The special PSUL tape for windows will help ensure high-quality and reliable sealing of seams and joints when installing window and other structures. PSUL is a pre-compressed sealing material presented in the form of a self-adhesive tape. Let's look at the main characteristics and scope of application of this seal, find out how to understand its markings and get acquainted with step-by-step instructions that will help you carry out problem-free installation in accordance with all the rules.

Description of the tape

Self-expanding tape is a black or gray strip of rectangular cross-section made of an elastic porous material resembling foam rubber - porous polyurethane elastomer. It is impregnated with an acrylic-based composition that provides resistance to adverse external influences. An adhesive layer protected with film is applied to one side.

After opening the roller, unwinding the tape and placing it in the seam, the thickness increases to the parameters indicated in the marking, while the width of the product remains unchanged.

Varieties

When choosing a sealant for the ridge of a corrugated sheet or metal tile, it is important that it meets the main principle: it must be suitable in shape and size to the roofing material, have high resistance to water and breathability. Only then will the installation process and operation of this element not cause difficulties.

The following types of seals are distinguished:

- Universal . The universal type seal is a tape made of high-quality polyurethane foam. It is laid between the roofing material and the ridge profile, occupying any necessary space. This material works as a filter, allowing air to pass under the roof, but preventing dirt, insects and water from entering there. It often has a self-adhesive backing, so it easily adheres to the surface of the roof slopes. This process is characterized by short adhesion times and simplicity.

- Profiled . This type is made from modified, denser polyurethane foam. One edge of the tape is cut based on the shape and size of the metal tile, so it fits perfectly to the roofing. To ensure air circulation, ventilation holes are made in it.

- Self-expanding . This type of seal is very popular due to its versatility. Under the influence of high pressure, polyurethane foam is strongly compressed, and when released it expands, filling the slightest gaps. It also comes with adhesive tape to make installation easier.

Types of seals

Remember! The design of the ridge depends on the type of sealing material. Metal tiles require the use of universal or self-expanding material, corrugated sheeting requires profile, soft roofing is not demanding in this matter.

Purpose, scope of application

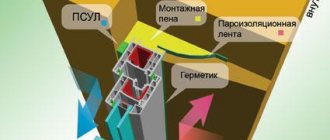

According to GOST 30971-2012, PSUL sealing tape is used to create ventilated assembly joints when installing window blocks. This product solves a whole range of problems:

- protects the mounting foam from moisture and sunlight;

- serves as an obstacle to the development of fungus and mold;

- thanks to vapor permeability, it removes moisture formed in the pores of the foam due to condensation during temperature changes to the outside;

- increases the service life and reliability of the seam;

- prevents freezing and seepage of water, penetration of air from the street and dust into the building.

In addition to insulating and protecting seams during the installation of plastic windows in accordance with GOST, PSUL tape is used for the following purposes:

- sealing seams of concrete parts, window sills, gaps between the wall and window and door frames;

- sealing of dormer windows, openings, roof structures;

- insulation from noise and vibration when installing air conditioners and fans;

- sealing joints of parts of prefabricated structures, roof elements, non-pressure pipelines (sewerage, storm drains);

- external insulation of wall panel joints;

- sealing the joints of wall beams made of wood and other building elements;

- filling cracks and gaps in areas where the chimney meets the roof, and ventilation duct joints.

Due to the specific properties of the material, self-expanding tapes can be used to seal joints with uneven surfaces.

PSUL tape on windows: a double-glazed window for a summer house increases its service life!

The main difference between new window technologies and old ones is the widespread use of polyurethane foam. It is with its help that PVC windows for dachas are installed in our time: it secures it, keeps heat out of the house, and is a jack of all trades. There is only one problem: when wet, polyurethane foam loses its beneficial properties. And no amount of old-fashioned platbands, canopies and moss pads will save you here: if the foam is not soaked by rain from outside, it will be saturated with steam from inside the room.

Places for installing PSUL tape to the box

Bottom line: after two years of operation of windows, 2-3 times more heat is lost through the wet mounting foam between the frame and the wall than through the double-glazed window, sashes and frame combined!

Technical characteristics and properties of PSUL

PSUL sealing tape has the following properties:

- resistance to various natural factors - precipitation, ultraviolet radiation, etc.;

- resistance to deformation;

- compatibility with any materials;

- maintaining elasticity throughout the service life;

- chemical neutrality;

- water-repellent properties;

- resistance to mold and mildew;

- ability to withstand pressure up to 600 kPa for several hours;

- high heat and sound insulation characteristics.

USEFUL INFORMATION: How to glaze a balcony with your own hands: step-by-step instructions

Technical characteristics of self-expanding material in the form of a tape made of foamed polyurethane with acrylic impregnation:

- operating temperature – from -50°С to +90°С (varies within 5°С depending on the brand);

- resistance to deformation – from 14%;

- thickness dimensions in compressed form - from 2 mm, in expanded state - up to 8 cm;

- thermal resistance – up to +1000°С;

- fire resistance class according to GOST 30402-96 – B1 (flammable building materials).

Features of the work

Firstly: the inner surface of the quarter, as a rule, has shell gouges and other damage. Secondly: the width of the external gap A between the front surface of the quarter frame, closed by the PSUL, is strictly defined for a given standard size of tapes. As a rule, inexpensive PSULs with a gap A of 3-5 mm, 6-10 mm are used. When the PSUL expands beyond the standardized values, their waterproofing ability decreases. It follows from this that it is necessary to putty and bring the inner surface of the quarter as parallel as possible to the window frame. Flaws. Unfortunately, our builders, both in the past and now, rarely indulge us with smooth openings. In brick houses, this is also supplemented by the need to seal the joints between the bricks. All this requires plastering and removing the inner surface of the quarter. This is labor-intensive and low-tech, especially in winter. Installation of a special vapor-permeable waterproofing tape under low tide

Features The tape is glued under low tide with one side to the window sill profile and the other to the bottom of the opening. It is necessary to very carefully waterproof the installation seam in the lower corners of the window opening. It is these places, as logic dictates, that are most critical for waterproofing. Rainwater flowing down the vertical surfaces of the assembly seam exerts maximum pressure at the junction of the ebb and the quarter.

Flaws . The importance of additional sealing at the junction of the flashing (waterproofing tape under the flashing) and the vertical PSUL is not emphasized.

The need to install a waterproofing tape under low tide is generally questionable, because low tide was invented for waterproofing. It does not prevent steam from escaping from under it. The junction of the waterproofing tape with the vertical PSUL is also leaky, like that of the ebb. Probably the most technologically advanced method of waterproofing in this area is the use of special sealants. They must have good adhesion to the joint materials, not destroy them and, most importantly, be durable when exposed to ultraviolet radiation. From all of the above, it follows that window installation using PSUL sealing technology works 100% only in ideal or specially prepared plastered openings. For greater clarity, we recommend watching the video.

Indicators of water resistance and frost resistance according to GOST

State standard GOST R 53338-2009, which contains a description of the material and provides its classification, divides self-expanding tapes into 3 classes according to the water resistance limit in the state of working compression:

- Class A – over 600 Pa.

- Class B – at least 400–600 Pa.

- Class B – no less than 200–399 Pa.

Also, the specified GOST provides for the division of products into types of execution:

- I – optimal for regions with an average monthly air temperature in the coldest time of the year down to -10°C. Minimum operating temperature – -25°С.

- II – for regions with an average monthly January temperature of up to -20°C. Minimum operating temperature – -45°С

- M (frost-resistant option) - for regions with an average monthly temperature in January below -20°C. Minimum operating temperature – -55°С

Modern construction, renovation and energy saving. Myths and reality

In the vast majority of cases, construction and finishing companies try to create for the client an ideal picture of the work they perform, in which, after installing windows, doors, roofing, etc. Comfort and coziness will reign in your home for many years. However, it is worth understanding that this is not the case.

In reality, the worst enemy of any structure is temperature. Temperature fluctuations entail changes in the volumes of substances and products made from them. If we talk about windows or doors, then you shouldn’t be surprised that cracks that were carefully sealed in summer will appear again in winter. And you should be aware that there is no escape from this. The gap is a condenser of moisture, fungus, a source of draft and a “thief” of your money at the same time. And one of the possible ways to combat it is the use of sealing elements that have a special set of characteristics, the main ones of which are compensation of the resulting temperature gap, protection from moisture and provision of ventilation. Such a seal is PSUL.

Tape marking

Tape markings should include:

- Brand name.

- The class of the seal according to the water resistance limit.

- Numbers represented as a fraction, where the numerator is the width of the product, and the denominator is the range of the optimal width of the sealed gap.

- GOST number.

Example:

Liplent PSUL A 20/8–20 GOST R 53338-2009

Tape of the Liplent PSUL trademark, class “A” in terms of water resistance, 20 mm wide, suitable for sealing seams with a thickness of 8–20 mm.

The type of product for frost resistance is indicated additionally.

Installation technology

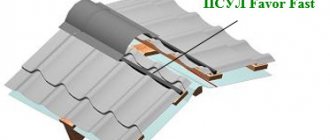

It is important to understand that regardless of the roofing material used and the roof structure, sealing tape is used to seal the ridge connection.

However, when working with profiled materials, the gaps become larger due to the shape of the profile, so these places most often become the causes of leaks. It is not recommended to neglect this measure, since repairs will cost more than purchasing a sealing tape, which costs no more than 100 rubles/m.

When laying, the following rules must be observed:

- The adhesive-based sealing tape must be glued onto a thoroughly cleaned and grease-free substrate.

- Profiled seals are fixed with galvanized screws.

- It is better to glue the tape at above-zero temperatures, as the glue will set better.

- Gluing is carried out only on a completely dry roofing surface.

- To speed up the expansion of the self-expanding tape, it can be heated with a hair dryer.

- The tapes are glued to the joint without stretching, twisting, or bending.

Seal installation process

Remember! To purchase the right material for sealing, all you need to do is go to any roofing center, knowing the parameters of your roof covering. With such a seal, the ridge will look more neat and aesthetically pleasing than using improvised means.

Tape selection

When choosing a self-expanding seal, you must focus on the following parameters:

- The width of the adhesive layer - the strength of adhesion depends on it. When installing windows, you should choose a tape with a width of 2 cm.

- The degree of expansion of the product determines the density of filling the gap. The optimal value is 20–30% of the initial compressed state, but not more than 60%.

When purchasing, do not forget to ask the seller for a certificate of conformity.

How to choose?

What to pay attention to:

- First of all, pay attention to the size of the adhesive part of the tape , that is, its width. This parameter is determined by the distance from the top of the quarter of the opening to the seam filled with polyurethane foam (ideally, the PSUL should evenly fill all free space). A quarter, as a rule, is not made very deep - its size is on average 20-30 mm.

- An equally important property of the tape is the expansion coefficient (measured as a percentage). Optimal efficiency of the PSUL is possible when it increases relative to the compressed size by no more than 30% . Seals with a coefficient of 50% or more are characterized by low mechanical density and are not able to provide the required level of insulation for a long time.

Skate design

Metal tile is a roofing covering that looks like ceramic tiles, but is made of profiled steel sheets with a polymer coating. The height of the wave (step) is about 25 mm. At the joints and bends of the roof, ridge strips (ridges) are used. They can be of different shapes:

- simple (triangular shape);

- tiled (semicircular);

- curly.

But any skate has a straight edge that lies on the wave surface of the coating.

Gaps up to 25 mm deep are formed at the joint, through which rain gets under the roofing in summer and snow sweeps in in winter . As a result, the structures become wet: the wood rots, the metal corrodes, and the insulation loses its thermal insulation properties. Therefore, when installing a metal tile roof, a sealant under the ridge must be used.

Price

When choosing a material, most customers are guided not only by the technical characteristics of the materials. It is important to conduct a comparative analysis of the price of seals:

| Rigid specialized polyethylene foam. | 20×1100 mm | 30–40 | 27–37 |

| Universal self-adhesive polyurethane foam. | 20×2000 mm | 150–200 | 75–100 |

| Universal self-expanding polyurethane foam (PSUL). | Roller length – 4 m | 100–150 | 25–37,5 |