A metal entrance door is presentable, reliable and provides excellent protection from bad weather and uninvited guests. More and more people prefer these types of models, as they have already proven their practicality, durability and high level of protection. But people live in houses of different years of construction and in private houses.

In addition, metal entrance doors are an integral attribute of a reputable office, law office and other public places, so different sizes of products are required. In this article we will find out how to determine the required size of a metal entrance door. In addition, we will find out how you can insulate the product box in order to survive the winter safely and comfortably.

What does a metal entrance door with frame consist of?

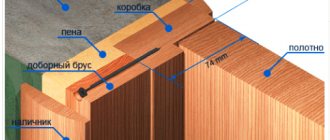

Let's find out what elements and parts are included in a standard metal entrance door. So this is:

- Directly the canvas itself.

- Frame.

- Framing,

- Special reinforcements that make the door a more reliable structure.

- Seal. It is necessary for warmth, and for the door to fit tightly to the jamb: it closes and opens without problems.

- Door trims are also part of the multi-component design.

- Various additional accessories: peephole, door lock, handle.

- Door locks for metal doors.

But this information will help you understand how to install an electronic lock on the front door with your own hands.

As you can see, there are many elements that make up a door. And it is necessary that they all function properly - only then will the product fully fulfill its role as the main “guard” of the home, and will not allow the owners of the house or apartment to freeze. But what kind of self-adhesive sealant exists for metal doors, and how to use it, this information will help you understand.

Recommendations

Please note that the size of the product is affected by the type of material from which it is made. For example, if the door is armored and thick, then the size for the same opening will be larger than that of a product made from a regular profiled pipe. In addition, the size largely depends on the seal that is used in this product. For example, the seal can be four- or six-rib, which gives additional rigidity and, accordingly, the thickness of the structure. You should also learn how to install the door correctly.

Taking into account the above and other nuances, the approach to choosing a metal entrance door should be individual. If the owners of standard standard housing built during the Soviet Union may not bother too much with the size, since they have a standard doorway, then those who bought housing in a new building will have to approach their choice with the utmost care: after all, modern housing has an individual layout, unusual solutions, different heights of ceilings and openings. But is it possible to change the lock on a metal door, and how to do it correctly, is indicated here.

In addition, you should definitely take into account whether the product is being selected for a house or apartment in a high-rise building. If in a private house, then there may be many more options, since it is possible to “adjust” the doorway. But if the product is selected for a high-rise building, then the walls there, especially load-bearing ones, cannot be touched, so you should select a door that exactly fits the opening in size. It is also worth learning more about what a magnetic seal for metal doors looks like and how it is used.

Door thickness

Metal doors can be made simply from a sheet of metal (cold version) or in the form of a frame with insulation inside. Use sheets with a thickness of 1.5-2 mm. The smaller one is unable to provide structural strength and protection against burglary. Sometimes it is increased to 3 mm. Thicker metal is not used so as not to significantly increase the weight of the door. The exception is bulletproof and fireproof products; they require reinforced hinges that can withstand the appropriate weight.

The thickness of the fabric in the manufacture of ordinary, standard insulated fabrics ranges from 60 mm to 80 mm. If the products are of a reinforced class, then this indicator will start from 80 mm and reach 100 mm.

This parameter is affected by:

- Sealant, its dimensions. This is a rubber contour that is located around the perimeter of the canvas. The seal ensures a stronger fit of the sash, as well as the tightness of the structure. 2 or 3 circuits are mounted on the door, then the total thickness of the door will be 80 mm.

- Insulation. Up to 25% of the heat leaves the room through the door. Several layers of insulation are installed into the canvas; their quantity and the density of the material determine the thickness of the sash.

Strengthening the door and increasing its thickness should not be thoughtless. The maximum weight of the structure cannot exceed 200 kg.

Standard door dimensions: thickness, height, width

Previously, entrance doors were sold separately from the frames, and the buyer purchased the door leaf itself separately and the trim separately. And now the usual practice is to sell a ready-made block along with the box, which simplifies the task for both the seller and the buyer. And the standard sizes adopted in our country take this point into account. Let's find out which door sizes are the most popular and recommended by state standards.

- So, if the height of the opening is from 207 to 210 cm, and the width is 88-96 cm, then the size of the metal entrance door with a frame should be 205 cm high and 86 cm wide.

- If the width of the opening is the same, however, the height is 98-106 cm, then the product must be purchased in the following dimensions: 205 cm in height and 98 cm in width.

- If the opening height is standard - 270-210 cm, and the width is atypical - 90-98 cm, then the model is selected with the following parameters: 205 cm in height and 88 cm in width.

- If the opening is very wide (100-108 cm) at a standard height, then the size of the metal door should be 205 cm high and 98 cm wide.

But how to choose a seal for metal doors, and what you should pay attention to, is outlined here.

Here are the sizes of metal entrance doors that are considered standard. Please note that the dimensions are included with the box. The given parameters can be taken as a standard, and based on them, calculate the size for individual planning.

Entrance structures of non-standard sizes

Non-standard dimensions of door leaves and openings are not uncommon nowadays. New high-rise buildings and cottages are filled with them. When building a private house, SNiP or GOST are rarely taken into account.

Builders recommend taking into account SNiPs. Absolute accuracy is not required, but it is not recommended to deviate significantly from the standard dimensions. Otherwise, the standards will be violated, and the wall with a passage will not be stable and reliable.

Based on the recommendations of builders and designers, there is a range of dimensions that need to be met when creating entrance passages:

- Width. The range of this parameter starts from 900 mm and ends at 2000 mm. The passage should not interfere with people walking and bringing in large items.

- Height. The indicator should, at its minimum point, exceed the dimensions of interior canvases and boxes. You need to start with 2000 mm. The maximum permissible height is 2400 mm.

Depth may vary. Depends on the material used. An important indicator is the design of the door leaf - universal or narrowly targeted. The first option includes classic models that can be purchased at any door store.

As for the individual or narrowly targeted purpose of doors, they can be:

- armored;

- with increased noise and sound insulation;

- fire protection.

If we look at it in more detail, steel with high levels of rigidity and impact resistance is used in the manufacture of armored door panels. Its average thickness is 60 mm. The weight of the canvas increases significantly. A standard single-leaf door according to GOST should not weigh more than 80 kg. For non-standard designs this parameter can reach 200 kg. This is not the maximum parameter for armored doors - it may vary depending on the degree of protection.

Fire protection structures must, in the event of a dangerous situation, allow people to freely leave the premises. The average width for fire models is 1300 mm. For double-leaf structures, the average leaf width is 2500 mm.

How to measure

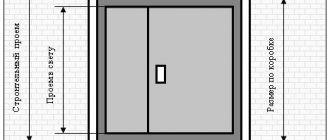

Before placing an order on the appropriate website or going to the store, you must carefully take measurements from your own doorway so that the selected product matches the declared parameters as accurately as possible. Several recommendations for taking measurements.

Take all necessary measurements from the wall. If old trim prevents this, remove them. In addition, it is necessary to clean the base of the door from crumbling plaster so that the dimensions most accurately reflect the actual parameters of the opening.

You can take measurements with a tape measure or a sewing centimeter. Once you have measured the height of the opening and its width, check the standard dimensions above, and if your measurements differ, measure them again. If the secondary control measurement showed the same results, it means that the product will have to be purchased non-standard.

GOST for imported models

Doors from European manufacturers attract buyers with their unusual design and thoughtful design. However, it must be taken into account that the dimensions of such structures correspond to DIN and the anthropometric characteristics of the country's population. For example, people in Finland are taller than people in southern Europe. Therefore, the doors will differ in height.

The difference in width between Spanish and French models is 90 mm. The minimum width for France is 590 mm, and for Spain 600 mm. This must be taken into account so that after the purchase you do not have to redo the doorway.

How to insulate with your own hands

When purchasing a metal entrance door, you need to think about protecting it from the cold, especially if the product does not provide any “built-in” insulation. The realities of our country do not allow us to get by with just a door leaf, and this is especially true for owners of private houses. Let's find out what points need to be taken into account when choosing material for insulation and when carrying out the work itself.

Keep in mind that the metal from which the door is made is an excellent heat conductor, so the outer, street side of the door will have almost the same temperature as the inner, home side. Due to the temperature difference on the outside, condensation is likely to form, which negatively affects metal elements, fittings, and the canvas itself. This happens when the door is not insulated. In addition, the lack of proper insulation of the metal entrance door leads to the fact that wind and cold penetrate into the gap between the leaf and the frame, which worsens the microclimate of the home. For those who want to learn more about how the insulation of an iron door occurs, you should follow the link.

Non-standard parameters

You can often find non-standard doorways. They are mainly found in modern houses with custom designs and wide openings. Therefore, a door model whose dimensions are regulated by GOST will not be suitable here.

When deciding to design an opening in a non-standard way, do not forget that this can affect the strength of the walls themselves. In any case, the width of the door entrance opening should not exceed 200 cm, and the height - 240 cm.

Material selection

So, in order to eliminate the above shortcomings, it is necessary to carry out work on insulating the door. Most often, special materials based on fiber or foam are used for this. Let's take a closer look at the issue of choosing insulation.

Fibrous

This category includes mineral and stone wool, which can be made from hard slabs or soft rolls. The advantages of these materials include their remarkable heat-insulating ability, non-flammability, and excellent noise-insulating qualities. Moreover, their installation will be completely uncomplicated, accessible even to a person far from any construction work.

Fiber insulation

But fibrous materials also have their downside - their fear of getting wet. If condensation accumulates on such insulation, over time this can lead to the loss of volume of the wool and subsidence. This subsidence may leave the top of the door unprotected. Due to this significant disadvantage, cotton wool is not used to insulate the entrance doors of private houses. However, it can be used if the door leads to a high-rise apartment.

Styrofoam

This category also includes polystyrene, whose bubbles are filled not with air, like polystyrene foam, but with nitrogen. These materials have a solid form, are produced in slabs, are easy to cut, and are easy to install.

Foam insulation

At the same time, the thickness of the slabs can be different, which makes it possible to choose the optimal one for a particular case. These materials are not afraid of moisture, so they are quite suitable for entrance doors in private homes.

Selection of box and canvas - nuances of high-quality installation

When ordering an entrance door, it is important to accurately determine the size of the opening in which it will be installed. It is especially difficult to take correct measurements when a new model is purchased in advance, and the old one has not yet been dismantled - the true width of the entrance door to the house is unknown. Free measuring is hampered by decorative elements: cashing on one side, slope on the other. Of course, immediately dismantling the door completely is not a feasible task, but you should not interfere with dismantling the decorations to obtain the correct dimensions of the opening; subsequently, this will guarantee quick and high-quality installation work.

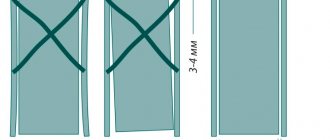

When planning installation in an opening, you need to ensure that the new structure fits freely in it. Moreover, it is important to take into account the installation gaps sufficient to install the door in a strictly vertical position, place fasteners and insulation. The gap width of 2 cm allows you to fill it with quality foam, ensuring reliable insulation.

Doors with additional side leaves, which, if necessary, expand the doorway Source domsdelat.ru

Most often, the box is purchased complete with canvas. However, sometimes it becomes necessary to buy it separately, for example, in an increased width, in order to avoid an additional slope device. It is more practical to choose a kit rather than a finished product; it will be possible to assemble and adjust it “on site”. If you purchase a ready-made door block, careful monitoring of its compliance with the door leaf is necessary.

Entry door installation steps:

- Preparation of the opening : dismantling the old door, necessary alignment of the planes, clearing the opening of debris.

- Installation of the door block with alignment and fastening.

- Adjusting the door leaf , or all the doors together in the box, monitoring the smooth closing and opening, checking the operation of the installed locks.

- Filling the installation gap with foam , if necessary, with additional thermal insulation materials.

- Installation of decorative elements and fittings.

Recommendations for carrying out insulation work

The frame at the metal door is made from a corner fixed in the walls with metal pins. And between the box and the wall itself there is usually a gap, which the craftsmen hastily seal with foam during installation. But foam is a very short-lived material that quickly deteriorates and, as a result, loses its performance characteristics. If the frame of your front door is insulated in this way, then it would be reasonable to remove the old foam and insulate it with new foam - cotton wool or polystyrene foam / polystyrene.

To carry out the work professionally, clean the wall adjacent to the box from any remaining foam or other old insulation. Remove the plaster to a solid base, remove the resulting dust.

But how to insulate the slopes of plastic windows, and which insulation materials are the best, is indicated here.

Wet the surface of the wall with water, and then use a mounting gun to blow out all visible cracks and holes in the wall with foam. Once the foam has expanded to a solid shape, cut off any protruding pieces.

Then lay the selected insulation in the gap of the box, fitting it tightly to the size of the opening.

These simple manipulations will make your home much warmer, and your door will be protected from condensation and reliable.

Rules for measuring opening dimensions

If the old entrance door is to be replaced along with elements of the supporting structure, extensions and platbands, then, when taking measurements, it is necessary to completely clean the opening. In this case, we are talking about removing not only the box and the remnants of the mounting foam previously laid in the gaps, but also the tray that hides the load-bearing part of the wall. After the opening is ready, the master takes measurements in the following sequence:

- The edges of the walls and lintels around the perimeter of the doorway frame are rarely even, which is why one size cannot provide accurate information for ordering an infill element. The width should be measured in 3 - 4 places - at the level of the threshold, lintel and at the center of the height.

- Unlike interior doors, the entrance metal structure is adjacent to the profile in the vestibules on 4 sides, not 3, since a threshold appears at the floor level. This steel element cannot be installed at the level of the finished floor, which is why the height of the opening should be determined from the floor slab, having previously removed the old layers.

Rice. 6. Taking measurements

- The height of the opening is fixed in 2 places with a single-leaf design, in 3 – 4 places along the width if it is necessary to install a one-and-a-half or double-leaf door.

- The thickness of the wall is also measured in several places along the entire perimeter of the frame, since determining the correct dimensions will depend

After taking the dimensions and fixing them on paper, you should present the drawing to the store, and the consultant will help you choose a ready-made kit.

Rice. 7. Non-standard entrance door installed to order

Quality Standards

Each metal door will find its consumer. The fact is that today this market is well developed. Domestic and imported manufacturers produce metal sheets, taking into account:

- safety standards;

- strength;

- fire resistance;

- level of security against hacking.

Based on the above, the following criteria follow that are observed by the majority of conscientious manufacturers. The thickness of the sheet must be at least two millimeters if one metal sheet is used, and no more than six millimeters if the sheets of the structure are spot welded to each other.

To make the canvas rigid, V or U-shaped “stiffening ribs” can be placed between the metal sheets. Standard metal products consist of two sheets of steel.

Typically, domestically produced products have thicker metal sheets. Imported products, on the contrary, are thinner. For example, Chinese metal products, regardless of size, cannot boast a blade thickness of more than three or four millimeters. However, if the canvases are made to order, then, in both cases, the thickness may be different.

Custom-made products may have more metal sheets in the fabric. Based on this, such canvases can have individual thickness, dimensions and decorative design. But the safety standards and dimensional parameters established by GOST R 51072–97, GOST 31173–2003 and GOST 6629–88 must be observed.