The choice of polyurethane foam directly depends on the tasks at hand. For comfortable application, saving money and your time, use a special design - a mounting gun. It allows you to manually adjust the required strip thickness and use the container volume to its fullest. If there is an extensive scope of work ahead, then it is better to purchase professional polyurethane foam. Its main difference is the special mount for the pistol with which the cylinder is equipped.

Types of polyurethane foam

For small-scale work, household or semi-professional foam is suitable. The cylinders are equipped with a tube, which is used to fill hard-to-reach places.

The following types are distinguished:

- universal. Can be used at – 10 °C without pre-heating the container. It is characterized by a fast polymerization process and a large yield of material;

- winter Apply to surfaces cooled to -18 °C;

- summer The properties of the material allow it to be applied to heated surfaces, up to +35 °C.

Foam can reduce the level of vibration, noise, and rattling.

Regulations

Any professional installer will tell you right away how many foam cylinders you need to buy to install all room doors, for example. But at the state level, rules have been developed for determining construction work, building mixtures and materials. The consumption rate of polyurethane foam can be calculated using the GESN tables (State elemental estimate standards).

What to consider when calculating the consumption of polyurethane foam?

1. Areas of processed building structures.

If you need to install a window, for example, then take the area of the window opening. It is calculated by the outer dimensions of the box.

2. Material of the building structure (stone, wood, panel part, PVC, etc.).

3. Thickness of the building structure.

What do the GESN tables say?

You can read about the consumption rates of polyurethane foam in the tables GESN 10-01-035 “Installation of PVC window sill boards”, 10-01-045 “Installation of PVC blocks in external and internal doorways”.

Treatment of empty cavities with polyurethane foam when installing PVC window sill boards

To obtain the data, we took into account a standard 750 ml cylinder of polyurethane foam, and one hundred linear meters as a meter.

Filling cavities between door frames and building walls with foam

To obtain the data, we took into account a standard 750 ml container of polyurethane foam and a meter of one hundred meters of square openings.

These are averages. In practice, the numbers may be slightly different.

Video text

Let’s take a can of professional polyurethane foam with a volume of product in the can of 875 ml.

The weight of a full cylinder with a spray foam gun was 1318.3 grams.

We will foam into a structure that imitates the space between the base and the door frame.

The height of the outer perimeter is: 201.5 centimeters; width: 102.5 centimeters; depth: boxes: 9.5 centimeters; width of the foamed seam: 3.5 centimeters.

For our experiment, we will invite two people with different levels of training and frequency of use of polyurethane foam, conditionally dividing them into: beginner and experienced.

The first thing we do is remove the dust using existing rags.

Next, we moisten the surface on which the polyurethane foam will be applied. The surface must be damp, not wet.

Related article: Iron shutters for summer cottage windows

The beginner begins to foam first; it is necessary to foam 2/3 of the depth of the door or window opening. The mistake is immediately visible here - foaming the polyurethane foam exactly along the seam, which after polymerization will lead to significant excesses and losses. After 24 hours, I cut off the excess and you can clearly see how large the overspending is.

After the first foaming, the weight of the cylinder with the gun was 828.8 grams.

After measuring the ratio of cut and filled volume, the losses were: 21.8%.

When filling the doorway with a beginner, the mass of the product in the cylinder decreased by 489.5 grams, i.e. To fill the doorway with polyurethane foam, more than half of the cylinder was required, the filling of which is 875 ml.

Next, we hand over the cylinder to a person with experience working with professional polyurethane foam. The seam is filled to 2/3 of the depth of the door or window seam. To reduce losses from cut foam after polymerization.

After 24 hours, I cut off the excess - which is actually not there - this excess, weighing 0.5 grams, can be considered a mathematical error. The mass of the cylinder with the pistol was 623.6 grams; let me remind you that the mass of the cylinder with the pistol before foaming was 828.8 grams. It turns out that to install the door frame, the master needed 205.2 grams of the product from the cylinder.

And this is more than two times less than for a person without experience working with professional polyurethane foam.

The weight of an empty cylinder with a spray foam gun was 466.5 grams. This means that the mass of the product poured into the cylinder was 851.8 grams.

It turns out that for a bottle with professional polyurethane foam, with a filling volume of 875 ml. – the master is able to supply at least 4 interior doors with a threshold of the standard size specified by us. For a beginner, the cylinder may not be enough for two boxes.

What determines the consumption of polyurethane foam?

1. From the brand of the foam itself.

More precisely, from such a technical parameter as “primary expansion”. One foam needs to fill a third of the gap volume, the other – half.

There are highly expanding, moderately expanding and weakly expanding foams. All household options are highly expanding. They have to fill quite large gaps. Therefore, they cannot damage the building structure. In addition, spacers are installed that maintain the position of the structure.

Medium-expanding and low-expanding foams are needed for more delicate work, “clogging” small cracks.

2. From the ambient temperature.

This is relevant if external installation work is being carried out. The colder it is, the more foam you will have to spend. This is why winter specimens disappear too quickly. After all, air humidity at sub-zero temperatures is low, so the foam increases in volume less.

Types of polyurethane foam

The consumption of the composition is largely determined by its type, that is, the components in the composition and technical characteristics. Let's look at the main types of polyurethane foam that craftsmen and amateurs have to deal with.

All types of polyurethane foam have the following characteristics:

- Output volume - the value indicated on the cylinder corresponds to the volume of the already hardened product. Moreover, the numbers indicated on the label will never coincide with the actual yield of the composition, because it is impossible to carry out the work under ideal conditions. Masters note that with an output value of 65 liters, you need to be prepared for 35 liters.

- Primary expansion - corresponds to the amount of material that is obtained immediately at the exit from the cylinder.

- Secondary expansion is the amount of mixture after drying. If you need to fill small gaps up to 1 cm, then it is better to choose compounds with a slight expansion, and then the final yield of the mixture will reach 100%. Expanding foam has a higher consumption.

- Viscosity - the foam should be viscous and under no circumstances flow down a vertical surface.

- Adhesion - the ability to adhere to different surfaces is of great importance, but this has a negligible effect on material consumption.

To calculate the yield of polyurethane foam, it is important that it meets all the required characteristics. A spoiled, unsuitable, low-quality composition is not suitable for work. It makes no sense to calculate its output, primary and secondary expansion. You need to buy original formulations from trusted manufacturers.

What quality criteria must polyurethane foam meet:

- Thermal insulation and sound insulation.

- High resistance to moisture.

- Can be used as an adhesive to connect different elements.

- Ability to fill a wide variety of gaps.

- Possibility of use for different surfaces - smooth and porous.

- Safety for humans and the environment.

- Ease of use of the cylinder.

- Resistant to open fire.

- Low electrical conductivity.

Household and professional foam has these qualities. The first is used at home for various jobs. It is easy to deal with, it is sold in cylinders with an already built-in mixture supply system. After reading the instructions, everyone can start working.

Professional compounds are used in conjunction with a pistol. It allows you to accurately dose the material and deliver it to the most inaccessible areas. This type of polyurethane foam has a high expansion coefficient. Best suited for large jobs.

There are also summer and winter mixtures, depending on the period of work. The former can be used at temperatures from -18 to +30 degrees. Summer type is used in conditions from +5 to +35 degrees. There are also all-season compounds that can withstand temperatures from -100 to +350 degrees.

Depending on the production technology, there are one-component and two-component foams. The first are compositions in the form of aerosols.

Two-component ones consist of main components and catalysts. To mix the components, the container must be shaken well. The chemical reaction in such compositions occurs later, which means the service life is longer.

Features of application

The following recommendations will help to make the foam output close to ideal:

- Before use, shake the container well to mix the components. If this is not done, not the required foam will come out of the cylinder, but a thick mass and air. After mixing, a homogeneous consistency is obtained, which comes out at the same speed.

- Before applying polyurethane foam, you need to wet the surface for better adhesion and hardening. This is a mandatory measure when using one-component mixtures.

- When applying, the container must be held vertically at all times. You need to start insulating from the bottom. The first layer can be up to 3 cm, then the composition can be applied again, but only after complete hardening, after about 8 hours.

- Only after hardening can you cut off the remaining material, touch it with your hands, paint, load, plaster. If you do this earlier, the polyurethane foam will lose its properties.

Smooth seam application technology

Applying the sealant should be done by holding the tube spout at an angle to the surface and evenly squeezing out the compound in a smooth motion along the entire seam. Squeeze out the amount of sealant with a small margin. The next step is to spray the surface of the seam and around it with a regular soap solution (just mix warm water with soap) of such a consistency that your finger slides over the surface of the tile. We treat the rubber spatula in the same way so that the solution does not stick or drag on it.

For a regular horizontal fillet weld, the application principle is simple: place the spatula at an angle of 90° so that the edge on its surface faces in the direction opposite to the movement. We smoothly move it along the applied sealant without pressure - just pull the spatula along the seam, it will move easily, since the surface will be slippery after treatment with soapy water. As a result, you will end up with excess sealant collecting on the spatula, and after going through the entire length of the seam, you can simply remove the accumulated mixture. Complete hardening of the seam occurs within two days, after which the treated surface can be safely used.

Foam consumption factors

The correct calculation of consumption depends on the following factors:

- Features of measurements. There should be no inaccuracies in the measurement, as this affects the final result. You cannot take approximate data into account. All measurements are carried out with appropriate instruments (tape measure, range finder, etc.).

- In addition to general data, the structure of the surface and the presence of defects are taken into account. Often, the type of surface is not taken into account in the calculations (this is a mistake made by inexperienced craftsmen). For a flat plane the material will be spent according to calculation, but for a profiled one you need to add a certain percentage to the calculated amount.

- The type of surface affects the magnification factor: brick wall 1.02–1.1 times (depending on the size of the joint); profiled sheet by 1.1–1.6 times (depending on the height of the profile).

- There are surfaces that absorb foam, which increases the consumption rate. This should be taken into account when working with aerated concrete and some bricks; overspending will immediately occur.

If the material is used for the first time, to check its absorbency, it is enough to moisten it. With rapid penetration of water into the structure, high absorption occurs.

- Street work. When carrying out work inside and outside, even with absolutely identical planes, the needs vary. This is due to the influence of street air flow. When there is strong wind, the need for raw materials increases. Therefore, it is worth immediately taking into account the increasing coefficient in the range of 1.05–1.15.

- Ambient temperature. This factor has a significant impact on the consumption indicator. At low temperatures (about -10 degrees), it is necessary to take 1.5 times more raw materials for the process. This is how the foaming coefficient influences.

- Difficulties of work. It often happens that hard-to-reach places need to be foamed. If such areas exist, then an increase factor of 1.1 times is added to the total requirement.

- Consumption indicators on packaging. These indicators are based on operation under ideal conditions. As a rule, it is difficult to create them, so it is not worth relying only on packaging data. The reserve is constantly taken into account 1.1–1.3 times. Which depends on the conditions created.

Foam consumption per 1 meter: table

To consider the consumption of polyurethane foam per 1 m of seam in the table, take Makroflex polyurethane foam 750 ml as an example:

The table takes into account the following parameters: depth, width of the seam. So, if we take into account that the depth and width are 6 mm, then the foam container is enough for 8.3 m.p. Accordingly, the greater the depth and width indicator, the greater the consumption, the footage of the treated area with one cylinder is reduced.

The data given corresponds to work carried out under optimal conditions. Each deviation is accompanied by an increase in consumption and a reduction in footage.

Calculation formula

The calculation formula includes data on dimensions and seam configuration. If the seam is rectangular, then the formula is used for calculation: P = W * D, where P is the flow rate, ml/1m.p of the seam; W – its width, mm; G – its depth, mm.

For example, for a seam with the same depth and width of 10 mm, the consumption will be 100 ml per 1 m.p. seam

But there are triangular seams, so the formula changes: P = 0.5 * W * D

To apply this, you need to cut the tip at 45 degrees.

Recommendations for economical consumption

How to save material? It is necessary to take into account the recommendations of the masters:

- The foam must remain at rest until complete polymerization.

- Professional tools are used for application.

- Before work, check the serviceability of the cylinder and its completeness.

- Only proven brands are purchased.

- The mass after application should not be exposed to UV radiation; for subsequent use it is protected by painting.

- During the process, follow the instructions indicated on the packaging.

Interesting video on the topic:

Polyurethane foam consumption: recommendations from experts (2 videos)

What type of foam is best for foaming plastic windows?

A standard cylinder contains various chemical elements that remain separate even during long-term storage. There are three types of foam for installation:

- Professional.

- Household.

- Soundproof.

Important! When purchasing professional foam, take into account the fact that you cannot simply use it. You will need to additionally purchase a mounting gun, which will regulate the amount of material supplied.

In addition to the standard division, the product is usually divided according to the seasonal principle - summer (at temperatures from +5 to +35) and winter (from -20 degrees), according to the type of flammability:

- flammable (B3);

- self-extinguishing (B2);

- fire protection (B1).

Fire-resistant foam

Well, the last category of division is the number of components. There are one-component and two-component ones. The second option has more useful qualities. Two-component material requires less time to harden, has less secondary expansion and is stored longer, with temperature maintenance.

Most professionals recommend paying attention to the professional theme because of its technological indicators. If your plans are not so big, then a semi-professional option will do. To work with it, you only need to put on an adaptive type valve (plastic tube and lever), which is included in the kit. Well, in the future, the time of year in which the work is carried out and the conditions in which the double-glazed windows will be used will be taken into account.

Variations

Selection of foam for installation

depends on the assigned tasks. For convenient application, saving money and your time, use a specialized design - a mounting gun. It allows you to manually adjust the required strip thickness and apply the volume of the cylinder to the end. If a large scope of work is expected, then it is better to purchase qualified foam for installation work. Its main difference is the non-standard mount for the pistol with which the cylinder is equipped.

Types of foam for installation

For small-scale work, homemade or semi-professional foam is suitable. The cylinders are equipped with a tube, thanks to which they fill hard-to-reach places.

There are these types:

- Multipurpose. Can be used at – 10 °C without warming up the container in advance. It has a fast polymerization process and a high yield of material;

- Winter. Apply to surfaces cooled to -18 °C;

- Summer. The characteristics of the material make it possible to apply it to heated surfaces, up to +35 °C.

Foam can reduce the level of vibration, noise, and rattling.

Polyurethane foam is produced in several types, each of which has its own consumption

Polyurethane foam is a popular, inexpensive and economical sealant that is actively used in construction, installation and repair work.

Mounting foam consumption per 1 sq. m.

The consumption of sealant primarily depends on the brand and is indicated on each cylinder. But these are average values given for ideal conditions when applied to theoretical surfaces. As a rule, the actual consumption of sealant and the theoretical one diverge.

Polyurethane foam is produced in several types, each of which has its own consumption. Normally, the average consumption is taken for optimal work conditions. Professional foam is designed for use with a mounting gun, has a lower coefficient of secondary expansion, and forms a more complete, durable seam.

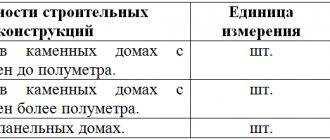

All consumption rates are given in accordance with the prescribed and regulated standards for the use of polyurethane foam at TEP prices for sealing joints with polyurethane foam: the assembly joint should be moistened using a spray gun, the container should be shaken before use, the foam should be applied from bottom to top to a joint depth along the entire perimeter with a thickness of 35-40 mm in an even layer. In this case, it is necessary to follow the manufacturer’s recommendations for temperature and humidity conditions. Consumption rates are calculated for the use of professional foam. According to TER10-01-047-1 standards, the consumption of foam for 100 m2 of opening up to 3 sq. m = 123.5 cylinders with a capacity of 0.75 liters. If the opening area is more than 3 sq m, the norm is reduced to 70.3 cylinders. The apparent contradiction arises due to a decrease in the ratio of perimeter to area (for example, 1x1 - perimeter 4 m and area 1m2 ratio - 4:1; 2x2 - perimeter 8m, and area 4m2 ratio - 2:1).

Which foam to choose

The work of installing an interior door depends on the technology, as well as on the correctly selected foam. Which polyurethane foam is best for interior doors? This question is asked by every person faced with the installation of a door leaf. To solve this problem, you need to know that polyurethane foam is classified according to different criteria:

- by composition;

- by scope of application;

- according to the degree of combustion;

- according to temperature of use.

Compound

All types of polyurethane foam available on the construction market have the same composition with minor additions, which is why they are called polyurethane one-component aerosol sealant. There are also complex compositions that are called two-component. But they are rarely used for domestic use.

The composition of one-component foam includes:

- prepolymers (polyol, isocyanate), which act as the basis of the foam;

- a mixture of butane and propane, acting as a propellant gas;

- elements that increase adhesion and the degree of foaming perform the functions of additives.

Areas of application

The scope of application is hidden in the name - installation, so it is used for any repair work:

- when installing windows and doors;

- when installing structures made of wood, metal, concrete or plastic.

Based on this, polyurethane foam can be:

- professional, which is used by experienced craftsmen. The foam is inserted into a special gun and dispensed in portions in the right places;

- semi-professional, which is sprayed with a plastic tube attached to a pressure lever. It is recommended to use it for solving small problems.

Flammability degree

This indicator is indicated on polyurethane foam cylinders. The following classes of foam are available on the construction market:

- B1 - polyurethane foam with fire-resistant properties;

- B2 - foam capable of self-extinguishing;

- B3 is a foam that is susceptible to burning.

Application temperature

Foam is used in different conditions, so temperature conditions have different effects on foam components. To avoid problems when installing doors or windows, select foam based on the temperature range in the room.

Depending on this, there are three types of polyurethane foam:

- summer, which is used at temperatures from +5 to +35 ° C;

- winter, which is used at temperatures from -18 to +35 ° C;

- universal or all-season, which is used at temperatures from -10 to +35 °C.

Properties

The popularity of polyurethane foam is explained by its performance properties, which are also its advantage. In this regard, polyurethane foam has:

- high adhesion to any materials;

- heat resistance;

- non-conductivity of electricity;

- high speed of setting and hardening;

- atoxicity before and after polymerization;

- non-flammability (only some types);

- moisture resistance;

- a combination of plasticity and elasticity;

- low thermal conductivity;

- slight shrinkage during the year;

- chemical resistance;

- high strength;

- good sealing effect, which cannot be achieved even with cement mortar;

- short time for foaming;

- lack of additional materials and tools;

- lack of power sources.

Installing doors on a mounting pin: what is important to know?

Installation of door frames and panels is a complex procedure for which it is important to select clear materials. The mounting foam for doors effectively fills cut openings and reliably fixes the entire structure. In order for the material to serve for a long time, it must be properly cured. At the smallest error, the room will be cold, and the service life of the door will significantly decrease.

What role does the mounting pin play when installing doors?

The mounting pin is required to close the gaps around the door frame. The material serves as a heat insulator, fills gaps well, protects areas from ducts, provides sound insulation and allows you to install doors without stopping the drill or hammer drill. The use of this material is especially relevant when installing lightweight door frames and panels, as well as in panel, block and frame booths.

Installing important wooden doors is not recommended. In such a situation, it is better to vikorize additional fastenings.

Which mounting pin is better for installing doors?

If you need a pin for interior doors, you can use a warehouse for waste storage. The price is lower, the price for professional sealant is lower, and the technical characteristics are sacrificed. When installing input groups, it is better to use acidic materials, since in this case more high performance characteristics are required. Good quality water from the professional mounting foam Bilife. These are the advantages:

- high noise, thermal insulation and fire safety;

- low consumption and high consumption of finished foam - up to 75 liters from one cylinder;

- the handiness of holding the frame of a special pistol;

- expansion of mass up to 300%;

- there is no need for additional insulation of the formed gaps;

- high level of storage;

- wide range of operating temperatures - from -10 to + 35⁰С, operating temperatures - from -40 to + 90⁰С;

For internal work, you can use the summer mounting pin. For outsiders, it is intended for all-season or winter use, since water has high frost resistance.

Basic stages of installing a door block

The door frame is attached to the wall or partition with the help of various fastening elements. It would seem that everything is simple, just before installation, take into account the nuances of the skin stage of the work:

- Value of height and width. The door frame is selected according to the dimensions of the door opening so that the block can be easily inserted into it.

- Assembling the door frame. Make sure the door blocks are always closed. If you think that no matter the sides of the box are damaged, it is better to carry out additional evaluation of the elements using self-tapping screws.

- Installation of fittings. If the block is fastened with hinges, then the core is screwed to the frame, and then to the wall.

- Marking at the bottom of the door leaf. In standard door frames there are no thresholds, and the gap between it and the bottom is approximately one to two centimeters. If the underlay is uneven, or in the future you plan to lay the underlay, if you need to set the door to the required height. For this purpose wedges are used, which can be produced using improvised tools.

- Displayed boxes. Place the block in the middle of the slit behind the rib using a self-design - a thread with a slight twist at the bottom. First, fix the bottom of the box, and then the top. After this, the screw is attached to the protidal side in the same sequence.

How to use polyurethane foam to foam windows and doors

As you know, the installation of plastic windows in the Russian climate is always carried out using polyurethane foam insulation, in other words, foam.

For comparison: in some European countries, mainly silicone or mortars are used for these purposes, and the use of foam is generally considered bad form.

With our frosty winter, this technology is completely inapplicable, since this will inevitably lead to mold on the walls of the opening and freezing of the window.

Practice shows that only the use of polyurethane foam can provide the highest thermal insulation. The same insulation materials as tow, mineral wool, etc. When installing plastic structures, they are generally not applicable.

The principle of operation and main features of polyurethane foam, as well as how to use it correctly, will be discussed in this article.

Some people believe that the foam between the walls of the opening and the window block, especially with significant installation gaps, allows installers to hide the measurement errors in this way and is the main cause of freezing.

In fact, this is not so, because the thermal conductivity coefficient of polyurethane foam is more than two times lower than that of the plastic windows themselves. Of course, this indicator is only possible with the correct use of foam insulation.

A random combination of certain factors on which the quality of the foam joint depends can lead to a negative result. These factors include:

- quality of foam and gun;

- thoroughly shake the container before use;

- the amount of foam squeezed into the gap;

- cylinder temperature;

- degree of moistening of surfaces in contact with foam;

- absolute humidity and air temperature;

- temperature of the surfaces of the opening and window block.

The structure of a high-quality foam joint after complete drying should be uniform and finely porous; there should be no large shells on the cut. Through holes and voids are completely unacceptable.

When squeezed, the foam should be soft and, after compression, straighten out (resistance to deformation), and not crack or become colored. Another important indicator is the adhesion of foam to surrounding surfaces, i.e. the quality of its adhesion to contacting surfaces.

Good adhesion and resistance to deformation will allow the foam to withstand loads caused by temperature deformations of the window profile at any time of the year.

The installation of plastic windows is most often simultaneously accompanied by finishing of the slopes. Unfortunately, in this case there is no way to check the quality of the foam joint after it has dried.

The resulting defects in the seams can make themselves felt only with the onset of the first frost, which will cause a lot of inconvenience associated with altering the window.

To prevent this from happening, you need to know how foam “works” and follow some basic rules for foaming a window. Today we will look at this issue.

The principle of operation of polyurethane foam

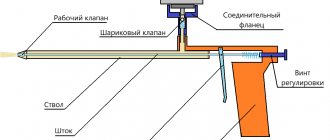

The contents of a polyurethane foam insulation cylinder consists of various components that do not mix with each other during storage. On top of the cylinder there is a compressed displacing gas, due to which the components are squeezed out.

The main component of the foam mass is the polyurethane components that occupy the middle of the cylinder. At the bottom there are foaming substances - diisocyanates.

How to check the quality of installation during window installation

Proper window installation is a continuation of the quality of the window structure itself. No matter how expensive or, on the contrary, cheap window you install, without proper installation in the opening it will not be a window, but a daily problem.

As for the window structure itself, manufactured at the factory with which you signed a purchase and sale agreement. The sales manager most likely spoke about it in great detail. What profile, its dimensions, number of chambers, brand of fittings, characteristics of the double-glazed window, etc. A product that is called a face. The main thing here is to understand one thing - until this structure is installed in the window opening of your apartment - for you it is a semi-finished product, but for the selling company it is a finished and paid product. Therefore, pay special attention to how and with what materials the window will be installed and what is stated in the contract about this.

It is best if it states that the installation is carried out in accordance with GOST 30971-2012 “Installation seams of joints connecting window blocks to wall openings.” This document reflects the optimal installation technology, if followed, you are guaranteed 20-year operation of the window structure.

To correctly install the window and comply with the requirements for window installation according to GOST, the master must have the following materials:

- Anchor plates, or dowels - for fastening the window structure;

- Wedges and straightening pads, which will serve as support for the window frame during installation and subsequent operation;

- Polyurethane foam to create the main sealing and insulation contour;

- Vapor barrier tapes to protect the mounting foam from moisture from the room;

- PSULs and waterproofing tapes to protect polyurethane foam from the street side.

For detailed information about the need and technology for using these products for the correct installation of plastic windows in accordance with GOST for window installation, see here.

It should be noted that it is impossible to install a window without fasteners and foam, but it is possible without other materials. And this will be exactly the same low-quality installation, thanks to which in a few years you risk meeting with installers again - only this time to reinstall your window.