processing the edge of the slab - smooth and L (selected quarter).

Storage and packaging.

TECHNOPLEX 35-250 slabs are packaged in UV-stabilized polyethylene shrink film. It is recommended to store the slabs indoors or under a canopy to avoid exposure to sunlight. Short-term storage of the material in its original packaging outdoors is acceptable, for example, at a construction site before installation of the material.

Fire resistance.

The TECHNOPLEX 35-250 brand contains a fire retardant, which gives the material self-extinguishing properties - the material is assigned flammability group G1 (low-flammability).

It is recommended to operate TECHNOPLEX 35-250 thermal insulation boards in the temperature range from -50 to +75 °C. In this temperature regime, all physical and thermal characteristics of the material remain unchanged.

TECHNOPLEX 35-250 is highly resistant to many substances, for example: sea water, salt solutions, anhydride, alkalis, diluted and weak acids, soap, salts, fertilizers, bitumen, silicone oils, alcohols, adhesives, water-soluble paints.

TECHNOPLEX 35-250 is inert towards inorganic building materials - concrete, lime, cement, gypsum, sand, etc., but partially decomposes under the influence of organic solvents, resins, solutions containing acetone.

It is especially important that TECHNOPLEX 35-250 does not dissolve or swell in water, practically does not absorb moisture, is durable and resistant to rotting. It is not digestible by animals and microorganisms, therefore it is not used by them as food and does not create a breeding ground for fungi and bacteria.

TECHNOPLEX 35-250 slabs are characterized by:

- High thermal insulation properties;

- Minimal water absorption;

- High strength characteristics;

- Stability of volume and shape;

- Increased biological stability;

- Resistance to microorganisms;

- Durability;

- Low vapor permeability;

- Easy to install, easy to cut and process;

- This is an environmentally friendly material.

Material characteristics

| Indicators | TECHNOPLEX 35-250 |

| Compressive strength at 10% deformation, not less (kPa) | 250 |

| Density, kg/m3 | 30,1-38,0 |

| Thermal conductivity at (25±5) °С, W/(m°C) | 0,029 |

| Calculated thermal conductivity coefficient under operating conditions, W/(m°C) A | 0,031 |

| Calculated thermal conductivity coefficient under operating conditions, W/(m.°C) B | 0,031 |

| Bending strength, MPa, not less | 0,35 |

| Water absorption,% by volume, no more | 0,2 |

| Vapor permeability coefficient, mg/(m h Pa) | 0,010 |

| Fire resistance category, group | G1 |

| Operating temperature range, °C | from -50 to +75 |

| Length, mm: | 1180, 2380, 3000*, 4000**, 4500** |

| Width, mm | 580 |

| Thickness, mm | 20, 30, 40, 50, 60, 80, 100, 120 |

- Products

- Stock

- Shipping and payment

- Objects

- Services

- Price lists

- Question answer

- Contacts

| The shops: | in Rybinsk: +7 st. Truda, 97 | in Uglich: +7 st. Lenina, 57 |

We deliver to the cities of the Yaroslavl region: Rybinsk, Yaroslavl, Myshkin, Tutaev, Rostov, Poshekhonye, Lyubim, Gavrilov-Yam, Danilov.

Scope of application

In what types of work can Technoplex 50 mm be used? The characteristics and dimensions of the material practically do not limit the scope of its application, so it is very popular in many works.

Thus, Technoplex was actively used in the insulation of facades. For this purpose, it is mounted with a special glue (like polyurethane foam). Since extrusion slabs do not lose their properties even underground, they are used both to create a thermal insulation layer on foundations and as insulation for underground utilities.

The material is no less actively used in the process of interior decoration. It can be mounted both on vertical surfaces and in floor screeds.

Advantages of Technoplex thermal insulation

Extruded polystyrene foam (EPS) of various brands, for example, URSA XPS, Penoplex or Technoplex, is considered today the most effective and promising thermal insulation material in construction. Extrusion is produced in rigid slabs of different thicknesses. Let's take a closer look at the technical characteristics of technoplex and answer the question - penoplex or technoplex, what is the difference.

EPPS Technoplex is often used for thermal insulation of private houses (blind areas, foundations and basements), insulation of balconies and loggias, and as a substrate for “warm water floors”. The advantages of XPS Technonikol boards are high strength, which is combined with low thermal conductivity. TechnoNIKOL today offers building materials that meet all international standards.

Application area

Technoplex is considered universal, therefore it is used in almost all construction sites. In particular:

- Foundations

- Interior of walls and facades

- Interior partitions

- Insulation of self-leveling floors and wooden floorings

- Arrangement of balconies and loggias

- Insulation of garages and outbuildings

It is worth noting that products with increased density can be used to modernize road surfaces.

Scope of application

In what types of work can Technoplex 50 mm be used? The characteristics and dimensions of the material practically do not limit the scope of its application, so it is very popular in many works.

Thus, Technoplex was actively used in the insulation of facades. For this purpose, it is mounted with a special glue (like polyurethane foam). Since extrusion slabs do not lose their properties even underground, they are used both to create a thermal insulation layer on foundations and as insulation for underground utilities.

The material is no less actively used in the process of interior decoration. It can be mounted both on vertical surfaces and in floor screeds.

Installation technology

When laying on horizontal surfaces - floors, flat roofs - the slabs are simply laid on a flat surface. The surface should be without sharp changes, the maximum deviation is 2-3%. This requirement must be met so that voids do not form. When laying, we monitor the joints; it is advisable to glue them (you can use tape) or fill them with the same foam/glue on which the slabs are attached.

When using Foam plastic for insulation of balconies

If two layers of thermal insulation are laid, it is positioned so that the EPS slabs of the second row overlap the seams of the lower one. They also say that the slabs are laid with alternating seams or “staggered”.

When mounting on vertical surfaces, double fastening is used:

- Glue or adhesive foam is applied to the plane.

- Additionally fixed with umbrella dowels.

According to the technology for installing slab insulation on facades, umbrella dowels are installed at the junction of two sheets (any two sheets) and two additional fasteners in the plane of the sheet. That is, there are at least 8 fasteners per sheet (indicated in red in the figure). More is possible. Less - no. Unless, of course, you want the insulation and finishing to come off. If the winds in the region are strong, it is better to put more. To insulate the inside, you can install less (see diagrams below).

Schemes for installing umbrella dowels when installing Penoplex on vertical surfaces

During installation, on the outer slabs and around openings, we install fasteners more often: three to four elements per slab. To keep the insulation rigid in the corners of the openings, a mesh is attached to it before plastering. It is attached at an angle of about 45°, securing the joint. Under such conditions, there will be no problems with finishing inside or outside.

If plaster, facade tiles, finishing stone and other heavy materials are subsequently applied to Penoplex, before installation, care must be taken to improve the adhesion of the material to the wall and to the finish. Even if you are installing a Penoplex Wall with stripes, it is better to add roughness to the slab using a metal brush. And from both sides. If the wall is smooth, it also doesn’t hurt to add roughness - for better adhesion.

If the wall is smooth, it also needs to be processed by putting a metal attachment on the drill

To work with Penoplex, a special adhesive mixture is recommended: Ceresit ST 84, illbruck PU 010, Titan 753, Ceresit CT-85, Kreisel 210 and 220, Baumit ProContact, STO Baukleber, Soudal Soudabond, Penosil Fix and Go, Den Braven, Krass.