But treating structures with sealant can be difficult in the winter due to weather conditions.

However, foaming window seams is especially important in cold weather, when good thermal insulation is required.

For such cases, there is a special winter version of the substance. To choose the right product, you first need to familiarize yourself with the features of frost-resistant polyurethane foam.

What does the concept mean?

Polyurethane foam for windows is a material that is used in construction or repair work for sealing, soundproofing and thermal insulation of joints.

Note. Its winter version allows you to use the product even in subzero temperatures.

Thus, installation of structures can be carried out almost at any time of the year, which eliminates the need for builders to stop work.

If you try to use the summer version in frosty conditions, there is a high risk of specific problems.:

- The product cannot reach the required consistency.

- The required hermetic base is not formed.

- The foamy mass after application crumbles when it hardens.

Such consequences can be avoided by winter sealants, the chemical composition of which develops resistance to low temperatures. Also, some types of funds can be used in the summer.

Features of the composition

Any polyurethane foam contains a liquid prepolymer, which is displaced from the container by a mixture of gases , after which it foams under the influence of moisture, expands and gradually hardens.

As a result, a relatively strong material is formed - polyurethane foam.

The difference between winter sealant and summer sealant mainly lies in the chemical composition of the propellant - a gas that displaces the filling mixture. This allows you to achieve more productivity from your products.

Soundproofing foam MaxForte

Unlike conventional polyurethane foam, which is an excellent conductor of noise, since it is light, hard, and has a closed cellular structure, which facilitates the unhindered passage of sound waves. Foam MaxForte

Therefore, when installing windows or doors, it is necessary to use special soundproofing foam, which, unlike conventional polyurethane foam, has properties important for sound insulation:

- High density to reflect sound wave;

- Elasticity to reduce vibration transmission;

- High-quality filling of cavities and cracks to prevent sound from leaking into the room

MAXFORTE SaundFLEX foam has these characteristics.

Compared to conventional construction foams, the use of MAXFORTE SoundFLEX foam adds more than 10 dB to sound insulation, which is equivalent to a noise reduction of 2-3 times.

The difference between regular mounting foam and soundproofing foam can be seen in the video:

If you squeeze a piece of polyurethane foam in your hand, it will simply collapse, unlike specialized soundproofing foam; it, like a “sponge,” will take back its shape, it does not harden and thus does not become a sound bridge.

Varieties

There are several classifications of polyurethane foam based on a number of parameters. So, according to the method of application, the product is :

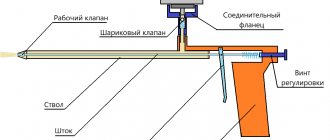

- Professional. To use, you need a special dosing gun, with which the mixture is supplied from a cylinder;

- Bytovym. No additional tools are required for use. The product is applied using the existing adapter tube.

The product is also classified by flammability class:

- Fireproof, B1. Typically used to treat fire rated doorways/windows and to seal joints near a fire source. Non-flammability is achieved due to the presence of fire retardants in the composition.

- Self-extinguishing, B2. Upon direct contact with fire, it melts and drips. If there is no open flame, it goes out immediately.

- Flammable, B3. It is recommended to use only in areas where the occurrence of fire is minimized.

Note. By the appearance of the cylinder, you can determine what type of sealant it is: non-flammable options have a pink tint, flammable ones are white or yellow.

Also, winter polyurethane foam can be divided into types according to composition :

One-component .

In manufacturing, polyurethane is used as the main component. The key feature of this type is secondary expansion.Therefore, when sealing seams, the product must be applied only to a third of the space, otherwise there is a risk of surface deformation.

It is considered the simplest and most convenient to use.

- Two-component .

One of the key disadvantages of the one-component option is the relatively short shelf life - up to 12 months. The reason is that the two components that cause the foam to harden are contained in one container. The two-component foam container is separated at the base by a special seal, which prevents the interaction of these substances. The limiter is removed immediately before use.

In addition to a longer shelf life, two-component foam hardens faster, has no secondary expansion and has higher quality characteristics.

Examples of manufacturers

Among the world's manufacturers we can highlight:

- Soudal (Belgium). It is considered a leader in the production of sealants. On the market for over 50 years.

- Penosil (Estonia). Despite the relatively young age of the company (30 years), it already produces more than 10% of the foam on the European markets.

- Dr. Schenk (Germany). The company has existed for more than 80 years and is constantly working on quality. As an indicator of results, the company became the owner of the ISO 9001:2008 certificate.

It is also worth noting the Russian manufacturer Profflex. An enterprise from Tula that produces exclusively polyurethane foam. The quality corresponds to the products of world leaders.

Main types and scope of their application

Two types of foam:

- Semi-professional;

- Professional.

The first type includes foam, which does not require the use of additional devices. The substance is sprayed through a special tube with a lever - adapter.

More often, the presented type is used to perform a small scope of work. If there is foam left in the container after use, it should be stored until the next use. Clean the tube with a special solution or regular acetone.

Professional or pistol (as the manufacturers dubbed the product). It is sprayed with a special gun, which doses and delivers (squeezes out) the material itself. The cost of a mounting gun is several times higher than the price of the foam itself, so it is not practical to use this type of material for one-time foaming.

Foam gun

How to choose?

When choosing frost-resistant sealant for window openings, you need to consider the following rules :

Check the cylinder for underfilling.

This phenomenon is not uncommon, and it has a negative impact on the properties of the product. Due to underfilling, the foam does not come out of the container completely due to low pressure.- Check for the presence of a secondary extension.

The substance must be applied taking into account this parameter. If you completely fill the cracks in the window with the product, secondary expansion may damage the structure. - Consider the production date. It is better to take foam that is less than six months old. The older the product, the longer it takes to harden.

- It is worth choosing the professional option. It is more reliable and has lower shrinkage, which prevents damage to the integrity of the seams.

Important. It is worth giving preference to products from trusted or reputable manufacturers.

A little about the manufacturers

The key to high quality material is the choice of a reliable and trusted manufacturer. It is no secret that the cost of a product can say a lot about its properties, because it is not possible to make a high-quality product from cheap ingredients. But the inflated cost is not always associated with the use of high-quality raw materials.

Often, overly promoted brands spend a lot of money on advertising a product, which automatically increases its price, and you simply get brighter and more memorable packaging, and not higher technical characteristics than a less expensive product.

Therefore, let’s consider proven brands with not inflated prices:

Soudal Soudal is a very high-quality product with a fine-grained structure. Differs in the absence of shrinkage. Available in several versions - winter, summer and fire-resistant. Has a slight odor. But it is not sold everywhere. Cost – 195-395 rubles.

"Macroflex" - has a high rate of adhesion and uniformity of structure. The foam yield stated on the packaging is true. However, recently a lot of fakes have appeared, which has led to numerous complaints about the deterioration of the quality of the product. The cost, depending on the type of foam, is 150-470 rubles.

“Penosil” has a good foam yield from the container, is distinguished by its bright white color and low coefficient of secondary expansion. Not intended for outdoor use. At temperatures above +35° it stops foaming. Price – 200-485 rub.

“Moment Montazh” - has a dense and uniform structure, is easy to paint, and is quite common in the network of hardware stores. It has a high rate of secondary expansion, and after a couple of years it may lose elasticity. The price is 145-245 rubles.

“Titan” has a dense structure, no shrinkage and a low rate of secondary expansion. Used for thermal insulation of heating and water supply systems. The foam yield can be defined as average, not full. The price varies from 200 to 265 rubles.

How to foam: nuances of technology and rules

When carrying out work on sealing seams, a number of features must be taken into account :

- The container with sealant must be kept in a warm room for at least 10 hours.

- The surface to be treated must be cleaned of dirt, snow and dust.

- When sealing, the container must be held upside down.

- It is important not to forget about secondary expansion.

- Before use, it is recommended to shake the container vigorously for 20 seconds.

Note. If these features are ignored, there is a high risk of reducing the quality of the insulating seam.

Difficulties and errors

There are a large number of low-quality products on the polyurethane foam market.

If you do not follow the rules for choosing a product, there is a high probability of running into a bad product , the use of which may cause damage to the integrity of the window structure.

It is also important to follow the rules for foaming windows, paying special attention to secondary expansion. It must be remembered that this principle can lead to structural failure.

Terms of use

Builders follow the work technology to ensure the correct functioning of the valves of the can and uniform polymerization inside.

The exhaust valve sticks due to the following reasons:

- heterogeneous heating of the contents inside, when part of the mass remains thickened;

- rapid and too strong heating of the aerosol container, while the accelerated transformation of the prepolymer causes the appearance of clots;

- the cylinder is stored upside down - the mass thickened in the cold clogs the valve.

In the latter case, the cylinder is placed with the valve up, and a little gas is expelled by pressing.

It is impossible to use an unheated cylinder - this will cause excessive consumption of foam and reduce the quality of the joint filling. It is optimal to keep the container at a temperature of +15° - +20°C for 24 hours.

Working at sub-zero temperatures

The working surfaces or seam cavity are cleaned from the adhesion of ice, snow, and dust. If the gap is wide, strips of foam plastic, fiberboard, cardboard, and other materials are placed in it so that the foam does not fall through. The surface is moistened with a brush or spray.

Procedure:

- shake the aerosol container for 30 seconds;

- the mixture is placed into the seam so that it occupies 1/3 or 1/2 of the space (options for a gun and a cylinder with a tube);

- After application, the foam is moistened to prevent the formation of frost or ice.

The frozen mass is protected from ultraviolet radiation with a finishing material, for example, plaster, putty, sealant, paint. You can cut off the excess only after 1 - 1.5 days, after complete drying.

How long does it take to dry

The initial setting time is 20-40 minutes.

The first crust on the surface of the mixture forms after 20-40 minutes , and the time until complete hardening can take up to a day or even more.

The polymerization period depends on the following indicators:

- frosty air temperatures;

- atmospheric humidity;

- composition of the material.

If the insulator is oversaturated with filler, unbound gas, a large number of open links inside is obtained. Expansion occurs quickly, but stabilization of shape is delayed. Insufficiency of active surface components leads to the combination of cells into large cavities.

The manufacturer coordinates the polymerization and expansion processes by introducing different volumes of blowing agent. The component opens closed bubbles and large cavities so that gas escapes and solidification occurs evenly.

Storing polyurethane foam

The foam inside the aerosol container has a shelf life limit. Chemical interactions begin, reactions occur slowly, but do not stop.

Rules for maintaining foam cylinders:

- It is better to organize the temperature in the storage area at +5°C;

- long-term storage at sub-zero temperatures reduces consumer characteristics;

- two-component formulations are stored longer, since the reagents are located in different sections of the cylinder or containers (depending on the type of release).

Valera

The voice of the construction guru

Ask a Question

When working with a gun, the cylinder can be left on the tool. This way, the working pressure will be constantly maintained in the aerosol, and the polymerization process will slow down. If after such storage there is no mixture coming out of the tube, you need to clean the valve.

Average prices in the Russian Federation

Among the most popular options for polyurethane foam are the following :

- Instant installation – from 250 to 300 rubles.

- Makroflex - from 325 rubles.

- Soudal - from 295 rubles.

- Penosil - from 285 to 315 rubles.

- Titan - from 345 rubles.

Note. It must be taken into account that the cost is determined not only by regional characteristics, but also by markups of individual stores.