Most manufacturers of metal-plastic glazing most often install their products using only polyurethane foam to fill the seams between the block and the opening. A window sill is mounted on it, and the drip profile is sometimes simply screwed on with self-tapping screws without laying any additional insulation.

If a heating and ventilation system is properly implemented in a room glazed in this way, then this approach may not cause any complaints for quite a long time. However, most often, installation gaps require a higher quality finish, which will prevent the penetration of moisture from the outside, and if it appears inside the seam, facilitate drainage to the outside.

Waterproofing

Waterproofing is the defense of objects, structures, and various structures from aggressive liquids (washing liquid, filtering liquid). With the help of waterproofing, the operation of buildings, structures and equipment becomes more reliable and durable.

Materials

Materials must provide complete reliable protection of structures under all environmental conditions. In order to properly purchase waterproofing materials, you need to familiarize yourself with their operation.

The following materials are considered waterproofing:

- metal sheets;

- roll and sheet materials (geosynthetics or PVC membranes, films);

- liquid application materials (liquid rubber, sprayed cork);

- mineral binders;

- dry building mixtures of penetrating action (penetrating insulation).

There are several types of waterproofing.

- Anti-filtration - protects against water entering buildings underground and under water. It also serves as a defense for the outflow of operational, technical and waste fluids.

- Anti-corrosion - protects materials from chemically hazardous liquid substances and water, from the attacking effects of the environment, from electrical corrosion that occurs during wandering underground currents.

- Painting - used in the form of an ultra-thin (up to 2 mm) cover, which has many layers: they come in the form of bituminous and copolymer varnishes, watercolors. It is used as anti-capillary and anti-corrosion protection, protects reinforced concrete and metal buildings.

- Plaster – looks like a multi-layer (up to 2 cm) special coating, which is more often used for reinforced concrete structures. This refers to structures such as: cement shotcrete, cool and hot asphalt plaster hydraulic solutions and resins.

- Pasting - made from characteristic stickers of rolled materials, which look like multi-layer (3-4 layers) coatings, protects external screeds and partitions. Unlike other insulations, it is more crack-resistant.

- Cast - used as particularly safe waterproofing. The installation consists of hot asphalt mastics, hydraulic solutions poured over a surface located horizontally (in 2-3 layers, 20-25 mm thick) and poured behind the partition or formwork on the sides (30-50 mm thick).

- Backfill - acts as filling into waterproof layers and macrocavities with bulk waterproofing materials. Similar to cast waterproofing, but is also used as thermal waterproofing.

- Impregnation is the impregnation of building products made of porous materials. More suitable for elements that are subject to intense mechanical influences.

- Injection - works by injecting binder material into the seams and cracks of building structures.

- Mounted - made from exceptional manufactured elements connected by mounting connections to the main structure.

- Surface - it is pressed using water pressure to the insulated surface that supports the structure.

- Penetrating - dry mixtures of cement, quartz sand with a certain chemical and granulometric composition and chemically active additives are used.

- Sprinkled - eliminates the ingress of water into roofs, foundations, ponds, basements and underground sheds. The coating is applied to the finished surface by cold spraying; after the spray hardens, it turns into a durable membrane.

Installation of vapor barrier on different surfaces

Vapor barriers can be installed on different surfaces.

For example, for the floor. In this case, the material is placed inside out against the floor beams. Vice versa for the ceiling. The film is unrolled and installed with the rough side inward.

Can be installed on walls. In this case, the following rules apply:

- you need to unroll the film on the wall and secure it with staples,

- vapor barrier sheets must overlap 100-200 mm,

- Excessive tension should be avoided,

- it is necessary to provide space for ventilation,

- as in the roofing version, all joints must be taped with single-/double-sided tape to ensure complete sealing.

When installing a vapor barrier on wooden structures, the wood must be pre-treated with an antiseptic.

Important! Installation should not be carried out in wet or rainy weather. The vapor barrier material must be dry.

Most often, the manufacturer provides instructions for proper installation along with the material, and these instructions should be used. Rolls should be stored on pallets at a distance from heating devices, indoors or under a canopy. No more than 25 rolls can be stored on one pallet. Rolls are also transported on pallets in closed vehicles.

Vapor barrier

Vapor barrier is a collection of different types of protection, thermal insulation materials and construction devices. They help cope with the ingress of steam, as well as the loss and absorption of dew.

Materials

Vapor barrier materials may not be responsible for complete vapor and hydraulic permeability. You can buy various vapor barrier materials in stores, but you should first of all read the reviews.

The following materials act as vapor barriers:

- polymer varnishes;

- rolled and sheet materials;

- vapor barrier films.

Vapor barrier tapes

The most common material for internal window insulation at the moment is GPL (hydro-vapor barrier tape) .

Its main features:

- Most products under this brand are made on a polyethylene base.

- On one side it is possible to apply a foil coating.

- The material does not allow moisture or air to pass through the tape itself, as well as through the places where it is fixed on the profile and opening.

- GPL is characterized by high resistance to solar UV radiation and is not destroyed by household chemicals.

In addition to GPL, there are a lot of products with similar characteristics that can be used depending on the type of finishing, wall material and climatic conditions.

Video instructions for installing a window using sealing tapes:

Installation of hydro and vapor barrier for windows

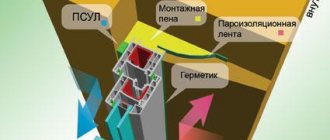

Sealing the space between the window block and the opening includes three main layers: central, external and internal.

- The central layer is in the vast majority of cases polyurethane foam.

Top view

It, together with fasteners, fixes the structure in the opening, protects the room from drafts and heat loss, and also prevents moisture from entering. The polyurethane from which the foam is made quickly deteriorates under the influence of solar ultraviolet radiation and other external influences, which is why it cannot be left open. Therefore, complete finishing implies the use of additional protection. - Outer layer - waterproofing. It is mainly necessary to prevent moisture from entering from the street; in addition, it insulates the opening and protects it from the negative influence of atmospheric factors, including UV radiation. One of the important features of external waterproofing is its one-sided vapor permeability, which ensures proper ventilation of the seam and prevents the accumulation of any liquid in it.

Expansion of PSUL tape over time

The most common materials are specialized tape products, for example, PSUL and sealing liquid mastics. - Inner layer - vapor barrier. Located on the side of the room, it prevents moisture from entering the installation seam. This is especially important when glazing rooms in which there are relatively many vapor accumulations - kitchens or bathrooms.

Vapor barriers are characterized by almost zero moisture permeability, have a hygroscopic outer surface, so water does not linger on it and dries quickly.

There are also foil types of vapor barriers used for dry finishing of slopes (lining, panels).

Most often, tape butyl rubber materials are used for installation; less often, acrylic or silicone sealants are used.

The choice of insulation products depends on the finish and the specific climatic conditions prevailing in the region. However, regardless of these factors, it is important to have all three layers and follow the technology for laying them. Only then can freezing of the seam, destruction of the insulation, and the appearance of moisture accumulations on the internal slopes be completely eliminated.

Application

Even though the air in the room seems dry, it contains a sufficient amount of moisture vapor. Often vapor barrier waterproofing is used in the construction of wooden houses.

Before insulating a building vapor barrier with staples, it is nailed to wooden buildings using a special stapler. Place the material so that it fits tightly, then seal the seams with adhesive tape.

In well-heated rooms, a vapor barrier is installed inside, and two layers of vapor barrier are made on the outside: on the inner and outer surfaces. This is done due to the fact that in summer the temperature outside is higher than in the building and steam, on the contrary, is directed from outside to inside, that is, into the room.

Vapor control materials on the market

Hydro- and vapor barrier films Grand Line®

The line includes hydro- and vapor barrier films and superdiffusion membranes. Grand Line H98 film has a number of advantages - the laying pattern, installation side, and overlap boundaries are indicated on the roll. Made from primary raw materials.

Roof vapor barrier Folder

Folder products offer several types of material:

- Folder Steam Regulator - this material can provide controlled vapor transmission, maintain the level of vapor barrier and allow excess moisture to pass through as much as possible.

- Alum H90 is a reinforced film with a foil layer that allows you to retain heat in the room and at the same time remove excess moisture.

- H98 – has a laminated layer, can be used with any thermal insulation material.

Related article: Roller grilles for windows

Hydro- and vapor barrier Tyvek®

The Tyvek line includes two vapor barrier membranes:

- Tyvek® AirGuard® Reflective – completely airtight. This membrane was developed to provide more efficient thermal insulation performance. The possibility of condensation entering is minimal.

- Tyvek® AirGuard® SD5 is a material with limited vapor permeability, thereby reducing the risk of condensation and condensation.

Delta insulation materials

- DELTA-DAWI GP is a simple single-layer polyethylene film.

- DELTA-NEOVAP 20 is a film with a reinforcing layer, due to which the risk of damaging the vapor barrier becomes much lower.

- DELTA®-REFLEX PLUS / DELTA®-REFLEX is a film with almost zero vapor permeability. This ensures that condensation does not get on the thermal insulation. This material also reflects heat back into the room.

Insulation from Icopal Fel'X

Icopal Fel'X insulation is a material consisting of three layers - polypropylene, SBS-modified bitumen and a non-woven base. These layers provide strength, waterproofing and protection to the roofing pie.

Hydro- and vapor barrier for roofing Izospan

The assortment includes several products:

- Izospan FS - consists of non-woven dense and metallized polypropylene film. Protects the structure from steam and also reflects heat into the building.

- Izospan B has two layers, the first layer is smooth, the second is rough, capable of holding condensation.

- Izospan D is a membrane that is a two-layer material. Performs the functions of hydro- and vapor barrier. The material is very durable and has high UV stability.

- Izospan DM - this material combines the functions of wind protection, waterproofing and vapor barrier. Consists of three layers.

Hydro- and vapor barrier Optima

One of the economical materials. The line includes Optima B - vapor barrier, Optima C - provides vapor and waterproofing, and Optima D - a universal hydro- and vapor barrier material with increased strength.

Waterproofing TechnoNIKOL

A three-layer membrane has high vapor permeability, quickly removes moisture and protects the insulation.

Hydro- and vapor barrier Ondutis

It is a fabric with the addition of a UV stabilizer and a protective layer.

- Ondutis V (R70) Smart is a classic film. Performs all necessary functions, protects the insulation and removes moisture.

- Ondutis D (RV) Smart - this film can be used as a vapor barrier on a warm roof and as a waterproofing on a cold roof.

In what cases will sealing tape help? ↑

To use sealing tape, the surface of the window opening must be perfectly clean and smooth. The distance between the window itself and the opening must be the same everywhere, only then will the waterproofing be reliable. Thanks to the sealing tape, moisture will not get into the seam and window opening, and steam will escape out.

Depending on the degree of compression of the tape, there may be one or another resistance to showers and wind loads. This parameter is usually equal to 20%.

The sealing tape is not attached to the window with fasteners, but is simply pressed tightly into a special groove in the profile

How is the material constructed?

Vapor barrier tape has a number of advantages that make it a popular material for furnishing residential premises:

- Allows you to isolate not only steam, but also excess moisture.

- Has no waste.

- Used sparingly.

- Does not emit harmful substances.

- Easy to install.

- The service life is practically unlimited.

Vapor barrier for plastic windows is done from the inside, since during operation of the room a lot of fumes are generated in it. This rule applies not only to the kitchen, but also to any other room. As a result of the temperature difference, moisture will settle on the glass. Vapor barrier of windows helps to avoid this unpleasant effect due to the fact that moisture cannot reach the polyurethane foam. Any insulator that does not allow water to pass through and has sufficient elasticity is suitable for the job.

Silicone sealant can be considered a convenient insulator, but it is not capable of covering a large area of the window, so a special tape is used that is wide enough to protect the entire seam. The insulator material is spongy, reminiscent of foam rubber. A special feature of the tape is its ability to swell and occupy hollow spaces after it is unpacked and installed.

Vapor barrier tape for windows will gain volume faster if you moisten it with water.

Types of mounting tapes for windows

The functions performed by the tapes are different and depend on the location of gluing, the condition of the opening, the features of the future finishing of the slopes, as well as the requirements for the window block. Next, we will consider the most commonly used materials common in the modern construction market.

PSUL

Pre-compressed sealing tape is used primarily on the outside of translucent structures. Its main purpose is to ensure unimpeded drainage of moisture from the area where the hatch connects to the opening.

Features of the device of vapor barrier material

The advantages of vapor barrier tape are: high hydro- and vapor barrier, cost-effectiveness and waste-free material, durability during operation, and so on.

Thus, in order for plastic windows to serve reliably and for as long as possible, it is necessary to provide triple protection. Often, installation companies or the owners themselves, in order to save money, violate the installation procedure discussed above. As a rule, such savings already after 2-3 years result in quite significant costs for eliminating negative consequences.

If the main function of the outer layer is to protect the insulation from sunlight and atmospheric phenomena, then the vapor barrier prevents damage to the thermal insulation by moisture inside the room. In any enclosed space where people are present, there is a large volume of moisture vapor. The difference in humidity indoors and outdoors becomes especially noticeable during the heating season. And because of this difference, drops of condensation begin to settle on cool surfaces.

In order to protect the thermal insulation from condensation, a vapor barrier is performed on plastic windows. Its principle is based on the fact that moisture is blocked from accessing the polyurethane foam. Various materials can be used to provide this protection. The main thing is that they have low vapor permeability and elasticity.

One of the optimal materials for this purpose is silicone. However, most often a special tape is used to protect the window seam. It is a spongy material rolled into a spiral, similar to foam rubber. Until the moment of use, the material remains in a compressed state. Thanks to special impregnation components, the material swells when exposed to moisture. When expanded after installation, the tape completely seals the existing gaps.

Schematic diagram of window installation and seam sealing.

This material allows you to provide the highest quality vapor barrier. Another advantage of this tape is that it can be easily and quickly installed with your own hands without the use of special tools. The porous material is immediately ready for use. You just need to first clean the joints, prime them and treat them with a dust removal agent.

The tape must be applied to one side of the seam. It is not recommended to bend it and pull it. At the corners, the strip must be cut to size and attached end-to-end. The degree of swelling of the material will depend on environmental conditions. At room temperature this takes from 1 to 4 hours.

It is important to understand the fact that you will not be able to provide a normal vapor barrier to the window if you use a tape for this with an initially lower degree of swelling than required by filling the joint. Outwardly, everything may look normal, but the tightness and strength in such conditions will be noticeably lower.

Installation features

The tape is applied both before fixing the window block in the opening, and on already installed structures. The first option is more convenient in cases with the installation of external insulation.

Let's consider the algorithm for using tape insulation using the example of gluing pre-compressed sealing tape (PSUL) and internal GPL-S with an additional strip of double-sided tape:

- We prepare the opening. If there is an old window unit, we dismantle it as carefully as possible, without causing unnecessary damage. After dismantling, we level the surfaces adjacent to the future structure and clean them of foreign contaminants.

- We perform a test installation of the block in the opening, temporarily fixing it. This is necessary to mark the edge of contact between the walls and the window, so that when gluing the tape is hidden behind the outer slopes.

- We measure the window block. In accordance with the obtained dimensions, we cut PSUL for gluing on the top and sides of the frame; we prepare diffuse tape to isolate the area where the molding profile is attached.

- We do the same with GPL-S (internal slopes) and butyl rubber tape (for the window sill profile). The material is measured for each side with an allowance of 10 cm to form corner joints.

- We apply the tape, gradually removing the protective layer from the adhesive surface of the PSUL.

We glue GPL-S to the inside of the window profile using a strip of double-sided tape (we do not remove the protective film from the main adhesive surface at this stage). - We fix the window in the opening. We wedge it, and then fasten it with anchors or using mounting plates. We fill the seams with polyurethane foam.

- After complete polymerization of the foam and rough preparation of the inner surface of the walls, we fix GPL-S on them (remove the protective paper and glue it to the slopes).

External finishing of slopes of plastic windows, plastering and insulation of slopes

After installing the window, the installers left... the slopes remained unfinished - such cases are not uncommon. How to insulate slopes yourself? And what does finishing of external and internal slopes of plastic windows include? Read the answers in our article.

Content:

- How to repair internal slopes?

- Finishing external slopes of plastic windows Plastering external slopes

- Metal slopes

- Window strip

- Waterproofing

How to repair internal slopes?

Finishing the slopes of plastic windows is nothing more than plaster. “And if I want plastic or plasterboard slopes, do I have to plaster them?” - you ask. We answer: not at all. But you need to tidy it up at least a little - so that malicious bacteria do not settle behind the plastic or drywall.

>To prepare the walls, do the following:>

Then use a wire brush to remove dust and dirt from the slopes.

To subsequently bond the mortar more firmly to the surface, you can deepen the seams between the bricks (in brick houses). Take a chisel, bring it with the sharp end to the seam and tap the blunt end with a hammer.

It is faster and better to prime slopes with a brush-brush than with a brush or roller.

>Plastering the slopes of plastic windows also consists of several stages:

Work on insulating the assembly seam ↑

As we have already said, polyurethane foam seals the window seam. To prevent moisture from getting into it from the street and from the room, it must be reliably insulated. This process consists of the following steps:

- Applying compressed sealing tape;

- Application of professional polyurethane foam;

- The use of vapor-permeable tape, which is most often made from butyl.

It is advisable to adhere to the principle “the inside is denser than the outside.” PSUL, that is, pre-compressed sealing tape, is used to create the outer layer and does not allow precipitation to penetrate into the seam. The only thing it allows you to do is allow water vapor to escape.

Vapor-proof tapes are glued on the inside of the installation seam and under the drainage on the outside. If all work is carried out competently and efficiently, then moisture will not penetrate the installation seam during operation of the windows, but will be removed through PSUL tapes in the side and top parts of the opening.

This processing technology guarantees the tightness of the assembly seam throughout its entire service life.

Correct installation of waterproofing. PSUL tape protects insulation from influences from the street

Types of window slopes ↑

Currently, the following materials are used when finishing window slopes:

- sheets of drywall, preferably moisture-resistant;

- GVL (gypsum fiber sheets);

- plastic panels;

- sandwich panels (using them does not require additional vapor barrier of slopes);

- cement mortar for plastering;

- various types of wood (when finishing slopes of wooden windows).

The client decides which type of material to choose for making slopes, taking into account criteria such as:

- design features of the building walls;

- type of window block;

- developer budget;

- design preferences, etc.

What causes hypothermia of the window opening ↑

If installers do not vapor barrier the installation seam and slopes in accordance with the requirements of building codes and regulations, then the client will face the problem of hypothermia of the window opening. Indeed, in this case, the thermophysical characteristics of the materials used change, and therefore the heat saving effect is not achieved through the installation of sealed windows. In addition, the lack of vapor barrier of slopes can contribute to the saturation of the building walls with moisture in the area of the installation seam, which will affect their thermophysical properties and increase the amount of heat loss.

Features of installing plasterboard slopes ↑

After completing the installation of the window block, they begin to attach a thin-walled profile along the entire perimeter of the window for the subsequent installation of sheets of moisture-resistant plasterboard.

Then it is necessary to fill all the voids with thermal insulation material. This will avoid condensation when the wall freezes due to the appearance of a “dew point” temperature on the surface of the slope. Moisture is destructive for sheets of drywall, especially not moisture-resistant ones, since under its influence the plaster and paint peel off.

To prevent the accumulation of moisture in the heat-insulating layer, it is necessary to cover its surface with a vapor barrier tape. Otherwise, condensation of water vapor will occur in the insulating material. After securing the vapor barrier, you can begin covering the profile with sheets of plasterboard.

Important! The joints of the plasterboard sheets with each other and with the window block are filled with a special acrylic sealant.

Using sandwich panels for finishing slopes ↑

Insufficient thickness of thermal insulation or its complete absence is one of the reasons for the appearance of condensation. Other reasons include cracks in the thermal insulation layer, defects in the vapor barrier device (for example, a violation of the continuity of the vapor barrier material). In cases where there is not enough distance to lay a layer of thermal insulation of sufficient thickness, it is recommended to use snow-white sandwich panels to finish the slopes. Their unique design, developed using the latest technologies, allows you to do without thermal insulation and vapor barrier of slopes. However, this method is not applicable if the interior design of the room requires a different color for the finishing of this element of the window opening.

How to make waterproofing in a wooden frame house

Waterproofing a window in a wooden building primarily depends on whether the work is being done in the opening of a new house or whether work is being done on an old block. If a window is being replaced or repaired, waterproofing measures are not much different from those for brick buildings. As for new wooden buildings, before installing windows and doors they need to be allowed to stand, or casing should be made and installation done into it.

Since a dry finish will most likely be used for the slopes, foil vapor barrier tape is glued to the inside. Application of PSUL from the outside is possible only on a window unit that has not yet been installed. In this case, it is advisable to first secure the street platbands (if they are provided for in the project) or install the slopes. When one of these conditions is met, a pre-compressed tape glued to the outer part of the profile, after expanding, will fill the gap between the platband (slope) and the frame.

Means for protecting the joints of windows and balcony doors:

- Silicone sealants

- Insulation with padding - cords, tow, moss

- Foil tapes

- PSUL tapes and butyl rubber tapes

To make the right choice, it is important to consider the type of window finish and the position of the joint. To protect the joints of frames and plasterboard and plastic slopes (dry cladding) and to protect windows with plastered slopes, various insulation products are used. For wooden windows installed in log houses, natural fillers are usually used - sphagnum, jute, flax tow, etc.

Waterproofing of roof windows

Mistakes made during the installation of roof glazing will have much greater consequences than the shortcomings possible during the installation of conventional windows. Therefore, if you have doubts about your own capabilities, it is better to entrust installation work to certified specialists.

During the installation of a window block into a roof slope, the installation of the waterproofing circuit is directly related to the thermal insulation circuit. The actual set of components and the order of work may differ depending on the specific window unit. In most cases the following items are supplied:

- Thermal insulation circuit;

- Waterproofing apron (design depends on the manufacturer);

- Drainage profile (dripper);

- Protective cover;

- Fastening kit.

First, a thermal insulation circuit is mounted on the roof sheathing. Its correct installation eliminates the appearance of cold bridges, freezing of the block and subsequent accumulation of condensate. Then a waterproofing apron is attached.

It is fixed on the window frame and provides a tight connection between the window and the under-roof insulating membrane. The longer part of the apron is mounted to the top of the roof, and the outline with tape is glued to the block profile. At low temperatures, the adhesive tape connection may not be reliable enough. Therefore, in winter, the apron is usually additionally nailed with a stapler.

A drainage profile is mounted above the window frame (on the sheathing) at a slight angle. It is necessary for collecting and draining condensate that can accumulate on roofs covered with metal tiles. Finally, a protective cover is installed on top of the entire structure. Its side elements lead directly under the roof. The casing has elastic seals around the perimeter, which additionally protect the block from external moisture and the formation of an ice castle.

More details can be seen here:

Fundamental differences in installing vapor barriers to different facade surfaces

If the film is used on the facade over insulation, then the material is placed on the outside and performs the function of waterproofing.

On the roof, the material is placed on top of the insulation according to the principle of constructing a ventilation facade.

If a cold roof is provided, the vapor barrier is attached to the bottom of the rafters.

Insulation in floors must be installed on the underside.

When thermally insulating walls and floors, we lay a vapor barrier on the outside of the insulation.

How effective is polyurethane foam against water ↑

Window waterproofing is a strip of material that is used for gluing between the opening and the plastic window before applying foam. Its main function is to protect the window from moisture and leaks. Polyurethane foam suffers the most from water. When wet, its structure is destroyed and its properties are lost. Since for some reason many people are sure that polyurethane foam is a reliable waterproofing material, let’s take a closer look at its properties.

Experts recommend calling it “polyurethane foam,” that is, based on the main material included in its composition. Its main purpose is not installation, but filling the existing joints between already installed structures, bridging voids, cracks, etc. It would be more logical to call it “overlapping foam”.

To protect against moisture and ultraviolet radiation, it is necessary to provide several layers during installation: heat, vapor barrier and vapor permeable

Under the influence of moisture, the foam increases in volume from 50 to 200-250%, hardens within 24 hours in a temperature range of +5-35 ° C and air humidity of at least 60%. It also absorbs moisture well, so it itself needs waterproofing; in addition, it is destroyed under the influence of UV rays. But polyurethane foam has sound and heat insulating properties.

Thus, when waterproofing windows, you should pay attention to other materials rather than relying on polyurethane foam.

Properly installed plastic windows protect the room from dust and noise, retain heat and last a long time. If any errors were made in the installation, then after a while a gap forms at the junction of the window and the wall, in which moisture collects and mold forms. Poor quality vapor barrier plays a role.

The installation seam needs to be carefully isolated from the ingress of water from the outside.

How to make a high-quality gap between the wall and the window, and not just plastic? It is important to prepare the opening, as well as the window structure. To do this, dirt, dust and other unnecessary elements are removed, and oily areas are degreased. Cleaned surfaces should be sanded and, if necessary, cracks should be repaired. During periods of sub-zero temperatures, the surface must be cleared of snow and/or ice. As a result, it should turn out clean and smooth.

What is vapor barrier used for in plastic structures?

It is worth considering that the more correctly the installation is done, the more reliable the structure will be and will last longer. Even if the windows are of high quality, if they are inserted incorrectly, you will not get the desired effect.

It is necessary to ensure that workers comply with the following conditions:

- The inside of the installation gap should be filled with foam that is thicker than the outside.

- The system must be three-layer. The first layer on the street side protects the entire cake from weather conditions, the middle layer is responsible for thermal insulation, and the inner layer protects against condensation.

Vapor barrier tape for plastic windows is necessary to protect the structure from water vapor.

To ensure that the vapor barrier does not interfere with plastering, special tapes should be used, over which the room can be finished.

Vapor barrier for PVC windows is an important stage of work, since without it it will not be possible to ensure that the room maintains a constant pleasant temperature

Replacing windows in a residential or commercial space is always accompanied by the protection of the weakest components of the structure: the seams between the frame and the wall. It is produced by filling the space between the window opening and the frame using polyurethane foam. This material has excellent sound and heat insulation qualities. However, with insufficient or incorrect protection under the influence of moisture and ultraviolet radiation, the foam begins to collapse and lose its original properties.

To avoid this, you need to take measures to seal the seams and protect the filler. To do this, waterproofing is used on the outside, which prevents natural precipitation from getting on the porous insulation, while on the inside, a vapor barrier for PVC windows is used, which protects the foam from the effects of water vapor.

The structure of vapor barrier for a plastic window is shown

Do-it-yourself waterproofing of a plastic window

Before starting repair work, it is necessary to establish the cause of condensation. In practice, this is facilitated by the following factors:

- the windows are located on the north side of the house;

- the wrong glass unit has been selected;

- the areas where the frame meets the wall are poorly processed.

In the first case, the formation of condensation is almost impossible to eliminate, however, there should be a minimum amount of moisture. As a rule, this does not interfere with the normal operation of the window and does not cause discomfort.

In the second case, it is important to correctly take into account the climatic features of the region. For northern latitudes, it is mandatory to install 3-5 chamber double-glazed windows. In the southern regions, a two-chamber one is sufficient.

In the first two cases, it is impractical to carry out repair work. The entire glass unit needs to be replaced. But if the problem is that moisture penetrates through the cracks formed where the window frame fits, it is necessary to perform comprehensive waterproofing. This, firstly, will eliminate leaks, and secondly, it will cost much less than a full window replacement.

Rice. 1. Do-it-yourself waterproofing of a plastic window

How to properly install a vapor barrier - basic steps

- Vapor barrier sheets are laid from top to bottom perpendicular to the rafters.

- The material should be rolled out according to the factory winding. Usually the laying side is marked.

- Each subsequent strip must overlap with the previous one.

- All joints must be taped with single- or double-sided tape.

- In places where pipes, risers and other things are bypassed, additional slats can be installed. The overlap of the material should be 10-20 cm.

- The material is attached with a counter-lattice to the rafters. It is acceptable to use nails.

- At the ridge, the overlap of the sheets should be 200 mm. It is better to lay more in the valley - 300 mm, and also on top of the material it is necessary to add an overlay along the entire width of the valley.

- The ventilation gap above the vapor barrier should be from 50 to 100 mm. Vents should be provided in the eaves area.

- It is recommended to minimize the number of holes. All holes must be sealed with tape to ensure the tightness of the entire layer.

- When adjacent to metal or other surfaces, fastening is carried out using double-sided tape.

Materials for waterproofing plastic windows

After determining the cause of condensation, it is necessary to prepare consumables. The list depends on the task to be accomplished:

- initial window installation;

- repair of joints;

- frame repair.

In the first case, you need polyurethane foam and waterproofing tape. In the second, only tape is enough. In the third, you need to use silicone sealants. Let's look at these materials in more detail.

Waterproofing tape for window

There are 4 main types of waterproofing tapes:

- moisture- and steam-resistant on a self-adhesive basis;

- insulated;

- pre-compressed;

- for external use.

The first 3 types of tapes are used only for interior work. The peculiarity of ordinary waterproofing tape is that it does not allow not only water to pass through, but also air. If the house is built of foam or aerated concrete, use is not recommended. If the joint has voids, a fungus will inevitably form in it, which will begin to destroy the stone. The price starts from 60 rubles per roll of 5 m.

The insulated tape differs from the first option only in that it is covered with a special reflective material, which prevents the penetration of cold from the street and the leakage of heat from the room. Relevant for use in cold regions. The price varies from 80 to 400 rubles. per roll 5 m.

Pre-compressed tape is mainly suitable for foam concrete structures as it allows air to pass through but prevents moisture penetration. In cold regions, it makes sense to use only in conjunction with an external diffuse tape. Price 60-300 rub. per roll 5 m.

Tapes for outdoor use are distinguished by the fact that they are resistant to natural phenomena: rain, snow, sun. However, they only protect against moisture from the street and prevent ventilation of the seams. They are optimally suited if renovations have already been made inside the premises. Price 80-500 rub.

To correctly identify the tape, it is enough to study the GOST standards:

- GOST R 53338-2009 “Vapour-permeable, self-expanding, self-adhesive tapes for construction purposes”;

- GOST 30971-2012 “Mounting seams of junctions of window blocks to wall openings. General technical conditions";

- GOST R 52749-2007 “Window installation joints with vapor-permeable self-expanding tapes.”

Rice. 2. Waterproofing tape for windows

Polyurethane foam

Polyurethane foam is used exclusively at the window installation stage. According to the principle of operation, liquid foam is blown into the cracks between the frame and the wall and begins to dry and expand, filling all the voids. Repeatedly blowing the seams with foam will no longer give the expected result. First you need to remove all the old foam and re-blow it. Only in this case will the waterproofing be done efficiently.

Another undeniable advantage of foam is that it does not harbor insects, bacteria, fungi and other parasites. On the other hand, there is a significant drawback - the foam fades very quickly in the sun and begins to crumble, so the seams must be sealed with waterproofing film.

The choice of manufacturer is not particularly important; pricing ranges from 40 to 200 rubles per jar.

Window sealant

This is a collective name for a whole group of finishing materials. Window sealants are sold in different forms:

- paste;

- tube;

- ready mixture in a bucket;

- dry mixture.

The first two options are suitable for sealing small seams, since they are sold in small volumes and cost up to 200 rubles. Ready-made mixtures are used if the work of installing the sealant will be completed in one go. After opening the can, the sealant dries out and becomes unusable. There are different displacements on sale from 1 to 20 liters. Cost from 150 rub. per liter

The dry mixture is cheaper, on average 300-400 rubles. per kilogram. When diluted, 3-5 liters of sealant is obtained. In terms of physical and operational properties, it does not differ from the finished mixture.

Selection of materials for installation of slopes ↑

When choosing materials for installing slopes, you should pay attention to their thermal characteristics. Then, when performing installation work, one cannot deviate from the requirements of the technology for carrying it out. In accordance with the requirements of GOST R 52749-2007, the installation seam, made of foam, must be covered with a vapor barrier material from the inside of the room. In this case, a special mastic or tape can act as a vapor barrier.

Professional installers of window systems and builders-finishers know all the intricacies of the technology for installing windows, slopes, ebbs and other elements of window construction, so they do not make mistakes. Amateurs who come to the market with the aim of making a quick profit, as a rule, ignore or do not know the rules for carrying out installation work. As a result, professionals have to correct their mistakes, and the client incurs additional costs.

Classification of vapor barrier tapes

Vapor barrier tapes are manufactured in two versions:

- tapes with one adhesive side;

- double-sided vapor barrier tapes.

Butyl vapor barrier tape for windows

The first type of tape is attached to the window frame of the window. The second allows you to choose the mounting location: both on the frame and in the opening.

In addition to differences in adhesive structure, tapes are divided into two types according to climatic design:

- for predominantly warm average annual weather, “summer” vapor barrier films are suitable;

- in the presence of sub-zero temperatures, “winter” tapes are used.

Advantages of tape materials

No need to wait for the foam to cure

There is no need to wait for the polyurethane foam to polymerize, since the self-adhesive vapor barrier butyl rubber tape and PSUL are glued before filling the seam with foam, and the vapor barrier after. In turn, sealants must be laid on top of the mounting foam when it becomes hard. Depending on temperature conditions, this can take from 20-30 minutes to 24 hours (in summer or at a minimum acceptable for work -20 ° C). For this reason, winter insulation with sealants may take 2 days.

Installation speed

All tapes are glued faster than sealants are applied, so for PSUL tape, fixation to the opening will take no more than 3 minutes. Vapor barrier and diffusion tapes take a little longer to glue - about 5 minutes. As for the sealant, due to the need to level it, the process takes 5 minutes or more.

Stage of evolution No. 1

| Materials used | Purpose |

| Mounting polyurethane foam | Filling the gap |

| Plaster mortar or silicone sealant | Protection of polyurethane foam |

The simplest method of increasing the moisture-proof properties of a window contour, which has been successfully used for quite a long time, is to use polyurethane foam, which has a whole set of qualities suitable for this:

- High level of adhesion with all types of building materials. So it doesn’t matter if your frame is plastic or wooden, brick walls or concrete, in any case, the polyurethane foam mass in question will stay in place;

Construction foam is effectively used even when working in a log house

- Low thermal conductivity . That is, you will immediately reduce heat losses, which to one degree or another are always observed in the area of window openings;

- Excellent tightness . Polyurethane foam not only fills the gap, but also expands in it, covering even the smallest and invisible gaps;

- Excellent sound insulation . Street sounds will also remain outside your home;

- Elasticity . Shrinkage processes, thermal expansion and other possible “movements” of the connected structural elements will not cause the appearance of cracks.

Application

The instructions for applying polyurethane foam are very simple:

- We clear the gap from dust and dirt . Yes, the substance in question has a high level of adhesion, as I noted above, but if various debris sticks to it even before adhesion to the mating surface occurs, then you can’t hope for high-quality fixation;

Diagram showing the problem of debris getting between the foam and the concrete surface

After removing dust and dirt, I recommend wetting the area being treated, this will speed up the expansion of the applied foam.

- We heat the balloon to 20 degrees Celsius , which is easiest to do by placing it in water at the appropriate temperature;

- Remove the cover and insert the supplied tube into the outlet hole . You can, of course, acquire a professional tool in the form of a special pistol, but for one-time work this is not rational, since its price is somewhat steep;

Ready to use can

- Shake the bottle . This must be done before each use so that the contents are mixed to the required consistency;

- We direct the nozzle towards the opening and fill it approximately halfway with a smooth line . In the future, the foam will expand and fill all the voids with itself.

Filling the gap with polyurethane foam

- After the substance has completely hardened, cut off its excess with a sharp knife.

Aligning a polyurethane seam with a utility knife

Protection

But here the problems begin, because of which the waterproofing of PVC windows began to evolve, without stopping at the described method. The fact is that the polyurethane foam itself needs protection from the external environment, and if it is not provided properly, then a number of the following problems can be expected to arise:

- Direct exposure to sunlight will lead to darkening and crumbling of the material ;

- Moisture falling on the frozen substance in the form of rain and snow will reduce its technical characteristics . The fact is that foam is not actually a waterproofing material and cannot adequately withstand direct contact with water;

- Temperature changes cause polyurethane foam to contract and expand, causing gaps to form .

The “movement” of the polyurethane seam can be minimized if, when installing the window, the frame is firmly fixed to the wall.

But everything is not so hopeless and you can even prevent the sudden death of the polyurethane foam with your own hands. Typically, one of two methods is used for this purpose:

- Applying at least a thin layer of plaster . At least, you will no longer be afraid of the harmful effects of the sun and raindrops, although the danger of moisture penetration still remains;

Why is it worth doing insulation?

First of all, it is worth noting that insulation is an essential part of a high-quality installation of a window system, which subsequently will not only last longer, but will be distinguished by high functionality. The main reasons requiring insulation:

- The window frame does not fit tightly to the surface of the slopes, leaving corresponding seams, which are often filled with polyurethane foam for sealing. This material shows excellent thermal insulation properties, but often reacts to moisture and temperature changes, undergoing destruction and loss of basic functions.

- Window frames without additional finishing are poorly protected from the influence of external factors. If insulation is not carried out, the joints will be susceptible to water ingress, which, under the influence of low temperatures, leads to destruction of the fastenings and subsidence of the window .

- After the structure shrinks, free spaces form between the window frame and openings, which lead to freezing and cold air inside the room.

- Insulated windows are not characterized by the accumulation of condensation from the inside, leading to the formation of fungus or mold.

Insulation of slopes protects the window opening from freezing and condensation

In addition to functionality, insulating window slopes will give the structure a stylish appearance that will harmoniously blend with the interior of the room.

Types of waterproofing materials for windows

There are three types of tapes on the domestic market - pre-compressed self-expanding sealing tape (PSUL), diffusion and vapor barrier tape.

PSUL is a self-adhesive polyurethane strip with open pores impregnated with special components. Due to this implementation, it is a vapor-permeable and waterproofing material: it does not allow external moisture to pass through, but at the same time allows ventilation of the assembly seam without interfering with the removal of water vapor. PSUL tape for windows, the price of which is comparable to other types of insulation of a similar type, is attached to the opening using an adhesive layer.

Diffusion tape

Diffusion butyl rubber tapes are made with a membrane that absorbs moisture and removes it through diffusion. They have hydro- and vapor barrier properties.

Vapor barrier tape

Vapor barrier tape for PVC windows is a foil material with two adhesive layers. Tapes are divided into 2 subtypes - internal and external - and are used in a three-layer insulation system for metal-plastic structures.

Sealants

Among the sealants for window installation, it is worth highlighting the sealants Stiz A, Stiz B and Stiz D, which ensure the effective functioning of the installation joint by creating an external vapor-permeable and internal vapor barrier layer around the mounting foam. They differ from all tape elements in their structure - the fluid consistency of mastics allows you to completely fill all cracks and irregularities, ensuring the seam is sealed against precipitation and air.

Let's compare the key advantages of these materials, dividing them into 2 groups - tape systems and sealants.