Transforming a balcony or loggia into a room where you can stay for a long time throughout the year, and not just in the summer, is a very popular type of renovation, and one of the most important stages here, along with proper glazing and heating, is insulation of the floor, ceiling and external walls . Nowadays you can easily find everything you need for such work in stores. The choice of heat-insulating materials offered by manufacturers is quite wide, but penofol has become one of the most popular insulation materials. It is worth telling in more detail about why it has gained such popularity, as well as how to insulate a balcony with penofol as efficiently as possible.

Penofol - the newest generation of insulation

- Penofol can rightfully be considered the latest and most modern development in the field of insulating materials. The whole point of penofol is the ideal combination of polyethylene foam and aluminum. In addition to the insulation function, this material perfectly provides comprehensive protection for the balcony.

- Foamed plastic has low thermal conductivity properties, and aluminum foil perfectly reflects heat. In combination, these characteristics guarantee low heat loss in the room. They are able to retain about 95% of the heat on the balcony.

- Penofol perfectly repels moisture and can be used to waterproof a room. The insulation will not allow raindrops or moisture evaporation to enter the room.

- The porosity of foam plastic remarkably absorbs external noise. This fact takes on special significance if the loggia faces a busy street.

Penofol can be installed without the use of other materials. This is due to the rich protective functions of the insulation. The hydrophobic properties of the material make it possible not to lay a moisture-proof layer underneath when carrying out work on insulating the balcony.

The main advantages of foil insulation

This material guarantees:

- Excellent protection against fire, which is caused by materials that do not support combustion.

- Environmentally friendly.

- Penofol guarantees excellent protection from external noise, thanks to a layer of foamed plastic.

- Penofol is not at all interested in any insects or rodents.

- Easy to install.

- The insulation block is thin. This will be convenient when installation is carried out in difficult places.

- Penofol has excellent insulation properties and practically does not release heat from the room to the street.

Physical characteristics of penofol

Penofol is one of the latest developments from manufacturers of high-quality multi-tasking insulation materials. It is made of aluminum foil and polyethylene foam.

The main positive quality of this material is its high thermal insulation performance. Its additional positive characteristics include the possibility of using it for steam, sound and waterproofing, as well as for reflecting heat flows.

If penofol is laid in two layers, then the waterproofing of the room can be neglected. In addition, the characteristics of penofol make it possible to provide stable warmth in the room during the cold season and, conversely, keep it cool on hot days. Modern manufacturers produce this material in rolls, in which its thickness can vary from 3 to 10 mm, that is, during installation it has almost no effect on the free space.

We insulate the balcony with penofol with our own hands

Penofol has a structure that makes it easy to cut it into sheets of the required size and shape; it adapts perfectly to any repair conditions. The polyethylene foam included in its composition makes it possible to fasten this material with screws or nails, without reducing its thermal insulation characteristics.

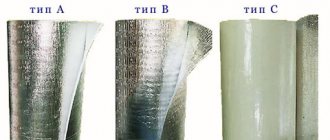

Penofol with different properties is labeled with different letters. The marking in this case means the following:

- A: covered with foil, which ensures its vapor- and waterproofing properties, on one side (it is recommended to strengthen such sheets by placing them with foil against the wall adjacent to the street);

- B: The same coating is located on both sides, so it can be attached in any direction;

- C: on one side there is foil, and the other is self-adhesive (this material is used on walls for which the issues of vapor and waterproofing are less relevant, that is, on those adjacent to the interior);

- R: has a relief surface, and is covered with foil only on one side;

- M: has the same surface, but covered with foil on both sides:

- ALP: covered with polyethylene film with lamination on one side and covered with foil on the other.

Penofol contains a filler that has a structure with completely isolated pores and, due to the air enclosed in them, provides excellent thermal insulation with minimal dimensions. Polyethylene is covered on one (and sometimes on both) sides with aluminum foil no more than 14 microns thick.

Modern penofol can be classified as an average-cost heat insulator: its cost is significantly less than penoplex and mineral wool, but at the same time it is somewhat more expensive than polystyrene foam. Its thermal insulation characteristics are correspondingly lower than those of polystyrene foam, but higher than those of the cheaper materials mentioned above.

Polyurethane-based compositions

For the installation of penoplex such products are often used. Most are sold in cylinders, so they are convenient and easy to use even for a beginner. The products are ready for use, they do not need to be mixed, and the consumption is economical. The most popular composition of the series is “Insta-Stik”. It is sold in 750 ml cylinders, the consumption when gluing is 12-15 sq.

Another well-known glue is Titan Stiro-753. Its consumption is approximately the same (about 14 sq. m). The product has a high peeling force (600 kPa), and the setting time is even shorter (15 minutes). Penosil Fix{amp}amp;Go Montage is frost-resistant; it is used at -65... 130 degrees. Using the described means, it is easy to connect foam sheets together, stick them on wood, attach them to a brick wall, or to concrete.

If necessary, the adhesive will provide adhesion to most building materials. Among them are plaster, stone, wood, expanded clay concrete blocks, metal, cork, cellulose. If the material had to be foiled, this product is incompatible with it. Foam is also not suitable for polyethylene, silicone, and Teflon. Here are the main characteristics of the material:

- drying – 10-12 minutes;

- complete hardening – 24 hours;

- possibility of cutting – within 30-40 minutes.

The product is used both for external work and for internal thermal insulation indoors; it is suitable for insulating loggias and balconies.

Main tasks of thermal insulation

The materials used to insulate a balcony from the inside can be very diverse. Mineral wool and solid insulation materials, such as polystyrene foam, penoplex, penofol and its other analogues, are also suitable. It is worth noting that working with solid insulation that does not separate into fibers is much more convenient. Installation is faster, additional insulation from the insulation itself is not required, it is easier to attach to the walls, it does not allow cold air to pass through, so a vapor barrier layer is not needed, which can significantly reduce the cost of work.

Option for insulating a loggia with penofol

You can insulate a balcony with penofol yourself. This process will not be difficult and will not require any special skills or tools. By glazing and insulating the loggia, you can turn it into a useful space that can be used at any time of the year, regardless of weather conditions. Such a hanging structure will not only preserve heat in the room, but also expand the space of the room by several square meters. They can be used as a relaxation room, an office, a library, or storage of various items that require certain temperature conditions and the absence of moisture.

Scheme for laying penofol insulation on a balcony

Insulating the balcony with penofol or similar materials will quickly and effortlessly insulate cold air, making the room comfortable. The costs of work and the purchase of material will be minimal.

Important nuances

The main heat loss during the cold season occurs through windows. The issue of insulation and heating of a glazed balcony must be approached comprehensively. On the one hand, prevent the cold from getting inside, on the other, prevent the heat from escaping. And also consider an additional heating system if the loggia or balcony will be used in the cold months for a long stay.

There are two options for panoramic glazing:

Tripartite;

Facade.

The first option is used on balconies and is the most problematic in terms of insulation. This is due to the fact that this design has fewer walls, which are easier to insulate. It is also necessary to consider whether the balcony slab can withstand the weight of insulated window profiles.

To insulate the loggia, you can safely use warm but heavy PVC profiles. The weight of the structure does not matter - the slabs have a high load-bearing capacity. The loggia is built into the facade of the house and only one side remains open. The balcony is a more open and less warm room due to its design.

To insulate a panoramic balcony, it is important to choose high-quality materials. Multi-chamber double-glazed windows with low-emissivity properties (low heat transfer) are recommended

It is better to use products from trusted brands:

- Rehau;

- Veka;

- KBE;

Warm double-glazed windows are an important condition for insulating a balcony with panoramic glazing. If you neglect it, you will not be able to maintain a comfortable temperature in this room.

Even when installing a heated floor system or using electric heaters, the heat will not be retained.

Before starting work, it is necessary to determine the load-bearing capacity of the balcony base and obtain permission from special authorities.

What is penofol, its pros and cons

Penofol is an insulation based on polyethylene foam, covered on one or both sides with aluminum foil. It is used both for independent insulation and in addition to other insulation.

Each material in the composition of penofol has its own roles. Polyethylene does not let cold into the room from the street, and foil reflects heat back into the room. Moreover, it protects polyethylene from vapors in the apartment.

In terms of its qualities, penofol outperforms other insulation materials in many ways..

Benefits of penofol

Foil penofol is a good waterproofing agent

- Costs less than penoplex and mineral wool

- Penofol reflects up to 97% of heat into the room! This is if it is covered with foil on one side. And if from two, it also reflects heat to the street in the summer. So even on the hottest day it will be cool on the balcony

- Penofol has fairly low water absorption - only 0.6 - 3.5% per day

- Penofol foiled on both sides is a good waterproofing agent and does not absorb moisture from the street

- Penofol belongs to non-flammable substances (group - G1). Polystyrene foam, for example, burns beautifully

- Operating temperature of penofol from -60 to +100 degrees

- Well protects the balcony from noise

- Penofol is easy to install, even self-adhesive is sold

- Penofol is one of the thinnest insulation materials. It comes in 3, 4, 5, 8 and 100 mm thickness. This means it saves interior space on the balcony.

Arrangement of a leveling screed

A leveling screed is necessary if the balcony slab has defects in its plane or a slope in any direction exceeding 1°. If these shortcomings of the builders are not corrected, the floor may creak or be inconvenient to use. Yes, and it is much more convenient to arrange lathing for laying a clean floor on a flat surface.

As a leveling mixture, it is best to use ready-made cement mixtures or polymer compositions based on epoxy resins. For quick work, self-leveling, lightweight, quick-drying polymer-based mixtures (Nipline, Skorline, Startoline) are especially good. It is enough to pour a liquid-consistent leveling mixture onto a previously laid vapor barrier, and it will level itself in an absolutely horizontal plane. No comb spatula or needle roller is required.

Remember that the balcony slab according to SNiP does not exceed a thickness of 100 mm. Therefore, its strength characteristics do not provide for heavy loads. The layer of floor leveler should not exceed 40 mm. in the lowest places of the balcony slab.

Insulation characteristics

- Penofol is a modern material that has a high ability to isolate cold air from the room. In addition, the material does not absorb moisture at all, protects well from steam, and therefore does not require additional vapor barrier.

- Penofol is usually produced in rolls, which may vary in thickness. Due to its solid shape and standard dimensions, the installation of insulation is greatly facilitated: there is no need to make a lathing to secure it, you can attach the sheet to the wall using liquid nails or any other glue, you can also use special plastic dowels.

- Insulating the loggia with penofol will not burden the structure. Penofol is made from polyethylene foam, then covered with a layer of foil, due to which the material acquires the ability to repel heat. If necessary, the sheets can be bent or cut. They are easy to cut even with a stationery knife.

- The insulation is quite thin, but effective; it will not take up much space, while creating sufficient noise and heat insulation.

Penofol

Recommendations from experts

When insulating a wall, it is necessary to provide an air gap between the protection and the finishing. It has a size of 5-10 mm and ensures air circulation and removal of water vapor. When laid tightly, damp areas are formed in which mold and rot appear. In addition to the unpleasant odor, mold fungi release spores into the air, which negatively affect the human immune system and cause allergies.

To reduce heat losses, it is recommended to install plastic or wooden windows with double-glazed windows. There should be no deep cracks on the horizontal or vertical surfaces of the balcony through which cold air enters the room. The edges of the fractures should be cut, and then the voids should be filled with cement mortar (to increase strength, install scraps of thin reinforcement or screws with a cut off head into the mixture).

https://youtube.com/watch?v=G1GqKzxMbIE

Necessary materials for insulating a balcony

Penofol, due to its qualities, can be used separately, without the use of additional materials; for greater effect, penofol can be combined with other insulation materials. Penoplex and mineral wool can be placed in the presence of a waterproofing layer in front of penofol, penoplex can also be located after penofol, then the latter acts as a waterproofing layer. Penofol can also be combined with polystyrene foam, in the same variation, when one acts as a waterproofing material, and the second as an additional thermal pad.

Also, when installing penofol, you need to prepare:

- wooden lathing slats for walls and ceilings;

- wooden logs and floor sheathing;

- liquid nails, paper clips, nails or screws for fastening penofol;

- screws or other adequate means of securing wood sheathing;

- aluminum tape (self-adhesive construction tape) or polyurethane foam for gluing seams at the joints of foam foam boards;

- polyethylene film to provide the lowest layer of gasket;

- rough and fine covering of the floor, ceiling, walls to complete the aesthetic design of the balcony.

Types of penofol

When deciding how to insulate a balcony with penofol, you need to take into account that there are different types of this material. Most often you can find type A on sale: in this case, the polyethylene base has a foil coating on only one side, with which you need to place the insulation towards the room.

Type B insulation has a double-sided foil coating. Due to this, you don’t need to think about which side to fix the material on: it repels heat in both directions, this allows you to keep warm air inside the room in winter, and in summer, to tear it away from the balcony, creating a pleasant coolness inside.

Insulation of balcony walls from the inside can also be done with type C material: such material is covered with foil on only one side, and glue is applied to the other side. For installation, you only need to tear off the protective film, press the insulation against the wall, and it will immediately attach without the use of additional materials. This installation method is especially convenient for places that are difficult to climb into, or for surfaces that have a semicircular or round shape.

In order for the glue to adhere well to the wall, it must be dry and clean.

Less commonly found on sale are insulation types M and R. They differ in that one of the sides has a relief shape. Type M has a flat part with foil, while type R has a raised part. Insulation of this structure is used in multi-layer structures, for example, for roof insulation. The foil can be additionally covered with plastic film: this is done for better preservation. This insulation is well suited for installing heated floors.

Type "A"

This type is lined with aluminum foil on one side only. For this reason, it makes sense to use it only together with other insulation materials.

Type "B"

This type is lined with aluminum foil on both sides. This makes its thermal insulation properties an order of magnitude higher than those of type “A”, and it can be used independently.

Type "C"

This insulation has a layer of adhesive material on one side. This makes it much easier and faster to mount it in place.

Type "ALP"

This type of penofol is used for insulating greenhouses.

Type "NET"

Penfol used in industry.

Type "M" and "R"

One of the sides of these types has a ribbed foil. This difference significantly increases the thermal insulation properties of the material.

Each type of penofol is capable of retaining up to 97% of heat in a room, and its performance is guaranteed at temperatures from -60 to 100 degrees.

The insulation almost does not allow vapor to pass through and does not absorb moisture. One cubic meter of penofol weighs between 44 and 74 kilograms. The weight of the material depends on the type.

Penofol prices in Moscow

We found out how much real penofol costs from the only one.

Average prices for some brands of penofol in Moscow:

| Penofol grade and width (mm) | Width (mm) | Length (m) | Area (sq.m) | Rozn. price per 1 sq. m (rub.) |

| Penofol 2000 type A with one-sided foil | ||||

| A-03 | 1200 | 30 | 36 | 44 |

| A-04 | 1200 | 30 | 36 | 49 |

| A-05 | 1200 | 30 | 36 | 55 |

| A-08 | 1200 | 15 | 18 | 73 |

| A-10 | 1200 | 15 | 18 | 81 |

| Penofol 2000 type B with double-sided foil | ||||

| B-03 | 1200 | 30 | 36 | 73 |

| B-04 | 1200 | 30 | 36 | 79 |

| B-05 | 1200 | 30 | 36 | 84 |

| B-08 | 1200 | 15 | 18 | 105 |

| AT 10 | 1200 | 15 | 18 | 115 |

| Penofol 2000 type C self-adhesive | ||||

| S-03 | 600 | 30 | 18 | 103 |

| S-04 | 600 | 30 | 18 | 110 |

| S-05 | 600 | 30 | 18 | 120 |

| S-08 | 600 | 15 | 9 | 155 |

| S-10 | 600 | 15 | 9 | 170 |

| Penofol type C self-adhesive (classic) | ||||

| S-03 | 600 | 30 | 18 | 150 |

| S-04 | 600 | 30 | 18 | 165 |

| S-05 | 600 | 30 | 18 | 180 |

| S-08 | 600 | 15 | 9 | 220 |

| S-10 | 600 | 15 | 9 | 255 |

| Penofol classic type A- LP (warm floor system) | ||||

| A-LP-03 | 600 | 30 | 18 | 125 |

| A-LP-04 | 600 | 30 | 18 | 140 |

| A-LP-05 | 600 | 30 | 18 | 155 |

| A-LP-08 | 600 | 15 | 9 | 190 |

| Penofol AIR (air ducts) | ||||

| Diameter (mm) | Length | |||

| AIR-08 | 100 | 20 | 125 | |

| AIR-08 | 135 | 6 | 300 | |

| AIR-16 | 100 | 20 | 215 | |

| AIR-16 | 330 | 6 | 510 | |

| Penofol Super NET with polyethylene foam mesh | ||||

| A | 1200 | 15 | 18 | 190 |

Prices for the same brand of penofol in different stores in Moscow sometimes differ like heaven and earth. Therefore, remember: if you see a price that is several thousand per square meter of penofol, then quickly run away from this store! This is either the wrong penofol or not a penofol at all.

What to prepare before starting work

Due to the characteristics described above, penofol can be used as an independent insulation material and does not require additional insulation. However, combination with other insulating materials significantly increases the resulting effect.

In some cases (with pre-waterproofing), penoplex or mineral wool is laid in front of the penofol, and sometimes penoplex is placed after the penofol and it is the penofol layer that acts as waterproofing. Sometimes, in the same variation, penofol is used simultaneously with polystyrene foam.

Do-it-yourself insulation of loggia walls with penoplex

Those who plan to insulate a balcony with penofol with their own hands must first prepare the following materials:

- wooden sheathing and floor joists, as well as slats for mounting on the ceiling and walls;

- liquid Nails;

- construction self-adhesive tape;

- paper clips for fastening;

- construction waterproofing film (for laying in the bottom layer).

Disadvantages of insulation with penoplex

- Difficult to install. It will not be possible to place the block on nails because this will ruin its waterproof and heat-insulating properties. You can only use staples, however, type “C” penofol provides an adhesive layer for installation.

- The insulation has low strength, which does not allow it to be laid under wallpaper or as an independent external insulation.

Step-by-step instructions for installing insulation.

How to properly insulate a loggia and balcony with foil penofol?

Even though this insulation is quite easy to install and performs many functions, it is necessary to adhere to certain standards and comply with technical conditions. This is the only way to achieve maximum effect from penofol insulation.

How to properly insulate a balcony and loggia with foil penofol?

So the side facing inward must be covered with aluminum foil. There is no need to put penofol under concrete, as this will only spoil the properties of the material. To maximize the effect of insulation, it is necessary to place insulation only on external surfaces, such as walls, ceilings, and floors.

Like any other work, the procedure for insulating a balcony should begin with preparatory work.

Preparatory activities

Before starting work, it is necessary to clean the walls of all excess and eliminate their defects. All cracks must be filled with foam. At the same time, it is necessary to decide on the additional material that will be used together with foil penofol, and determine the number of layers. As a rule, work is carried out in two layers. For walls, you can use penoplex as an additional material, for the ceiling - only penofol, and for the floor - polystyrene foam.

Also, it is worth performing an antifungal primer and waterproofing using a waterproofing film.

Floor insulation

To insulate the floor, the following measures must be taken:

- A frame of beams is mounted and secured to the floor with screws. It is also necessary to take into account that there should be space between the wall and the beam. The surface should be as flat as possible so that the insulation does not crawl out of the frame.

- After laying the insulation, the surface should be as dense as possible. To correctly calculate the length of the material, you need to add 40 centimeters to the length of the loggia.

- The first layer of sheathing is laid, which must be covered with black finishing material.

Work algorithm: how to insulate a loggia with your own hands

An insulated loggia or balcony successfully serves as a storage room where you can store canned food and other food supplies.

There are options for using a loggia or balcony as a dressing room or dining area, etc. How to insulate a balcony with your own hands - the main options for modern insulating materials will help you carry out the thermal insulation process carefully and with maximum heat-saving effect.

In general, the thermal insulation of a loggia or balcony, as mentioned above, consists of the following stages:

- Window installation;

- Insulation of floors, walls, parapets and ceilings;

- The loggia is being finished, i.e. lighting, ventilation, etc. are installed.

According to the recommendations of repair specialists, a balcony or loggia should be insulated in the summer. Thus, in winter it is possible to carry out repair work if the air temperature is not lower than -20°C. But in autumn and spring, you should take into account the increased humidity of the surrounding air.

Using penoplex instead of penofol

Insulating the balcony from the inside with penoplex is also a common option. This material is produced in the form of lightweight, compact slabs that are convenient to install with glue. You can also use plastic dowels with a special plate for installation.

When laying out the next row, shift it. Avoid matching vertical seams, otherwise the structure will leak.

Penoplex slabs are easy to cut, so you can adjust the size of the slab to the area of your structure, cut out a part of any shape using a stationery knife or a metal file. The technology of insulating a balcony from the inside using penoplex involves filling all joints with polyurethane foam. Thanks to this, it will be possible to make the room airtight, getting rid of all the cracks.

Loggia insulated with penoplex

Balcony insulation with penoplex can be combined with penofol. This approach will allow you to obtain additional insulation, reflect warm air, and increase the room temperature by several degrees. After you have secured the penoplex, glue penofol on top of it. As a result, you will receive reliable sealing of the balcony, the thickness of which will be minimal.

How to install insulation?

The technology for insulating a balcony with penoplex and penofol is not very complicated, and you can master it yourself. First of all, it is important to prepare the wall. It is necessary to cover all large cracks with cement mixture or fill them with foam. The wall itself must be cleaned of debris, grease, and dirt so that the glue adheres well. After this, you can glue the insulation. Make sure that the foil faces the inside of the room; penofol, like penoplex, is mounted joint to joint. To close the seams, you can use foil tape.

If finishing is planned, it may require lathing. For this, wooden slats are usually used, the size of which is 20 by 40 mm. There should be free space between the decorative coating and the insulation; the resulting air gap will create a layer of additional insulation.

Place the slats at a distance of no more than 45 cm from each other. This should be done parallel to the ceiling or floor. Check the evenness of the slats using a building level. Installation must begin from the bottom up.

Don’t forget that you will have a plinth, so the first rail should not be placed close to the floor, but with some indentation, which will then cover the plinth.

Once the sheathing is ready, you can attach any wall finishing materials you like to it. Quite often they use drywall or lining.

Common mistakes

Common mistakes when insulating:

- Insufficient thickness of the thermal insulation layer, which leads to freezing of part of the walls with condensation and the formation of mold on the decorative finish. Izolon has thermal conductivity at the level of foam plastic and is inferior to extruded polystyrene foam, so the thickness of the protective coating should be 100 mm and above.

- Laying 10 mm thick isolon on the floor followed by the use of electric heating. Due to insufficient thermal insulation, the system operates in constant mode, which causes excessive energy consumption. For example, the power of a heated floor for a balcony with an area of 3 m² reaches 500 W, per day the electricity consumption will be 10-12 kW/h, and in a month the parameter will reach 300-370 kW/h. With an average price of 5 rubles. per kW/h, additional costs for the apartment owner will amount to 1.5-1.85 thousand rubles.

detailed instructions

Insulating the loggia with penoplex and penofol together will give a better result. The insulation materials combine well, complement each other, and provide reliable insulation of your home from the external environment.

Using penofol and penoflex to insulate a balcony

If you do not plan to finish with panels, then you need to start work by installing the sheathing. To do this, use a dried wooden beam of small thickness. It is convenient to attach it to dowels; a gap must be left between the wall and the outer elements. It is better if the sheathing cell matches the size of the foam board that you will place in it. Try to place the insulation in such a way as to avoid the formation of cracks.

Make sure that the insulation does not peek out beyond the sheathing: it must remain inside. When finished, seal all joints with foil tape. After this, you can stick penofol over the existing insulation and begin installing the decorative coating. Make sure that there are no gaps and that the material does not overlap.

Modern building insulation materials have a small mass and volume, allowing for high-quality insulation of any structure without the help of professionals and at the same time incurring minimal material costs.

Video:

Laying penofol with an inner layer

Scheme for insulating a loggia with penofol.

As with floor insulation, in this case you will need penofol. This is the next stage of work. The rolls are laid on foam boards. Before this, you need to carefully seal all the joints. It must be remembered that penofol is placed with foil inside. It is fastened with self-tapping screws. In addition to retaining heat, it serves as a vapor barrier film. The seams are taped with special tape. It is advisable to lay it evenly and not overlapping. After this, installation of the sheathing begins. It is necessary to ensure ventilation of the insulation and to secure the facing layer.

For lathing, it is optimal to use wooden slats with a cross-section of 40 x 20 mm. They are nailed to the surface parallel to the floor, that is, horizontally, at a distance of 40-45 cm from each other. Lastly, they are nailed at the window. Levelness is checked using a building level. If necessary, you can use polystyrene foam when you need to level the surface. By the way, you can also insulate a loggia with polystyrene foam, but this method is more effective. Once the sheathing is ready, you can begin the exterior finishing. For these purposes, lining or plastic panels are suitable.

Vapor barrier of the floor on the balcony

To insulate this area of the loggia from steam, a slatted sheathing is installed. After it, a vapor barrier strip is placed. Boards or plywood will serve as the floor surface. Linoleum or laminate should be laid on top of them. In the latter case, an additional thin polyurethane backing is needed.

Be sure to place vents in the space under the floor. They need to be connected to ventilation ducts. Then the vapor barrier of the balcony will function normally.

To create insulation from steam and at the same time insulate the floor, you can use Izospan. This material is cut into small rectangular pieces and overlapped. Its size should be about 8-10 cm. To prevent the edges of the vapor barrier gasket from coming apart, they are glued with construction tape.

Insulation of the room with penofol

In order for thermal insulation to make sense, all surfaces of the balcony should be insulated. You need to start work by eliminating the gap that is left in the balcony railings to allow rainwater to drain. The gap is eliminated using polyurethane foam or any other materials.

After this, you need to cover all other gaps (that is, between balcony railings and walls, holes in surfaces, as well as gaps between walls and frames). The process begins after the glazing is completed. It is also necessary to take into account external hydro- and thermal insulation, which is carried out with siding, lining or other suitable materials. In addition, it must be remembered that, according to building standards, the balcony floor has a 40-degree slope towards the street, which is also done to drain rainwater.

If desired, the slope can be easily eliminated by leveling the floor with a concrete screed or installing wooden logs for leveling. After the preparatory work is completed, you can proceed directly to the insulation.

Do-it-yourself insulation of walls with polystyrene foam and penofol

Thermal insulation of a balcony or loggia is carried out according to the following algorithm:

- Preliminarily carry out waterproofing, for which a polyethylene film is attached to all surfaces with liquid nails. It is recommended to use film no thicker than 2 mm.

- On the ceiling and walls, arrange a sheathing under penofol to create a pocket of air 2 cm high. Lay the sheathing on the floor on the joists, and the height of the joists should not exceed 4 cm. The joists are fastened with screws (or bolts). Depending on the design of the balcony, other methods of attaching wooden parts to concrete can be used.

- Cut plates from roll insulation, taking into account the design features of the surfaces on which they will be mounted. The plates are attached to the grid with staples in two rows. If desired, you can use screws or liquid nails. Experienced craftsmen advise not to place plate joints in the corners of the balcony: penofol is flexible enough that it can be bent in the right places as needed.

- Remove the gaps formed between the plates by gluing construction film on them or treating them with silicone foam. Quite good results are achieved when using mounting silicone.

- Install another layer of sheathing on all insulated surfaces. The second pocket of air should have the same dimensions as the first.

Installing a frame made of thin bars will create an air gap around the foam foam, which helps to increase the efficiency of its use.

- Install a rough covering on the sheathing (this can be wooden panels, lining or other material). If lighting, heated floors, sockets or an electrical network for other purposes are planned on the balcony, it is recommended to install all this into the same covering.

- Install the desired decorative coating on top of the preliminary one. Laminate, carpet or linoleum can be laid on the floor, walls can be painted, covered with wallpaper and tiles or trimmed with decorative panels, and the ceiling is usually either painted or decorated with specially designed slabs.

If the process of selecting materials is carried out competently and all precautions are followed when laying penofol, then the thermal insulation made as described above will ensure a room temperature of at least 6 degrees, even if it is frosty outside and the door to the balcony remains open.

Covering the balcony with foil insulation

If the insulation of the loggia with penoplex and penofol is carried out simultaneously with the installation of a heated floor or the installation of additional heaters, then even in winter you can arrange an office, a relaxation area or a sports hall on the loggia. The use of penofol in combination with modern insulation elements will completely relieve you of moisture, cold and extraneous noise on the loggia or balcony. We also advise you to pay attention to the article: how to insulate a loggia with your own hands.

How to attach penofol to the wall

How to attach penofol to the wall with your own hands

Today, such a multifunctional building material as penofol is increasingly being chosen to protect and insulate the surfaces of walls and floors.

Having a slight thickness and a heat-reflecting surface, penofol can provide good results in preventing heat loss at home.

You should know that penofol can provide the maximum possible effect in insulation together with other thermal insulation materials. So, what penofol is and how it is installed on walls or to the surface of other insulation will be discussed in this article.

Where is penofol used?

Penofol is widely used both for insulation of private houses and for thermal insulation of industrial facilities. Having high thermal insulation properties and a very small thickness, penofol is able to completely replace insulation materials such as polystyrene foam and mineral wool (though not everywhere).

Penofol has received the widest use:

- When insulating the internal walls of a house, ceilings and floors;

- Thermal insulation of pipelines, as well as individual elements of heating and plumbing systems;

- For insulation of ventilation, air conditioning systems, etc.

The use of penofol is very popular in the automotive industry, as well as where it is necessary to reduce large heat losses. In addition, penofol is used to decorate the surfaces of baths and saunas, as well as drying and freezing chambers.

Simple installation and ease of use make penofol simply an indispensable building material. As an example, we can cite the installation of heated floors in an apartment where it is not possible to use special mats for heated floors or foam sheets due to their large thickness.

How to attach penofol to the wall

Insulating walls with penofol is quite simple. For these purposes, depending on what building material they are made of, you can use metal staples or special glue.

When insulating, penofol sheets are fixed to the wall surface end-to-end, and in some cases, on the contrary, with a slight overlap on each other. To prevent heat loss, the foil part of the penofol must always face the inside of the insulated room.

Also, to prevent heat from escaping through the joints between penofol, they should definitely be covered with metallized tape or, as a last resort, regular tape.

Penofol should be attached to the wall, observing another important rule.

It is recommended that a small gap of 1-2 cm be maintained on both the outer and inner sides of this material. The gap between the penofol and the insulated surface is needed in order to avoid the accumulation of moisture between them.

Rate this article and share the link:

samastroyka.ru

Insulation of floors and ceilings using penofol

Scheme for insulating a loggia with penoplex.

Thermal insulation of the floor is an important component of the renovation. The technology is similar to the previous one. First, you need to level the floor surface, remove old baseboards, and so on. Then the sheathing is made from beams. Their height depends on how many layers of insulation are required. The frame is attached, retreating 10 cm from the edge of the wall. The step between the beams is 50-60 cm. The sheathing is fastened with a puncher or hammer. First, drill a hole, insert a dowel and nail a self-tapping screw. At the next stage, the insulation is installed. It is important that the rolls fit tightly together. It is recommended to cut penofol sheets slightly larger than the distance between the beams. This will ensure they fit snugly.

After this, plywood sheets are laid. When attaching them around the entire perimeter, it is necessary to leave a small gap of 1 cm. The sheets are fastened with self-tapping screws every 45 cm. Thermal insulation with penoplex involves a concrete screed with a layer of about 4 cm. Insulation of the ceiling is similar to insulation of the floor. But there are also differences. Here, after laying the first layer of insulation, it needs to be fixed with a wooden strip using self-tapping screws. The slats are taken in length equal to the width of the loggia. The joints are filled with polyurethane foam. The second layer of penofol will be attached with horizontal slats.

Their length is equal to the length of the loggia. That is, you get a kind of lathing of crossed slats. The outer slats are placed at a distance of about 10 cm from the wall, and the third is placed between them. Penofol is overlapped with a margin. Next, the slats are fastened with self-tapping screws in increments of 50 cm. Finally, the ceiling structure, like the floor, is leveled and finished using panels.

Arrangement of sheathing for a clean floor

Since it is planned to use penofol (isolon), which has a metallized aluminum surface, as insulation, ceramic tiles or thin flooring (linoleum, laminate, parquet) cannot be directly laid on it. Due to the porous structure of the insulation, such a coating will “walk” underfoot and creak.

Therefore, when the screed has fully gained technological strength (indicated on the packaging), it is necessary to make a lath.

There are two options for laying the sheathing bars - longitudinal (along the length of the balcony) and transverse (along the width of the balcony (loggia). The first option is preferable for balconies of regular shape, the second for wedge-shaped, rounded, curved, corner balconies.

Be sure to focus on the material from which the clean floor will be laid. If these are panels (chipboard, moisture-resistant plasterboard 10-12 mm), it is necessary to take into account the dimensions of the material so that there is always a block at the places where the plates join. Otherwise, chips may occur during operation.

The bars prepared to size are drilled with a thin ∅ 2.5-3 mm. drill, laid out in increments of 400-450 mm. and with a thin long nail inserted into the drilled holes, drilling locations for plastic dowels are marked.

To securely fasten the sheathing, dowels of at least ∅ 10 mm should be used. Pay very close attention to the markup. Most balcony slabs have voids. If you drill holes for fastening the sheathing and get into them, the floor will “play.”

The second important condition is the use of a depth stop (limiter) for the hammer drill. The balcony slab is only 100 mm thick. Therefore, it is not worth drilling deeper than 80 mm. Otherwise, you will have problems with your neighbors living on the floor below because of the hole in the roof of their balcony (loggia).

List of tools and materials

Scheme of insulating a balcony from the inside without installing a vapor barrier.

To organize the insulation of the floor, ceiling and walls of the loggia, you need to purchase the necessary tools and raw materials. To insulate the floor, walls and ceiling you will need: a building level, polystyrene foam boards, foam foam rolls, dowels, nails, hammer, screwdriver, drill, tape, polyurethane foam, primer (putty), glue. In addition, facing material (panels) will be required. When insulating a floor with penoplex, sand, crushed stone, water and cement are needed to prepare concrete. To insulate the floor, walls and ceiling of the loggia, you will also need wooden slats with a cross-section of 20 x 40 mm.

Complex insulation of the floor, walls and ceiling of the loggia with penofol and penoplex is the best option.

Overview of thermal insulation materials

The insulation market is annually replenished with new types of high-quality products with low thermal conductivity, but the new options are mostly improved modifications of traditional materials for thermal insulation.

Technoplex is the best development of the TechnoNIKOL company. This is an already popular general purpose extruded polystyrene foam, improved by including processing additives and a steam generator.

There are universal insulation materials that are equally suitable for cladding floors, ceilings and walls (extruded polystyrene foam boards, for example, Penoplex), and there are materials suitable only for finishing one area of the balcony. Let’s assume that the floor is covered with expanded clay, but it is not used for the walls and ceiling due to its flowability.

Review of modern insulation materials, affordable and safe:

To decide the best and fastest way to insulate a balcony, you need to analyze the installation conditions. Let's assume that on balconies with limited space it is better to use thin materials - penofol, polyethylene.

If space allows or you need to raise the floor to the height of the flooring in the room, then any thick insulation in the sheathing will do - mineral wool, glass wool, polystyrene foam.