The level of protection of the house from street noise and cold is affected not only by the quality of the entrance doors, but also by the material that helps them fit tightly to the frame. The absence of cracks creates a good seal, preventing drafts from spreading: in this case, sounds and smells from the outside will not be able to penetrate inside the house.

The classification of materials for door seals is carried out according to some basic characteristics. We are talking primarily about the size, material of manufacture and types of doors for which this seal was developed.

For example, wooden and iron doors are decorated with different types of tapes, although they are very similar in appearance. To choose the right equipment for your door, it is important to navigate this classification.

RECOMMENDED ON THE TOPIC

- How to make a sewer system in a country house:...

- Laying carpet: simple methods

What is a seal

It is a flexible material that has the shape of a strip of small width and provides a seal between the door frame and the leaf itself. Its fixation is mainly carried out on entrance doors, although due to its versatility it is well suited for a large number of other tasks, for example, for gluing vents, window frames and other things.

The seal is easy to install, since most of the material is fixed to the metal using an adhesive mixture, the layer of which is located on one side of the product. Its installation is always carried out around the perimeter of the door leaf. In some situations, they may have a special groove, which has optimal dimensions for securing the seal. It is not necessary to fix the material in this way, since it holds well even on flat metal, fulfilling its main function.

Advantages of using a sealant

The purpose of the material lies in its name. The main advantages of the seal include a number of the following qualities:

- It protects your home from the penetration of cold and hot air from outside, dirt, dust and foreign odors.

- Significant reduction in heat loss.

- It increases sound insulation performance, which is why when fixing the seal it is possible to reduce the level of extraneous noise and significantly prevent their penetration into the premises from the entrance or street.

- A high degree of sealing of the door frame due to the tight fit of its components.

- Increased fire safety indicators, since the material acts as a kind of barrier to the spread of smoke and fire.

- A high-quality seal does not change in size and eliminates the formation of gaps under the influence of sudden temperature fluctuations.

Note! The material also provides a shock-absorbing function, which is expressed in a softer contact of the door with the frame, thereby eliminating the occurrence of loud knocks and squeaks.

Care

In order for the gaskets to last as long as possible and not lose their performance characteristics, you need to follow the rules of care.

- At least twice a year, wash the sealing inserts against dust and dirt, then wipe them dry.

- Use only mild detergents.

- Lubricate with grease 2 times a year in warm weather to prevent premature drying.

If you follow the rules of care and operation, you can avoid replacing sealing materials in the next 10-15 years.

What criteria must a seal meet?

In addition to performing its main function, the material must be of high quality and meet the following requirements:

- Strength of materials used in production. They influence the service life of the seal. If the materials are not of sufficient quality, the tape will quickly begin to peel off from the door and will no longer be suitable.

- Resistance to regular mechanical influences. If you glue a seal to a low-quality metal entrance door, it will quickly wear out under the influence of various external factors, as well as during the constant opening and closing of the door leaf.

- It should be elastic and bend well. In addition, the sealing tape should not tear when covering door gaps and cracks, but at the same time be very soft to reduce the sound of impact when closing the doors.

- Complete sealing and adherence to surrounding surfaces. Thanks to this, it prevents cold air, moisture, foreign odors and dust from entering the house from the entrance side.

- After compression, the seal must fully return to its original state, maintaining its shape.

- High wear resistance. It should easily tolerate even significant temperature changes without loss of density, without peeling off or hardening.

Important! The seal must be manufactured in accordance with all standards and be able to withstand a long period of operation.

Rubber gaskets

Rubber door seals, thanks to various adaptations, can be adapted to any, including harsh, operating conditions. For their production, acid-resistant, oil-resistant rubber of high technical or food quality is used. Most often, a rubber seal is used for metal doors facing the street. They have a number of positive properties, namely:

- increased degree of moisture and air tightness;

- resistance to various temperatures, ultraviolet rays, precipitation;

- long service life.

The rubber seals on the door are not in danger of cracking, and they are inexpensive.

Door seals by profile type

Regardless of the type, all materials are manufactured in the form of a tape having different widths, thicknesses, lengths and colors, thanks to which they blend perfectly with the color of doors and frames to preserve an aesthetic appearance. In addition, due to the difference in their dimensions, they allow you to select and fully seal cracks and gaps.

A profile is a form of insulation that can have a cavity inside the material. Its purpose is to eliminate gaps and seal cracks of various sizes. When compressed, the premium seal does not suffer any damage. This feature is characteristic of high quality polyvinyl chloride and polyurethane. Profile shapes are marked in the form of English letters P, V, E, D, O, K, C and others.

Foam sealing tapes

They are affordable and are in significant demand in the market. Self-adhesive film, the thickness of which can vary, is fixed to the foam rubber in various ways, taking into account the material of the door frame. If it is made of wood, then fastening to it is carried out using wallpaper nails, and for a metal structure, a suitable solution is to use a durable adhesive composition intended for this material.

The disadvantage of foam tape is that it does not have a high level of wear resistance, which is why it quickly becomes unusable and needs to be replaced. In addition, as a result of its own porosity, which is especially noticeable in material with a large width, there is a greater transmission of cold air. For this reason, insulation is more suitable for interior doors than exterior doors.

Tubular seals

Externally, they look like a thick, dense tourniquet, inside of which there is a rather impressive empty cavity. Thanks to this and the high strength of the material itself, it is possible to achieve a tight fit of the door to the jamb with the absence of any unnecessary gaps or cracks. The tubular seal is made from rubber, which has a porous structure, which helps retain heat in the room and increases sound insulation performance.

It is often self-adhesive, making it much easier to install. After some time, any such material disappears, but basically such a seal can be used freely for several years, after which it is no less easily replaced by another. In most cases, it is used on entrance doors that face the street.

Groove seals

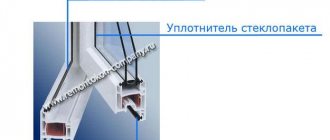

Their production is carried out specifically for plastic doors with different designs.

Compared to a thick tubular seal, this material is made of softer rubber. Installation of such products is not difficult: you just need to carefully install them in the door grooves. With this method of fixing the seal, it is extremely little influenced by external factors, for example, negative weather conditions and sudden temperature changes, due to which its service life is an order of magnitude longer. The disadvantage of the material is that it is only suitable for door structures made of plastic.

Magnetic seals

They are manufactured as frames that follow the contours of the doors down to the millimeter. They are used for metal door structures, and experts advise giving them preference because of their highest strength and quality. Each product has two components, one of which acts as an insert with a magnet, and the second in the form of a soft material. The cost of such a seal is quite impressive and its installation requires adherence to certain rules, but it has significant resistance to wear, ensuring a long period of operation.

Magnetic seals have a high level of tightness and shock absorption, due to which no noise is made when opening and closing the door, and due to the full attraction of the door leaf to the frame, there are completely no cracks or gaps between them. The main disadvantage may be that due to the presence of such a design, in some situations it may be necessary to apply more significant physical effort when opening and closing the canvas. In addition, special attention should be paid to the threshold seal, which is designed not only to insulate doors in their lower part, but also to the increased load that the dense rubber or caoutchouc from which it is made can withstand.

Glass seals

A variety of products that are produced specifically for glass components of doors of various sizes. Their profile has an individual cross-section, and the material used in production is soft and flexible silicone. To fix such a seal, it is optimal to just moisten it with water and immediately after that fasten it to the required area of the door structure. This type of silicone has its own characteristic feature, due to which, after a certain period of time after wetting, the material firmly adheres to surfaces made of glass and does not lag behind them, unlike other ordinary products with a self-adhesive base.

Contour seals

They are distinguished by their ease of use, being fixed to the door along its perimeter. If the door structure has a special groove, then the material can be placed in it, or it can be laid along the edge in the case where there is no gap or gap. Most often, seals of this type are made from foam rubber and rubber. For rooms with an increased level of fire hazard, a thermally expanding type of insulation is often used. Outwardly, it looks like an ordinary material, but with a significant increase in temperature during a fire and the presence of smoke, it has the property of expanding and foaming. Thanks to this, air does not enter the room and the fire can be extinguished more quickly.

Three-circuit seals

Products that consist of three circuits and are designed for fire doors, providing an increase in sound insulation performance.

They are well suited for use not only in residential buildings, but also in offices. Additional rigid ribs lead to a significant increase in the thickness and weight of the door leaf, which is why it is necessary to first ensure that the frame and its fittings have maximum strength. Three-circuit seals, when installed on entrance doors, best prevent the penetration of cold from the street into the room.

Liquid types of insulation

They can also be used to insulate iron entrance doors, but when using them, certain conditions must be observed. They are supplied for sale in metal cylinders, and such compositions are applied to the required areas during spraying, after which they harden in a matter of time, helping to improve thermal insulation qualities. The peculiarity of liquid insulation is that they do not like places with increased dampness. In addition, for the most correct spraying, you should have certain skills in order to avoid the door acquiring unnecessary cosmetic defects.

Note! Liquid insulation materials contain no harmful substances, which is why they are completely safe for human health and the environment.

Pile compactors

One of the main representatives of these insulation materials is felt. Now there are also synthetic versions of fleecy seals on the market, but due to the fact that the previous material is made from natural wool, it still largely surpasses similar solutions in its performance today. Felt comes in different varieties, which are labeled accordingly. Any of them is suitable for doors; it is only important to cut the material correctly, having previously taken the required measurements.

Among artificial pile insulations, thin pile strips with an adhesive base are in high demand. Their task is to prevent dust from entering the room. It is rarely used as a seal for entrance doors, but is often attached when installed on the door structures of sliding wardrobes.

TEP seals

The most expensive and at the same time the most reliable option, during the manufacture of which thermoplastic elastomers are used. Such materials have impressive wear resistance, meaning that manufacturers claim that their service life without the need for replacement can reach 15-20 years.

The advanced flexible plastic can withstand incredibly low temperatures and provide good thermal insulation even at -50°C. In addition to the high price, some difficulties may arise during its installation, but if you adhere to all the necessary rules during installation and operation, then the second drawback can be avoided, and the high cost becomes completely justified.

Foam rubber and polyurethane types

Foam tape is the most affordable, simplest option. The presence of a self-adhesive base allows you to insulate the doorway in a short time, without the need to make any effort or have additional material. It can also be secured with small nails if the surface is made of wood. Foam rubber is a good protection, but its fragile structure does not allow it to withstand difficult operating conditions; it is negatively affected by: humidity, dirt, temperature changes.

Gradually it becomes unusable, shrinks, crushes, crumbles. Most often, foam rubber tape is used as a seal for interior doors.

A type of door seal is a polyurethane product, which, thanks to the self-adhesive film on one side, is easily fixed to the door. Its area of application includes wooden doors. Metal structures quickly damage the product, as a result of which the heat-protective qualities decrease.

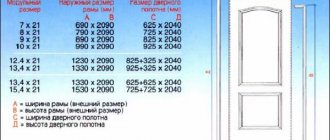

Seal sizes

The material is manufactured in various sizes. The size of the seal must be selected in accordance with the size of the gap or gap. If the width of the first varies within 1-4 mm, then preference should be given to a rectangular profile, for example, made of polyvinyl chloride (PVC) or foam rubber. For gaps up to 3 mm, the optimal solution is profile material C, K and E. Gasket types P and V are excellent for gaps in the range of 3-5 mm. Material with wide cavities inside the O and D profiles is the best option for entrance doors and is fixed in the gap between the door leaf and the frame, and their dimensions can reach up to 0.7 cm.

In most situations, products are sold in large rolls. Their footage may vary depending on the manufacturer and type of seal. When purchasing, you need to take into account that for one entrance door you need 5-6 m of material. For interior door structures, you may need a little less, but it is still better to buy with a small reserve, which, even if it remains, can be useful in the future for replacement if the sealing tape partially wears out in some area.

Note! If there is a need to seal the gap between the frame and the door leaf, then the first step is to take measurements. To do this, you need to place a piece of plasticine wrapped in plastic film between them and close the door. After opening it, the resulting impression allows you to correctly determine the optimal width of the seal.

Replacing the seal on PVC windows

If it loses its performance qualities, when the sealing material cannot protect against noise, moisture and cold, it must be replaced with new products. To successfully complete this job, you must first prepare some tools and materials. If you have to do this work for the first time, you can watch the video to get acquainted.

Materials and tools

For this work you will need:

- New seal;

- Sharp knife;

- Glue.

On a note! When purchasing a sealing gasket for a window block, buy it with a reserve, since errors are inevitable when cutting during operation.

All work on replacing the seal must be done consistently and carefully. First you need to remove as much of the old seal as possible.

Then:

- First, it is recommended to remove the sash from its hinges. If this is not done, it will be problematic to install gaskets on the hinges.

- Before removing it, you need to remove the trim.

- At the bottom, remove the tightening pin using a chisel or other sharp object.

- Leaving the top hinge in place, close the sash, turn the handle 90 degrees and open the window.

- After these manipulations, slightly push the frame towards you and remove it from its hinges.

- Turn the handle down. Then remove the remaining old material. Please note that the top loop must be moved up, thereby freeing up space for removal.

- Then clean the grooves with a brush, remove all accumulated deposits and you can begin installing a new seal.

- Before installation, ensure that the sealing tape is directed correctly (so that the protrusion is directed into the groove). Carefully adjusting the seal with a chisel, tuck it into the profile.

- At the next stage, we do the same procedure on the frame.

- We install all the elements in their places. Why: insert the frame in a vertical position into the upper and lower loops; Reinstall the pin and trim.

- At this point we can assume that the work of replacing the seal is completed.

Types of seals for metal doors by material of manufacture

Each of them has its own positive and negative sides, which you need to familiarize yourself with before purchasing.

Foam rubber

A budget option that is in greatest demand on the market. The foam seal has a self-adhesive base that allows the material to be fixed to the door. The texture and thickness of the tape varies. It is secured to wooden door structures using wallpaper nails. The foam seal is fixed to the metal entrance door using a special glue designed to work with this material.

Its main advantage is its affordable cost, thanks to which anyone can purchase such insulation, but it should also be taken into account that it is characterized by extremely low wear resistance, which is why its service life is very short. In most cases, the foam seal needs to be replaced after a year, and in adverse weather conditions, sometimes wear occurs even faster. Taking into account this nuance, giving preference to it, it is advisable to immediately purchase the material with a reserve or consider purchasing higher quality options with a longer service life.

Silicone

The material resembles rubber, but it has greater softness and ductility, which causes it to wear out quickly and become damaged under regular mechanical stress. In addition, after a certain period of time, the silicone seal acquires unnecessary stickiness, which is also one of the inconveniences that arise during operation.

A product made from it also has its own advantages. Silicone is distinguished by its high lightness and aesthetic appearance, and its composition does not contain harmful substances that can negatively affect the environment and human health. For this reason, it is very often preferred when insulating doors in schools and other child care institutions, hospitals and clinics. Due to the ease of use, replacing the silicone sealing tape also does not pose any significant difficulties.

Felt

Seals made from this material are also among the most popular products in Soviet times, along with those now made of foam rubber. Today, felt sealing is also often preferred, even despite more modern solutions, due to its many significant advantages.

The key positive quality of felt is its high resistance to wear during operation. This natural and at the same time durable material withstands harsh weather conditions well and is not subject to wear and tear over a long period, especially when installed correctly.

Due to the fact that felt is still made from pure wool, its internal structure does not deteriorate over time compared to synthetic sealing materials, so it does not lose its original properties. This insulation has a high density, ideally absorbing extraneous sounds, saving heat well and featuring a significant level of fire safety.

Not so long ago it was widely used for insulating doors and window frames, but today consumers choose it less and less, preferring other modern options for several reasons:

- First of all, it is made from natural wool, which is why in most situations its cost is quite impressive.

- Compared to seals made from other materials, such products are not easy to install on the door. To perform the installation correctly, you must have certain skills, which not everyone has, and be extremely careful during the fixation process.

- Before installation from sheet material, you need to cut out the felt strips yourself, unlike other types of seals that go on sale ready-made and, in some cases, in a mortise form, without the need for additional preparatory work.

Considering all the features, it is not the best option for insulating doors, although it can compete with many of the modern solutions even today.

Polyurethane

Seals made from this material have fairly good performance characteristics.

Their main positive qualities include ease of installation, since on one side they have a self-adhesive film applied, which adheres well to different surfaces. In addition, polyurethane seals are characterized by a long service life and low cost, but they have little resistance to abrasion, which is why this option is not the best for fixing on doors. It is especially advisable to avoid gluing them on door structures that are subject to constant use, since the material will wear out quickly enough and will need to be replaced.

Plastic

Seals made of plastic have increased sealing performance. Most of them have a hollow internal structure, which makes it possible to achieve an additional sealing contour in the form of an air gap on the sides of the door structure. Due to this feature, heat is retained in the room. Plastic seals have an affordable price, but during their installation there is a possibility of some difficulties arising, since the material must be fixed into the groove. Taking this into account, you need to select a product in accordance with the structural features of the door on which it will be installed in the future.

Rubber

They are the ones most often used for insulating metal doors, and due to their versatility, the material is used to cover not only entrance doors leading to the entrance or to the street, but also interior door structures. It can be fully fixed on products made of wood, chipboard and any metal. Rubber seals come in two varieties. In the first case, they have an adhesive base, and in the second, the products are manufactured for installation in a door profile specially prepared for them. There are door designs on sale that are initially made with the appropriate inserts, which are necessary for further installation of the seal.

One of the main advantages of rubber materials is their wide variety, since they are manufactured not only in the form of bundles of different diameters, but also according to the principle of tubular products with an internal cavity. In addition, when installing such a seal, it is possible to significantly increase the thermal insulation and sound insulation performance. The material withstands prolonged exposure to sunlight, significant temperature fluctuations, as well as other negative environmental influences. Rubber seals are also characterized by a long service life, low cost, water resistance and high elasticity, so you don’t have to worry about cracks.

Important! When purchasing, it is imperative to pay attention to the shelf life of the material, which loses its elasticity over time.

Execution color

Today there are products on sale in a variety of colors, thanks to which you can freely choose the most compatible shade with the door and frame on which the seal is attached. White material can be preferred when there is a need to insulate door structures made of plastic of a similar color.

The black rubber seal is great for protecting entry doors from cold penetration and extraneous noise. In general, for metal structures it is optimal to choose a material of dark shades and colors that go well with it.

For colored metal-plastic doors, you can choose a material of a similar color and even purchase it from the same manufacturer that produces them. Transparent silicone sealing strips combine well with door structures and are visually less noticeable on their surface.

Insulation

Owners of wooden entrance doors often suffer from drafts and cold that enters the home through cracks. In addition, wood perfectly transmits sounds, which is also not always desirable. Additional insulation of the door will help, and you can do this with your own hands.

You will need

- leatherette or leatherette according to the dimensions of the door, taking into account 10-15 cm allowances on each edge,

- foam rubber,

— construction nails (50g),

- furniture nails with a wooden head (100-150g),

- decorative string

Instructions

- Remove the front door from its hinges and place it on a work surface (stools or table). Remove parts that will get in the way: handles, keys and other protruding parts.

2. Make a base for the rollers that will bridge the gap between the door frame and the door itself. If the door opens outward, cut out 3 strips of material for the rollers, approximately 14 cm wide. The length of one strip is equal to the height of the door, the remaining strips are equal to the width of the door. If the door opens inward, cut 4 strips 14 cm wide. Two strips are equal to the height of the door, two to the width of the door.

3. Attach the strips of material to the door with construction nails along the edges, leaving the side on which the hinges are attached. Leave 1.5 cm from the edge of the door. If the door opens inward, attach the strips to its four sides.

4. Take a strip of foam rubber 3 cm wide and wrap it in leatherette nailed at the bottom of the door. You should get a roller that needs to be secured with nails.

5. Make a door-sized canvas from the material, but do not forget about an allowance of 10 cm on each side. Place the canvas on the door, having previously inserted the foam rubber into the remaining, already nailed, strips of material. Foam rubber should also be placed under the main door leaf.

6. First nail down the partial edges of the canvas with construction nails, then the bottom one, which should fit onto the roller nailed below, and the top one. Secure the remaining rollers so that the main fabric goes inside the roller. Secure the canvas, but make sure that it does not warp anywhere. Lastly, fasten the side on which the loops are hung.

7. All that remains is to decorate the door: nail the furniture nails according to the pattern chosen in advance. Additionally, this will keep the foam from moving downwards. Stretch decorative string or fishing line between the nail heads. If you decide to abandon the pattern, you will just have to nail a few nails around the perimeter of the door. Cut out the holes for the lock, attach the handle and hang the door in place.

Useful tips for choosing a seal for a metal door

When purchasing material, it is recommended to take into account a number of the following nuances:

- When giving preference to self-adhesive tape, it is imperative to check the shelf life of the adhesive layer, which should contain small particles of fiberglass.

- A rubber seal should be selected with medium hardness, because if it is very soft, it will quickly become unusable, and if it is too hard, it will prevent the door from closing.

- It is better to give preference to a black seal, since in many cases products of a different color have a shorter service life.

- To ensure the sealing qualities of the material, you need to lightly press on it. Ensuring complete tightness during further use will be indicated if the seal then quickly acquires its original shape.

- When selecting a material that requires additional gluing, it is advisable to use high-quality silicone glue.

- It is best to avoid using foam rubber seals when insulating metal doors. If they are opened and closed regularly, such tapes deteriorate extremely quickly and need to be replaced.

Having figured out how to choose a seal for a metal entrance door, you will be able to choose the most suitable option and avoid purchasing low-quality material, which very soon may become unusable, losing its positive qualities.

Video:

How to replace

During preparatory work, old gasket material is removed and the grooves are cleaned.

- Laying begins from the corner of the frame without stretching, distortion or twisting. To do this, the cord is inserted with pressure into the groove along the entire perimeter. To facilitate installation, treatment with silicone grease is allowed.

- When the cord is laid, the end is cut as close to the beginning as possible, without a gap at the junction. The joint is glued with glue suitable for the insert material. After the glue has cured, you need to check whether the sash opens and closes easily and whether there are any drafts.

- If it turns out great, then apply a layer of silicone grease to the gasket to reduce friction.

It is better to entrust the replacement of glass unit gaskets to specialists.