To make a sliding door with your own hands, you need drawings, a description of the work plan and step-by-step instructions, because this is a rather non-trivial task, especially for a beginner. At the same time, installing a sliding door is an opportunity to save space, which is especially important when the room area is limited.

In this way, you can still zone the room, without having to build durable floors. You can even make such a design with your own hands, using new materials or old fabric - you just have to purchase a special mechanism and components for it. Today we will dwell on this type of work in detail.

DIY sliding door

How do sliding systems work?

The compartment door is designed in such a way that its doors slide apart to the sides. This can be either one or two door leaves, moving parallel to the ceiling or sliding inward. And if the general operating principle of such doors is the same, then the installation and opening methods are different. Let's talk about this in more detail.

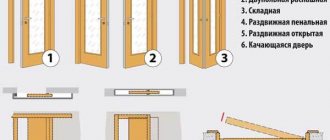

Table No. 1. Main types of sliding systems.

| View | Description |

| Mounted | In this case, the canvas is fixed on guides - on the ceiling or directly above the opening. This way the doors will move along the wall with a slight indentation from it. It is not recommended to install furniture or any other objects near the door - they will be an obstacle to the door panels. |

| Hanging | In this case, the door leaf is fixed to the cut of the opening. Accordingly, the door moves close to the wall, which looks more neat and aesthetically pleasing. Hanging doors allow you to place pieces of furniture next to the opening - they won’t get in the way. |

Table No. 2. Types of interior sliding doors by opening method

| View, illustration | Description |

| This is the most primitive version of sliding doors, so even an inexperienced person can handle the manufacture of such a model. The design comes with either one or two panels. |

| The movement of the canvas does not occur along a smooth guide, but along a circle. This option is ideal for rooms with curved ceilings and is good for corner cabinets. The design has a very original appearance, but not every person can handle its manufacture. |

| They also come with one or two doors and move in different directions according to the same principle as sliding doors. The difference is that they slide into special recesses in the wall, which makes this design very convenient, because you can place furniture near the wall without any problems. Of course, making such a door will be a little more difficult, because you will have to provide for a niche in the ceiling. |

| The design is designed in such a way that a separate guide is fixed for each blade. Such doors are often installed as interior partitions and for decoration. They can be assembled in a single part of the opening - just pull one panel by the edge, and the others will follow it. Of course, this is also a rather complex system, just like the radius, so it’s not easy to make. |

| The canvases are fixed in the opening and move towards each other. The design assumes the ability to open only one half of the opening. However, you can place various objects against the walls that will definitely not interfere with the opening of the doors. |

| This is a very simple hinged door design. The canvas moves on rollers attached to the top. The disadvantages include not the best sound insulation. |

Design diagram with top movement mechanism

Instructions

- The first step is to print out all the furniture panels and select panels with the most beautiful pattern and without knots as doors. This will make the cabinet more beautiful and durable.

- At first I wanted to make shutter doors, but I couldn’t find the right size.

- The design of a wardrobe with sliding doors is extremely simple and will be understandable to everyone. Schematic drawing without doors:

- I pre-cut all the parts to size with a jigsaw and slightly rounded them with sanding paper.

- We screw 6 legs onto the bottom panel measuring 121.8 x 60 cm. 2 legs on the right with a distance of 10 cm from the wall and 2 legs with a distance of 1 cm from the wall on the left. We place two more legs under the future central post.

- We screw the bar to the bottom to prevent small objects from rolling under the cabinet and hard-to-reach debris from accumulating there.

- Since a gas pipe will go through the cabinet, we cut a groove in the middle pillar:

- Next, using the corners, you need to secure all the shelves on the walls and the central rack. Each shelf is attached to 4 corners.

- After installing all the shelves, you need to secure the upper and lower plastic guides for sliding doors and prepare the rollers as in the photo below.

- Next, we install a countertop and a corner that will prevent objects from falling behind the cabinet and liquids from draining.

- Using a Forstner drill, we make 5 recesses in each door. 2 at the bottom of the door for rollers, 2 at the top for guides and 1 recess for a recessed handle, which will not interfere with completely sliding one door behind another.

- We install the doors inside the cabinet. The DIY balcony cabinet is ready!

What mounting options are there?

Depending on the type of structure, the following installation methods are distinguished:

- With two guides. They are fixed on the ceiling to a wooden beam (which is previously installed there) and from below. Thus, the canvas is securely fixed, allowing it to move smoothly and without obstacles. The only disadvantage that can be highlighted is that for the lower profile in the floor you will have to make a recess in advance using the gating method. If it is not embedded into the floor, the structure will look unsightly and the profile itself will quickly become unusable. In addition, contaminants often accumulate in it.

Doors with two tracks - With one guide. For canvases of this type, special fasteners are provided. They are installed in the opening and move along the profile, which is located on top. An additional rail is not installed at the bottom, because usually such doors have a small mass.

Glazing with plastic structures

Plastic windows are usually installed by the same companies that specialize in their production, so when purchasing structures, you can immediately arrange their installation. If it is not possible to invite craftsmen to carry out the work, then the installation is carried out with your own hands. Glazing a veranda using metal-plastic structures is a little more complicated than with wooden frames.

Full glazing option.

It will not be easy to carry out glazing work alone, so the best option is to have 1-2 partners who will help maintain the accuracy of the installation. Installation is carried out in the following sequence:

- First, you should take care of selecting plastic structures for the veranda at the dacha that are suitable in size. Most likely, you will have to make an individual order from a specialized company. At the same stage, you need to choose the type of fittings: sliding, turning, tilting, tilt-and-turn windows. Sliding windows are the most convenient to use - they can simply be moved to the side, while when using tilt-and-turn systems, the open sash will take up space in the room (interestingly, sliding systems are usually less durable than tilt-and-turn systems).

- The most difficult thing is to mount the metal-plastic frame into the veranda opening, which requires the help of several partners. Before starting installation, it is recommended to temporarily remove the window sashes from the frame so as not to damage the glass during work. The frame is fastened using reliable fasteners recommended by the manufacturer (the choice of fasteners will depend on the type of material from which the veranda at the dacha is made).

- After installation work, gaps will necessarily form between the structure and the walls, which must be closed using construction foam. Soft rubber seals are used to eliminate gaps. Only after this is the installation of the sashes with glass carried out.

If the glazing of the veranda was made with a metal-plastic window structure, then it is recommended to insulate the room and install heating elements to ensure its year-round operation.

Materials for making sliding doors

The reliability of the structure will also depend on the quality of the materials from which it is made, so special attention should be paid to this point.

The sliding system is a mechanism that consists of guides, rails and rollers. It can be made from various materials:

- Steel. It is these durable mechanisms that are best suited for installing heavy interior doors. They securely fix the canvas and do not deform under load. The only drawback is the noticeable noise when the doors move.

- Aluminum. Guides made of this metal should be chosen only if you plan to install a weightless canvas. One of the advantages of such a mechanism is the silent movement of the canvases.

- Plastic. A mechanism made from this material is used only for simple hinged doors.

It is recommended to use only durable, steel guides

Note! An equally important point is the choice of material for the canvas itself. In this case, the purpose of the structure will be of great importance.

Table No. 3. The most popular materials for making door leaves.

| Material | Description |

| Wood | Sliding doors are usually made from natural solid wood, which are best suited to a classic interior. It should be taken into account that the canvas will have a large mass, therefore the fastenings must be as strong as possible. In addition, if you make your own door from natural wood, you need to take care to protect the structure from fungus using special treatment. |

| MDF or chipboard | Such materials are often used to make doors, because they are much cheaper than natural wood, but at the same time have good resistance to temperature changes and humidity. However, it should be noted that MDF is much easier to saw - it is from this material that a structure of any shape can be cut. In addition, it is environmentally friendly compared to chipboard. Most often, craftsmen prefer to choose laminated panels, because such a door does not need to be primed or painted. It is strictly not recommended to use chipboard for sliding doors in a children's room, because this material contains toxic synthetic resins. |

| Plexiglas | In this case, we are not talking about standard glass, but a special organic material that is resistant to mechanical damage. Such doors have an unusual appearance - they can be matte, glossy, with or without various patterns. Of course, such a canvas serves as a decoration rather than as protection from noise or prying eyes. An excellent replacement for glass construction are polycarbonate sheets. This material also has an unusual appearance, but it is quite durable. Another obvious advantage of polycarbonate is the huge variety of colors. |

Glass doors are often used by designers to create respectable interiors.

If you have the desire and opportunity, you can combine the listed materials. Some craftsmen prefer to install glass or mirrors in wooden doors.

Important point! It is important to use only high-quality material in your work, otherwise the door leaf may become deformed. This especially often happens when natural wood is poorly processed and dried.

Plastic structures

An indispensable option for “warm” glazing. Advantages: high degree of tightness, the ability to install various fittings and anti-burglary mechanisms in the profile, a large selection of laminated surfaces of various colors and for different materials. The main disadvantage is too much weight. Therefore, it is not recommended to use it for external glazing (balconies, loggias). In some cases, the use of special lightweight structures is allowed. But any choice of PVC profile and double-glazed windows is allowed if the structure is strong enough. A more suitable option for glazing verandas and terraces in a wooden house, because you can install laminated PVC frames to look like wood.

Making a sliding door

Even a novice master can handle a simple version of the sliding design. We will look at the main stages of manufacturing a sliding door.

Before starting installation, you must prepare all materials and tools

Materials and tools

During the work we will need the following devices:

- electric drill, screwdriver;

- chisel;

- electric jigsaw;

- Bulgarian;

- building level;

- roulette;

- Screwdriver Set;

- a simple pencil and a ruler.

In addition, you will need to prepare materials:

- chipboard sheets for door leaves;

- guide rails, rollers, fittings;

- bars with a cross section of 5×5 centimeters;

- anchor fastenings;

- decorative additions;

- self-tapping screws

Calculations and drawings

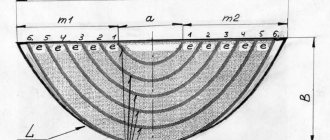

It is recommended to draw up a drawing of the door leaf with dimensions. To do this, we will need to first measure the doorway (it is necessary to take into account the distance to the ceiling in order to determine the method of installing the sliding doors). In addition, you should take into account the distance from the opening to the corners, because in all cases it is not enough for the sash to slide out freely.

If you decide to install a frame over a doorway, then first of all you need to take into account the thickness of the floors - if there are too crooked walls, the measurements may not match, so they will have to be double-checked several times. In addition, you should make sure that the floor is level and not sloped.

This is what the measurement diagram looks like

According to the standard, the canvas has the following dimensions:

- width – from 40 to 90 centimeters;

- height – 275 centimeters.

When making a door yourself, you should not make it too large, because the rollers may not withstand excessive load.

When choosing the classic version of sliding doors, you need to make a leaf that will be 20-50 millimeters higher than the opening. The width of these doors should be 20-30 millimeters larger on both sides.

The table shows the maximum dimensions of door leaves. The possibility of deviation from these values is not excluded, but only to a lesser extent

In the case of installing a cassette mechanism, it is necessary to cut out the canvas exactly to the size of the opening, because first the mechanism itself will be installed, and only then the niche.

By combining materials, you can make the door leaf weightless. Here are some of the most popular lightweight design options.

If you think that it will be easier to make a door leaf from wooden blocks, then the following diagram of their connections will be useful in your work

In this case, you should use polished timber, which will not have to be further processed. In order to make the most accurate cuts, it is advisable to purchase specialized carpentry equipment.

The process of making a sliding door: step-by-step instructions

Step 1. First of all, we need to cut out a door leaf of the required size from a sheet of chipboard. This can be done at home, but it is better to turn to professional furniture makers. Next we need to process the edges. This is quite simple to do, using an iron or hair dryer with hot air, after which the edges can be cut off with a utility knife.

Treated and untreated chipboard edges

Important point! During work, you must use protective gloves for your hands and special glasses for your eyes.

Step 2. Now you need to take a wooden beam and measure the required length from it.

You should mark and saw off the beam using a jigsaw

Now, according to preliminary markings, we will need to fix the beam above the doorway (in our case it will be held on by four long screws)

Step 3. Now you need to measure the required length of the rails.

You can cut the metal guide using a grinder

Now you should make holes in the guide for the screws

It is necessary to place it on a chair, holding it with one hand, and drill through holes.

Step 4. Next you will need to screw the guide rail to the wooden block above the opening.

You need to hold it with one hand and screw in the screws one by one

Important point! If the guide is installed without a bar, then it is necessary to fix it a few centimeters further from the wall, otherwise the door will touch the trim when moving.

It is necessary to carefully check the correct position of the bar and the guide using a level, because the ability to freely open the door depends on this.

Step 5. Now you need to attach the metal fasteners from the kit to the door leaf.

We attach the hanging mounts for the rollers with self-tapping screws

Step 6. Now you should mark the location where the door handle is attached.

It is important not to make mistakes in the calculations and put marks on all sides

Now you need to make holes using a drill along the marking lines

This is necessary in order to place a jigsaw blade there and cut out a recess for attaching the handle.

You should also cut out the hole carefully, moving exactly along the marked lines.

Tips for choosing a jigsaw

It’s better not to rush here and, if necessary, make a few more holes with a drill on the other side.

The door handle mount should be installed in the resulting hole, after which you will need to insert the door handle itself

Step 7. The next step is to insert the rollers into the top guide.

You need to insert two rollers into the guide

Now you need to screw the door lock from below

The groove in the door leaf must be made using a grinder and a special circle.

Step 8. Next you need to hang the door leaf.

Using the screws located on the rollers, you should set the canvas to the optimal level, after which it can be secured with nuts

Next, you need to insert the clamps into the guide and wrap them up - this will be needed so that the door does not go beyond the rails

Step 9. The fastenings will need to be covered with decorative trim in the color of the door leaf.

First you need to measure the exact length of the extension, and then you will need to cut it to size with a jigsaw

The extension can be secured to small nails with decorative heads. It is important to carefully fix it on both sides. Now we need to mark and cut the side panels for our door. Then all that remains is to install them according to the same principle.

Upon completion of all work, it is necessary to check the functionality of the structure - the door should move smoothly along the guide without any obstacles.

Video - Sliding door from an ordinary one. DIY compartment door

This is the simplest option for making a sliding structure at home, which is suitable for beginners. If desired, you can also install a lower guide with rollers. In this case, it will be necessary to make a recess according to its dimensions in the floor. It is worth noting that this is a more modern option, because such a mechanism operates silently.

Important point! In this case, when hanging the door, the door leaf is first inserted into the lower guide, and then into the upper one.

Let's start installation

We start installation from the opening. You need to measure the height in three places: the left and right edge, in the center, and we also measure the width in three points - top, center and bottom. If you have a desire to frame the opening decoratively, you need to measure the minimum and maximum thickness of the walls; measurements are taken in the corners too, not just on the sides.

Instructions:

Removing the old door leaf

The first thing you need to do is get rid of the old door. We remove not only the door itself, but also everything that will interfere with our work: hinges, trim and, of course, the door frame. Here is the point: if the box does not interfere with the installation of a new entrance, you can leave it, but this happens extremely rarely, so it is better to immediately get rid of the unnecessary part.

Photo from the site legkovmeste.ru

Alignment of walls

We carefully process the edges to which the box was attached; most likely they will look untidy after installation. Our task is to put them in order and make them perfectly even; for this we strongly recommend using a level. The opening must have completely clear dimensions and edges. There should be no excess brick or exposed drywall anywhere.

The lower surface of the opening and the floor must be parallel to each other and absolutely horizontal, the error can be a maximum of 5 mm. You need to check the side parts with a plumb line, and they can also have a deviation of no more than 5 mm. Ideally, the walls should be smooth, then the doors will fit tightly.

Photo from the site stroyday.ru

Installation of the box

Let's proceed directly to installing the box. We will level it using wedges, and to adjust the floor, these wedges need to be moved or recessed. Thus, relative to the floor and walls, you will align the position of the doorway

After making sure that everything is level, we secure the structure with screws - use the screwdriver very carefully, the slightest shift to the side can damage the surface

We fix the upper guides

When the door frame is ready, you need to place the door itself close to it and mark where it is located along the top edge. Then we do the same thing, only now we insert the door into the opening. This is a necessary action, because the floor may not be perfectly level - this is how you check the horizontal and if everything is correct, measure 70 mm up from the line. This is the place where we will install the rail; we fix the wooden beam here with self-tapping screws.

Photo from www.youtube.com

We fasten the rail to the lower surface of the beam, not too tightly at first. We check whether it is installed evenly and whether there is enough space between the door and the wall, then we secure it completely.

Assembling the carriages and installing limiters

This stage is quite simple - you need to install carriages with rollers. The main thing to consider is that the tips should protrude slightly beyond the boundaries of the holes. We insert each into the prepared groove of the rail and check how freely the movement occurs. It is necessary to install limiters along the edges so that the rubber shock absorbers are directed inward.

Bottom groove

We retreat 15 mm from the edge of the sash and drill 2 holes, the diameter of which is 7 mm and the depth is 20 mm. We make a groove between these recesses; it will be needed for the lower guide.

Photo from the site strport.ru

The groove should be 18 mm deep and 2-3 mm wider than the bottom guide. It is difficult to make a straight hole on your own, so it is at this stage that an electric drill will come in handy.

Fastening

It is necessary to attach to the carriages carefully and exactly in the middle, retreating at least two mm from the sides of the sash

It is also important to take into account that the round cutouts on the brackets are turned towards the wall

Installing the canvas

We attach the door to the rail and connect the right carriage with the hole in the bracket on the same side. We insert the tip of the bolt into the hole in the fastener for the adjustment nut. We fasten the brackets with bolts. Now we install the lower part, this is not difficult to do - you just need to slightly lift the door itself and insert it into the recess.

We screw the lower guide to the floor with self-tapping screws, now it is fixed, double-check that everything is installed evenly and that there is no gap between the door and the floor. If there are errors, tighten the screws more.

So, the sliding door is installed, to consolidate the information, we recommend watching a video on how to install sliding doors with your own hands.

When the job is done. You can start decorating; doors of this type themselves decorate the space, and if you additionally add a certain style, they will become a bright and stylish spot.

Advantages and disadvantages of sliding doors

Before you start manufacturing sliding doors, you need to carefully study all the advantages and disadvantages of such structures. It is worth considering that sliding doors are also not suitable in all cases.

Interior sliding doors can be incredibly aesthetic

The following advantages of sliding doors should be highlighted:

- such doors take up minimal space compared to any swing models;

- you can open and close the canvas without much effort; even a child can handle such actions;

- even if there is a draft in the room, the door will definitely not slam or open from it;

- this is the best way to divide a room into several zones, because glass sheets are often used as decorative partitions;

- some door designs do not provide for a threshold, so this option is suitable if disabled or elderly people live in the apartment;

- the design is perfect for any room, including the bathroom, kitchen, bedroom;

- If you have additional funds, you can install an automatic door opening mechanism.

Installing this design allows you to visually expand the wall

However, it is necessary to note the disadvantages due to which some people refuse to install interior sliding doors:

- if the canvas moves along the wall, then it is impossible to place furniture near it (it turns out that the design conceals useful space);

- poor sound insulation from extraneous sounds is often observed - this is due to the fact that there are gaps between the canvas and the frame;

- Because of such doors, heat in the room is worse retained;

- the cost of installing sliding doors will be significantly higher compared to the standard option;

- if you buy budget components, the door may fail within a few months;

- If you are going to install compartment doors with two leaves, then it will be more difficult to cope with this process, because these parts should be perfectly matched to each other, so you will have to involve a professional craftsman in the work.

Video - Installation of sliding doors in thin ceilings

Only if it is assembled correctly will you be able to evaluate the ease of use of sliding doors, so when installing it yourself, you must carefully take measurements. Even minor deviations will lead to the design not functioning properly. The work must be carried out slowly and carefully, then the result will definitely please all household members.

You can learn more about how to make sliding doors with your own hands by reading our article.

Aluminum windows

A very practical option for a country house or city house is windows with aluminum frames. These are often installed on unheated verandas. Among the advantages of aluminum structures:

- Long service life. A properly installed structure will not require replacement for 50 years.

- Attractive appearance. Windows do not need to be painted every 2-3 years; they do not fade or become deformed.

- Easy installation and maintenance.

- Light weight, which does not create additional load on the foundation.

Despite numerous advantages, aluminum windows also have disadvantages. The design will not be cheap; the first generation profiles quickly heat up in the heat and freeze in the cold. The tightness of the windows provides warmth and protection from noise, but requires frequent ventilation of the room. Aluminum windows are best installed on verandas made of materials that allow air to pass through: wood or brick.

There are 2 options for aluminum profiles on sale: cold and warm. The first is suitable for unheated verandas, which are used only in summer. They provide single glazing without additional insulation. Windows with a warm profile are suitable for houses where people live all year round. Such windows are equipped with special gaskets and inserts that guarantee excellent sound and heat insulation. It is not necessary to make all windows sliding. A more convenient option is a combination of fixed and sliding glazing.

Fabric preparation

For work, you can use not new material, but an old door. But it will need to be well processed. Please note that you may have to use several old sheets to make sliding doors on rollers. You can construct them with your own hands only after painstaking planning. They must be lightweight, so there is no need to additionally insulate or upholster the interior doors.