Manufacturers of building materials offer various cleaning products for reusable tools. These include flushing the spray foam gun. Let's consider three ways to remove the working mass from the internal and external walls of devices, depending on the degree of hardening of the foam. Let's take a look at a short list of rules for using cleaning products. After reading the article, it will be easier to choose the optimal flush for the gun and complete the task without the help of professionals.

Gun for polyurethane foam Source prom.st

Cleaning the gun from dried foam

Types of tools Cleaning methods Cleaners Care instructions

A mounting gun is a necessary tool during construction or renovation. With its help, plastic windows are installed, entrance and interior doors are mounted, utility lines are sealed and other technical operations are performed. At the end of the work, it must be cleaned, otherwise the solidified solution may make the device unsuitable for further use. We tell you how to clean a foam gun using special products in different ways.

Certificate of conformity

The Zubr brand foam cleaner, and in addition other versions of this substance, must have a certificate of conformity. GOST determines the safety of using these ingredients, and also the possibility of using them without special protective equipment. This parameter also indicates the possibility of ignition and susceptibility to explosion in case of prolonged heating. These options for building mixtures receive the following certificate of conformity: ROSS VE.AD83.H04410. The presence of such a mark guarantees that the product has passed the necessary tests, and in addition has received proper assessments from specialists and can be used in practice.

Types of instruments

There are household and professional designs.

- Household ones are usually represented by plastic models. They are inexpensive because they are not designed for long-term use. They are beneficial to use when renovating one apartment (several doors, windows, sealing a balcony). It is better to carry out all work promptly, within a couple of days. Then the internal cavities become clogged with sealant, and it is not possible to clean them. Therefore, this type is considered disposable.

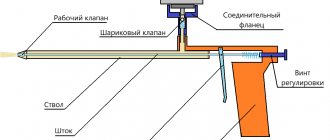

- Professional ones are made from metal. They are more resistant to chemical compounds of both the foam itself and its cleaner. Such models are more durable than plastic ones. They are a simple design: a metal barrel, an adapter for attaching a cylinder, a trigger, a handle and an adjustment screw. Depending on the manufacturing company, designs may differ slightly with different devices. But their main difference from household ones is the presence of a mechanism for regulating the quantity and speed of supply of the composition.

Structures are divided into non-removable (usually plastic), partially or completely collapsible (metal). The last two types allow you to wash the device and change worn out parts.

Foam gun

428

Buy

Design and variety of pistols

Polyurethane foam is sold in a liquid state under pressure in sealed containers. Release is carried out using disposable plastic nozzles (household version) or a separately purchased gun (professional or semi-professional type). In both cases, the device of the foam gun is represented by a tube and a trigger mechanism.

Design features

Although the principle of operation of the nozzles is similar, they are noticeably different in structure, composition and functionality. Thus, structurally, separately purchased tools are divided into 2 types:

- One-piece.

These are plastic samples with a metal rod for distributing the working mass. Such models are classified as semi-professional pistols for performing tasks within 1-2 days.

They are relatively inexpensive, but difficult to clean and cannot be repaired. The main reason is the integrity of the structure and high adhesion of polyurethane foam to polymer materials. That's why professionals consider them disposable.

Disposable gun type Source prom.st

- Collapsible.

Here, practicality is explained by the possibility of free access to individual components of the tool. In case of clogging or sticking of the foam to the inner walls of the structural elements, you can remove dry residues and clean the tubes.

This is a professional type of pistols that consists of two prefabricated parts. Here it is possible to replace individual elements and repair the instrument as a whole.

The table provides a brief overview of the individual components of the pistol.

| Component | Functional significance |

| Trunk | The task of this structural element is to supply and adjust the direction of dispensing polyurethane foam to a specific work area. |

| Trigger | Transfer of action to the built-in mechanism in the cylinder. When the trigger is pressed, the working mass is released from the cylinder into the barrel. |

| Pistol (grip) | The most convenient (ergonomic) part of the tool that fits in the palm of your hand. The more comfortable it is for the user, the better the control of the tool and the foaming of the object as a whole will be. |

| Adapter | If we draw an analogy with a weapon, then this structural element acts as a clip for cartridges. Here the device is charged for subsequent release of polyurethane foam to the work area. |

In addition to the basic components, there is a fixing screw. It acts as a regulatory mechanism regarding the supply of polyurethane foam.

Gun with adjusting screw Source karkas32.ru

That is, the mass feed rate and its volume are adjusted. There is a tip on the barrel - a fitting. The only distinguishing feature can be the diameter of the passing hole.

See also: Catalog of companies that specialize in finishing materials and related work

Operating principle

It is worth noting in advance that before releasing the polyurethane foam, it is necessary to perform 2 steps. It doesn’t matter whether this is a household option or whether this or that gun is used. Initially, it is necessary to place the cylinder in a room with a positive temperature for at least 6 hours. The second step is to thoroughly shake the liquid mass. Shaking is carried out approximately 15-30 times in the up and down direction.

Next you need to do the following:

- fix the tool using threaded connections until there is tight contact (the signal here will be a characteristic hissing sound - the release of air or foam);

- press the trigger in a smooth motion;

- point the barrel at the working base.

The gun and cylinder are ready for use Source master-plus.com.ua

When the trigger is pressed, the process of foaming the polymer liquid and the primary stage of its expansion occurs. Due to the pressure set in the cylinder, the foam is released through the fitting under acceleration. On the surface, the working mass increases in volume again by 60-90%. The efficiency of the tool is adjusted by the degree of pressure on the trigger and the adjusting screw.

Cleaner for spray foam gun

The standard product is a 500 ml aerosol can into which a solvent is pumped under pressure. The main active ingredient is dimethyl ketone, to which various additives are added. Using this aerosol you can clean not only tools, but also tidy up your hands, clothes, and other surfaces.

Polyurethane foam cleaner Tytan Prof Eco

291

Buy

During work it is necessary to observe safety precautions:

- keep away from fire, batteries and direct rays of the sun;

- do not allow the container to heat above 50 degrees;

- ensure that the substance does not get into your eyes;

- when using at home, ventilate the room well;

- After use, wash your hands with soap.

Cleaners are divided into those that dissolve uncured polyurethane foam and those that work with dried solution.

The former perfectly clean canister valves, gun adapters, as well as their internal parts. Well-known companies producing this type of solvent include Tytan. They produce a kit: foam plus solvent. Many manufacturers offer solution-soaked wipes that are suitable for external treatment of instruments.

The latter act on hardened polyurethane foam, softening it for 10-15 minutes, after which it can also be washed with softening wipes. Among the manufacturers of this type of product are TechnoNIKOL and Makroflex.

Product examples

Most chemical foam removers have similar composition and instructions. The price range is 100-300 rubles per cylinder. Product examples:

- Henkel;

- Profflex;

- Penosil;

- Marconflex;

- Monta;

- SOUDAL;

- Grover remover;

- Bison expert.

Many manufacturers produce foam complete with a solvent for it, for example Tytan.

If you urgently need to remove foam from the gun, but there is no bottle at hand, then use substitutes. These are acetone, white spirit and other paint and varnish solvents, gasoline, turpentine. Using them is a little more difficult than ready-made cylinders, which are screwed onto the gun in one movement, but if you follow the instructions, you will maintain the serviceability of the gun using these methods.

Advice: Disposable pistols should not be cleaned with solvent. They are inexpensive, it will be more profitable to purchase a new tool.

When purchasing and using flushing fluid, always read the instructions. Store cylinders away from direct sunlight and heat sources.

The mixture is explosive, so avoid smoking near an open container. Even if the container is empty, do not disassemble it or burn it.

Basic rules of care

If the tool is used for work frequently, then to extend its service life it is recommended to follow a few simple rules.

- Store the gun with a screwed-on container that still contains foam that has not expired.

- If the polyurethane foam runs out, remove the packaging and be sure to rinse the device. As long as the solution is fresh, this is quite easy to do.

- If you replace the cylinder with a product from another manufacturer, it is recommended to rinse the device. Different companies produce sealants that differ in composition. The mixture resulting from mixing them is sometimes impossible to remove.

By following these simple recommendations, you will not only preserve your working tool, but also save your time. It will take much more time to clean a gun from dried polyurethane foam than to free it from fresh solution.

A short video that clearly shows all the cleaning methods:

Tips and recommendations for use

To use this substance rationally, you will need to take into account a number of tips from experts. In practice, the following popular recommendations should be highlighted:

- use cleaners immediately after excess sealant appears, so as not to encounter additional difficulties;

- work only with protective glasses so that the chemical composition cannot get into the eyes and damage the visual organs;

- It is required to thoroughly shake the cylinder before use, which will allow the contents to be properly mixed with the gas;

- It is recommended to use a small amount of the composition, applying it to the surface, and also to a special soft, lint-free cloth;

- When working, it is recommended to refrain from heating, and in addition to store the cylinders in a closed place where the sun's rays do not penetrate.

Compliance with these recommendations will allow you to avoid a number of difficulties when working with a substance such as an assembly and construction sealant cleaner.

Important. Immediately before use, it is recommended to study the rinsing instructions in order to correctly apply the substance, eliminating unpleasant consequences.

If the foam has dried out

Dried foam is a mistake in handling a mounting gun, which is made by people who are unprofessionally involved in repairs. This problem occurs even when the need to clean the gun is forgotten for 1 day - during this period the sealant manages to “grab” inside the tool and does not allow the start lever to be pressed. It is not recommended to apply more force, since the pressure will not be enough to squeeze out the frozen sealant in the barrel, and the parts of the mechanism may not withstand the load and will become unusable. To rid the instrument of foam, perform the following steps:

- Remove any building compound that has hardened on the outer parts of the tool. To do this, use a construction knife, which is used to carefully cut off the adhering compound. It is important not to scratch the piston.

- Wear protective gloves and fill the syringe with acetone. The tool is lowered towards the floor and solvent is dripped into the initial part of the barrel, near the trigger. It is necessary that acetone does not get on the plastic parts of the mechanism.

- Carefully and smoothly, without sudden movements, pull the trigger. When time has not been lost too much, liquefied sealant will begin to come out of the nozzle.

During the procedure, you must be careful and not rush. After completing the cleaning of the hardened building composition, connect a cylinder with a specialized solvent and rinse the tool mechanisms. After washing - when the barrel and other mechanisms of the mounting mechanism are cleaned - the tool can be used further.

Cleaning the Main Valve

When the trigger of the gun remains motionless after applying acetone, this indicates that the ball valve is jammed with dried foam. Cleaning this mechanism of the mounting gun is more difficult than other parts, since the procedure requires disassembling the tool. To free the main working systems when the valve is stuck, you need to follow the algorithm:

- Near the clamp for cylinders with polyurethane foam, you need to find a valve with a metal ball.

- The area is carefully filled with acetone or dimexide and left alone for 8-10 minutes.

- Install a bottle of cleaner for mounting guns and pull the trigger several times.

Full flush

If, after releasing the valve, it is not possible to flush the device’s channels with foam remover, you need to try pouring the solvent deeper. To get to the inside of the mounting gun, partial disassembly is carried out. Before starting, fix the device in a stationary position and clean off all visible polyurethane residues. To remove the valve, you need to follow the instructions:

- The crown for fixing the cylinders is carefully unscrewed counterclockwise and the ball valve is removed.

- The solvent is poured through the crown socket so that the liquid stands inside the device and left for half an hour.

- The valve is put in place to check the effectiveness of the method - you need to press the ball several times. If the mass is dissolved, it will come out of the nozzle along with the solvent.

- The gun, after cleaning from clots, is assembled in the reverse order and washed with a washing solution.

You can wash the gun using these methods only when the polyurethane foam has recently hardened in the system - the polyurethane has not yet hardened completely and can be dissolved with simple compounds. If you leave the device for a period exceeding 7 days, the methods will not be effective enough for cleaning, since fully cured polyurethane is not susceptible to household solvents.

Safety precautions

Regardless of what cleaning composition is used and how the gun is cleaned from polyurethane foam, during cleaning work the barrel of the tool must not be directed towards people or animals. The sealant is under pressure, so there is a possibility of it coming into contact with the skin and eyes.

You need to be especially careful when using a solvent to clean polyurethane foam. Such compositions are caustic and can cause serious chemical burns if they come into contact with the skin.

It is prohibited to clean the instrument near an open flame. It is not recommended to smoke in the room where foam is applied or tools are cleaned with solvents.

If solvents and cleaning compounds accidentally come into contact with the skin, the area should be thoroughly rinsed with running water. In case of contact with mucous membranes, it is strongly recommended to immediately contact a medical facility.

Expert recommendations

If the sealing material is cleaned from the gun in a timely manner, the tool will last a long time. Therefore, it is recommended to put it in order immediately after use. While the mass has not yet hardened, it is not difficult to remove it - it will be enough to use a cleaner in a bottle from a hardware store. But, you need to ensure that the product is produced by the same manufacturer as the foam. Different companies have differences in the components of polyurethane foam and solvent.

If cylinders from individual manufacturers are used when working with polyurethane foam, then before replacing them, clean the device with the appropriate composition. When mixing different types of polyurethane foam, a conflict of components may occur, which will lead to the formation of more persistent blockages in the gun channels. Solvents may not work at all in such situations.

Precautions when working with cleaning products

Respirator Source FFP1 with valve. Photo by Leroy Merlin

Cleaners contain various chemical compounds, so safety regulations must be followed:

- carry out work in ventilated areas;

- use gloves, goggles and other personal protective equipment;

- during storage, the cylinder should not be exposed to ultraviolet rays;

- It is prohibited to store and use aerosol cans at high ambient temperatures;

- If a cleaner that is not intended for cleaning foam from hands comes into contact with the skin, the area must be thoroughly rinsed with water and treated with a hypoallergenic cream;

- If the cleaner gets into your eyes, rinse them thoroughly with water and consult a doctor.

How to disassemble the device

The first thing to do is unscrew the cylinder from the gun. The outlet of the screw should be kept as far away from you as possible so that any remaining foam does not get into your face. Next, the remaining sealant should be removed mechanically.

A screwdriver or a metal rod is suitable for these purposes. After this, the tool is disassembled in the following sequence:

- First, unscrew the mechanism that is responsible for supplying the mixture from the cylinder. It is unscrewed using an adjustable wrench or pliers.

- Next, the trigger mechanism is disconnected and the pin is pulled out with pliers using a rotating motion.

- If necessary, unscrew all bolts and nuts and the foam supply tube.

- Only the skeleton of the pistol should remain.

Cleaning methods

Cleaning the gun with a special means

After removing the cylinder from the dismountable device, foam accumulates mainly in the barrel . You need to remove it before it dries. The most common way to clean a gun is to use solvents and other chemicals . It is advisable to purchase the composition of the same brand as the sealant. Solvents for both fresh and dried foam are commercially available.

The method of use is indicated on the packaging of the product. Most often it looks like this:

- The cylinder with the composition is placed in the adapter.

- The barrel is turned away from you and the trigger is pulled.

- Continue flushing until the flowing liquid is free of foam.

Then the cylinder is removed and the correctness of the trigger stroke is tested. If the jamming persists, repeat the procedure. After removing the cylinder, the device is cleaned of its remains by pressing the trigger.

Cost of foam cleaners

All such products are highly toxic , so you need to work with them carefully. It is important to follow safety rules:

- Avoid contact with eyes and bare skin;

- clothing must be completely closed, while hands are protected with gloves, and eyes with special glasses;

- if the product does get on an area of skin, it is washed with plenty of water, and after that you need to see a doctor;

- Do not carry out the washing procedure near fire or heating devices;

- Upon completion of work, hands should be washed thoroughly with soap;

- After the procedure, the room is ventilated with a through flow of air for half an hour.

If there is a lot of foam, combine mechanical and chemical cleaning methods

. If there is a lot of foam in the gun, it can be cleaned mechanically . To do this you will need to disassemble it. The sequence of work looks like this:

- If some of the foam on the outer parts of the gun has already hardened, cut it off with a utility knife.

- Carefully disassemble the device so as not to damage its parts and fasteners.

- Clean each part individually with a soft cloth. This can be done using a special solvent, acetone or nail polish remover. If necessary, use a small knife or thin wire to clean individual parts. If there is a lot of old foam on the parts, you can soak them in the product and then clean them with a brush. You can drip a little product into the barrel to soften the dried sealant. If the gun has parts made of plastic, during the cleaning process it is advisable to ensure that no solvent gets on them, otherwise they may become deformed.

- When all parts are clean, the gun can be assembled.

Valera

The voice of the construction guru

Ask a Question

If the foam mounting gun has dried out, you can do this: after trimming the sealant from the outer parts with a knife, the cleaner is dripped onto the base of the barrel. The last one goes down. After 5-10 minutes they try to gently press the trigger. If this does not work, the product is dripped onto a ball located in the area where the balloon is supposed to be screwed. This will help clean out a valve that is clogged with sealant. After 15-25 minutes, a can of aerosol is installed in the gun and the usual cleaning procedure is carried out.

DIY cleaner

To save money, you can resort to making your own cleaner. The effectiveness of such substances is lower. They are not recommended for washing the gun and removing foam from ceramic and plastic bases. But in all other situations this option has the right to life. To make the product you will need:

- acetone and other organic solvents, acetone can be replaced with liquid Cosmofen;

- means for pumping compressed air;

- metal container with lid and sprayer.

Slightly soluble cleaner Cosmofen 10 1 l. Photo by Leroy Merlin

The sequence of actions is as follows:

- the components are placed in a prepared container, which is filled 2/3;

- the container is closed with a lid;

- Finally, compressed air is pumped into the container, an electric pump is used for this;

- Before using a homemade cleaner, the container must be shaken.

Anti-foam analogues: Dimexide and others

Many performers prefer to save money and, as an alternative to special means, use improvised pharmacological and chemical substances : vegetable oil, soap solution, soda, vinegar, Cosmofen, white spirit, acetone, kerosene, gasoline, solvents.

Classic laundry soap. Photo by Maxidom

Each of the tools is recommended to be used to solve specific problems. There are separate recommendations for removing foam from doors, others from clothes and hands, and others from plastic windows and other surfaces. In each case, there are products that cannot be used for certain stain removal jobs. For example, Dimexide is an excellent foam remover, but using a pharmaceutical hand cleaner can lead to an overdose and allergic reactions.

White spirit 1 l. Photo by Leroy Merlin

Despite a number of alternative solutions, you need to remember that cleaners show the best results . Therefore, before carrying out work using polyurethane foam, it is recommended to purchase a special product, of a similar brand with polyurethane sealant, to increase efficiency.

How to clean the nozzle on a cylinder

To remove the mounting foam, remove the sealant column from the fitting directly on the cylinder (the upper part where the nozzle is fixed). Carefully screw in a self-tapping screw whose diameter is smaller than the hole. Next, pull the screw - foam will come out with it. After this, lightly squeeze the fitting - when the hiss of escaping air is heard, the cylinder can be used in the future, since the foam in it remains under pressure. The nozzle is cleaned according to the following algorithm:

- The nozzle consists of an adapter and a long tube, which is disconnected from the second part. This manipulation is not difficult, since the elements are inserted into each other.

- The tube is cleaned using a long self-tapping screw, which is used to pull out foam columns in turn from 2 sides. The remaining foam can be pushed out with a knitting needle.

- The adapter is cleaned of mounting foam in the same way as the tube.

This is interesting: Types of men's haircuts and their names photo 2019

To release the tube, this element is gently kneaded - fingers are squeezed in the areas where foam remains. Air bubbles in the foam will come out and the column will decrease.