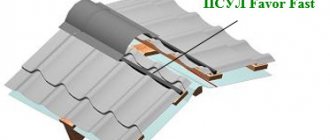

Packed in stretch film, 2 rolls each. Scope of application - PSUL Robiband-50 is intended for the protection of various construction joints and junctions, such as: connection of roofing elements, ventilated facades of various types, sandwich panels, SPK interface units, etc.

Material properties:

- non-flammable

- water-repellent

- chemically neutral

- remains elastic (impregnations do not harden)

- not affected by UV rays

- not affected by mold and fungi

Permeable self-expanding sealing tape Robiband PSUL

This material is an integral part of the Robiband system, used to organize a ventilated assembly seam. The Robiband system fully complies with modern technical standards.

In its line of PREMIUM ROBIBAND brand products, the Robitex company uses the latest butyl rubber adhesive layer (BKKS), which provides ultra-high adhesive-cohesive qualities and stickiness to surfaces. According to test results, the new BKKS showed excellent durability results. The conditional service life is more than 20 years.

Brief Product Description

The material is a self-adhesive elastic polyurethane foam tape impregnated with a special composition. The tape is supplied compressed and rolled into rollers. A wide range of standard sizes of tape sealant allows you to select a material to protect seams of almost any size. There are two types of Robiband PSUL tape: gray and black. The tapes differ somewhat in characteristics and type of impregnation. Gray tape has better performance than black tape. The tape placed in a joint or seam expands independently, completely filling all irregularities and gaps, providing reliable protection of the seam from all adverse climatic influences.

Material properties:

- not flammable;

- water-repellent;

- chemically neutral;

- remains elastic (impregnations do not harden);

- not affected by UV rays;

- not affected by mold and fungi.

Characteristics of materials

You can see the technical parameters for each type of PSUL in the results of certification tests

Sizing Robiband PSUL

The maximum degree of protection is provided by a tape whose size in the sealed seam does not exceed 20% of the height of its full expansion. When expanded by 80%, dust and sound resistance will be ensured. With any expansion of the tape, the foam will be protected from UV rays.

WARNING:

The use of PSUL tapes with a deliberately smaller size than necessary in a particular case can lead to undesirable consequences, such as the occurrence of leaks, blowing out of the PSUL by strong (hurricane) wind, and also squeezing out the PSUL with foam. High-quality sealing and protection of the seam is ensured only by correctly sized tapes.

| Width of adhesive layer, mm | Max. extension, mm | Length of tape in roller, m | Optimal sealing gap, mm |

| 10 | 20 | 6 | 4-5 |

| 12 | 30 | 4 | 6-9 |

| 15 | 40 | 4 | 8-12 |

| 17 | 50 | 4 | 10-15 |

| 20 | 50 | 4 | 10-15 |

It is possible to produce other standard sizes upon request

Application of Robiband PSUL tapes

The Robiband PSUL tape is immediately ready for use and does not require special tools for installation. The surfaces of joints and seams must be cleaned of dirt. Absorbent and fragile surfaces require preliminary priming. The tape is glued to one of the seam surfaces. When gluing the tape, do not pull it out or bend it in the corners of the opening. All corner and longitudinal connections of the tape are made end-to-end. The joined pieces of tape are pressed tightly against each other. The rate of expansion of the tape depends on the temperature of the air and surfaces.

Time to restore the form of PSULs (*min recovery time is not regulated)

| Time to restore shape to working condition (about 25% of full expansion), hour, no more: | PSUL II (class B, C) | PSUL III (class G), PSUL 50-3 (class D) | PSUL 50+ (class C) |

| at +10C | 24 | 20 | 48 |

| at +20С | 3 | 2,5 | 2 |

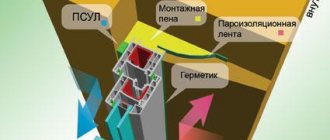

Only the integrated use of the Robiband system ensures the necessary reliability and durability of the assembly seam. The use of each material separately or their incomplete combination only partially improves the characteristics of the seam and does not provide comprehensive protection against a wide range of negative impacts on the seam during its entire service life.

Basic sizes

| Width of adhesive layer, mm | Max. extension, mm | Length of tape in roller, m | Optimal sealing gap, mm |

| 10 | 20 | 6 | 4-5 |

| 12 | 30 | 4 | 6-9 |

| 15 | 40 | 4 | 8-12 |

| 17 | 50 | 4 | 10-15 |

| 20 | 50 | 4 | 10-15 |

PSUL tape: types, brands, installation technology

PSUL tape for windows - what kind of material is it? PVC window installers know that this is a pre-compressed sealing strip. It is an integral element of high-quality installation of plastic and wooden windows.

This material cannot be classified as innovative, since it has been used for more than two decades. But new modifications of PSULs appear regularly, claiming to be the most reliable and high-quality ones.

PSUL tape for windows - what is it? Material characteristics, GOST and scope of application

The special PSUL tape for windows will help ensure high-quality and reliable sealing of seams and joints when installing window and other structures. PSUL is a pre-compressed sealing material presented in the form of a self-adhesive tape. Let's look at the main characteristics and scope of application of this seal, find out how to understand its markings and get acquainted with step-by-step instructions that will help you carry out problem-free installation in accordance with all the rules.

Technical characteristics of PSUL tapes

If you compare the technical characteristics of seals from different manufacturers, you will find that all of these products, despite the difference in brands, meet the requirements set for them.

All enterprises strive to produce competitive products, so you can buy any sealing tape to install windows yourself. She is guaranteed to complete her task. Any Psul tape, the technical characteristics of which correspond to those given below, will serve faithfully for at least 20 years.

- Expandability from 10 to 70 mm.

- Presence of an adhesive layer.

- Resistance to temperature changes (operating range from -50°C to +70°C).

- Deformation under mechanical influence is no more than 15%.

- UV resistance.

- Vapor permeability in a compressed state is no more than 0.25 m2∙h∙Pa/mg.

- Neutral to chemicals.

- Resistant to moisture, therefore painting with vapor-permeable water-based paints and varnishes is allowed.

Application area

PSULs are sold in rolls (reels), which ensures ease of transportation and use. These seals are produced in widths from 10 mm to 40 mm to protect seams of different sizes. At the request of the customer, manufacturers are ready to make tapes of any standard sizes.

The scope of application of seals is wide. They are used to protect assembly seams when installing metal, plastic, wood, and glass structures into concrete, wood and brick openings. Required for the following types of work:

- when installing windows and balcony blocks as a sealant and heat insulator;

- when installing thresholds and window sills;

- when installing roofing structures as damper joints;

- when installing ventilation and air conditioning systems to eliminate gaps, noise and vibration;

- during the construction of building structures to seal joints and as a sound and heat insulator.

The pre-compressed self-expanding sealing tape can have two adhesive sides. One is for fixing the translucent structure to the plane, the second is for attaching to the slope.

What is PSUL tape and its purpose

Explanation PSUL sounds like sealing tape, pre-compressed. This product is an elastic polyurethane or butyl rubber strip with a self-adhesive layer on one side covered with a protective film. The sealing strip has a porous structure.

To improve material properties such as durability and wear resistance, the base of the mounting tapes is impregnated with special compounds, for example, acrylic. PSUL self-adhesive sealing tape is produced in various densities and colors (gray, black, green). For ease of assembly, the product is manufactured in rolls.

Self-expanding products are designed to create a protective layer against water, as well as a vapor-permeable layer on the assembly seams on the outside of the building at the junction of the wall and the door or window. The use of PSUL tape for making seams when installing windows or doors is regulated by such regulatory documents as GOST 30674-99 and GOST 30971-2012.

PSUL mounting self-adhesive tape is glued to the opening, expands by the required amount, and then fills the gap located between the opening and the window or door. Due to the high elasticity of the material, as well as the ability to expand, the seal is able to hide any unevenness in the joint space. This property expands the scope of application - it can be used to fill gaps in other structures, for example, when constructing a roof.

In addition, PSUL tape protects plastic windows from the effects of precipitation, noise, wind and ultraviolet radiation. The use of a seal of this kind helps to securely secure window or door blocks in the openings.

Installation technology

The PSUL, placed in the seam, gradually increases in volume, filling all the gaps. But this does not happen instantly. It takes time to expand. The speed of filling the seam directly depends on the ambient temperature. For better installation quality, it is not recommended to use PSUL at temperatures below -5°C.

For the installation of plastic windows, the self-expanding sealing tape PSUL “Robiband” is recommended. Products of this brand have long established themselves as high-quality and reliable.

According to GOST 30971-2002, when installing windows, it is required to provide a protected installation seam. This can be done using PSUL. To install the tape, perform the following steps:

- measure the width of the seam formed between the window opening and the window block;

- determine the location of the seal on the window frame;

- check the deviations of the opening walls vertically and horizontally (in this way they obtain information about the expected width of the gaps);

- using a pencil and a ruler, mark the location of the seal on the window frame;

- remove the packaging film from the roll and cut off 3-5 cm from the end of the tape;

- remove the protective paper from the adhesive side and glue the tape along the previously made markings on the window frame;

- gradually move along the box, gluing the seal around the perimeter;

- A larger sealant is glued to the wider seams;

- at the corner joints of the box, each strip of tape should hang down by 1-2 cm;

- the joined sections are bent and pressed against each other;

- install a frame with a seal in the window opening;

- strengthen the frame with self-tapping screws.

Installation

PSUL is completely ready for use; its installation does not require the use of special tools and devices. The sealant is selected according to the width of the seam.

Installation of pre-compressed sealing tape occurs as follows:

- The PVC window and window opening are prepared for installation. To do this, dirt and loose plaster are removed, the surface is cleaned of dust using a vacuum cleaner, and wiped with a damp cloth.

It is recommended to treat the surface of joints and seams with a special dust-removing compound.

- The surface of the quarter is coated with an acrylic primer for exterior use.

- Markings are made and fasteners are installed.

- A few centimeters (3–5) from the beginning and end of the roller are cut off and not used. A piece of sealant is cut to the required length and the paper layer is removed.

- The tape is installed on the outside of the frame facing the street, with a distance of 3–5 mm from the outer edge of the quarter. The product is pressed to the surface.

The PSUL is glued end-to-end, there should be no overlap. Vertical seams are filled without interrupting the tape at cross joints. Do not bend the seal at the corners.

- After filling all the gaps between the window and the wall, you must wait until the tape expands to its free state.

The rate of increase in the thickness of self-expanding material to working condition:

- at a temperature of 0°C the tape expands to the optimal size in 48 hours;

- at an outside air temperature of +18–20°C, the expansion process lasts 2–3 hours;

- at +30°C expansion occurs in 0.5 hours.

Advice. You can speed up the expansion process of the PSUL using a hairdryer.

The last steps after taking the tape to the final dimensions will be to apply sealant to the joint between the frame and the window opening and cover it with flashing and drainage.

Concept

PSUL sealing tape is placed into joints or existing seams, after which it expands independently, filling cracks and gaps. Any, even minor, design defects will be hidden with the help of Robiband Psul. No weather influences can affect the heat level inside the room.

The most basic purpose for which PSUL tape is required is to create a ventilated assembly seam when installing doors or windows. It is made from polyurethane film to which acrylic is added. All these components in one material create excellent moisture-resistant and thermal insulation qualities. In addition, it can be used for a long time. The presence of an adhesive base on one of its sides also adds convenience to working with the tape.

Description of the tape

Self-expanding tape is a black or gray strip of rectangular cross-section made of an elastic porous material resembling foam rubber - porous polyurethane elastomer. It is impregnated with an acrylic-based composition that provides resistance to adverse external influences. An adhesive layer protected with film is applied to one side.

After opening the roller, unwinding the tape and placing it in the seam, the thickness increases to the parameters indicated in the marking, while the width of the product remains unchanged.

Characteristics

When Psul tape is used, the characteristics on the positive side appear constantly. These include the following main features:

- When compressed, the self-expanding Psul sealing tape is only two millimeters. After installation at its destination, it can expand up to 8 cm. This means that almost any gaps, even significant ones, will be hidden after installing the tape.

- It is resistant to deformation (more than 14%).

- Able to withstand atmospheric phenomena (solar radiation, moisture, temperature changes).

- During operation, it is not subject to rotting or the appearance of various fungi and mold on the surface. At the same time, it has excellent vapor permeability properties. Rooms arranged with such tape “breathe” perfectly.

- It is a material that is very difficult to burn.

- It is capable of filling existing unevenness formed even during brick laying.

- PSUL characteristics indicate that it is resistant to a large number of types of organic and inorganic solvents.

- All work on its installation can be carried out at any temperature and weather conditions.

- The service life is at least 50 years.

Manifested qualities of PSUL tape

When using Robiband PSUL, the characteristics are selected depending on the needs and environmental conditions. In any case, there are much more positive qualities than negative ones. Due to this, the expanding Psul tape is in great demand in the building materials market. More information about the types and properties of PSUL tape can be found on the company’s website https://robitex.ru/shop/psul/

Main advantages

When it comes to combining the pros and cons of using PSUL tape, the main emphasis is on the advantages:

- During installation, you can easily cut the tape and bend it in the desired direction. There are no difficulties during gluing.

- Convenient packaging.

- It can be combined with various surfaces, which can be not only metal, plastic, but also concrete and stone.

- Regardless of the temperature and weather, the quality of insulation will remain at the required level.

- It is very difficult to move it from its place once attached to the surface.

- Environmental friendliness and fire safety.

But these are only the main advantages that the PSUL tape has. In addition, it can be noted that it is widely used in various industries.

Application area

There are several types of PSUL seals, depending on the scope of application and installation conditions. They can be used in any case for waterproofing. But in addition to this, they perform the functions of sound insulation, steam and heat insulation.

For example, when replacing old windows with new ones, a weak point immediately appears - the junction between it and the wall. Most often it is filled with polyurethane foam. But it deteriorates very quickly during operation. Especially if there is increased exposure to moisture and sunlight. In order to fill the resulting gaps efficiently and profitably, Psul Robiband tape is used. It is also capable of protecting the polyurethane foam itself from destruction.

Another area of application is balcony blocks. The most commonly used tape here is butyl psul. In addition, this material is suitable for roofing under certain conditions. Its main quality is sufficient here - waterproofing. It seals drainage joints, joints of roofing materials, attic windows, etc.

Application of PSUL tape

Tape selection

When choosing a Robiband waterproofing tape for installation, you should pay attention to certain qualities and factors:

- Extension degree. The density of filling the seam will depend on it. An optimal ratio is identified in which the expansion does not exceed the initial (compressed) position by 20-30 percent. More critical condition – 50-60 percent. In this case, the density for the PSUL tape will be different.

- Width of the layer with glue. This will affect the tightness of the fit to the base, which is pasted over, as well as the strength during use.

- The Robiband sealing tape must have a minimum width of 2 cm if windows are being installed. The wider the material, the better it exhibits its qualities during operation.

As an example, we can give the following calculation: the width of the seam is 1 cm. In this case, the degree of expansion would best be within 30-40 units. This suggests that the tape will increase by approximately 20-25% of its original state.

The price will be influenced not only by the size of the Robiband butyl tape, along with the length of the roll, but also by the composition, the presence of additional components, the features of the functions and types. Everyone knows that the price will increase depending on the number of resellers. This suggests that the best option is to purchase the tape from a manufacturer or intermediary.