Comfort for many years

If you are reading this article, then you understand how important high-quality installation of windows in accordance with GOST is and you want to understand whether you should opt for Robiband mounting tapes from the Robitex company? The article provides a comparative analysis of tapes with analogues.

It turns out that installation is different from installation, even though it was done according to GOST. By saving 150 rubles on the purchase of high-quality mounting tapes, you can get a huge number of complaints (leaking, blowing and freezing) and the bill for reinstalling the window and altering the slopes is about 15,000 rubles. And if we are talking about installing a large construction project, then multiply this amount by the number of windows. Losses can amount to millions of rubles. Why does this happen and why are Robiband mounting tapes more profitable than their analogues?

PSUL tape

Pre-compressed self-expanding sealing tape (PSUL) Robiband is a polyurethane foam coating that has an adhesive surface. The product is impregnated with a special neoprene type composition. The tape is sold in rolls. It comes in black and gray shades. Moreover, the latter has better characteristics than the first.

The use of Robiband tape is quite simple. It is enough to place the PSUL in a seam or joint, and it will expand on its own, filling the entire space. The surface must first be cleaned of dust. The tape is glued to only one side of the seam; it must not be pulled out or deformed.

The product has the following properties:

- resistant to various climatic factors;

- does not burn;

- has chemical neutrality;

- not susceptible to ultraviolet radiation;

- not susceptible to mold and fungal microorganisms.

In this case, the properties of the tape do not change. It is sold in lengths of 4 and 6 m. The maximum expansion can be from 1.5 to 5 cm, thereby closing a gap of 0.3 to 1.5 cm.

Main advantages

When it comes to combining the pros and cons of using PSUL tape, the main emphasis is on the advantages:

- During installation, you can easily cut the tape and bend it in the desired direction. There are no difficulties during gluing.

- Convenient packaging.

- It can be combined with various surfaces, which can be not only metal, plastic, but also concrete and stone.

- Regardless of the temperature and weather, the quality of insulation will remain at the required level.

- It is very difficult to move it from its place once attached to the surface.

- Environmental friendliness and fire safety.

But these are only the main advantages that the PSUL tape has. In addition, it can be noted that it is widely used in various industries.

Tape NL

The waterproofing vapor-permeable tape is made of artificial membrane-like non-woven material. The use of Robiband tape ensures the reliability of the joint. It is used for waterproofing the lower construction seam.

The tape has 2 adhesive strips on one side (and can be made on both sides to order). One is used to fix the product on the structure, and the other is used to attach it to the wall.

NL Robiband tape has the following properties:

- The steam permeability index is no less than 0.15 units.

- Adhesion to the original surface from 0.1 MPa.

- Capable of withstanding pressure up to 1 thousand PA.

- Operating temperature during operation is from -45 to 80 0C.

- Resistant to direct sunlight for 8 months.

Sold in widths from 8 to 12 cm and a standard length of 12.5 m.

Compound

The basis of the material is a butyl rubber polymer composition, which remains plastic and adhesive in the range from −40 to +100 °C. It can cover the tape on one or both sides, and is protected on top with anti-adhesive paper. Thanks to the properties of butyl rubber, such tapes have high performance characteristics.

Butyl rubber is a synthetic rubber based on isobutylene. The substance is characterized by high heat, cold, light and ozone resistance. Butyl rubber allows air to pass through approximately 20 times less than natural rubber. Resistant to moisture and aggressive environments - solvents, alkalis, acids, alcohols, vegetable and animal fats.

VM tape

The VM Robiband vapor barrier tape is made of aluminum foil, which is reinforced with special artificial threads. The latter are extremely durable.

The use of VM B Robiband tape is recommended for internal vapor barrier of construction joints in order to subsequently treat the slope with plaster. There are 2 adhesive strips on the surface of the product. They are usually located on different sides, but upon customer request they can be placed on one side. One strip helps secure the tape to the structure, and the second is attached to the slope or wall.

The technical properties of the VM Robiband tape are the same as the previous one (NL). The product is sold in skeins of 12.5 m in length. The width of the tape is 8, 10, 12 and 15 cm. It is sold ready for use, so no special tools are needed.

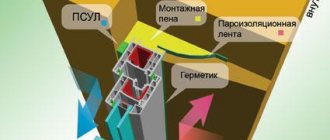

Concept

PSUL sealing tape is placed into joints or existing seams, after which it expands independently, filling cracks and gaps. Any, even minor, design defects will be hidden with the help of Robiband Psul. No weather influences can affect the heat level inside the room.

The most basic purpose for which PSUL tape is required is to create a ventilated assembly seam when installing doors or windows. It is made from polyurethane film to which acrylic is added. All these components in one material create excellent moisture-resistant and thermal insulation qualities. In addition, it can be used for a long time. The presence of an adhesive base on one of its sides also adds convenience to working with the tape.

Sun tape

Robiband BC tape is also aluminum foil, which is reinforced with special durable synthetic threads. It has 2 adhesive strips on different sides (but the manufacturer can place them differently upon request).

The use of Robiband BC tape in a frame house is intended only for internal vapor barrier of construction joints. In this case, in the future the slopes should be finished using a dry method (for example, using plastic slopes, sandwich panels, etc.).

One adhesive strip is fixed on the structure, and the second on the wall. The product has the same technical characteristics as the previous one. The tape can be purchased in lengths of 12.5 m and widths from 8 to 15 cm.

Lenta VS+

The use of Robiband tape BC+ in a wooden house also involves internal vapor barrier of construction joints in order to subsequently carry out finishing work on slopes using the dry method.

The tape is sold in rolls of 12.5 m and a width of 8 to 15 cm. The width should be selected as follows: add 4.5 cm to the thickness of the gap. If necessary, use wider varieties.

One adhesive strip is fixed to the slope or wall, and the other full width will be attached to the structure.

Dimensions and approximate cost

Diffuse insulating tape for installation outside (under low tide):

- Width -70 mm;

- Length in a skein – 25 m;

- The price of a skein is 436 rubles.

PSUL for use at sub-zero temperatures:

- Width – 20 mm;

- Thickness – 8 mm (40 when uncompressed);

- Length – 5 m;

- Price – 160 rub.

Internal duplicated tape:

- Width – 100 mm;

- Length per skein 25 m;

- The price of a skein is 377 rubles.

Inner metallized tape:

- Width – 45 mm;

- Length – 24 m;

- Price for 24 m – 523 rub.

Tape for window sill profile:

- Width – 200 mm;

- Length – 12 m;

- Price – 600 rub.

Tips for choosing

Before purchasing any type of Robiband tape, experts advise first asking the seller for a passport for such a product or certificates of conformity. They definitely need to be viewed and verified. This is a confirmation of the quality of the product, so doubts will disappear.

If this is your first time choosing and using such a tape, it is best to first consult with a specialist in this field. He will tell you about all the options for Robiband tapes, their features, applications, differences, and also tell you what is preferable to purchase.

Installation work can also be carried out at low ambient temperatures. In this case, it is recommended to use a special construction hair dryer to preheat the tapes if necessary (in particular, for PSUL). For her, under such conditions, the increase in size will occur 2 times faster.

Do not unwind the entire roll while working. In the future, if part of the product is no longer needed, it is quite difficult to wind the tape back, and this is wasted money. It is best to use the product by carefully unwinding the required amount from the roll.

In general, the use of Robiband tapes will help to efficiently insulate a building and protect it from the effects of negative conditions.

Installation features

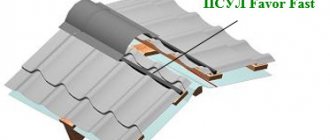

The tape is applied both before fixing the window block in the opening, and on already installed structures. The first option is more convenient in cases with the installation of external insulation.

Let's consider the algorithm for using tape insulation using the example of gluing pre-compressed sealing tape (PSUL) and internal GPL-S with an additional strip of double-sided tape:

- We prepare the opening. If there is an old window unit, we dismantle it as carefully as possible, without causing unnecessary damage. After dismantling, we level the surfaces adjacent to the future structure and clean them of foreign contaminants.

- We perform a test installation of the block in the opening, temporarily fixing it. This is necessary to mark the edge of contact between the walls and the window, so that when gluing the tape is hidden behind the outer slopes.

- We measure the window block. In accordance with the obtained dimensions, we cut PSUL for gluing on the top and sides of the frame; we prepare diffuse tape to isolate the area where the molding profile is attached.

- We do the same with GPL-S (internal slopes) and butyl rubber tape (for the window sill profile). The material is measured for each side with an allowance of 10 cm to form corner joints.

- We apply the tape, gradually removing the protective layer from the adhesive surface of the PSUL.

We glue GPL-S to the inside of the window profile using a strip of double-sided tape (we do not remove the protective film from the main adhesive surface at this stage). - We fix the window in the opening. We wedge it, and then fasten it with anchors or using mounting plates. We fill the seams with polyurethane foam.

- After complete polymerization of the foam and rough preparation of the inner surface of the walls, we fix GPL-S on them (remove the protective paper and glue it to the slopes).

It should be remembered that the tape must be selected in accordance with weather conditions. When working in winter, it is possible to glue only material intended for use in low temperature conditions.