Floor screeding on a balcony is done in two cases: when it is planned to insulate it and to extend the life of the concrete base. The balcony slab is located in the open air and is therefore exposed to the sun and moisture. Over time, cracks begin to appear in it, and the concrete begins to crumble. It is dangerous to go out onto such a loggia or balcony, so it is necessary to screed the floor. Some people believe that screeding on the balcony will only increase the load on the slab. This is true, but there are several ways to give your balcony a second life. The technology for pouring screed is quite simple, so you can do all the work yourself without hiring expensive specialists.

How to determine whether a screed is needed?

To answer this question, it is enough to visually assess the condition of the floor on the loggia. If there are swellings on the concrete slab, rust spots appear, or cracks are present, this indicates that urgent restoration of the floor is necessary. In addition, a screed is made on the loggia to insulate the base. This usually happens when glazing a balcony or loggia is planned. A screed is necessary for installing any floor covering or installing a heated floor system.

Most people make the loggia an extension of the apartment. Some even set up small rooms there. In order for the balcony to be warm and durable, floor screed is simply necessary, otherwise all finishing work will go to waste. How to do it yourself, and which option to strengthen the slab to choose? We will consider all possible methods of screeding floors on a loggia, and you will choose the best option for yourself.

Preparing the work area

Before you start mixing the material to fill the floor on the balcony, you need to carefully prepare the surface for future events. Of course, you should remove all unnecessary things that were stored on the balcony. Then you should begin dismantling work, that is, get rid of the previous coating. As a rule, dismantling is a fairly dusty and dirty task, so you should take care of your safety in advance - wear goggles and a respirator.

Preparing the work area

Construction dust can seriously affect your health, so take the issue of protection responsibly. After preparation, you can begin to destroy and eliminate the old coating. To do this, you will need to prepare a number of the following tools, without which dismantling is simply impossible:

- scrap;

- hammer;

- nail puller;

- chisel;

- and an iron scoop or shovel.

It is worth noting that dismantling can be complete or partial. It depends on the quality of the old coating. If it is in more or less decent condition, then it can be safely used as the basis for a new coating. But professional builders recommend getting rid of the consequences of previous renovation work in order to achieve the spectacular desired result that will last for many years.

Preparing the base

To complete this step, the old floor covering is removed from the surface of the slab. The slab itself must be processed, removing all loose and cracked pieces. This can be done using a regular hammer. If the condition of the balcony slab is deplorable and it was necessary to remove the concrete down to the tension reinforcement, the metal must be coated with oil paint or primer. This must be done, otherwise rust may appear through the screed. The resulting chips and irregularities should be repaired using cement-sand mortar or tile adhesive.

USEFUL INFORMATION: Features of the dry screed device

Then you need to remove all debris and thoroughly prime the slab. To do this, it is recommended to use a deep penetration primer. It is usually applied in two layers: the second time it is primed only after the first layer has completely dried. Further work can begin in approximately 7-8 hours. This is exactly how long it takes for the soil mixture to dry completely.

Preparation of the solution

Mixing concrete mortar can be done in two ways: using an electric drill with a “mixer” or an ordinary shovel.

Mixing the solution

Balconies are a small space, so you can mix the product needed to fill it without the help of electrical appliances.

The issue of proportions is important. In order to mix a solution of the correct composition and consistency, it is necessary to carry out this work in the following proportions: 2 parts sand, 1 part cement and 1 part crushed stone.

Applying cement mortar to the balcony

Water is also used for mixing. It is added after combining all the ingredients. It is worth adding it in small portions, since carelessness can make the solution too liquid and not suitable for the planned work.

Surface reinforcement to improve quality characteristics

Dry screed

Dry screed is ideal for older houses. It does not increase the load on the balcony slab, serves as additional thermal insulation and is quickly installed. Among the disadvantages, it can be noted that a dry screed will not give special strength to the floor on the loggia.

Installing a dry floor screed on a balcony is a rather complex process that requires a certain level of skill. If you are not sure that you can do the job yourself, it is better to call a specialist or try another method.

The work is carried out according to the following scheme:

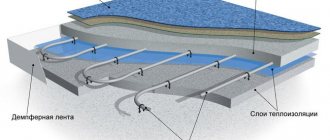

- A waterproofing film is laid on the slab. It is important that the edges extend onto the walls by about 5-7 centimeters. The waterproofing can be secured using damper tape.

- They put up beacons. This is a metal profile that will help simplify the pouring process. Remember that beacons are installed strictly according to level!

- Add a layer of thermal insulation. Some builders use sand for these purposes. This is not the best solution: such floors turn out cold. If you do the work yourself, we recommend using dry ready-made Knauf backfill.

- The mixture is leveled into beacons using the rule. In those places where the backfill has sagged, it is necessary to fill in the missing part. The dry mixture should lie flat.

- GVL (gypsum fiber sheet) is laid on top of the backfill. It is recommended to do this in two layers, overlapping the joints. The sheets are fixed with glue.

- Install the floor covering.

With certain skills, you can cope with such work with your own hands and quite quickly - within one day.

USEFUL INFORMATION: Technology of laying parquet boards on plywood: price per square meter

Types of screeds used on balconies and loggias

In the current realities, several screed technologies are used:

1) Wet (strong, reliable, durable);

2) Semi-dry (adding a small amount of water, relatively quick hardening);

3) Dry (simple method of application, high speed of laying materials).

During the work, building materials are used: GVLV, GSP, DSP, cement, sand mixtures, liquid solutions, tools, etc. When choosing, you need to take one nuance into account. A balcony slab differs from a loggia slab in the method of fastening and may not withstand the heavy weight of a wet screed. Therefore, it is important to pay attention to the other two options.

Self-leveling solutions should be highlighted in a separate line. Before use, the compositions are diluted with water, and the surface is leveled due to the spreading of the liquid. Mixtures are produced on the basis of:

- Plaster. Mainly used when finishing styling is required. The key disadvantage during operation is poor resistance to humidity;

- Cement . The compositions are intended for rough finishing and smoothing out many defects. They are distinguished by strength and durability.

Finishing mixtures significantly improve the attractiveness of the substrate and are divided into epoxy, polyurethane and three-dimensional interpretation materials.

Wet screed

This is the best option for doing the work yourself. This method is based on pouring the loggia floor with cement-sand mortar. Even a person far from construction can cope with this task. Among the disadvantages of this method, one can note the increased load on the balcony slab. In addition, wet screed requires time and certain conditions. If you decide to make loggia floors using this method, we recommend planning the work for spring - summer.

The work is performed as follows:

- Install waterproofing. If you used a special mastic as a primer, then the need for additional protection from moisture disappears. If you are laying film, the edges should extend onto the wall by at least 10 centimeters. After completing the work, the excess can be trimmed with a knife.

- A reinforcing mesh is laid on the waterproofing. It is better not to use metal for reinforcement, this will make the structure even heavier.

- Beacons are installed. The distance between the guides should be about 50 centimeters, the profile height should be 5. It makes no sense to make the floors on the loggia thicker.

- To fill, you can use ready-made mixtures or make the solution yourself. To give the screed greater strength, it is recommended to add frost-resistant reagents to the solution.

- The screed is poured at the level of the beacons. Remember that the solution must be smoothed in one direction. It is best to do this from the far wall towards the balcony door. The solution must dry for at least a week, only after which you can proceed to the next stage of work.

- Your next steps depend on what kind of flooring you decide to use. If you plan to lay tiles or linoleum, then simply prime the surface. In the case of installing laminate, you will have to apply a layer of leveling putty.

Materials to complete the work

From the information above, it becomes clear that the choice of materials for the base is determined by the type of screed. But besides this, it is also worth considering possible options for finishing coatings. In this case, everything depends on the degree of improvement of the balcony itself.

If you have high-quality glazing, insulation and heating using radiators or a heated floor system, you can use any materials. If the balcony is glazed, but not heated, then the only positive thing here is its protection from precipitation.

The lack of heating makes the room susceptible to temperature changes, which can cause condensation.

Therefore, the use of moisture-resistant materials in this case is the most reasonable solution. As a finishing coating, you can use linoleum, moisture-resistant laminate, carpet, and tiles.

Rain, snow and sub-zero temperatures in winter - all this has a direct impact on the unprotected structure. Materials that can “survive” in such conditions include: ceramic tiles, decking boards, porcelain stoneware.

An open balcony requires the use of materials that are most resistant to all kinds of weather conditions.

Return to content

Non-standard solutions

There are quite original ways to insulate loggia floors. Please note that it is insulating, not strengthening. We will talk about how to insulate a loggia as much as possible without using a “warm floor” system. The methods are quite simple, so you can easily do it yourself.

USEFUL INFORMATION: How to make cheap renovations in an apartment: save wisely

Option #1

Make a floor screed using polystyrene foam or penoplex. These materials will serve as excellent insulation. They do it like this:

- the balcony slab is leveled and foam sheets are laid on it. The sheets should not be too thick, because the screed itself will still go on top.

- Waterproofing and reinforcing mesh are laid on top of the foam.

- after this the screed is poured. The recommended layer thickness is 3-5 centimeters.

Option No. 2

Floor screed using expanded clay. This material has good thermal insulation properties, but you need to know how to work with it. You can do the work yourself according to the following scheme:

- A waterproofing layer is laid on the concrete base, and beacons are placed.

- A layer of expanded clay is poured between the beacons. This must be done so that at least three centimeters remain on the main screed.

- Expanded clay is a fairly light material, so when pouring the screed it will most likely float, so it needs to be fixed. This can be done using cement laitance.

- When the milk has set, you can begin the main filling.

Determining the finished floor level

After choosing the material, you need to determine the floor level. This is done using different types of levels:

- water level;

- laser level;

- bubble level.

If you use a water level, otherwise known as a spirit level, proceed as follows. A mark is placed anywhere on the wall of the loggia. Using a spirit level, a mark is made on all walls at the same level. A line (the so-called horizon) is drawn through the obtained points. The highest places on the floor are visually located, and the distance to the drawn line is measured.

The floor thickness is subtracted from the resulting smallest value. The resulting length is measured from the horizon to the floor. From the intended point, using a spirit level, a line is drawn that determines the level of the future floor.

The easiest way to determine the level of a finished floor is to use a laser level. It is installed at the highest point of the floor and turned on. Laser dots or lines will show a flat horizontal line, which will be the floor level.

To check the floor level with a bubble level, you need to visually determine the highest angle of the balcony and make a mark. Then the floor height is measured upward. Next, using a level, a line is drawn along the mark along the entire perimeter of the balcony. This method is not used for high-quality alignment, as it produces a significant error.

On open balconies, floors should be sloping towards the street. This is necessary to prevent atmospheric moisture from accumulating. A centimeter of slope per meter of width will be enough.

Installation principle

As in any other room, the floor on the balcony must be level. Another mandatory requirement regarding reliability and strength applies particularly to the balcony and loggia. The thing is that it is on the balcony that many people tend to store a huge amount of unnecessary things, the total weight of which sometimes even exceeds the weight of the furniture in a single room. Another habit that remains in apartments and, accordingly, their owners is related to washing.

Scheme for laying concrete floors.

Despite the fact that today technology has come so far that you can wash and dry and even iron clothes without any special effort. And yet, a large number of residents of certain regions of our state continue to dry wet laundry on the balcony. Accordingly, the humidity level is just off the charts.