Houses are different, and they need to be insulated in different ways.

The use of various technologies and materials in construction leads to the fact that it is impossible to give a universal answer to the question: what to consider when attaching penoplex to the walls of a house? Methods for fastening and preparing surfaces have been developed for different surfaces and operating conditions. You need to know this in order to control those who insulate the house. And even more so for those who insulate the house with their own hands, using their potential.

Houses can be made from stone and wood building materials. Already at the stage of surface preparation, peculiarities in the work begin to appear.

When preparing concrete and brick surfaces, you must:

- clean the walls from dirt, deposits, paint, fuels and lubricants, and then remove dust;

- treat the areas where the fungus is spreading with copper sulfate (antiseptics);

- remove efflorescence on brick;

- clean and seal cracks in the insulated wall;

- apply a deep penetration primer;

- smooth out unevenness with putty;

- apply a deep penetration primer after filling.

Preparing the tree is much easier. It is treated with impregnations that prevent wood rotting. Wall material such as oriented strand board or thermal wood may not be treated. Then a base of impregnated timber is installed, which ensures ventilation of the facade.

A few words about the material

Before starting to describe the technology of thermal insulation work, you should understand the main characteristics of the material itself. Penoplex is the commercial name for extruded polystyrene, a synthetic polymer insulation.

This heat insulator is available in panels of different thicknesses and has the following properties:

- Significant coefficient of resistance to heat transfer . If you are planning to insulate walls from the inside, Penoplex is one of the most effective materials in terms of heat preservation.

- High mechanical strength , which distinguishes this modification of polystyrene from other brands of insulation. The compression resistance of the panel is about 25 t/m2, and therefore insulating the walls from the inside with Penoplex provides a fairly strong basis for plaster and putty.

- High-quality sound insulation . Thanks to their porous structure, wall panels absorb loud sounds well.

- Non-hygroscopic . The material does not get wet and does not allow moisture to pass through, including water vapor. Indirectly, this is also the reason that Penoplex does not become infected with bacteria and fungi.

The disadvantages of a heat insulator include toxicity when ignited, as well as relatively high cost. The price of Penoplex is significantly higher than the cost of polystyrene foam used for similar purposes, so this material is unlikely to be suitable for the most economical insulation.

General installation rules

Correctly attaching penoplex is very important to obtain a high-quality layer of thermal insulation. First of all, you need to secure the starting bar. It can be made independently (we use a wooden beam), or factory-made from perforated metal. In the second case, it is better to purchase a strip in accordance with the width of the insulation, complete with the required number of corners (the corner can be external or internal).

Installation of the strip is carried out as follows. A horizontal line is drawn along the perimeter of the building according to the level. To fasten the “starter” it is better to use dowels. Its use will prevent the insulation from sliding down and maintain the “geometry” of laying the insulation, which is especially important when doing work yourself.

The side of the penoplex on which the adhesive composition will be applied must be rolled with a needle roller to create roughness. The slabs must be installed from bottom to top with an offset of half a slab in each horizontal row.

During installation, the plates are pressed against each other as tightly as possible. For a more durable and “warm” connection, the second row is inserted into the grooves of the first. In order to save adhesive composition, it is possible to seal the joints with polyurethane foam upon completion of installation.

Main Differences

Since almost every developer, in the process of constructing a residential building or outbuilding in our climate, is faced with the need to insulate the house, before the heating installation stage, or even earlier, he has to decide which insulation is better: polystyrene foam or mineral wool. Despite the fact that these two insulation materials are used most often in the construction process, there is a big difference between their main characteristics. Due to its sealed structure, polystyrene foam does not have the ability to remove air masses outside. Therefore, if we compare whether polystyrene foam or mineral wool is warmer, the answer will be in favor of polystyrene foam. Thanks to the closed cells, warm air is retained inside the slab and is not vented outside, unlike porous stone wool.

Vapor permeability

Vapor permeability is the main difference between these two types of thermal insulation. For expanded polystyrene it ranges from 0.13 mg/(m*h*Pa) to 0.03 mg/(m*h*Pa). Stone wool indicators range from 0.4 mg/(m*h*Pa) to 0.6 mg/(m*h*Pa).

Comparative characteristics of insulation materialsSource moybalkon.com

This clearly demonstrates that mineral wool insulation removes vapors much better. During the operation of the insulation in the heating mode of the house, vapors are retained on those layers of the wall pie that have the lowest vapor permeability. This means that when using mineral wool alone, the dew point will most likely be located inside the insulation, which will lead to moisture accumulation inside the insulation. If the insulation becomes damp under the influence of vapors, this will lead to a significant deterioration in its properties. Therefore, it is necessary to install a vapor barrier layer inside the house on top of mineral wool. While polyurethane foam thermal insulation itself is non-hygroscopic and does not require the installation of additional membranes.

Fire safety

When polystyrene foam or mineral wool are compared in terms of flammability, thermal insulation made from mineral wool wins undisputed primacy.

Consequences of neglecting fire safetySource avatars.mds.yandex.net

All types of polystyrene foam insulation quickly ignite and maintain flammability. Moreover, when burning they melt and fall off in burning drops. Stone wool can withstand high temperatures up to 1000 degrees, does not ignite or burn, which makes its use more preferable in rooms with a risk of high temperatures.

Price

When deciding whether polystyrene foam or mineral wool is better for insulating a house, one cannot ignore the issue of price for the material. Currently, for one cubic meter of stone wool you will need to pay about 2.5 thousand rubles

The same volume of polystyrene foam insulation will cost a little more, and will cost 2.6 thousand. This is a little more expensive, but it is also worth considering the price of vapor barrier, which will cost approximately 15 rubles per square meter.

Choosing insulationSource scientificarab.com

Operation and installation

Installation of polystyrene foam thermal insulation is not associated with the release of airborne particles and dust, unlike stone wool, which generates a lot of dust when cutting. To install EPS layers, you do not need to wear personal protective equipment such as goggles and a respirator, which makes the installation process simpler and more comfortable. It is worth noting that when joining polystyrene foam slabs, there will be a small distance between them, or in other words, a cold bridge. To avoid heat loss in such places, it is necessary to carefully foam each of them. While when joining mats of mineral wool insulation, such gaps do not arise. The mats fit tightly to each other, leaving no gaps or cracks.

Mastic: the basics

Bitumen-polymer mastics are one of the most common materials due to their price and ease of use. This technology has found wide application in insulating the plinths of buildings operating in extremely unfavorable conditions of constant humidity, the presence of reagents, and mechanical stress. They provide quick and reliable installation of penoplex with stable resistance to harmful external factors. Mastics are sold in tubes, ready for use. The tube is installed in the sealant gun.

The composition is applied around the perimeter and pointwise to the center (when laying the second one and then next to it, it is also applied to the grooves). Then the installed insulation is pressed for a short time. The glued insulation can be repositioned within one hour.

Specifications

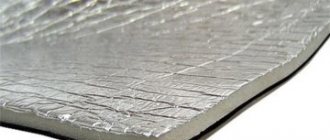

Fine-cell structure of expanded polystyrene

Extruded polystyrene foam Technoplex XPS is distinguished by a homogeneous structure with closed gas cells. The number of closed pores is almost 100%, which ensures minimal water absorption and stable thermal conductivity characteristics. Graphite nanoparticles in the material give it a grayish tint and increase the strength of the slabs.

Technical characteristics of Technoplex insulation:

- thermal conductivity index – 0.032-0.037 W/(m*K);

- water absorption – 0.2%;

- vapor permeability – 0.014;

- density – 26-35 kg/m3;

- compressive and bending strength – 100-150 kPa;

- operating temperature – from -70 to +75°C;

The low weight of the insulation simplifies transportation and installation; the overall weight of the building structure increases slightly. High resistance to deformation allows the slabs to be used in areas with high loads. They are effective in arranging all types of roofs (pitched, flat), and external insulation of foundations subject to soil pressure.

Dry mixes: simply reliable

The use of dry mixtures allows you to glue penoplex to concrete and brick without much expense or hassle. The dry mixture is added to the water in proportions determined by the instructions for use. The solution is mixed using a drill mixer attachment operating at the lowest possible speed. The resulting mixture is applied to the surface using a notched trowel; the grooves are filled with the trowel. The insulation, installed in place, is held for one minute.

When attaching penoplex to a concrete wall and brickwork, a cement-based mixture is used as the main fastening element.

Laminate swelling is another problem that can be solved

Disassembling the laminate and replacing the dies or even the waterproofing layer may also be necessary if swelling appears on the surface of the coating after it has been laid. Repair of the flooring with replacement of individual elements will be necessary if the defect arose due to a large amount of water spilled on the floor.

If there was no excess moisture on the laminate, then most likely the issue was a violation of the installation technology. To remove swelling on the laminate in the second situation, remove the baseboards and see if you or the craftsman who designed the floor left the necessary expansion gaps when the material expanded. The tiles should not lie flush against the wall; there should be a gap of 1-1.5 cm. If there is none, do it, and the laminate will lie flat.

Adhesive foam: quick installation

Adhesive foam allows you to very quickly insulate smooth stone surfaces. Thanks to the high adhesion of the adhesive composition, smooth slabs are perfectly fixed on flat concrete surfaces without subsequent displacement. The application technology is as follows. Adhesive foam is applied around the perimeter and in the middle of the slab along the long side using a foam gun. With the grooves filled with glue, the plate is pressed for 30 seconds. The average setting time for adhesive foam is 20 minutes. Further work with penoplex, installation on dowels and grouting is possible after 2 hours.

Disc dowels: long lasting strength

The use of disc-shaped dowels is justified in the case of a large insulation area or uneven façade surfaces. For fastening to dowels you need: a hammer drill (impact drill), a drill of the appropriate diameter and length, and a hammer. Holes are drilled with a recess of 50-60 mm into the base. The holes are filled with polyurethane foam. Then the dowel is driven in with a hammer so that the dowel fungi do not protrude above the surface of the slab. It is best to use dowels in combination with metal screws to increase the reliability of the connection. Installing 5 dowels per slab is sufficient. Adjacent sheets are fastened with one dowel. It must be installed in the seam between the slabs.

Liquid nails: will be a bit expensive

Liquid nails can be used to attach thermal insulation to a well-leveled and primed base. Glue is applied using a sealant gun pointwise around the perimeter and center of the sheet. Fastening is done by briefly pressing it to the surface.

Expensive adhesive significantly increases installation costs. Even with high-quality bonding to the surface and ease of use, the technology of using “liquid nails” is economically feasible for small areas of insulation.

Self-tapping screws: cheap and cheerful

Fastening with self-tapping screws using a screwdriver is permissible when insulating a wooden wall over a previously installed sheathing. In this case, it is recommended to install a washer under the screw head to avoid surface destruction and increase the reliability of fastening.

The most widely used method of fastening is the use of bitumen (adhesive) compounds and disc dowels. [flat_ab >

The resulting insulation layer is airtight, able to withstand large mechanical loads and has an increased insulation coefficient.

After installing the insulation, a reinforcing mesh is installed followed by cladding.

Now you don’t have to think: “How to glue penoplex? How to mount it correctly? The use of materials specifically designed for penoplex to the walls will allow you to avoid unnecessary waste of effort, money, time and get a durable layer of thermal insulation made by yourself.

Hello to all readers!

With you, as always, Sergey Zlobin, the author of this blog. Today I want to consider a small but relevant topic for many: how to attach penoplex to the wall. I think there is no need to explain what penoplex is, what properties it has and what it is used for. By the way, it is also called extruded polystyrene foam, abbreviated as EPS.

Let's get straight to the point: let's talk about all the methods of fastening to various wall surfaces. The most common, of course, are concrete and brick. After all, the technology for installing penoplex involves, first of all, insulating the stone facade of the building. For wooden and plaster walls, such insulation is used much less frequently. So, let's start from the very beginning...

From this article you will learn:

Material Information

Penoplex is the same extruded synthetic polystyrene. This polymer insulation is produced in various thicknesses with the following properties:

- helps to effectively retain heat;

- has good mechanical strength and provides a strong base for plaster and putty;

- has high-quality sound insulation;

- does not absorb liquid;

- resists the emergence of harmful microorganisms.

The disadvantages of the material are its toxicity and rather high price, so it is unlikely that you will be able to save money on it.

Preparing the wall surface

First of all, we clean the concrete and brick from possible dirt, dust, old paint, any random oil stains, etc. If the walls are not smooth, then you will have to work with putty and try to bring them into a plane. We proceed with wood and plaster by analogy (except for putty).

For this dirty work, sandpaper or mesh, spatulas, scrapers, and brushes are used. In a word, whatever tool we have, that’s what we work with.

Cleaned walls should be primed. Conventional deep penetration primers are appropriate here. It often happens that the basement of a building “works” in harsh, damp conditions. Therefore, fungus, moss or other unnecessary vegetation forms on it. A simple method to get rid of it is to treat these parts with a solution of copper sulfate. A proven “old-fashioned” method. But you can also use more modern antiseptics, they are much more effective.

If there are efflorescences on a brick wall, they must be removed. You can read how and how to do this in this article - link. This is done in order to prevent the destruction of the material, which we will not see behind the layer of insulation and final finishing.

Next, along the entire perimeter of the building, strictly along the horizon, we attach the starting plinth. It can be in the form of a wooden block or a special perforated metal profile. The goal is to make it easier and faster to attach the penoplex: it does not accidentally move down and is positioned evenly relative to the walls.

Advantages of polystyrene foam insulation

Today, there are two types of foam-based insulation in use: polystyrene foam itself (classic foam sheets) and extruded polystyrene foam (“Technoplex”, “Penoplex”). In terms of properties, they are almost identical, except that the extruded one is a little denser, making it easier to cut and glue (it is more flexible and does not crumble when cut). So in the future we will talk about polystyrene foam in general.

Here are the advantages of this material:

- low cost;

- durability (provided that it is not exposed to direct sunlight);

- elasticity (this property is actively used for additional insulation of the foundation, which we will talk about a little later);

- excellent thermal insulation properties;

- additional sound insulation;

- low moisture permeability (extruded is completely impermeable to moisture).

In a word, there are enough advantages. Some people are afraid of polystyrene foam because of its flammability, but when a topcoat is applied to the insulation, it will protect against the spread of fire.

All methods of fastening this insulation

- The first, and perhaps the most used option is the use of a special adhesive bitumen-polymer mastic. A typical example is the well-known one. Mastics, as a rule, are sold ready-made. All that remains is to apply it in separate dots on the surface of the penoplex slab. Then press it firmly against the wall and wait a while.

- The next method is the use of dry cement-based mixtures. Ceresit products are in particular demand. For example, a brand of dry glue, Ceresit ST-85, is very popular among builders. This is the perfect combination of price and quality. The mixture, diluted with water and thoroughly mixed with a mixer, is applied to the entire surface of the insulation with a notched trowel and attached to the walls.

- Adhesive foam is also a fairly common fastener for penoplex. It comes in the form of cylinders, like regular polyurethane foam. The method of application is simple: screw the can into a gun, apply it to an EPS sheet, apply it to the wall and wait 5-10 minutes. This method is most often used for gypsum and plastic surfaces.

- Installation of polystyrene foam with disc-shaped dowels is usually done on concrete and brick. Here a special fungus is used to attach the insulation. It is also called an umbrella. 5 such umbrellas (4 at the edges and 1 in the center) are quite enough to securely fix the foam sheet to the wall. To work, you will need a hammer drill, a drill of the appropriate diameter and length, and a hammer.

- Another option for fixing penoplex to the wall is to use liquid nails. It is used less often than others and is quite expensive. Typically, liquid nails are used when working on small areas, for example, when insulating a balcony or loggia. There is no need to talk about insulating the house from the outside. The price will be exorbitant.

Quite often a mixed method of attaching penoplex to walls is used. The umbrella dowel is combined with bitumen mastic, dry mixture or foam. The result is excellent. Reliability and durability of installation work is guaranteed for many years.