When designing balconies, verandas and outdoor terraces, people often ask the architect to “make the railings disappear.” This is a difficult task. Fencing is an important design element with competing priorities. For example, they should be low enough so as not to obscure the view of a person sitting.

It is necessary that the vertical bars of the fence be spaced so far apart that a child cannot squeeze between them or get stuck. Children should not be allowed to climb onto the railing easily and comfortably. Finally, the fence must be securely fastened so that you can lean against it without the risk of breaking it.

Technical requirements for balcony railings

GOST 25772-83 divides balcony railings depending on the height of buildings into two groups: in houses up to 30 meters high (BP) and more than 30 meters high (BV).

A separate category includes stairs and balcony railings for preschool institutions (PD). According to the design of the frame, depending on the degree of its filling, the fencing of stairs and balconies is divided into lattice (R) and screen (E), consisting of slabs of various materials. A separate group includes combined modifications (K), which have elements of gratings and slabs in their design. According to GOST 25772-83, balcony railings and stairs are marked indicating the type, main dimensions (length and height), type of filling, and this GOST is given at the end.

Rice. 2 Metal fencing for balconies made of nickel-plated and chrome-plated pipes

This standard imposes the following requirements for balcony railings:

- Balcony railings for low-rise buildings (up to 30 m) should have a height from the floor of 1 m and a slab height of 0.9 m; for buildings with a height of more than 30 m, the height of the railings and their size should be 1.1 m and 1 m, respectively .

- The use of lattice balcony railings in the construction of new houses is currently prohibited, only screens are permitted. Screen structures must have fasteners that allow the plate to be securely fixed and easily replaced.

- Elements of metal frames of balcony parapets must be joined together only by welding.

- Frames and fencing elements must be made of corrosion-resistant materials or protected from moisture using standard methods.

- The distance between the balcony railing bars should not exceed 110 mm.

- The railings must withstand pressure (concentrated loads) of more than 100 kgf. (100 kilograms per linear meter).

- The presence of mechanical defects in the form of curvature, burrs on the parapets is not allowed; if metal fences are used, there should be no sharp parts in their design, scale or rust on the metal surface.

Rice. 3 Plastic balcony railings

Rules

It is enough to know the safety standards regarding protective fences and comply with them when designing certain architectural elements. Generally accepted standards require that any areas located at a height of more than 75 centimeters from the ground or other surface be equipped with fencing.

Fences differ from conventional railings in two aspects: they are higher and are necessarily equipped with vertical intermediate elements. There are also certain requirements for the maximum concentrated load on the fences, limiting it to 90 kilograms.

Requirements for fencing

Surprisingly, the first mention of the need to make fences can be found in the Bible. In Eastern countries it was customary to eat and spend time with guests on the roof

And so it was necessary to surround it with a fence so that one of the guests would not fall off it as a result of carelessness. The main regulations describing modern requirements are based on the same principle

It should be safe to be on the balcony. In this regard, the following rules have emerged:

- Height of the balcony railing. According to GOST, the minimum height in a standard multi-storey building with a height of up to 30 m is about 1 m. This situation is considered a little more strictly in SNiP. According to these instructions, the same coefficient should be equal to 1 m. 20 cm.

- Load. Railings that are installed as fences must withstand a stress of 30 kgf/m.

- Jumpers. It is allowed to use only vertical jumpers, and the distance between them must be at least 12 cm.

According to the law, violation of these requirements allows the owners of the apartment to be fined and obligated to remodel the balcony at their expense. In the most serious cases, the court may decide to deprive the property rights with the sale of the home and compensate for legal costs from the amount received. The owner will only have a small part of this amount left.

Rules for installing a fencing system

According to the law, the balcony and the entire surrounding area are under the jurisdiction of the owner of the property right, and therefore housing and communal services can order apartment owners to eliminate shortcomings associated with the operation of balconies. According to the technical passport of the building, housing and communal services have the right to check the technical condition of balconies, and, therefore, issue instructions to the property owner, which states the following:

1. Checking the status of mortgages. If they have become unusable, you need to remove the old balcony covering and make a screed and install new metal strips 10-18 cm high.

2. The existing finished balcony fencing is welded to the embedded parts using a welding machine. But, if the main fence still has a strong foundation, then the main metal structure is reinforced under the metal-plastic components, using additional railing elements or restoring the existing old elements of the fencing system.

3. The use of brickwork as a fence is strictly prohibited if this is not provided for by the basic design of the building. As a rule, a brick fence can only serve as a decorative element, and even then not always. The reason for the ban is the load, which should be no more than 100 kg per m2, and for bricks this requirement exceeds several times, which creates a precedent for the danger of using a balcony in general. Use only light and durable metal structures as fencing elements.

It is recommended to seek help from specialists who will help you correctly calculate all elements of the fencing system that will be used for your balcony. Welding work can be carried out independently if you know the basics of using a welding machine when carrying out critical work. In any case, you will have to interact with supervisory authorities and departments so that they finally approve the design of a new balcony and allow the reconstruction of existing elements of the fencing system in an apartment or office center.

If you have any questions and you don’t know where to start making a balcony fencing, contact our company for help, and we will help you correctly calculate the units and components for the fencing system, as well as perform high-quality repairs and redesign of your balcony in accordance with the requirements of GOST and SNiP.

The nature of the finishing of the fences

Based on the nature of the decoration, you can make the balcony and the wall of the house merge with each other, placing emphasis on the integrity of all components of the building and the laconicism of the decorative techniques used.

You can choose another option - decorative finishing of the balcony, decorating the entire facade of the house. By using various landscaping ideas to decorate your balcony, your balcony can become more elegant and look more comfortable.

Landscaping the loggia using:

- Horizontal flower beds that are mounted at different levels of fences;

- Brackets with flowerpots;

- Pendant with vines;

- Lattice twined with grapes.

Very often, the unique appearance of a building, its solidity, success, and completeness are due to the original balcony railings.

Materials for making fences

There is a wide variety of ready-made solutions for making balcony railings. Recently, more and more owners are opting for combined types of structures, in which metal serves only as a basis for other materials: tempered glass, stainless steel, aluminum, etc. Let’s look at the most common options:

- Aluminum. The advantage of this material is its resistance to precipitation. It is also neutral to acid and other aggressive substances. It also has certain disadvantages. One of them is that under the influence of sunlight and weather conditions, it loses its shine over time. When installing this fence, you have to resort to installing and securing special pins. Conventional welding will not help in this case. The most common use of this metal is as guide profiles for installing special impact-resistant glass.

- Steel. Stainless steel will last much longer than aluminum. At the same time, the appearance of such metal is much better, and if it darkens, you can restore its shine with the help of regular grinding. You can perform this operation yourself using an angle grinder.

- Iron. This material is most often used for making metal balcony railings with your own hands. And there are several reasons for this. The first is that installing such a fence, provided you know how to work with a welding machine, is quite easy. Second, railings can be made in almost any price category. Some people can afford to install a forged product, while others can afford to buy suitable material at one of the metal reception centers or a hardware store. It's quite easy to work with.

Carefully! When working with aluminum and stainless steel, you must remember that GOSTs prohibit the use of horizontal jumpers in the fence. Violation of this rule can significantly affect the safety of being on the balcony

Exterior works

Option 1. Finishing with siding

They decorate the outside of the balconies with their own hands either with siding or corrugated sheets. There is also a completely economical option, using PVC lining, but, as practice has shown, it “lives” until the first hail or heavy wind. Those. in at least three years everything will have to be redone.

But siding and corrugated sheets have sufficient strength for effective use. This section will describe all the options, and I’ll start with siding technology:

- Siding in 90% of cases is attached in a horizontal position. In principle, it can be installed on a perfectly flat slab, but it is better to make a frame from a wooden beam.

- For the frame, I take a beam with a cross-section of 40x40 mm and impregnate it with an antiseptic. Then I cut the parts to size and begin attaching them to the fence.

Frame for siding

- First, I attach two vertical fragments close to the walls, and then install the sheathing fragments in increments of no more than 60 cm - this way the sheathing will not “play.” At the corners I place two beams end to end: they will experience the heaviest load.

- I attach horizontal bars at the top and bottom: I install the bottom one on anchors, which I screw into holes drilled in the end of the balcony base. The top one can be laid on the railing - in this case it will act as a support for subsequent glazing.

All beams must be level. This can be done using mounting wedges, which are driven into the gap between the beam and the base. Due to this, we can visually level even the most crooked balcony with cladding.

- I begin the installation of siding by installing corner strips: I secure the internal corners along the walls, and the external ones at the junction of the planes. I set the corner strips exactly vertically, since the geometry of the entire structure directly depends on this.

Correct fixation of siding

- I attach the starting strip to the bottom beam of the sheathing, aligning it horizontally.

- I place the siding panel cut to size into the corner strips. I snap the lower edge onto the starting bar, then I level the part and fix it with self-tapping screws, screwing them into the technological holes.

- I place the self-tapping screw for fastening the siding in the middle part of the groove and tighten it in such a way that there is a gap of about 0.5 - 1 mm between the panel and the head. This will ensure that the siding freely deforms with temperature changes and prevents cracking and swelling.

Result of work

- I install the following panels using the same principle. The last panel sometimes needs to be sawn lengthwise so that its upper edge is level with the top beam of the sheathing. In this case, the attachment point can be masked with a drainage strip or finishing profile for siding.

Important note: to perform most operations it is necessary to use a suspension system, since it is almost impossible to secure the frame and install siding while inside the balcony.

The best solution here would be to contact specialists who have permission to work at heights. But if you decide to do everything yourself, at least get high-quality insurance!

Option 2. Finishing with corrugated board

External cladding using corrugated sheets - a profiled metal sheet with an anti-corrosion coating - is done slightly differently. The large size of the cladding parts somewhat reduces the labor intensity of the process, and the material is not so expensive. Therefore, for a beginner who is just trying his hand at finishing, corrugated sheeting is the most suitable option:

- The sheathing for the sheathing is two or three belts of wooden beams impregnated with an antiseptic. The lower beam is fixed no more than 50 cm from the lower edge of the balcony railing, the upper beam - at the level of the railing or slightly lower.

Option with corrugated sheets on a wooden frame

- We fix the beams to the parapet either with metal screws or anchors. If the fastening is carried out on a metal frame, then you can also use bolts, which are inserted into pre-drilled holes and secured from the inside with nuts and wide washers.

- Sheathing the balcony with corrugated sheeting is done in such a way that the stiffening ribs are vertical - this will ensure unhindered water flow.

Installation of profiled sheets

- Sheets of material are fixed with special self-tapping screws with thermal washers. Also, self-tapping screws are used to fasten the sheathing elements together at the overlap point.

- After installing the main part, additional elements are installed: external and internal corner trims, canopies, ebbs, etc.

Correct and incorrect fastening of self-tapping screws in metal

State regulations requirements

If there is a need or desire to replace balcony railings in connection with repairs, reconstruction or redevelopment, then be sure to first familiarize yourself with the legislative side of this issue. The design and installation of balcony fencing must be carried out strictly in accordance with the requirements of SNiP regulatory documents.

The GOST set of rules regulates the following basic provisions:

- The total height of the fence on the balcony of high-rise buildings, the height of which is up to 30 meters, must correspond to 1 meter;

- In apartment buildings with a height of more than 30 meters - 1.2 meters;

- The immediate height of the railing on the balcony is at least 0.9 meters;

- On an open balcony, the distance between the base and the lower horizontal rod of the sheathing should not exceed 100 mm;

- The distance between balusters (vertical lintels) should not exceed 0.12 meters;

- It is prohibited to install wooden balcony fencing in high-rise buildings;

- The railings must withstand a load of 30 kg/m.

It must be remembered that failure to comply with the rules leads not only to a risk to the health and life of the people living in the apartment, but also to the likelihood of being subject to penalties if checked by the relevant organizations. The prospect of remaking or updating the entire structure looks even sadder.

A safe, beautiful and cozy balcony will be a great place to relax!

Combined designs

Granite railings

Metal grilles on the balcony look great in combination with other materials. True, it is quite difficult to carry out such work, so not every master will undertake it, and the cost of the combined fencing is higher than usual. Combined designs are presented with small curbs made of stone or other material and steel sections.

To make stone railings, there is one condition: the floor must be able to withstand heavy loads. Therefore, this option is not available for standard apartment buildings. Granite, brick, and sibit can be used as materials for stone fencing.

Sometimes balcony owners prefer to combine metal and glass in their fences. Such designs are very airy and look simply excellent. There is no need to worry about the fragility of the structure, because it uses only heavy-duty glass - tempered or triplex. The main condition is that the material be able to absorb heat; such glass will withstand incandescence up to 200 degrees.

Basic parameters of balcony railings

If aesthetic appearance is a priority for you when decorating the facade of a house, then in any case you will have to take into account the parameters of the balcony railings. One of the important indicators is height. According to the rules, the top edge of the railing should not be lower than the middle of the person’s body. But this is a relative indicator, since people are different. Therefore, it is often believed that it is somewhere around 0.9-1.1 meters. It depends on the distance between the balcony slabs - the larger it is, the higher the fence.

If we turn to the standards in this area, for example, GOST, then the height is 1 meter, and SNiP provides for 1 meter 20 centimeters. In any case, if there are children in your house, then the height can be made larger.

Another parameter that is worth paying attention to for those who will make a fence from individual elements is the size of the gaps. According to the rules, they should not exceed 10-12 cm

This is primarily for the safety of children.

Limits have also been established for the horizontal loads that the railings must withstand, namely:

- 30 kgf/m – for hospitals and preschool institutions;

- 150 kgf/m – for gyms;

- 80 kgf/m – for residential buildings.

Rice. 15. Fence height parameters.

Balcony cladding materials

For both interior and exterior decoration, we need to purchase a considerable amount of raw materials. Naturally, it is very important to plan your budget in advance in order to understand what price category we can target.

Decorative corrugated sheeting used for exterior cladding is more expensive than plain sheet metal

I will give examples of the cost of various products in this table:

| Material | Unit | Average cost, rubles |

| Wooden beam (pine), 50x50x6000 mm | PC. | 90 – 180 |

| Metal profile for frame, 3 m | PC. | 50 — 120 |

| Wood-like decorative corrugated sheeting | m. linear | 700 – 740 |

| Plain corrugated sheeting with plastic coating | m. linear | 250 — 450 |

| Self-tapping screw for colored corrugated sheets | PC. | 5 — 8 |

| Siding Grand Line | PC. | 110 — 180 |

| Starting bar 3m | PC. | 100 – 350 |

| Corner (external or internal) 3m | PC. | 220 — 450 |

| Insulation 100 mm | pack 4 pcs. | 1400 -1700 |

| Insulation 50 mm | pack 4 pcs. | 650 — 800 |

| Vapor barrier film | roll 25 m | 670 — 750 |

| Polyethylene foam foil | roll 15 m | 1100 — 1300 |

| Foil vapor barrier | roll 25 m | 700 — 900 |

| Antiseptic impregnation for wood | 10 l | 800 -1200 |

| Lining for wall cladding (pine) | 1 linear m | 100 -150 |

| Lining for wall cladding (alder) | 1 linear m | 180 — 250 |

| Clamp for MDF | 100 pieces. | 50 – 80 |

| Liquid Nails | 100 ml | 60 — 120 |

| MDF panels Kronostar | pack 6 pcs. / 3.9 m2 | 950 – 1100 |

| MDF panels EвpoStar | pack 6 pcs. / 3.9 m2 | 1200 — 1500 |

| PVC wall panels | PC. | 120 — 250 |

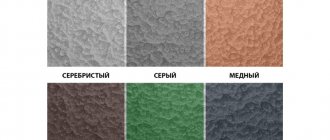

Palette of MDF panels "Kronostar"

In addition, you should find out the volume of purchases, which, by the way, is determined not only by the area being finished. Many materials are supplied in the form of panels of a strictly defined length (for example, MDF panels - 2.8 or 3.66 m), and therefore, before calculating the amount of material for cladding, you need to find out all the dimensions of the areas to be finished. This way we can select the number of panels that will allow us to complete the cladding with a minimum amount of joints and waste.

Materials for balcony railings: advantages and disadvantages

Balcony railings can be made of stainless steel - this is a practical and attractive material from which both sophisticated and simple solutions are obtained. Among the possible options for stainless steel fencing are those with clear or curved lines, hollow, solid or blown with a round cross-section. The main advantage of such railings is that they will be strong and incredibly durable. For their installation, argon arc welding is used.

Their analogue can be aluminum, which has less weight.

Stainless steel balcony railings

By the way, stainless steel balcony railings are perfectly combined with other materials - modular blocks, glass or metal sheets. The result is a stylish and modern solution with an airy effect - it can be combined with any type of façade design. Among the advantages of stainless steel are its absolute ease of maintenance and immunity to moisture and other weather conditions. In addition, these handrails can be left “as is”, without painting, or they can be additionally painted, which will increase the attractiveness of the structure.

Railings made of brick, stone or concrete are massive and durable. However, balcony railings of this type are not very simple to implement, but they guarantee high stability of the entire structure. However, when choosing such materials for handrails, you need to carefully calculate the maximum weight that the ceiling can withstand. Also, a stone fence requires a lot of space - but the result will be spectacular and large-scale. To create such fundamental façade decorations, natural (granite or marble) as well as artificial stone can be used. To produce artificial stone, mixtures based on sand, granite chips, and high-quality cement are used.

Concrete balusters on the balcony as a fence

You can use various design tips to determine how to make your own railings - they can be made according to standard or individual sketches, in different sizes and shapes

It is also important that all installed elements comply with safety standards and match the style of the facade design

Balcony railings can be made of cast iron or metal (steel). Metal handrails will be susceptible to corrosion, and therefore they must be coated with a special compound that will fight rust.

Old cast iron balcony railing

Metal fences are often forged - they can take on the most imaginative shapes and are quite easy to install. In addition, these handrails can be easily selected according to the size of the balcony and installed without taking up space. As for cast iron fences, they are considered more durable, although they have more weight.

Forged metal railings for the balcony

Plastic or glass also makes excellent fencing.

The result is a creative and modern design that looks incredibly impressive. Fences of this type can be all-glass or using metal elements - then glass blocks and stainless steel handrails are placed one after another. The result is an outwardly fragile, but quite reliable structure. Plastic handrails are also popular due to their low price and light weight. However, they also need to be attached to a reinforced metal frame.

Glass fencing with stainless steel frame

Wood is considered the most unsuitable material from the point of view of safety and practicality - although it looks natural and aesthetically pleasing, it can rot due to high humidity. Wood is completely unsuitable for balconies in apartment buildings and wooden balcony railings can only be used as decor on a metal base. But for the terrace of a private house made of wood, such a solution would be quite justified, however, in this case, an appropriate protective coating for wooden railings will be required.

Beautiful wooden railings in a country house

If you do not want to use standard solutions in the form of metal rods, then they can be supplemented with other materials - in this case, you get mixed-type railings. They can represent only a decorative solution or be an element in preparation for glazing.

Content

- Balcony fencing - what are the requirements for it?

- Glass as an ideal material for balcony railings

- Glass stair railings

- Relative price of glass staircase

- Fastening glass inserts

- Fashion and design issues

Balcony fencing - what are the requirements for it?

Usually, news is widely circulated in the media when someone falls from a balcony... Therefore, without going into reasoning, it should be noted that the most important function of a balcony railing is to reliably ensure the safety of all people using it.

The railings must withstand:

- the weight of the child leaning on them;

- an adult leaning on them;

- random impacts (including strong ones).

In addition, fences must be decorative and attractive, have an unusual, innovative design, otherwise why deviate from the traditional architectural concept at all?

Balconies in apartment buildings have a reinforced concrete base that can withstand a load of at least 1125 kg/m2. Balconies built in private houses (and cottages) are, as a rule, significantly less durable. In this regard, another requirement for a balcony railing is the specific lightness of the structure, so that the railings do not weigh excessively and do not create a dangerous load on the balcony itself.

Glass as an ideal material for balcony railings

In light of the technical requirements listed above for the design of a balcony railing, the ideal embodiment of such railings is a glass-metal structure.

Such railings have a steel frame made of profiled stainless steel. And sheets of glass inserts are placed between the fence posts. However, there are options here:

- Firstly, the frame can also be created from carbon, anodized steel.

However, this option is not acceptable for balcony railings. Zinc or chrome coating tends to “peel off” as a result of prolonged exposure to temperature changes and precipitation. As a result, the frame of anodized railings is capable of receiving pinpoint damage to the coating within a season, which will become sites for the development of corrosion. As a result, rusty stains will appear on the railings and this situation cannot be corrected in any way (only replace the black metal parts with stainless steel).

Stainless steel fences, the price of which is undoubtedly higher, will ultimately cost less if you take into account their unlimited service life and the absence of the need for any maintenance.

- Secondly, the types of glass itself:

Regular glass (no more than 4 mm thick)

This type of glass is completely unsuitable for forming balcony railings with its participation. An accidental kick on such a fence can turn the railing into fragments, and this in itself is dangerous. In addition, if we assume that a small child will also be present on the balcony, this will also endanger his life. Summary: Glass objects made from ordinary glass should not be placed at floor level.

How to install a fence on a balcony yourself

If you have the necessary knowledge, tools and materials, it is quite possible to arrange a balcony on your own.

To do this you will need metal:

- Profile or round pipes with a diameter of up to 18 mm and a length of 1000 mm;

- Channel;

- Fittings;

- Guide profiles (horizontal and vertical);

- Anchor bolts;

- Corner.

Before starting work, you should decide on the dimensions of the future structure and make a preliminary sketch. Then, using a special computer program or on your own, design an exact drawing of the fence on paper.

Next, we stock up on tools:

- Drill (perforator);

- Hammer;

- Welding machine;

- Measuring level;

- Bulgarian.

The plan for subsequent work looks like this:

- We find the places of mortgages (seats) at the base of the balcony;

- We make a fence by welding, the length of which must correspond to the length of the balcony;

- We install the lower and upper beams, weld the fence to them;

- Using reinforcement, we weld the embedded beams;

- We attach meter-long guides to the wall using anchor bolts;

- We weld the side profile pipes and the upper horizontal level;

- We paint the frame and make its cladding.

For the safety of work, all flammable objects are removed from the balcony. Do not carry out work in the open space of the balcony during rain. Each profile fastening must be carefully checked.

Installation of forged railings using screws

The installation technology is very simple:

- first, holes are drilled into which the starting supports will be inserted;

- special glue is poured;

- the starting support is installed;

- a hole is prepared for mounting the finishing support, glue is poured again;

- the finishing support is installed;

- the free space between the main supports is marked;

- holes are drilled for mounting intermediate supports. They are being installed;

- power parts are being prepared. Using an angle grinder, the required length is cut;

- holes are drilled for the mounting bolts;

- all power elements are fastened;

- the free space between the power parts and the racks is covered with a special filler;

- the structure is fastened with fastening bolts and nuts;

- To create a more beautiful appearance, you can cover the drilling areas with soil, as well as filing to achieve the desired size.

Many owners of private houses do most of the work with their own hands. They mainly use a welding machine. Of course, having experience working with metal and knowing the basics of welding, they can easily make such forged jewelry. There is only one thing I can advise them. Before starting work, prepare in advance the required number of electrodes, bent steel angles and profile pipes.

Lathing for roofing and railings

Useful video on the topic

DIY installation of half-timbered fencing:

The process of making forged products:

Pro tips for choosing forged fencing:

It is not always permissible to experiment with the railings of high-rise buildings, but no one can prohibit creating a beautiful design for a summer house or country cottage. A little skill, imagination, creative inspiration - and your balcony will be decorated with fences made of wood or metal.

YOU MAY ALSO BE INTERESTED

How to make your own balcony railing

If you want to install a balcony railing yourself, then be sure to consult with a designer. Also, sketches of various designs of handrails can be easily found on the Internet for any different design of a balcony or loggia.

Norms and restrictions

If you have chosen a cast-iron structure or a metal other than stainless steel, then after installing it, be sure to apply a special mixture that protects the material from corrosion, and then paint it.

Balcony railings are quite important elements. Despite their aesthetics, they must comply with modern SNiP requirements, which are fundamentally aimed at the strength and reliability requirements of such a structure.

SNiP also determined the permissible height of the railings on the balcony, which must correspond to the general proportions of the structure.

The first determining factor is the average height of a person. According to SNiP requirements, the height of the balcony railing must be at least level with the midpoint of a person’s abdomen. Therefore, these figures fluctuate between 90-110 centimeters.

But today it is recommended to set the height a little more than this indicator, on average 100-120 centimeters

Also, special attention should be paid to decorative elements, which should be installed to the maximum height, for greater practicality and safety.

Large holes and openings in the structure are not allowed, as well as the presence of sharp corners and other decorative elements, in order to protect the safety of children on the balcony. Smooth parts and small holes are the key to your safety.

If the structure of the balcony railing is not solid, but consists of two or more elements, there should be a distance between them not exceeding the standards established by SNiP. In accordance with such standards, the gap can be no more than 12 centimeters.

Oddly enough, an excellent example of correct structures are balcony railings installed on old houses (Khrushchev-era buildings). In pursuit of fashion or comfort, owners forget that, first of all, these structures serve to protect people on the loggia or balcony.

Although this work is quite labor-intensive, you can do it yourself, the main thing is to remember all the standards and not skimp on reliable materials.

Installation process

In the case of using stainless metal, such work will seem like assembling a construction set. You should buy the following materials: channels, corners, rods and metal pipes.

In order to make high-quality and reliable handrails, it is recommended to use a round pipe or profile, but for the grille you need to take metal rods with a diameter of 10-16 millimeters.

Next, you need to perform the work in a certain sequence. First the base is welded. To do this, you need to take metal corners and weld them to the base of the balcony along the perimeter.

After this, the frame itself is welded from the profile. The frame is attached to the wall using self-tapping screws. Next, the fence is welded to the finished frame.

To make installation more convenient and quick, it is recommended to weld the structure to the frame already assembled. If you first draw up a sketch of the finished structure, the work done will be most effective and quick.

On the fence, as mentioned above, you can install wooden or metal handrails made of stainless steel. The metal structure can be left unchanged, but the wooden elements must be treated with a protective mixture and painted as you like.

What types of fences are there for balconies?

Metal

— are in particular demand among consumers due to their high strength;

— pronounced possibilities of combinations of metal and other materials;

- affordable and wide range of prices.

Stainless steel

— With polished stainless steel in fences, we can talk about their strength and durability.

— They are not pretentious and do not require special care, and in case of contamination they can be easily cleaned with a damp cloth.

— They do not require additional protective coating. The original steel shine does not disappear or wear off over time.

— Immunity to precipitation and high humidity.

— The appearance is always spectacular, stylish, modern, while the fences give the impression of air, light, weightless.

— Any form of fencing is possible.

— Steel goes well with any materials.

Forged railings

Of course, the best option for cottage-type houses and country mansions, especially if everything is done in the same style: fences, stair railings, balconies and other elements of buildings.

Forged fences are considered elite, unsurpassed, luxurious, giving the building uniqueness and success.

Reliability of balcony railings

When designing such a balcony, it is important to take into account the requirements for ensuring the reliability of the fences. It is important to use only those structures in which welding was used. Ancient terraces and balconies of wealthy citizens of those times are decorated with similar delights

This was not just a fashion statement. It was customary to pass on real estate by inheritance, so everything that was done on the estate was done with high quality, to last for centuries, by special foreign craftsmen. What’s interesting is that despite the fact that each era used ornaments and decorations corresponding to the fashion of that time, the technology remains unchanged to this day

Ancient terraces and balconies of wealthy citizens of those times were decorated with similar delights. This was not just a fashion statement. It was customary to pass on real estate by inheritance, so everything that was done on the estate was done with high quality, to last for centuries, by special foreign craftsmen. What’s interesting is that despite the fact that each era used ornaments and decorations that corresponded to the fashion of that time, the technology remains unchanged to this day.

The fashion of the present time allows freedom of creative expression, allowing you to choose any fences, using the rich experience of ornate Baroque, Rococo or experimenting with new trends of high-tech and minimalism.

Modern life is a great experimenter and combinator, so combining strength, reliability, the art of visualization and decorative talent is more difficult, but more interesting.

News from partners

Balcony railings and railings: photos and their criteria

Depending on the type of fencing, they can be installed to completely cover the entire balcony or be made in the form of a parapet. Also, adhering to the general style of the house, you can make balcony railings either from one material or by combining them with each other.

There are several ways to make parapets:

- Using laser cutting - this type of work is gaining popularity, and is distinguished by its speed of production, the presence of beautiful and even lines, as well as the ability to make the most intricate patterns.

- The use of a variety of abrasive materials allows not only to carefully polish a certain type of fence made of metal or wood, but also to give it the desired structure.

- Forged materials not only have a beautiful and expensive appearance, but also have an acceptable cost, which is an order of magnitude higher than all other materials. The advantage here is the presence of smooth lines, with various curves and handmade work, guaranteeing complete individuality and exclusivity of the parapet.

Balcony railings can serve a variety of purposes. The most popular and familiar since Soviet times is the protective function and the need to dry clothes. But in modern times, this moment is a thing of the past, and now it is very rare to see such a picture.

It is very pleasant to relax here, especially in the summer; many housewives use flowerpots of various lengths and heights, planting hanging types of flowers in them. This slightly Mediterranean style gives the home extraordinary grace and appeal.

Glass fencing

Glass fencing is gradually gaining popularity. The parapet is made of sheet glass with metal inserts. Glass, which is used for installation in balcony railings, consists of several layers that are connected to each other with an adhesive composition.

Glass heated to 600 degrees becomes plastic and you can give it any shape with your own hands. But it is better to order such parts from a specialized workshop. When producing glass balcony fencing, it is necessary to follow a sequence of operations. The following rules must be observed:

- If the sheet size is less than 600*375 mm, the glass thickness must exceed three mm.

- With a sheet size of 2500*1600, the thickness of the sheet should not be less than 7 mm.

Glass balcony railings are secured to the base by welding, bolted and anchored connections. It is permissible to perform this operation with the participation of adhesive compositions. To install a sheet of glass on support posts, use the following methods:

- mounting on frame;

- installation with fittings;

- spot installation;

- clamps, this method is used only when working with steel frames.

Methods for installing fences on the balcony

The main factor influencing the way the railings are installed is the material they are made of. A common feature in all technologies is the need to install a solid foundation for the fence. It is created by fastening a large-section metal profile along the outer perimeter of the balcony ceiling. The base is attached to the ceiling with anchor bolts. The upper part of the side elements of the fence is also attached to the walls using anchor bolts.

The assembly of the railings begins from one edge and then follows along the entire perimeter. First, the vertical posts are secured, then the railings are installed, and finally the walls of the fence are sewn up. This is how prefabricated metal and wooden railings are installed.

Video: how to choose forged railings

Forged fences are installed in a different way. Since they are a solid structure, they are simply welded at the bottom or bolted onto a metal base profile. The sidewalls are attached to the walls of the building through mortgages, to which the fence itself is welded or screwed.

During installation work, you must follow the safety rules:

- Prevent the possibility of strangers appearing under the balcony being repaired.

- Protect yourself, materials and tools from possible falls from height.

- If welding work is planned, ensure that flammable objects are not in the work area.

Choosing the right type of railing for a balcony and its installation work is not a particularly difficult task. It is enough just to study all the available fencing options and correctly assemble them, without deviating from the technology conditions and safety requirements.

How to choose a railing installation company?

The recommendations are simple:

1. Explore offers in your area. The main selection criterion should be the experience of the installation team. Feel free to check if installers have diplomas or training certificates.

2. A team of 2-3 people per work shift must install 15 - 20 linear meters of fencing. This is quite enough, but after ordering railings, you can wait from 5 to 10 days. This is an established practice.

Choosing a reliable company for installing railings is half the success!

Firms that quote longer terms are most likely intermediaries. If a shorter period is offered, it may be a scam.

3. Do not make 100% advance payment for work. If you are not satisfied with the quality of installation, it will be easier to terminate the contract and return the money.

4. The contract must clearly indicate the cost of work, terms, payment terms, and guarantee.

If you have entrusted the manufacture of railings to a specialized company, then the designer must justify to you the choice of materials and compliance with all requirements. If the balcony collapses, he will be held responsible.

Basic materials for the manufacture of balcony railings

Making balcony railings with your own hands is not so easy. To do this, you must have certain construction skills and have the necessary tools. But the main difficulty lies in choosing the right material. It must fully comply with the main material of the balcony, fit into the overall appearance of the structure, and have all the necessary characteristics for this purpose.

Railings can be made from the materials listed below.

Stainless steel

Stainless steel fencing is the most acceptable option for exterior design. They can be hollow, solid, figured. Stainless steel is successfully combined with polycarbonate, plastic, and glass. Such ready-made structures are noticeably cheaper than products made from metal alone.

Stainless steel balcony railings

Metal fencing for balconies made of stainless steel has the following obvious advantages:

- Gives sophistication and a certain style, decorates modern designs.

- Has a very long service life.

- The material is absolutely resistant to corrosion and rotting.

- Does not require any care.

- Has sufficient strength.

- There are many design options to suit any situation.

Stainless steel can successfully highlight modern design styles. But it is not recommended to use the material on old or wooden balconies.

Stone

From stone

Stone or brick are sometimes used as fencing. These materials are not relevant in cases where balconies are located in multi-storey buildings. But they are suitable for private houses. The main advantages of this choice:

- Beautiful appearance, emphasizing the antique style. Stone fencing looks especially presentable on the open terraces of private houses.

- Solidity, reliability.

- Increased strength, resistance to damage and external influences.

And now a few important disadvantages:

- The heavy weight makes it impossible to use stone and brick for apartment buildings. The weight exceeds the permissible load on the balcony slabs. Can only be used if there are good supports.

- Complexity and high cost of production.

- Stone or brick railings on the balcony take up too much space.

Forged steel

Forged metal balcony railings have always been popular as a classic option. Artistic forging has the following advantages:

- Looks great on any balconies.

- Forged products allow you to create completely unique designs, whatever their owner desires.

- With a little care, the products last a very long time.

- They don't take up much space.

- Quickly installed.

It is worth noting that forged elements have a relatively high cost, as they are made by hand.

Metal

This is the most common material for making railings. You can choose from metal rods, corners, fittings, strips and other elements. Main advantages:

A very reliable and functional balcony can be built from reinforcement. It will be no worse than its forged counterpart, but will cost much less.

Tree

Wooden railings for balconies are used only in wooden or frame-panel houses. This way they best suit their purpose. The main advantages of wooden elements:

- Environmentally friendly.

- Aesthetic appeal. You can create any ornaments and figures from wood, decorating your balcony with them.

- Light weight.

- Easy to process and install.

- Possibility of self-production.

- A wealth of options to choose from.

- Wooden fences can be successfully complemented with metal or stainless steel elements.

In order for wooden fences to last a long time, they require regular maintenance at least once a year (impregnation, painting, varnishing).

Plastic and glass

Glass railings

These elements are not used independently on balconies, as they do not have the required strength. To enhance them, they are combined with metal elements. Let us list the advantages of these materials:

- The ability to create beautiful modern balconies.

- Resistance of plastic and glass to rotting, corrosion, and ultraviolet radiation.

- Relatively low cost of materials.

- Large selection of design options.

- Modern glass is resistant to mechanical stress. Tempered glass is especially famous for this.

- Durability. Glass can last more than 60 years, and high-quality plastic will certainly last 20 years.

- Lack of care.

Types of fencing: features, pros and cons

Wooden railings on the balcony

Wooden fences are distinguished by good aesthetics, since the texture of this natural material alone can become a design highlight. It is also important that wood is very easy to process and truly original railings can be made from it.

Photo:

Posts, railings and internal sections can be made from rectangular, round or square timber, or they can be provided with an artistic groove. To prevent cracking, only dried wood with a minimum percentage of moisture should be used for production.

The main disadvantage of wood is its susceptibility to rot, which reduces the strength of the structure and thereby creates a safety hazard.

To slow down this process, treatment with antiseptics and coating with alkyd-urethane varnishes are used. Coating with such a varnish will make the wood resistant to moisture and sunlight, and also creates a hard film on the surface that prevents the accumulation of dust and dirt.

Wooden railings in a private house - photo

To increase the reliability of wooden railings, they are additionally reinforced with metal fasteners. These can be corners, struts and brackets, fixed at points of maximum load.

Metal balcony railings

Metal railings are highly durable and have a high degree of safety.

The metal retains its strength at any temperature and prolonged exposure to solar radiation, and with timely painting, the metal is not afraid of corrosion.

The main metals used to create enclosing structures on balconies are aluminum and steel. For corrosion protection, they are subjected to galvanic treatment, applying a layer of zinc or nickel oxides. To preserve the protective layer, welding is not used when assembling the railings, but bolted connections are used. To improve aesthetics, you can use decorative versions rather than ordinary nuts and bolts.

If the metal does not have a protective coating, it is permissible to use welding. After installation, welded seams are cleaned, primed and painted along with all structural elements of the fence.

Photo:

For the manufacture of balcony railings, round and profiled metal pipes, profiles and sheets are used. Internal sections can be sewn up with large-diameter metal reinforcement.

Wrought iron railings for the balcony

The main advantage of forged railings is their decorative qualities. Forging uses solid metal rods and strips that can be easily bent. Using this technology, you can create original openwork fences with any number of twisted elements.

In terms of mechanical strength, forged railings are superior to all other options for constructing metal fences. However, it should be borne in mind that forged rod fences are not able to protect from wind and prying eyes. In addition, dust penetrates completely freely through them.

Photo gallery:

Stainless steel railings for the balcony

Stainless steel is convenient because there is always a thin film of oxides on its surface, which prevents the development of corrosion. As a result, stainless steel railings will retain their original appearance even without painting or other anti-corrosion treatment.

The steel color of unpainted fences is ideal for balconies of modern architecture buildings.

When developing the design of stainless steel railings, it is best to stick to modern styles, where this metal will fit best.

Photos:

The individual fencing elements are fastened to each other with bolted connections. Welding is possible, but extremely difficult and expensive due to the need for special equipment. For railing assemblies, only stainless steel fasteners can be used. Ordinary steel is not suitable for these purposes due to electrical incompatibility.

Note! In contact with stainless steel, steel bolts corrode and break very quickly.