The seal for the metal entrance door is attached at the last stage of installation of the door leaf. With its help, it will be possible to reduce the gap between the metal sheet and the frame, and this, in turn, helps to reduce the intensity of heat outflow from the room. It is difficult to imagine doors without a seal, since this material helps to reduce the amount of error that is always provided for during installation. It is available in several varieties, which allows you to choose the most suitable option.

Material functions

The range includes seals of various thicknesses, depending on the size of the gap that needs to be eliminated. Seal material – rubber, foam rubber, silicone, fleecy tape, polyethylene foam, polyvinyl chloride, polyurethane foam.

You can select products for any opening structures:

Carrying out installation yourself does not require any special skills or additional materials.

The purpose of the seal is to reduce heat loss during the cold season and eliminate drafts. Thanks to the porous structure of the material, complete tightness is achieved, and warm air will not be able to escape the room.

The use of self-adhesive windows has another advantage: it reduces the level of street noise. Wooden windows do not have the property of suppressing sound, so this problem can be partially solved with the help of additional insulation.

For home furniture, you can also use stickers so that when closing the doors do not knock, do not become deformed from impacts, and do not let dust and moisture into the cabinets.

Stickers vary in thickness, material and purpose. To figure out which seal for doors or windows is better, you need to know the properties of the material from which it is made.

For interior doors, you can choose a self-adhesive strip that matches the color so that it does not affect the appearance. Indoor models do not have a temperature load and are not susceptible to weather conditions, so you can attach foam rubber or silicone pads to them, which will last a long time in mild conditions.

The purpose of the seal is to reduce noise when closing and improve sound insulation.

For an entrance iron structure, rubber tubular stickers with a cavity in the middle would be a more suitable option.

They are made of dense rubber, therefore they are durable and ensure a tight fit of the sashes.

A wooden entrance door can be sealed with rubber flat self-adhesive pads simultaneously on the side of the leaf and the door frame.

This method allows you to create the most dense insulation. If there is a gap above the threshold, you can buy special thick rubber to eliminate the gap.

Silicone

Silicone stickers are mainly used to seal glass products. They do not change their appearance, as they are invisible due to their transparency. The profile for glass structures has a varied cross-section, which is designed to reduce the impact force when closing. Both self-adhesive silicone strips and simple ones that need to be moistened with water and applied to the surface are available for sale. The water dries and the silicone sticks securely.

To equip glass structures in home saunas, heat-resistant e-shaped silicone material is used, which can withstand temperatures up to +250 degrees.

Silicone is widely used in construction due to its properties:

- elasticity and ability to take any shape;

- resistant to temperature changes;

- environmentally friendly, does not emit harmful substances when heated;

- resistant to moisture.

The silicone self-adhesive seal has the most important advantage - impact resistance. This property allows the product to be used for a long time.

Silicone linings are used in bathrooms to seal shower doors. You must first clean the surface, degrease it with alcohol or gasoline.

What is door insulation made of?

In order to choose the most suitable door seals for your home, you should also be aware of the materials used to make them.

Rubber

Most often, entrance doors are equipped with a rubber seal. Moreover, the manufacturing material is not simple rubber, but its modified varieties that can withstand the most extreme operating conditions, including severe frost and heat. In addition to the draft, the doors may also creak, but this can all be fixed.

Silicone

The performance characteristics of silicone products are slightly lower than those of rubber ones. This is explained by the fact that it is not possible to provide silicone with additional resistance to aggressive external influences even by introducing appropriate additives into its composition. For this reason, silicone liners are mainly produced for wooden interior doors that are used in comfortable conditions.

Foam rubber

It is the material used to manufacture the cheapest door insulation, which fails within one year. The reason for this may be temperature fluctuations, dirt and moisture, which provoke crumbling and disintegration of the foam rubber. The material gradually loses its original volume, which affects the functionality of products made from it.

Magnet

An innovative development, which is mainly used to complete expensive metal doors. The average person is familiar with a magnetic seal from household refrigerators and freezers, in which permanent magnets around the perimeter of the doors are attracted by poles of attraction. Most often, metal doors are equipped with three-circuit magnetic seals. The location of the two circuits is the door leaf itself, while the third is mounted on the door frame. The main disadvantage of such products is the rather high pressing density, which a child or an elderly person will not always be able to cope with. If the action of the magnets is weakened, then proper tightness and sound insulation will not be ensured.

It is recommended to install magnetic seals even on simple metal doors made of steel sheets, without decorative decorations. This seal includes soft filling and a magnetic insert.

Handles for interior doors: how to choose and install

Advantages of a magnetic door seal

The soft filler is made of thermoplastic elastomer, which has the following advantages:

Felt

Typically, sliding doors are decorated with a felt seal, which helps save room space. Such tapes cannot provide special protection from noise and cold. They are used exclusively to prevent dust from entering the cabinet or room.

Rubber

Rubber is the most resistant material that is not afraid of temperature changes, exposure to acids and aggressive substances - oils, gasoline.

Creates a durable seal for entrance door frames that are at the interface of warm and cold air.

Can be used in the most unfavorable environmental conditions.

Rubber door seal is a reliable solution , as it is made of a soft material that changes shape and does not crack due to its thickness of 2 mm.

A soft rubber band is necessary if the surfaces are uneven. A stiffer material will not tightly close the cracks, as it is less susceptible to deformation.

The profile has different shapes, which makes it possible to choose the optimal model for entrance doors. The width should be selected based on the size of the gap.

Important!

Only PVC can be more durable than rubber. It costs more, but will last much longer.

Silicone

For metal doors it is inferior, according to some indicators, to products made from rubber. The material has increased elasticity, which facilitates its installation on surfaces of various textures. However, the main disadvantage here is the inability to modernize the composition with special additives that slow down the destruction of the structure under the influence of moisture, ultraviolet radiation, and temperature changes. As a result, silicone seals are rarely used to seal external doors.

Which material is better

You need to select insulation for the front door based on your goals: to ensure tightness, temporary insulation, long-term use.

For example, if you plan to replace wooden structures with metal-plastic ones, then you can use inexpensive foam rubber insulation, the service life of which is 1 year. Further, under the influence of temperature changes and dust, the foam rubber loses its properties and crumbles. Such insulation will be inexpensive, but will not last long, especially in outdoor conditions.

For heavy metal doors, it is necessary to glue durable rubber. Its shelf life is up to 15 years. A correctly installed product does not stretch, shrink or peel off during use. Rubber, which is used for entrance iron structures, is usually porous, which makes it possible to retain heat in the room . You can determine the end of the product’s service life by the appearance of the rubber layer: it will begin to peel off in some places.

For internal structures, silicone or rubber linings are the best. They have the same properties and last a long time. For small gaps, you can buy thin rubber or silicone. At the beginning of the process, you need to measure the width of the gap and select a specific brand of product in the store.

Foam rubber

Foam rubber sealing is the most cost-effective solution. Often they resort to its use with the expectation of serving for one season. Such products can no longer withstand regular use of doors.

An old foam rubber seal often begins to disintegrate and crumble under the influence of humidity and sudden temperature changes. Over time, the material clumps into a lump, loses its original elasticity and ultimately ceases to cope with the assigned tasks.

Gluing rules

How to glue a seal to a door. Installing self-adhesive elements is not difficult, but there are several nuances that need to be learned before starting work so as not to damage the product.

The seal for wooden doors should be installed as follows:

- The first step is to remove the old stickers from the tree, if there were any there.

- Measure the width of the gaps and select the size of the insulation, as well as the total length of the perimeter with a margin of 50 cm.

- Clean with sandpaper to ensure that old dust and debris do not interfere with installation.

- The area must be wiped with a cloth soaked in alcohol, acetone or gasoline.

- Measure the length of the sides with a tape measure and measure on the prepared material.

- Remove the protective strip from the seal and stick it first on the top side, then on the bottom, then on the sides.

To make the joints at the corners look neat, cut the strips at an angle of 45 degrees. The product will completely stick in 2 – 3 hours. After this, the door can be opened and closed.

Important!

Seals for interior doors should be selected according to color to make them look aesthetically pleasing.

The self-adhesive seal for metal doors is mounted in a similar way . The doorway is cleaned with sandpaper and wiped with white spirit or gasoline.

Next, the protective tape is removed and the box is sealed. To completely seal the entrance, you need to glue the door itself at the junction.

In this case, the sealing material should be selected taking into account the double lining, otherwise the entrance structure will be difficult to close.

Thin self-adhesive overlays are suitable for plastic windows. Before installation, wash the plastic and dry it. Next, moisten the cloth in a degreasing composition and wipe the windows in the place where the self-adhesive is to be installed.

The surface of the plastic is smooth, so this procedure will be easier. You will need to remove the protective tape and glue the cover. Then carefully trim the corners.

Advice!

If there are pieces of material left, they can be used for kitchen furniture: stick under the doors to make them close more softly.

With the help of various modifications of seals, you can inexpensively solve several problems at once - reduce noise levels, save on coolants, eliminate furniture defects. Depending on the budget, it is possible to insulate the room for a period of 1 to 15 years.

Varieties by purpose

Each individual type of door structure can be equipped with a specially designed seal. Products for entrance doors are hollow and internally dense tubular seals. It is due to the thick material and the internal cavity that the door leaf fits securely to the frame.

The rubber used to produce such products is porous, which allows the thermal insulation effect to be enhanced several times. This type has a self-adhesive base. This is both a minus - they come off quickly, and a plus - you can install a new door seal without effort or problems.

There is another option, which is designed for doors between rooms. This is the case in which there is no need to withstand drafts, so soft rubber or silicone is most often used for its manufacture.

A separate group is represented by gaskets for plastic doors. The main feature is that they can be quickly replaced. Thanks to the special configuration, installation consists of installing them in a groove. Thus, the influence of the environment on it itself is reduced, and it copes with its work at any temperature. This universal type can be installed for internal and external plastic doors. It must be taken into account that it is not suitable for any other purposes.

A separate type is represented by seals for glass doors, which are most often made of silicone and have a special profile section. To install the seal on the door, you need to wet it and then install it on the end. Once dry, it adheres tightly to the glass. Depending on the material used, products are divided into several types.

Types, selection, installation of seals for metal doors

If a draft appears in your apartment or unpleasant odors begin to seep out from the entrance, the front door is to blame. Sealing metal doors will help solve this problem at minimal cost.

A metal door often fails to cope with the task of retaining heat in the house, even if it is filled with insulation. Formally, it is considered insulated, but you are unlikely to be interested in formal features, the main thing is that the door actually retains heat in the home.

It is glued along the entire perimeter of the door, and if it has a double door, then on each of them. A seal that is too thick can create problems with closing the lock (see Installing locks on a metal door: easier than you thought), and a seal that is too thin will not solve the problem of insulation and sound insulation, and will let odors into the apartment, since the door will not fit tightly to the jamb.

Moscow service areas:

Company

| VAO

| SAO

|

NEAD

| SZAO

| Central Administrative District

|

Southern Administrative District

| SEAD

| South-Western Administrative District

|

SHOW MORE

Classification: main types

Seals are produced by many manufacturers and differ in the following parameters:

- Material type. It can be rubber, silicone, polyethylene foam, plastic, foam rubber.

- Construction . The material in question can be made entirely of one material or be equipped with a metal clamping strip.

- Fastening system . The seals are self-adhesive (an adhesive substance is applied to one side, protected by paper tape) or attached to self-tapping screws. But the latter can only be installed on wooden doors.

For reference. You can make a seal yourself by wrapping a strip of foam rubber in leatherette or artificial leather. Another option for eliminating door gaps is to insulate the entire structure (see How to insulate a metal entrance door) and install an overlap around the perimeter of the door leaf.

As a rule, the seal is sold in the form of a roll, the length of the tape is about 6 meters - this is just enough for installation on a standard door. In the package you will find installation instructions and fasteners, if needed. But for a metal door, self-adhesive seals are mainly used.

Service areas in the Moscow region:

|

|

SHOW MORE

Seal for metal doors: how to glue the rubber seal

Although metal entrance doors are cast in special molds, their surfaces are not ideal, especially when it comes to the edges of the door leaf. You can observe a poor fit to the box, slight distortions on different sides, and all this can lead to the penetration of cold air, unnecessary noise and even unpleasant odors.

To rid a metal door of these shortcomings, it needs to be pressed tightly against the jamb, and in this case a special seal will be the best assistant for a homeowner.

Classification of sealants by texture: liquid foam rubber, flexible and pile tapes

Based on texture, flexible, liquid and pile types of products are distinguished. Each type of seal is used for specific purposes. Flexible tapes have the form of profiles with a smooth surface. Silicone and rubber are used for their production. This category also includes magnetic gaskets for door structures.

Foam rubber is the most popular material for gluing doors and windows.

Liquid options are used to insulate the fabric. The material is under pressure inside the cylinder. This version of the seal resembles the liquid equivalent of foam rubber. Pile products were among the first to appear on the market. Felt is mainly used for their production. Pile sealants are available in the form of tapes and strands. There are artificial analogues of this material made from synthetics on sale.

Features of using liquid door sealant

Liquid seals are designed to insulate metal entrance doors. The non-standard form of release requires careful handling of the material, as well as compliance with certain rules when applying it. Foam rubber in liquid form is located inside a metal container. The composition is applied to the required area of the structure by spraying. The insulation on the door hardens in a matter of seconds. Therefore, you need to act not only carefully, but also quickly. After hardening, the material significantly increases the thermal insulation qualities of the door structure.

A distinctive feature of the liquid sealant is its dislike for areas with high humidity levels. It is not recommended to use the material where there is constant dampness. Proper spraying of foam rubber requires some knowledge and good dexterity. It is advisable to practice before doing this or entrust this work to professionals, otherwise you can ruin the appearance of the door structure.

Note! Insulation materials in liquid form do not contain harmful substances. This material is not hazardous to the environment or human health, so there are no special restrictions on its use.

Sprayable liquid insulation can be used to seal doors

Characteristics of pile seals for doors

Pile sealants include felt products. You can also find synthetic analogues of this material on the market. Since felt is made from natural animal hair, it provides excellent sound and thermal insulation. Analogs of artificial origin are much inferior to it in these indicators. There are several types of felt. Taking this nuance into account, products are marked in a certain way. All types are suitable for sealing door structures. To properly install the product, you need to correctly cut the material taking into account the size of the canvas.

Advantages of natural felt:

- wear resistance;

- long service life;

- ability to withstand operation in harsh weather conditions;

- environmental cleanliness and safety;

- large margin of safety, the material retains its structure;

- high density, ideal sound absorption;

- fire safety.

In the category of artificial analogues, thin-thick pile strips, which are fixed to the surface using an adhesive base, are in particular demand among buyers. These products prevent dust from entering the living space. Artificial materials are used extremely rarely as a sealant on entrance doors. They are more suitable for compartment-type cabinets.

Pile compactors of various sizes

Why do you need to seal a door?

- From the penetration of excessively cold or hot air flows;

- From the occurrence of a draft effect - a dangerous phenomenon that causes illnesses in households;

- For a better fit of the canvas to the frame of the doorway. This is a kind of lock that protects the locks from play, and if the door is constantly in what is called free flight, then ultimately the key will not be able to get into the keyhole.

What basic requirements must a high-quality seal for an iron door meet?

- Possess exceptional sealing properties;

- Ensure the smoothness of the chassis - good to help open and close;

- Provide breathability and be a good door shock absorber;

- Withstand sudden changes in temperature;

- Be elastic and pliable - do not harden or soften under any influence.

The video shows a seal for a metal entrance door:

Which ones are used for a metal entrance door?

There are several types of seals on the construction accessories market, differing in the following indicators:

- Type of material of manufacture . The most common are products made of rubber fabric, silicone base, plastic, foam rubber bands or products made of polyethylene foam material;

- According to the method of fastening . This group includes self-adhesive sheets, magnetic or pressing, with special glue applied to one side, or installed on additional fasteners.

Installation of filler

In order to forget about the sounds behind the door, you can replace the old filler with a more current one, which is only possible with a collapsible door. Let's talk about the order of work:

- Remove the door from its hinges. We place it so that the outer part of the door is at the bottom, and the inner part is at the top (where the work is to be done).

- We remove the fittings.

- We dismantle the inner door leaf.

- We remove the filler that is currently present in the structure.

- We install the current filler. If you need to place the material on glue, degrease the surface and apply the adhesive in thin strips.

- As a result, the filler will have joints, which we foam or fill with mineral wool.

- We return the sheet removed from the door to its place.

- We install the fittings.

- We hang the door.

The most popular types

- Made from rubber base. Moreover, you can find specimens with a variety of profiles, and each can be used based on the parameters of the metal door frame; sometimes the doors themselves are equipped with a groove of a certain cross-section, and in this case you should select a similar rubber seal profile. The cost is low, the technical characteristics are excellent, the material is durable and strong.

Silicone base variations . These types of seals belong to the environmentally friendly class, do not emit any allergens into the atmosphere, and are therefore recommended for installation in all children's institutions.

- Polyurethane, foam rubber or plastic products with an adhesive layer on one side. They themselves are cheap, so they have a limited service life.

- Magnetic seals appeared relatively recently, but are gradually becoming more popular every day because they are easy to use . But if there are too many magnets on the door, it will be difficult for the child to open the door - the degree of contact is too strong. They showed the best performance on doors without decorative pressure or powder coating. They are usually made of an elastic base and a magnetic insert.

Information from the article will help you understand how to use foam insulation for doors for maximum results.

But this article will help you understand what self-adhesive foam insulation for windows looks like.

Which seal is most suitable for a wooden entrance door? can be found in this article: https://resforbuild.ru/paneli/utepliteli/uplotnitel-dlya-derevyannyx-dverej.html

You may also be interested in learning about what self-adhesive door insulation is.

Which one is suitable for a Chinese metal door?

If you have a Chinese front door installed, then at first it will function well, but over time you may notice some dents around the entire perimeter, and cold air from the outside begins to leak through them. This can happen because the metal itself is of low quality, it does not have the properties of real steel - strength and durability from any physical impact, and the door frame wrinkles from frequent slamming.

To correct the situation - rather than buy a new iron door design, first carefully inspect it and measure the perimeter of the door leaf. According to experts, the best insulation would be a rubber model, even with a profile. If you don’t find the material you need, you can try purchasing a soft but thin self-adhesive foam tape; it will perfectly flow around the entire perimeter of the canvas. But for reliability, apply an additional layer of glue to the contours; you can use the same silicone construction glue, which is intended for such work.

Video of replacing a seal on a metal entrance door:

What to look for when purchasing?

When choosing a seal for steel doors, you need to carefully inspect it and check its quality.

In particular, you should perform the following actions:

- Read the label on the product, which indicates the expiration date, all the necessary information about the seal and the material used for its manufacture.

- By pressing it is worth checking the elasticity and tightness characteristics. The material should be medium hard, then it will not interfere with the door closing well. When pressed, it should quickly restore its original shape. This is a sign of high quality material.

- If the seal is on self-adhesive tape, then you need to find out the expiration date of the glue. Otherwise it could just dry out. Also, small particles of fiberglass should be applied to the adhesive part.

Most often you can find such products on sale from Germany, Sweden, Poland or Turkey. A good product should not harden when the temperature drops, or peel off when it fluctuates; release toxic compounds into the air.

Application (how to glue)

The insulating material itself should be installed on the metal door frame, but not as tightly as possible. This will ensure the best fit, which will affect the thermal insulation and noise protection properties. Moreover, the position of the installed door does not matter; in any case, it is possible to glue the insulation along the perimeter of the door jamb.

If you have a rubber or foam version, adhesives like Moment are suitable, and other types also adhere well to it.

Before starting work, you need to properly degrease the base for the glue; this can be any solvent or alcohol-based product.

Here's a video showing how to glue a rubber seal to a metal door:

First, apply a thin layer, spread it a little with a spatula and leave to dry for about 10 minutes. Then do the same with a strip of insulation, degrease and apply a thin adhesive layer, and leave for the same time. As soon as the layer dries a little, you can install a strip around the entire perimeter and press it firmly. Wait about 15 minutes for the result, and you can close the door with the key.

But what is the price of liquid insulation in Polinor cylinders, you can find out from this article.

What is the best insulation for an attic roof and how it should be used is described in this article.

It may also be interesting to learn more about which insulation is best for the roof of a house.

This information will help you understand which ceiling insulation for a cold attic is the best.

But what kind of insulation for the ceiling inside the house should be used and how to choose it correctly, this article will help you understand.

Reviews

Peter

: After installing wooden euro-windows, we discovered that the rubber was partially missing from the double-glazed windows. The installer company had already closed, so we had to find it ourselves. We searched for almost three months - everywhere it was sold only in rolls of 400 m. And only in PermOknaService they offered us the right solution. The master came and installed everything himself. The rubber seal was exactly the one we had on the other structures. Even with the cost of the work, it turned out cheaper than if we had ordered a bay.

Marianne

: I ordered repairs to the seal on plastic windows in a cottage. We were offered three options - the dispatcher immediately honestly warned us about one option that it was not very good. We chose an average-cost chamber seal for 90 rubles/m. The total cost of replacing the seal was 720 rubles.

Kalashnikova Vera Petrovna

: The balcony door was blowing, the cracks were just terrible. We tightened the pressure, changed the clamps and tires - nothing helped. Then we were advised to use the Schlegel seal. We bought it. I installed it myself and I want to note that it is really very easy to install. Thick, dense - closed the cracks. I will definitely recommend Schlegel to friends and acquaintances with such problems.

Volkov Anton Antonovich

: The purpose of our contact to PermOknaService was to replace the seal on double-glazed windows. The price seemed quite reasonable to us. However, the master said that the rubber seal on the windows was still quite good and suggested that we limit ourselves to adjustments. This way we saved 400 rubles

Peter

: We were looking for a specialist who could replace the rubber cord on the balcony door. PermOknaService immediately told us how much the window seal costs. The price seemed reasonable. We ordered and did not regret it. The sealing rubber holds on the frame and sash firmly, without waves.

Manufacturers and prices

A linear meter of profiled thermoplastic sealant brand Deventer (Germany), costing 200 rubles, is a long-lasting and durable material;

Self-adhesive tape seal brand Victor V702, Moscow, elastic and durable material, with good thermal insulation properties. The cost of a bay of 3 linear meters is 330 rubles.

Profile form

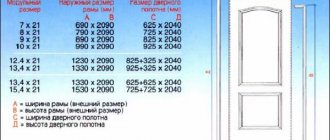

The tape is the main structure of all profiles, but it is given different shapes in production. A void may form inside the tape, improving the thermal insulation qualities of the material. For simplicity, the manufacturer marks tapes of different shapes with letters of the Latin alphabet, which are similar to the profile shape: P, V, E, D, O, K, C.

To accurately select a seal, measure the gaps between the canvas and the opening they will close. This is an important condition for choosing the shape of the tape:

- for minimum gaps of 1-3 mm - polyurethane foam and foam rubber seal,

- 3 mm gaps are perfectly closed by tape with a profile in the form of the letters C, E and K,

- gaps of 3-5 mm are laid with material shaped like the letters P or V,

- for particularly large gaps greater than 5 mm, it is recommended to buy a seal marked O or D.