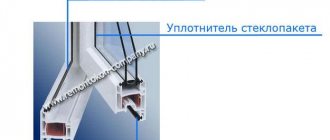

To prevent a metal door from letting in cold air and noise from outside the room, it must have a seal on it. This rather simple but very important fitting becomes unusable over time and therefore requires periodic replacement. When purchasing it and installing it yourself, it is necessary to take into account certain nuances, then the product will perform all the functions assigned to it. Next, let's look at what a seal for iron entrance doors is, how to choose and install it correctly.

What is a seal

It is a flexible material that has the shape of a strip of small width and provides a seal between the door frame and the leaf itself. Its fixation is mainly carried out on entrance doors, although due to its versatility it is well suited for a large number of other tasks, for example, for gluing vents, window frames and other things.

The seal is easy to install, since most of the material is fixed to the metal using an adhesive mixture, the layer of which is located on one side of the product. Its installation is always carried out around the perimeter of the door leaf. In some situations, they may have a special groove, which has optimal dimensions for securing the seal. It is not necessary to fix the material in this way, since it holds well even on flat metal, fulfilling its main function.

How to choose a seal for different types of doors

When purchasing a seal, you must first take into account the type of door and where it will be used. This is important because the choice of a product with certain properties and characteristics depends on the operating conditions.

Seals can be installed on different types of doors:

- Input - predominantly a tubular version made of rubber is used. If you have a good budget, it is possible to install a magnetic door seal.

- Glass - products made of aluminum and silicone.

- Plastic - rubber types of products with a special configuration and groove type of installation.

- Interior - foam rubber products on an adhesive base and brush seals for compartment-type doors.

Note! It often happens that only one seal is suitable for a specific model of plastic door. In such cases, it will not be possible to find an analogue. Therefore, when choosing doors, you must check whether it is possible to replace the seal on the front door with products from another manufacturer. Otherwise, in case of repairs, you will have to update the entire structure.

Self-adhesive tubular seal for the entrance door.

Advantages of using a sealant

The purpose of the material lies in its name. The main advantages of the seal include a number of the following qualities:

- It protects your home from the penetration of cold and hot air from outside, dirt, dust and foreign odors.

- Significant reduction in heat loss.

- It increases sound insulation performance, which is why when fixing the seal it is possible to reduce the level of extraneous noise and significantly prevent their penetration into the premises from the entrance or street.

- A high degree of sealing of the door frame due to the tight fit of its components.

- Increased fire safety indicators, since the material acts as a kind of barrier to the spread of smoke and fire.

- A high-quality seal does not change in size and eliminates the formation of gaps under the influence of sudden temperature fluctuations.

Note! The material also provides a shock-absorbing function, which is expressed in a softer contact of the door with the frame, thereby eliminating the occurrence of loud knocks and squeaks.

What criteria must a seal meet?

In addition to performing its main function, the material must be of high quality and meet the following requirements:

- Strength of materials used in production. They influence the service life of the seal. If the materials are not of sufficient quality, the tape will quickly begin to peel off from the door and will no longer be suitable.

- Resistance to regular mechanical influences. If you glue a seal to a low-quality metal entrance door, it will quickly wear out under the influence of various external factors, as well as during the constant opening and closing of the door leaf.

- It should be elastic and bend well. In addition, the sealing tape should not tear when covering door gaps and cracks, but at the same time be very soft to reduce the sound of impact when closing the doors.

- Complete sealing and adherence to surrounding surfaces. Thanks to this, it prevents cold air, moisture, foreign odors and dust from entering the house from the entrance side.

- After compression, the seal must fully return to its original state, maintaining its shape.

- High wear resistance. It should easily tolerate even significant temperature changes without loss of density, without peeling off or hardening.

Important! The seal must be manufactured in accordance with all standards and be able to withstand a long period of operation.

How to seal doors in different ways: recommendations

Each type of seal has its own installation nuances. The groove profiles are equipped with a special fastening in the form of a brush. To install such a seal, no additional materials are required.

The main difficulties of this process lie in adjusting the dimensional parameters. Most people fail at this task. Rubber is not only flexible, but also stretches well. After which it easily returns to its original state. For this reason, when cutting the material or when pressing it into a groove, you need to carefully ensure that you do not accidentally stretch the rubber. Experts advise, on the contrary, to “press” it slightly.

Installing the rubber band is a quick and easy process.

Trimming of material is carried out only after the groove seal is installed in place. You should not rush with this, otherwise you may cut off more than necessary. As a result, the structure will not be airtight and the work will have to be redone.

Installing self-adhesive tape is not particularly difficult. To work with the material, you only need a painting knife. This tool is necessary for trimming the seal to adjust its length. The tape is applied to a previously cleaned and degreased surface from left to right, and from top to bottom on the sides. In other words, the starting point is the top corner.

The protective layer on the adhesive side must be removed carefully and gradually. Be sure to ensure that the material does not stretch. A free piece of adhesive tape (about 10 cm) must be fixed, only after that a little more of the protective layer is removed and the next section is glued.

A high-quality seal will keep the room warm and protect it from dust and noise. This is possible provided that the material is selected and installed correctly. The technology itself usually does not cause difficulties, so anyone can handle the installation of the tape. All that is required is to follow the manufacturer's recommendations, avoid rushing and carefully coordinate your actions.

Door seals by profile type

Regardless of the type, all materials are manufactured in the form of a tape having different widths, thicknesses, lengths and colors, thanks to which they blend perfectly with the color of doors and frames to preserve an aesthetic appearance. In addition, due to the difference in their dimensions, they allow you to select and fully seal cracks and gaps.

A profile is a form of insulation that can have a cavity inside the material. Its purpose is to eliminate gaps and seal cracks of various sizes. When compressed, the premium seal does not suffer any damage. This feature is characteristic of high quality polyvinyl chloride and polyurethane. Profile shapes are marked in the form of English letters P, V, E, D, O, K, C and others.

Foam sealing tapes

They are affordable and are in significant demand in the market. Self-adhesive film, the thickness of which can vary, is fixed to the foam rubber in various ways, taking into account the material of the door frame. If it is made of wood, then fastening to it is carried out using wallpaper nails, and for a metal structure, a suitable solution is to use a durable adhesive composition intended for this material.

The disadvantage of foam tape is that it does not have a high level of wear resistance, which is why it quickly becomes unusable and needs to be replaced. In addition, as a result of its own porosity, which is especially noticeable in material with a large width, there is a greater transmission of cold air. For this reason, insulation is more suitable for interior doors than exterior doors.

Tubular seals

Externally, they look like a thick, dense tourniquet, inside of which there is a rather impressive empty cavity. Thanks to this and the high strength of the material itself, it is possible to achieve a tight fit of the door to the jamb with the absence of any unnecessary gaps or cracks. The tubular seal is made from rubber, which has a porous structure, which helps retain heat in the room and increases sound insulation performance.

It is often self-adhesive, making it much easier to install. After some time, any such material disappears, but basically such a seal can be used freely for several years, after which it is no less easily replaced by another. In most cases, it is used on entrance doors that face the street.

Groove seals

Their production is carried out specifically for plastic doors with different designs.

Compared to a thick tubular seal, this material is made of softer rubber. Installation of such products is not difficult: you just need to carefully install them in the door grooves. With this method of fixing the seal, it is extremely little influenced by external factors, for example, negative weather conditions and sudden temperature changes, due to which its service life is an order of magnitude longer. The disadvantage of the material is that it is only suitable for door structures made of plastic.

Magnetic seals

They are manufactured as frames that follow the contours of the doors down to the millimeter. They are used for metal door structures, and experts advise giving them preference because of their highest strength and quality. Each product has two components, one of which acts as an insert with a magnet, and the second in the form of a soft material. The cost of such a seal is quite impressive and its installation requires adherence to certain rules, but it has significant resistance to wear, ensuring a long period of operation.

Magnetic seals have a high level of tightness and shock absorption, due to which no noise is made when opening and closing the door, and due to the full attraction of the door leaf to the frame, there are completely no cracks or gaps between them. The main disadvantage may be that due to the presence of such a design, in some situations it may be necessary to apply more significant physical effort when opening and closing the canvas. In addition, special attention should be paid to the threshold seal, which is designed not only to insulate doors in their lower part, but also to the increased load that the dense rubber or caoutchouc from which it is made can withstand.

Glass seals

A variety of products that are produced specifically for glass components of doors of various sizes. Their profile has an individual cross-section, and the material used in production is soft and flexible silicone. To fix such a seal, it is optimal to just moisten it with water and immediately after that fasten it to the required area of the door structure. This type of silicone has its own characteristic feature, due to which, after a certain period of time after wetting, the material firmly adheres to surfaces made of glass and does not lag behind them, unlike other ordinary products with a self-adhesive base.

Contour seals

They are distinguished by their ease of use, being fixed to the door along its perimeter. If the door structure has a special groove, then the material can be placed in it, or it can be laid along the edge in the case where there is no gap or gap. Most often, seals of this type are made from foam rubber and rubber. For rooms with an increased level of fire hazard, a thermally expanding type of insulation is often used. Outwardly, it looks like an ordinary material, but with a significant increase in temperature during a fire and the presence of smoke, it has the property of expanding and foaming. Thanks to this, air does not enter the room and the fire can be extinguished more quickly.

Three-circuit seals

Products that consist of three circuits and are designed for fire doors, providing an increase in sound insulation performance.

They are well suited for use not only in residential buildings, but also in offices. Additional rigid ribs lead to a significant increase in the thickness and weight of the door leaf, which is why it is necessary to first ensure that the frame and its fittings have maximum strength. Three-circuit seals, when installed on entrance doors, best prevent the penetration of cold from the street into the room.

Liquid types of insulation

They can also be used to insulate iron entrance doors, but when using them, certain conditions must be observed. They are supplied for sale in metal cylinders, and such compositions are applied to the required areas during spraying, after which they harden in a matter of time, helping to improve thermal insulation qualities. The peculiarity of liquid insulation is that they do not like places with increased dampness. In addition, for the most correct spraying, you should have certain skills in order to avoid the door acquiring unnecessary cosmetic defects.

Note! Liquid insulation materials contain no harmful substances, which is why they are completely safe for human health and the environment.

Pile compactors

One of the main representatives of these insulation materials is felt. Now there are also synthetic versions of fleecy seals on the market, but due to the fact that the previous material is made from natural wool, it still largely surpasses similar solutions in its performance today. Felt comes in different varieties, which are labeled accordingly. Any of them is suitable for doors; it is only important to cut the material correctly, having previously taken the required measurements.

Among artificial pile insulations, thin pile strips with an adhesive base are in high demand. Their task is to prevent dust from entering the room. It is rarely used as a seal for entrance doors, but is often attached when installed on the door structures of sliding wardrobes.

TEP seals

The most expensive and at the same time the most reliable option, during the manufacture of which thermoplastic elastomers are used. Such materials have impressive wear resistance, meaning that manufacturers claim that their service life without the need for replacement can reach 15-20 years.

The advanced flexible plastic can withstand incredibly low temperatures and provide good thermal insulation even at -50°C. In addition to the high price, some difficulties may arise during its installation, but if you adhere to all the necessary rules during installation and operation, then the second drawback can be avoided, and the high cost becomes completely justified.

How to wash frosted glass on which dust has settled

Glass is one of the favorite materials of furniture and decorative items designers. Its possibilities with modern technologies are almost limitless.

Recently, interior designers have been using glass not only for making furniture elements. Partitions, doors, steps and even entire walls are made from glass. The active use of glass has led to the emergence of diversity in its surfaces. Frosted glass, as well as surfaces with a pattern or coating, are very popular.

Glass is widely used in kitchen interiors. Glass furniture expands the space and makes it lighter. Even glass hoods made of tempered glass that can withstand high temperatures have become fashionable.

In the bathroom, we have long been accustomed to glass shelves and shower cabins.

In addition to ordinary silicate glass, plexiglass (plexiglass) is often used, which has a number of advantages over ordinary glass, such as lighter weight and greater impact resistance.

The widespread use of glass requires deep knowledge of the handling and care of such material.

How to care for such unusual glass?

How to wash frosted glass on which dust has settled, dirt has accumulated, stains from greasy fingers, as well as other contaminants remain.

Note that frosted glass is susceptible to the action of many chemicals. Strong acids and alkalis, together with contamination, can also damage spraying. It is also not recommended to use gasoline and acetone to remove stains. Any products containing abrasive particles are also not suitable for cleaning frosted glass. If you want to wash frosted organic glass, then you should forget about products with alcohol.

Also, you should not try to scrape difficult stains from the glass, such as paint splashes or traces of adhesive tape. You will only scratch the matte finish and it will be impossible to restore it.

It would seem that with so many prohibitions, there are no longer any methods left for washing this capricious glass. But it is not all that bad.

Ordinary silicate glass can be easily washed with special alcohol-containing products. A universal dishwashing detergent is quite capable of dealing with minor stains and other dirt. Even ordinary soap foam will be a good help in the fight against dirty corrugated glass.

And of course, folk remedies that have been selected over the years by trial and error will always come to the rescue.

- The traditional method of washing any glass is using ammonia. Ammonia is added to water in the proportion of one tablespoon of ammonia per liter of water. The mixture can be poured into a container with a spray bottle and applied directly to the glass, or you can soak a soft cotton cloth in the solution and wipe the glass, paying special attention to heavily soiled areas.

Then the surface should be thoroughly wiped with a dry cloth. The fabric should not leave lint on the glass. Instead of fabric, you can use crumpled paper.

The disadvantage of this method is the strong smell of ammonia. Therefore, you need to use this product in a well-ventilated area.

- Another fairly well-known and popular means for washing any glass, including frosted glass, is an aqueous solution of vinegar. One tablespoon is added to one glass of water and applied to the glass either using a spray bottle or using a cloth soaked in the solution. It is not recommended to leave the glass to dry; it should be thoroughly wiped until completely dry.

- Finely ground chalk will help remove stains on frosted glass. Take about two to three tablespoons of chalk powder and make a water slurry. Add chalk to a glass of water and shake well. Soak a soft cotton cloth in the solution and apply it to the glass. To remove chalk, wait until the chalk composition dries and then remove it with a dry cloth or paper.

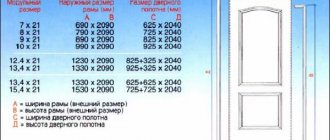

Seal sizes

The material is manufactured in various sizes. The size of the seal must be selected in accordance with the size of the gap or gap. If the width of the first varies within 1-4 mm, then preference should be given to a rectangular profile, for example, made of polyvinyl chloride (PVC) or foam rubber. For gaps up to 3 mm, the optimal solution is profile material C, K and E. Gasket types P and V are excellent for gaps in the range of 3-5 mm. Material with wide cavities inside the O and D profiles is the best option for entrance doors and is fixed in the gap between the door leaf and the frame, and their dimensions can reach up to 0.7 cm.

In most situations, products are sold in large rolls. Their footage may vary depending on the manufacturer and type of seal. When purchasing, you need to take into account that for one entrance door you need 5-6 m of material. For interior door structures, you may need a little less, but it is still better to buy with a small reserve, which, even if it remains, can be useful in the future for replacement if the sealing tape partially wears out in some area.

Note! If there is a need to seal the gap between the frame and the door leaf, then the first step is to take measurements. To do this, you need to place a piece of plasticine wrapped in plastic film between them and close the door. After opening it, the resulting impression allows you to correctly determine the optimal width of the seal.

Types of seals for metal doors by material of manufacture

Each of them has its own positive and negative sides, which you need to familiarize yourself with before purchasing.

Foam rubber

A budget option that is in greatest demand on the market. The foam seal has a self-adhesive base that allows the material to be fixed to the door. The texture and thickness of the tape varies. It is secured to wooden door structures using wallpaper nails. The foam seal is fixed to the metal entrance door using a special glue designed to work with this material.

Its main advantage is its affordable cost, thanks to which anyone can purchase such insulation, but it should also be taken into account that it is characterized by extremely low wear resistance, which is why its service life is very short. In most cases, the foam seal needs to be replaced after a year, and in adverse weather conditions, sometimes wear occurs even faster. Taking into account this nuance, giving preference to it, it is advisable to immediately purchase the material with a reserve or consider purchasing higher quality options with a longer service life.

Silicone

The material resembles rubber, but it has greater softness and ductility, which causes it to wear out quickly and become damaged under regular mechanical stress. In addition, after a certain period of time, the silicone seal acquires unnecessary stickiness, which is also one of the inconveniences that arise during operation.

A product made from it also has its own advantages. Silicone is distinguished by its high lightness and aesthetic appearance, and its composition does not contain harmful substances that can negatively affect the environment and human health. For this reason, it is very often preferred when insulating doors in schools and other child care institutions, hospitals and clinics. Due to the ease of use, replacing the silicone sealing tape also does not pose any significant difficulties.

Felt

Seals made from this material are also among the most popular products in Soviet times, along with those now made of foam rubber. Today, felt sealing is also often preferred, even despite more modern solutions, due to its many significant advantages.

The key positive quality of felt is its high resistance to wear during operation. This natural and at the same time durable material withstands harsh weather conditions well and is not subject to wear and tear over a long period, especially when installed correctly.

Due to the fact that felt is still made from pure wool, its internal structure does not deteriorate over time compared to synthetic sealing materials, so it does not lose its original properties. This insulation has a high density, ideally absorbing extraneous sounds, saving heat well and featuring a significant level of fire safety.

Not so long ago it was widely used for insulating doors and window frames, but today consumers choose it less and less, preferring other modern options for several reasons:

- First of all, it is made from natural wool, which is why in most situations its cost is quite impressive.

- Compared to seals made from other materials, such products are not easy to install on the door. To perform the installation correctly, you must have certain skills, which not everyone has, and be extremely careful during the fixation process.

- Before installation from sheet material, you need to cut out the felt strips yourself, unlike other types of seals that go on sale ready-made and, in some cases, in a mortise form, without the need for additional preparatory work.

Considering all the features, it is not the best option for insulating doors, although it can compete with many of the modern solutions even today.

Polyurethane

Seals made from this material have fairly good performance characteristics.

Their main positive qualities include ease of installation, since on one side they have a self-adhesive film applied, which adheres well to different surfaces. In addition, polyurethane seals are characterized by a long service life and low cost, but they have little resistance to abrasion, which is why this option is not the best for fixing on doors. It is especially advisable to avoid gluing them on door structures that are subject to constant use, since the material will wear out quickly enough and will need to be replaced.

Plastic

Seals made of plastic have increased sealing performance. Most of them have a hollow internal structure, which makes it possible to achieve an additional sealing contour in the form of an air gap on the sides of the door structure. Due to this feature, heat is retained in the room. Plastic seals have an affordable price, but during their installation there is a possibility of some difficulties arising, since the material must be fixed into the groove. Taking this into account, you need to select a product in accordance with the structural features of the door on which it will be installed in the future.

Rubber

They are the ones most often used for insulating metal doors, and due to their versatility, the material is used to cover not only entrance doors leading to the entrance or to the street, but also interior door structures. It can be fully fixed on products made of wood, chipboard and any metal. Rubber seals come in two varieties. In the first case, they have an adhesive base, and in the second, the products are manufactured for installation in a door profile specially prepared for them. There are door designs on sale that are initially made with the appropriate inserts, which are necessary for further installation of the seal.

One of the main advantages of rubber materials is their wide variety, since they are manufactured not only in the form of bundles of different diameters, but also according to the principle of tubular products with an internal cavity. In addition, when installing such a seal, it is possible to significantly increase the thermal insulation and sound insulation performance. The material withstands prolonged exposure to sunlight, significant temperature fluctuations, as well as other negative environmental influences. Rubber seals are also characterized by a long service life, low cost, water resistance and high elasticity, so you don’t have to worry about cracks.

Important! When purchasing, it is imperative to pay attention to the shelf life of the material, which loses its elasticity over time.

Clean frosted glass without damaging the coating

Frosted glass is often found in the interior: it is used to make kitchen tables, doors in cabinets, or, for example, they are inserted into interior doors. Of course, sooner or later fingerprints will appear on them, which are not so easy to clean. Very often such contaminants are encountered in homes where there are small children.

Reasons why stains are difficult to remove

It is much more difficult to remove greasy handprints from such glass than from ordinary glass. The main difficulties are as follows:

- they have roughness (unlike glossy ones), so they are more difficult to clean;

- During manufacturing, they are coated with a special coating that gives them a matte finish, so if you clean the dirt that appears incorrectly, you can damage it.

Methods for cleaning frosted glass from greasy marks

Since such surfaces are very different from ordinary ones, it will not be possible to wash them using the usual methods used for washing glossy glass interior items. There are several methods for cleaning frosted glass from stains without streaks:

- remove greasy stains using:

- chalk mixture (mix a glass of water and 3 tablespoons of chalk);

- acetic acid (add a spoonful of vinegar to a glass of water);

- window cleaners (they are best used to wash fresh prints).

ammonia (dissolve 1 spoon of ammonia in a liter of water);

In order to clean frosted glass from stains, you need to moisten a cloth in one of the above solutions and wipe it on both sides, then wipe it dry. Sebaceous stains need to be treated most carefully. You can wash glass in this way using a special rubber spatula or suede for cleaning;

Execution color

Today there are products on sale in a variety of colors, thanks to which you can freely choose the most compatible shade with the door and frame on which the seal is attached. White material can be preferred when there is a need to insulate door structures made of plastic of a similar color.

The black rubber seal is great for protecting entry doors from cold penetration and extraneous noise. In general, for metal structures it is optimal to choose a material of dark shades and colors that go well with it.

For colored metal-plastic doors, you can choose a material of a similar color and even purchase it from the same manufacturer that produces them. Transparent silicone sealing strips combine well with door structures and are visually less noticeable on their surface.

Useful tips for choosing a seal for a metal door

When purchasing material, it is recommended to take into account a number of the following nuances:

- When giving preference to self-adhesive tape, it is imperative to check the shelf life of the adhesive layer, which should contain small particles of fiberglass.

- A rubber seal should be selected with medium hardness, because if it is very soft, it will quickly become unusable, and if it is too hard, it will prevent the door from closing.

- It is better to give preference to a black seal, since in many cases products of a different color have a shorter service life.

- To ensure the sealing qualities of the material, you need to lightly press on it. Ensuring complete tightness during further use will be indicated if the seal then quickly acquires its original shape.

- When selecting a material that requires additional gluing, it is advisable to use high-quality silicone glue.

- It is best to avoid using foam rubber seals when insulating metal doors. If they are opened and closed regularly, such tapes deteriorate extremely quickly and need to be replaced.

Having figured out how to choose a seal for a metal entrance door, you will be able to choose the most suitable option and avoid purchasing low-quality material, which very soon may become unusable, losing its positive qualities.

Video:

Popular products for cleaning frosted glass on doors

Today it is fashionable to use glass surfaces in the interior of a room, in furniture or for decorating doors. Frosted and tinted glass is especially popular.

However, over time, unpleasant external contaminants appear on the glass. It is enough just to grab such a door with your hand, and stains can no longer be avoided. Therefore, let's look at how you can efficiently clean frosted glass.

Door with decorative design

Difficulties that may arise

Care may be accompanied by some difficulties. The fact is that such material undergoes special processing during manufacturing to obtain a unique surface. Therefore, many are concerned about the question of how to clean the stains that have appeared on the doors in the bathroom or other room without damaging the top layer of the material.

Attention! Even taking into account the fact that indoor glass of this type is difficult to clean, you still shouldn’t despair, since there is a way out of this situation.

Methods and means for cleaning

To make your task easier, try to wash at the moment when contamination is first detected.

How to clean fresh stains? Here is a suitable cleaning composition:

In one of the selected prepared compositions, a foam sponge is moistened and the glass is treated on one and the other side. If you can’t clean it the first time, repeat the procedure. After the glass has been washed well, wipe it with a dry cloth.

Dishwashing gel is also suitable and will do an excellent job of removing greasy stains and stains. It does not contain abrasive inclusions that can cause damage.

Dishwashing liquid

However, we note that if the contamination has been on the surface for a long time, then it simply cannot be removed using this method. In this case, you will have to use acetone or an alcohol solution.

When using such products, it is recommended to act as carefully as possible, making sure that the substance does not come into contact with moving elements or the seal. If such a nuisance does occur, you should immediately remove the product with a rag.

But it happens that the above methods turn out to be powerless, then you will need to move on to radical actions. A steam mop will help get rid of stubborn dirt. Using this device, treat the surface and then wipe it with a soft cloth.

Steam Mop

In order not to waste a lot of time and effort on removing old dirt, it is recommended to wipe it as often as possible using a suede cloth.

Simple tips for proper care

To make a door leaf with glass look attractive for a long time, follow a few simple tips and recommendations:

- Wash exclusively with cold water; remove any remaining moisture after washing using a rag or napkin;

- Starch can be applied to add shine and maintain a clean appearance. To prepare the solution, dissolve 1 tbsp. starch in 1 liter of running water;

- If the glass is exposed to direct sunlight, it is recommended to wash it in the evening to avoid streaks.

Important! When removing grease stains, it is best to apply the pre-prepared composition and only then distribute it evenly.

Methods that are strictly prohibited to use

In order not to spoil the texture of the glass, it is worth learning about the products that are not allowed to be used in your work.

- Abrasive compounds - along with dirt, they can also remove a layer of factory coating;

- Compositions containing silicone, acids and alkalis will destroy the surface.

A scraper or ordinary newspaper does not guarantee the desired result. In this way it is difficult to even remove excess moisture.

Remember that with regular care you will not have problems removing difficult stains. If you listen to the rules outlined, you can admire the magnificent door with an unusual design for a long time.

Cleaning methods are shown in the video.