SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

One of the important elements of a window opening, which improves its appearance by covering the installation joints, is the window sill. It can be made from different materials. However, the most popular is plastic, which is due to the widespread use of metal-plastic windows. Installation of a plastic window sill consists of several successive steps, the implementation of which will ensure the achievement of optimal performance.

The window sill is an important element of the window opening

Distinctive features of plastic window sills

Metal-plastic windows have long gained credibility. They are very popular among consumers due to the fact that they are characterized by high performance characteristics, are easy to install and have a long service life. After replacing the window, the slopes and window sill are immediately installed.

Thanks to the presence of stiffening ribs, the surface of the window sill is very durable

A metal-plastic window is a universal product that can be matched with different window sill options, which are selected in accordance with the stylistic goal. The most common option is plastic products. This design is best combined with the material of a modern window, creating a single composition with it.

The plastic window sill is characterized by distinctive advantages. The product is resistant to moisture, sunlight and temperature changes, and is not prone to rot, mold or corrosion. The surface does not deform and does not change its original shape and appearance. The material is completely safe for human health, is durable (due to the presence of stiffeners), reliable, and resistant to chemical influences. It has high thermal insulation properties, which is due to the presence of air chambers in the window sill structure.

The product is lightweight, which ensures easy installation of the PVC window sill, while it does not shrink during further use. The surface does not require painting or other treatment options to prevent possible rotting or corrosion. She is easy to care for. Plastic window sills are characterized by their low cost compared to other materials.

Despite its advantages, plastic window sills have their drawbacks. If used carelessly, dents or holes may appear on the surface of the product, which is a consequence of the fragility of the product. If there is a glossy coating, scratches may form on it, which will cause an unsightly appearance.

Plastic window sills are resistant to moisture, sunlight and temperature changes

Important! A plastic window sill can become deformed when exposed to high temperatures, so do not place a hot kettle or pan on the surface.

Insulation

To insulate the window sill, instead of foam (or together with it), an additional layer is laid under it, which will protect the slab from the cold. The most commonly used is polystyrene foam or a type of insulating wool (mineral, basalt, fiberglass).

Window sill insulation is necessary in order to reduce temperature changes in the slab, as well as reduce the formation of cold bridges. In some cases, this procedure is necessary to prevent the formation of condensation, mold or mildew.

This article explains more about the insulation procedure.

Which plastic window sill to choose: product types

Before installing a window sill on a plastic window, you need to select the type and size of the product. The most budget option is a surface covered with PVC film. However, such a window sill does not tolerate temperature changes and quickly absorbs dust and dirt, which leads to the loss of its original attractive appearance.

The CPL-coated laminate product is manufactured by pressing paper sheets impregnated with melamine resins. This window sill with a multi-layer base is characterized by resistance to temperature changes and chemical influences.

Most often, do-it-yourself installation of a PVC window sill with EPL coating, which has high strength and performance characteristics, is carried out. Products are produced by extruding plastic material through extrusion holes to obtain the required shape.

Window sill made of laminated paper with CPL coating is resistant even to chemical attack

The internal space is divided into several chambers with vertical and diagonal stiffening ribs, which ensures strength, rigidity and reliability of the structure, which does not bend or break. At the same time, the thermal conductivity of the product also increases.

The surface, thanks to the presence of an antistatic coating, does not absorb dust and dirt. This window sill is available in a wide range of colors, which allows you to choose a product that matches the specific interior of the room.

Texture, color and design of a plastic window sill

Depending on the type of coating, a plastic window sill can be matte, glossy or laminated. The first type of product can fit into any interior. The surface can be painted in a variety of colors. A matte window sill brings a feeling of coziness and warmth to the environment, but such a surface is prone to absorbing dust and dirt.

Important! If the matte surface is accidentally damaged, it can be restored using a special product.

Plastic window sill can be matte, laminated and glossy

A glossy product has a more attractive appearance. The surface has antistatic properties, so dirt and dust do not accumulate on it. The product is easier to care for. However, the surface is susceptible to mechanical stress; small visible scratches quickly form on it, which worsen its appearance. In addition, the glossy window sill cannot be restored.

Laminated window sills are covered with a special film, which gives the products texture, increased strength and durability. To obtain a white product, one layer of film is applied. The colored window sill has a two-layer coating that contains dye. The price for installing a plastic window sill of this type is the highest and starts from 1100 rubles. per linear m.

There is a separate type of product in the form of a wenge window sill, made from a mixture of PVC and wood flour. The unique production technology allows us to obtain a durable, scratch- and UV-resistant product. The price for installing a window sill of this type starts from 1,300 rubles. per linear m.

The plastic window sill can be made in white, colored or wood-look. The latter option finds its application in wooden houses. It can also be used in tandem with wooden windows. However, this design, unlike a wooden window sill, is characterized by resistance to moisture, no processing for further use, and a long service life. The “wood” imitation is achieved by using the appropriate laminated film.

The colored plastic window sill has a two-layer coating containing dye

Important! The use of such a coating in window sill manufacturing technology makes it possible to obtain a product that imitates natural stone in the form of marble or granite.

Plastic window sills are produced in lengths up to 6000 mm, widths of 100-600 mm in increments of 50 mm, and 600-1000 mm in increments of 100 mm, which directly affects the price of installing a window sill on a plastic window. The height of the product reaches 18-22 mm.

Components needed when installing window sills and slopes with your own hands

To install a window sill and slopes on a plastic window, it is not necessary to have certain skills and abilities. Even a novice master can handle this. To achieve a good result, an important step is the selection of the necessary components.

When installing a PVC window sill, you will need to purchase not only the slab of a certain type, but also connecting elements, as well as a double-sided end cap. The last element is represented by a strip with two spouts, used for decorative framing of the end sides of the window sill. The plug is divided in the middle, fixing one part to the right and the other to the left of the slab. To join the window sill at an angle and connect it along its entire length into one solid structure, connectors are used.

To install the window sill and slopes, you will need to purchase connecting and fastening elements

Slopes are used to frame the side elements of the window opening. They cover the mounting seams of the frame with the opening and give the window a complete, aesthetic appearance. The most common option is plastic slopes, which are characterized by strength, reliability, good thermal insulation properties, low maintenance and quick installation. The video “Installing slopes and window sills” will allow you to familiarize yourself in detail with the selection of elements and installation conditions.

To protect the window frame from the negative influence of the environment, it is necessary to install a drip lining on its outside. The structure can be made of aluminum, plastic or metal. The second option is the most widespread. Metal castings are the most inexpensive and short-lived, since they have a low level of resistance to the negative influence of atmospheric conditions.

Aluminum ebbs are more durable, have reliable protection from mechanical damage, and thanks to a special coating on the surface, they absorb the noise of raindrops.

Characteristics

There are no standard window sills, since even in a typical house, the length of the slab for different openings can differ by up to 10 cm. The width also differs for different windows, since different heating equipment may be used in different rooms, the design may change, or a PVC frame of a different width may be installed. .

Therefore, to install the window sill, individual measurements are required. But the fabric is most often made from a standard board, which has a certain size.

Let's look at the example of PVC slabs:

- the length of a typical PVC panel can be from 150 to 600 cm. For a window sill, it is cut to the required length;

- the width of the blade varies from 100 to 700 mm, and the typical size changes in increments of 50 mm (100,150,200...700);

- PVC window sill thickness – from 13.5 to 20 mm in the thin part and up to 40 mm in the presence of capinos;

- the internal space of such a slab has cavities (chambers) similar to a window profile;

- The appearance of such a slab depends on the chosen coating. It can be smooth, textured, any color or with a different pattern, for example, imitation wood.

Methods for installing a window sill on plastic windows

Before installing a plastic window sill, you should study possible methods of installing the product.

All installation options are very reliable, they differ only in the way the window sill is fixed under the window frame

The oldest option for installing a window sill on a plastic window is to fix the product using a special compound. Today, this method is used extremely rarely due to the emergence of more convenient and reliable methods.

The easiest way to install a PVC window sill with your own hands is to use self-tapping screws. First, holes are made in the window frame into which hardware must be screwed. For greater tightness, the joints should be treated with an acrylic-based compound. To achieve maximum rigidity and reliability of the structure during installation, special gaskets are placed under it, and the resulting gaps are filled with polyurethane foam.

The window sill can be installed using spring metal brackets. These fasteners are fixed to the stand profile using self-tapping screws. Then the PVC plate is installed in the groove that was formed between the bracket and the window frame.

There is an option for installing a plastic window sill yourself, which does not involve the use of fasteners in the form of brackets and screws. The plate is installed in place. Wooden wedges are driven under it until its surface is pressed as tightly as possible against the window frame. In this case, it is necessary to constantly check the level of the structure. The window sill should have a slight slope towards the room to prevent condensation from getting onto the frame.

After installing the window sill, the cracks must be sealed with silicone

All free space that has formed is filled with polyurethane foam. This type of installation is the longest, but it can be considered the most reliable.

Important! After filling the space under the window sill with polyurethane foam, it is necessary to install weighting on the slab in order to create the necessary resistance when the material hardens.

All window sill installation options have their pros and cons. They differ only in the way they fix the product under the window frame, and all other stages are identical.

How to install a window sill: preparatory stage

How to install a window sill correctly? First of all, you need to prepare the tools necessary to ensure maximum efficiency of work, and components that will make the installation process simple and convenient.

You can cut a plastic window sill with either a jigsaw or a grinder

To install the window sill you will need the PVC product itself, a corner, a building level, a marker with a tape measure, sealant for joints and seams, foam for filling the gaps between the slab and the wall, a jigsaw, a hammer drill, a screwdriver, screws, and self-tapping screws.

Many people are interested in the question of how to install a window sill if the window is already standing. First of all, the necessary measurements are taken. Carrying out this stage is extremely important, since the strength and appearance of the future structure will depend on the correctness of its implementation.

Related article:

Dimensions of plastic window sills: how to choose the right option

What parameters are considered standard? Pros and cons of using PVC material. What to look for when purchasing, how to take measurements.

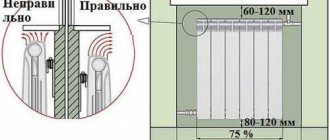

The length of the window sill should be several centimeters greater than the distance between the side slopes. This is explained by the fact that the product is inserted 2-3 cm into the grooves made in the wall. The width of the product is selected taking into account its protrusion above the radiator, which is installed below. This value should not exceed 8 cm. Otherwise, hot air will not rise to the window from the radiator, which will cause condensation.

The distance between the window sill and the stove should also not be less than 10 cm. Otherwise, a closer location will cause air circulation problems, which will worsen the microclimate in the room.

The width of the window sill is selected taking into account the protrusion above the radiator

How to install a plastic window sill: taking measurements and preparing the window opening

Before installing a plastic window sill, the product is prepared according to the measurements taken. The required length and width are marked on the plate using a marker. Then, using a jigsaw, the PVC structure is cut. Work must be carried out in safety glasses and work gloves, since plastic is a very fragile material, so small particles can fly out when cutting it intensively.

The cutting process can also be carried out using a special hacksaw or grinder. In the first case, the process will be lengthy. Using a grinder, you can achieve perfectly smooth edges of the product.

Important! When making cuts, do not put excessive pressure on the slab, as this can lead to cracks and chips in the product.

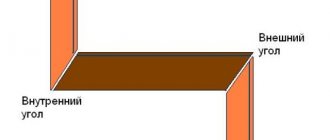

Before you properly install a plastic window sill, you need to prepare a seat for it. Since the structure is mounted with some penetration into the side niches of the opening, it is necessary to make appropriate grooves for it on both sides in the wall. The process is performed using a chisel and hammer. The resulting openings are thoroughly cleaned of debris and primed.

Before installing a plastic window sill, it must be cut according to the measurements taken.

After this, you need to attach special spacers or wedges to the window frame, which are fixed for reliability using gypsum mortar. The installation elements must be positioned in such a way that the required inclination is ensured. Then you install the window sill on the seat with your own hands and check how smooth and tight it becomes. If necessary, the edges of the structure are trimmed.

Important! The window sill should have a slope towards the room of 1-2°.

The process of installing a window sill on a plastic window with your own hands

As mentioned earlier, there are several ways to fix the product when installing a plastic window sill. At this stage, the most popular and reliable option is being considered, which involves the use of wooden spacers and polyurethane foam.

How to install a window sill without a support profile? The product is mounted on a prepared seat. Wooden beacons are installed under the structure with a pitch of 80 cm. They ensure the horizontality of the structure, which is controlled by the building level.

If you install a window sill without a support profile, you will need to install wooden beacons

Under the slab at the front end there are wooden blocks, the distance between which should be about 50 cm. It is necessary to ensure that the load-bearing elements do not extend beyond the plane of the wall. The distance between the wooden blocks and the side walls should not exceed 10 cm. Before installing the window sill, the horizontal position of the window sill is checked again. If the value does not correspond to the previously obtained result, the pads are adjusted in thickness.

To pre-fix the window sill, the cavity between the slab and the concrete surface must be filled with polyurethane foam, a can of which is placed in warm water a few minutes before starting work. To prevent the binder from lifting the window sill during expansion, a weight is placed on the slab. Next, all free space is thoroughly filled with foam.

Important! Do not overload the structure to avoid deformation of the window sill.

In this position, the window sill must be left alone for 2-3 days. Excess foam should be removed with a utility knife. If possible cracks are found, they are filled with acrylic sealant. At the end of the installation process, to give the structure a complete look, special plugs are mounted on its ends with glue. After installing the window sill, you can begin installing the slopes.

The window sill should have a slight slope towards the room

Dismantling the old structure

If you need to replace the window sill, you will need to remove the existing tab. At the first stage, the slopes are dismantled.

Further actions are carried out taking into account the method of installing the old window sill:

- When disassembling a PVC panel, first remove the side plugs. Next, we open the decorative strip and embroider the joint filled with sealant. Remove foam from the support strips, clean the places where the edges are attached. After this, you can remove the window sill block.

- When the structure is fixed with foam plastic, it is not easy to disassemble. The board is cut with a jigsaw or angle grinder. After this, the parts are removed from their fastening points.

- If a special profile was used during installation, the road lining is removed and the screws are unscrewed from the mounting bracket.

Installing a plastic window sill on the balcony

Modern balconies and loggias are actively glazed through the use of metal-plastic double-glazed windows. This process is accompanied by the installation of a PVC window sill. The installation of a window sill on a balcony is mainly carried out at the time of glazing. However, this can be done later with your own hands. How to install a plastic window sill with your own hands so as not to regret the work done?

How to install a window sill on a balcony if the window is already there? To do this, you need to prepare metal brackets. They are needed if it is not possible to install the structure under an existing window. Metal brackets should be secured to the parapet using anchors. These elements will help strengthen the window sill, which will lead to an increase in payloads.

The distance between the metal brackets should be no more than 1 m. Using a building level, check the horizontalness of the fastenings. Before fixing the holders, to simplify the installation process, the thread is tensioned strictly horizontally.

After the brackets are completely fixed, the window sill is installed on the loggia or balcony. It is fixed at the bottom of the slab using self-tapping screws. After completing the installation process, the structure is treated with sealant. The procedure is performed to get rid of cracks that are formed as a result of uneven edges. You can learn more about the installation process by watching the video “Installing a plastic window sill.”

Polyurethane foam is not used to fill voids after installing the window sill on the balcony

Important! When installing a window sill on a balcony, unlike installing it in a window opening, polyurethane foam is not used to fill the voids.

What tools and materials will be needed?

Depending on the material of the window sill, the following tools and materials may be needed to install it on a metal-plastic window:

window sill plate;- end caps;

- hammer drill or drill with a set of drills;

- Bulgarian;

- chisel;

- hammer;

- tape measure and pencil;

- level;

- polyurethane foam and a gun for it;

- PVA glue;

- acrylic sealant;

- wooden blocks;

- electric jigsaw or hacksaw.

On a note. For a tighter fit of the window sill to the frame, polyvinyl chloride gaskets, as well as perforated plates for securing the window sill, may be useful.

Procedure for replacing a plastic window sill

Over time, a PVC window sill may become damaged or lose its original appearance as a result of abrasions and ingrained dirt. In this case, it is important to know how to change the window sill.

Before removing the plastic window sill, preparatory measures are carried out, which are determined by the type of slopes. They can be monolithic, that is, installed using plaster, or panel-based (made of PVC plates or sandwich panels). The window sill is mounted under the slopes, so before it is removed, they must be partially or completely dismantled.

When using plastic slopes, the profile used to frame the corner is removed. Then the finishing panel is carefully opened, for which the sealant seam is first opened. Next, the mounting foam is removed from the plane of the support rails, and the junction of the edge of the structure is cleaned. This is necessary for easy removal of the window sill.

Before removing the plastic window sill, partial dismantling of the slopes is performed

If the slopes are finished with plaster, to replace the window sill of a plastic window, two horizontal lines should be drawn along the edges of the opening with a distance of 25 mm from the top of the window sill. According to this marking, trimming is carried out using an angle grinder with a diamond wheel. The process is carried out with extreme care to eliminate the possibility of damage to the frame. Using an angle grinder, an undercut is made along the plane of the wall, the depth of which is equal to the width of the protrusion of the structure beyond the slope.

Helpful advice! The installation depth of the window sill usually reaches 30-40 mm, so to dismantle the slopes you will need a circle of 180 mm.

Since the slab, with the modern installation method, is not attached to the window frame or stand profile, but is fixed using polyurethane foam, simply tearing off the product will be quite problematic. Before removing the window sill, the structure must be cut into fragments using a jigsaw. If the slab is set on cement mortar, an angle grinder should be used to separate the structure. Next, each element is removed from the seat.

If the window sill was fixed to the delivery profile, then the ebb from the outside of the window is removed. It is necessary to unscrew several screws from the profile.

If the window sill was fixed with foam during installation, tearing it off will be quite problematic

Width

If the thickness of the walls allows, the window sill can be used for relaxation or as an additional workplace, a laptop table, an extension to the tabletop, etc. In this case, the width of the panel is made as large as possible (up to 1000 mm).

If there is a heating radiator under the window, the protrusion should be such that warm air rises freely. That is, the battery remains at least half open.

Another limitation on the width of the window sill can be the protrusion of the cornice from the wall. Ideally, the curtain is located at a distance of about 2 cm from the edge of the panel.

In this way, it acts like a screen: it directs hot air onto the glass. In this case, the glass does not fog up. If the protrusion of the window sill from the wall is more than 5 cm, it is recommended to install reinforcement corners from below.

Methods for restoration and repair of plastic window sills

With prolonged use, the slab loses its original appearance. The surface becomes very dirty, scratches and cracks may form on it, marks from hot objects, flower pots, stains from exposure to chemicals and sunlight.

First of all, the question arises of how to clean stains from a plastic window sill. To do this, you can use conventional detergents and cleaning products, but they do not always bring the desired result. In this case, it is not necessary to change the design to a new product. You can explore several ways to update a plastic window sill.

The PVC product is covered with a protective film, which turns yellow or peels off over time. To eliminate such a defect, you can use a special wax for laminate flooring or a solvent-based cleaner for plastic. The surface is coated with the selected composition and then wiped with a dry soft cloth.

An excellent way to update a plastic window sill is restoration using a PVC lining

To restore a window sill that has small cracks and scratches, you can use specialized mixtures with a plastic effect. They are sold in powder form. After drying, the material acquires the same properties as plastic. A thick putty mixture is prepared from powder and water, which is used to seal all visible defects.

Helpful advice! To achieve maximum effect, it is recommended to use a primer instead of water when preparing the finished composition.

The prepared solution is applied to visible damage. After this, you should wait 10-15 minutes and sand the sealed areas with sandpaper, and the surface can also be polished with a special product for plastic.

To repair deep scratches, it is better to use liquid plastic, which penetrates the pores of the material and sets quickly. To ensure that the restored surface has a uniform texture, it can be additionally covered with self-adhesive decorative film.

To eliminate minor defects, you can use a special wax for laminate flooring.

How to make a window sill from an old slab and give it an aesthetic appearance

A simple and affordable way to restore a plastic window sill is to cover the surface with laminated film. The material is presented in a wide range of colors, in a single color design, and it can also imitate a variety of textures.

The surface is pre-leveled using a putty mixture. The film of the required size is cut out with a margin of 3 cm at the edges. After removing the inner layer, the self-adhesive product is evenly distributed over the entire surface, eliminating the formation of blisters or waves.

Another option for solving the question of how to update a plastic window sill is to restore it using a PVC overlay, which can be used for slabs no more than 6 cm thick. This is a simple and economical way to quickly solve the problem of a swollen or cracked window sill. The lining is made of pure polyvinyl chloride, which is characterized by strength, moisture resistance, and resistance to ultraviolet rays.

Restoration begins with filling large cracks with glue, after which it is necessary to degrease the surface and spread it with an adhesive composition. An overlay of the required size is applied to the window sill and pressed with a weight. The surface must dry for 6 hours. The end edge is heated with a hair dryer and bent to the shape of the window sill.

Important! When using a glossy or laminated overlay, heat treatment is not used, as the product will lose its attractive appearance.

Installing a window sill under a plastic window is a simple task. However, to achieve a good result, it is important not only to choose the right product, but also to follow a certain algorithm for carrying out installation work, which will be the key to high-quality, durable and aesthetic window design.

Constructions

For non-standard windows and walls, in addition to classic rectangular window sills, you can purchase or manufacture products of unusual shapes:

- arched;

bay windows;

hedgehog - almost all complex shapes;

Bar counters are appropriate under a kitchen or dining room window; they are usually a continuation of the window sill and are made of the same material as the kitchen countertop.

Wooden window sills made from massive rough boards (with uneven edges) look original.