A balcony in an apartment is a platform for which many unique ideas have long been invented. It can continue to be used for storing things or converted into a new functional room. After the transformation, the space will take on a new life. This event is preceded by several troublesome measures, and one of them is insulating the floor on the balcony.

We insulate the balcony floor correctly

Why is this necessary?

Choosing insulation

Preparation for installation

Two methods of insulation

- Rack construction

- Heated system

It is difficult to find “extra” square meters in any apartment. Every free space becomes useful. It would be a mistake in such conditions to neglect the balcony room, leaving it the role of a warehouse for rarely used items and outright rubbish. A thrifty owner will definitely turn it into a full-fledged room, but for this it is necessary to take care of heating, which is impossible without thermal insulation. Let's look at how to properly insulate the floor on a balcony.

Why is thermal insulation necessary?

When thinking about the functionality of a balcony room, you need to understand that finishing work will clearly not be enough to turn it into a full-fledged room. Even high-quality glazing will not save the situation. It is necessary to close the space from the street, but this is very little. Temperature changes will leave no chance for new design and will make staying on the balcony as uncomfortable as possible.

Therefore, the first thing to do after glazing is effective thermal insulation. It will be required for all surfaces: ceiling, walls and floor. This is the only way to prevent heat leakage and, accordingly, make the heating devices operate more efficiently.

If the room will not be heated, the use of insulating materials will significantly smooth out temperature changes and make its use more comfortable.

Instagram balkony_vkazani

The latter option is especially relevant for areas with warm winters, where sub-zero temperatures are rare. But in any case, high-quality thermal insulation will be necessary.

- Balconies and loggias

How to insulate a balcony from the inside with your own hands: a detailed guide

Choosing a method depending on the task

For some residents, it is enough for the temperature on the balcony not to drop below positive values. And for other owners of an insulated balcony, it is important that the temperature there does not fall below 20 degrees.

Because one owner uses the balcony to store workpieces or dry clothes. It will be enough for him to be able to go out onto the balcony without wearing a winter down jacket.

And another owner seeks to increase the living space of his apartment and arrange a comfortable room on the balcony for permanent use.

Important! If you insulate a balcony with cold glazing, this will help you gain only 5 °C compared to the temperature outside.

What is the best way to insulate the floor on a balcony?

Before you start work, you should select the type of material. Its choice determines the installation technology and the set of necessary components. Several options are possible.

Foamed polyethylene

Based on it, a whole group of roll-type insulators is produced. Their distinctive feature is their small thickness, so they are most often used together with other materials. The optimal choice can be considered a foil coating of this type, which allows you to save thermal energy through additional reflection. In addition, foil is an excellent hydro- and vapor barrier.

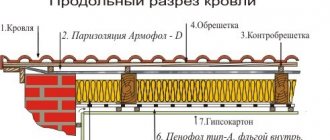

Perhaps the most famous insulator of this type is penofol. On sale you can find three varieties of it, marked with different letters.

- A. Only one side of the panel is covered with foil.

- B. Both sides are foil-coated.

- C. Foil is only on the outside; an adhesive layer is applied to the inside.

The latter type is a little more expensive, but it is very convenient to install.

Instagram hit_stroi

It is important to position the reflective layer correctly. The insulation is laid overlapping or end-to-end. In any case, it is fixed with foil tape. This creates a continuous reflective sheet.

Expanded polystyrene

The most affordable polystyrene foam insulator is polystyrene foam. Available in the form of slabs that are easy to place in the desired location. It is characterized by low thermal conductivity, light weight and insensitivity to moisture. Negative qualities include fragility, flammability and possible toxicity. The latter depends on the quality of the selected foam. In addition, the vapor permeability of the material is almost zero. However, this is not important for the balcony.

In all respects it is superior to extruded polystyrene foam. Produced under the brands penoplex, technoplex, etc. It has high insulating characteristics, low weight, and is produced in the form of slabs. Non-toxic, moisture-proof, low vapor permeability. Disadvantages include flammability and higher cost than polystyrene foam.

Mineral wool

The general name for fiber insulation, produced in the form of rolls or slabs. Their general advantages include low cost, low thermal conductivity and sufficient elasticity, which allows filling the insulated space without voids. Unfortunately, cotton wool does not tolerate high humidity at all. They absorb water, after which they lose their insulating properties. In addition, over time they may lose their shape.

There are several varieties of mineral wool. Slag is made from blast furnace waste. It is toxic and is not used for residential premises. Glass wool is produced from waste from the glass industry. The main disadvantage is the fragility of the fibers. The resulting particles are dangerous to the human body. Therefore, special care is required when working with it. In addition, fiberglass shards should not fall into rooms where people are present.

TechnoNIKOL

The best choice for insulation is basalt or stone wool. It is absolutely safe and has good insulating properties. But at the same time, its cost is higher than that of its analogues.

Expanded clay

Porous clay balls of various fractions. It has a fairly low thermal conductivity, is an environmentally friendly material, and is not flammable. The only disadvantage is, perhaps, the rather high cost of the insulator. However, it is used quite rarely for balconies, since for high-quality thermal insulation it will be necessary to lay a high layer of expanded clay. This will put a significant load on the concrete slab, which is most often undesirable.

We have listed the most popular options. It is possible to use other, newer materials. For example, ecowool or polyurethane foam. They have excellent insulating characteristics and last a long time. During operation they do not lose their properties. But at the same time, their installation is carried out only by professionals using special equipment.

- Balconies and loggias

What is the best material to make a balcony floor from: 5 practical options

Preparatory work

Once the insulation has been selected, proper preparation for its installation must be carried out. To begin with, it is worth assessing the general condition of the floor. If it is satisfactory, that is, the surface is without defects, relatively smooth, and does not crumble, you can proceed to the next stage.

Instagram balcon_dizain

The base can be tiled. Dismantling will be unnecessary, provided that it is well preserved. The insulation fits well on the tiled surface. No special preparation is required.

If there are significant defects in the base in the form of cracks, chips or potholes, it is advisable to eliminate them. It does not matter that the surface will subsequently be covered with an insulator. The flaws will become reservoirs of sorts where moisture will begin to accumulate. Subsequently, colonies of microorganisms can settle here, and pockets of erosion will appear. Therefore, all defects are carefully repaired.

The protrusions are chipped off, the cracks are carefully repaired. That is, they expand at an angle so that the repair compound can fill them as tightly as possible. Then everything is well cleaned of dust and primed. After the primer has dried, the defective areas are filled with sealant, putty, etc. After the composition has completely dried, the “patches” are cleaned so that they do not protrude above the floor level. It is most likely not worth installing a screed. It will significantly make the structure heavier.

The next important stage is waterproofing. Balcony slab is porous. This means that if insulated from the inside, it will still absorb moisture coming from outside. Water through the capillaries will quickly reach the heat insulator and begin to destroy it.

Instagram konstantin_remont_kvartirperm

Therefore, it is necessary to lay a layer of waterproofing coating. You can choose any option. The easiest way to work is with mastic, which is applied using a roller or brush. But you can also lay rolled fabric.

- Balconies and loggias

How to lay the floor on the balcony: 7 practical materials

Features of penoplex insulation

Insulating the floor on a loggia using penoplex has its own characteristics. The fact is that due to the strength of the material, it is not necessary to use logs when laying it under the flooring; plywood sheets can be laid directly on the foam plastic. The stages of work will be as follows:

- A leveling screed is made on the prepared floor, which is necessary to prevent deformation of the insulation boards.

- After adjusting to size, the foam boards are glued directly to the floor with special glue. It is convenient to use a type of insulation that has a groove connection system. If it is not there, then you need to use polyurethane foam along the joints between the slabs, as well as between them and the walls.

- To increase the efficiency of floor insulation, you can lay penofol (isolon) on top with the foil side facing out, gluing the joints with reinforced tape.

The following photograph demonstrates the insulation process in this way.

How to insulate the floor on a balcony: 2 possible methods

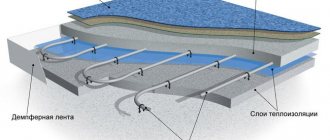

The method of installing thermal insulation depends on the material that will be laid. According to the rules, it is mounted on a base that has been pre-treated with waterproofing. The floor will need to be raised to the height of the insulation cake. The thermal insulation coating is covered with another layer of vapor and waterproofing on top. Next, the subfloor is laid, and the floor covering is installed on top. Let's look at two options for arranging such structures.

Insulated construction on racks

The easiest way is to place the rough flooring boards on the joists. So that they are aligned to the required level and raised to a height sufficient for installing the insulation. Metal corners, brackets in the shape of the letter “p”, etc. can be used as racks holding the logs. The work is performed in the following sequence.

- We clean the base, remove dust and debris that has fallen on it.

- We mark the surface for the racks. The mounting step for the longitudinal joists is 50 cm. In addition, you will need a stand for each of the jumpers. We start marking from the wall, retreating 5 cm from them.

- A. We use a water or laser level for this. We will use it to level the height of the lag installation.

- We install racks or brackets. We securely fasten them to the base.

- We put the logs in place. We correctly align them along the “zero line” and control the horizontal using a level.

- We lay insulation between the joists. We cut off fragments of the roll or slab with a small margin so that the material has to be lightly compacted. This way you can close all the voids.

- We lay a diffuse membrane, which will become a vapor and waterproofing barrier.

- We install a subfloor made of plywood. We attach the sheets to the racks.

Instagram interior_inside_home

Next, you can lay the selected floor covering. It can be board, linoleum, carpet, laminate. The latter is chosen quite often. It is practical, functional and at the same time beautiful. It's not difficult to install it.

- Floor

How to insulate a floor in a wooden house: useful instructions

Materials and tools

Before starting work, you need to buy basic and auxiliary materials and prepare a set of tools. Materials you will need:

- insulation (its quantity is equal to the insulated area);

- Chipboard, plywood or OSB (chipboard is better, since it only exhibits linear expansion during fluctuations in humidity and temperature);

- waterproofing material (the specific choice of waterproofing agents will be discussed in a separate work);

- vapor barrier film (needed when using soft insulation);

- primer;

- wooden beam (specific dimensions depend on the thickness of the insulation);

- metal U-shaped supports for attaching timber or studs;

- polyurethane foam;

- self-tapping dowels for fixing supports to the base of the balcony;

- electrical tape (painting tape) for gluing insulation joints;

- wood screws for connecting the timber to the supports.

Attention: the tiles are laid on a screed, which requires completely different materials and tools, which you can read about in the material “Technology of wet floor screed with expanded clay.”

The tools you need to have on hand are:

- electric drill or powerful screwdriver;

- hammer drill (needed only for leveling the base of the balcony and removing the plaster layer from the bottom of the walls to the thickness of the thermal insulation);

- jigsaw or wood saw;

- construction knife with replaceable blade;

- roulette;

- construction pencil.