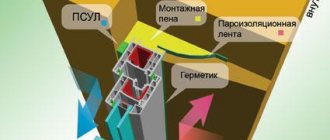

When constructing windows and doors from structures made of polyvinyl chloride or wooden profiles, various seals are used. They can use silicone sealants, insulating cords, foam insulation and other materials. The most common product for filling the seams between plastic windows and the opening are seals in tape format, which are also called PSUL tapes for windows. So what is this material?

Diffusion tape vapor-permeable NL (low tide) butyl

Diffusion vapor-permeable moisture-proofing tape (based on non-woven material) NL butyl

DESCRIPTION of the moisture-proof vapor-permeable tape (under tides) butyl NL:

permeable (diffusion) tape NL Profband made of membrane-type synthetic non-woven material is intended for waterproofing the lower assembly seam from external moisture of a translucent structure ( under the tide ), as well as any other construction seams and joints. The tape has two adhesive strips on one side (or on different sides only on request). One strip is intended for attaching the tape to a translucent structure, the other is for attaching the tape to a wall or slope. A wide range of tape sizes allows you to choose a material to protect seams of almost any size. The use of Profband waterproofing tapes provides reliable protection of the mounting foam from the penetration of moisture from outside the room and facilitates its removal from the foam to the outside, ensuring ventilation of the joint. The adhesive layers' adhesive strength far exceeds those required by GOST 30971-2002.

APPLICATION:

permeable tape NL Profband is ready for use and does not require special tools when installing it. The surfaces of joints and seams must be cleaned of dirt. The tape must be glued tightly along its entire length. Any gap or leak is a channel for rainwater to enter. At the corners, the tape must be folded so that the bent parts form sides to protect the lower corners of the window opening. The tape must be overlapped.

Size selection:

To ensure reliable protection of a seam or joint, the tape must be glued to the wall or slope with the entire width of the corresponding adhesive strip. Therefore, the width of the tape is selected as follows: it is necessary to add 40 mm to the width of the installation gap (rounded up). If necessary, a wider tape can be used.

Material properties:

• Resistance to vapor permeation: 0.053 (m2*h*Pa)/mg • Adhesive adhesion strength: not less than 0.3 (3.0) MPa (kgf/cm2) • Water resistance: not less than 600 Pa • Operating temperature: from -36 to +70 С°

Can be produced in non-standard and custom sizes.

Compliance with these recommendations will allow you to install the PSUL tape most correctly and help protect the installation seam from harmful environmental influences. Pre-compressed sealing tape is packaged in boxes and must be shipped to the installation site while maintaining the integrity of the packaging. If the integrity of the packaging is damaged, the manufacturing company is not responsible for the further use of the product. Storage and transportation of PSUL tapes must be carried out according to the recommendations indicated on the packaging. PSUL tape should be stored and transported at temperatures from +5 to +30 C, in a dry place protected from direct sunlight. To correctly select the size of the PSUL tape, it is necessary to remember that the tape performs its functions only in a compressed state. That is, for a gap of 5 mm it is necessary to use PSUL tape, which has a maximum expansion of 20 mm, for a gap of 6-10 mm it is necessary to use PSUL tape, which has a maximum expansion of 30 mm, and so on. When choosing a tape, you need to consult with our specialist who will select the right product for you. The use of tapes with an expansion of a gap that is obviously smaller will lead to the failure of this tape to fulfill its functions, as well as to the rapid destruction of the assembly seam. If the thickness of the PSUL tape is incorrectly selected, the manufacturer is not responsible for the use of the manufactured products. Pre-compressed sealing tape is used in accordance with GOST 30971-2002 to ensure vapor permeability of the assembly seam. PSUL tape is used at temperatures from +5 to +40 C. Using PSUL tape at negative temperatures will lead to an increase in the time it takes to release the tape. To avoid increasing the release time, the tape must be kept at room temperature for 24 hours. During the installation process, to speed up the release time, it is necessary to treat the tape with a heat gun. Otherwise, the release time will increase many times over. The PSUL tape is attached to the pre-treated, free of dirt and dust, degreased surface of the window or door block (or any other material being mounted). It is advisable to treat the surface on which the PSUL tape is attached using BR-1 or BR-2 solvent. When installing the tape, it is necessary to ensure a tight fit to the surface using short-term (3-5 seconds) pressing.

Features of PSUL tape production

Initially, PSUL sealing tape, pre-compressed, providing sealing and protection of seams from moisture, began to be produced in Germany. Currently it is also produced in Russia.

Despite the individual technologies of various manufacturers of sealing materials, their manufacturing process has a number of common features and production stages:

- The main component for the production of the seal is polyurethane foam, the characteristics of which affect the performance properties of the material.

- The polyurethane foam base is coated with an impregnation of acrylic or other composition, which gives the material greater wear resistance and increases service life.

- After applying the acrylic solution, its excess is removed, then the product is sent to the drying chamber.

- During the drying process, excess moisture evaporates, resulting in better adhesion of all components (acrylic solution and polyurethane foam).

- Next comes the stage of polymerization and assembly of the product.

- At the final stage, adhesive and reinforcing layers, as well as a protective paper film, are applied to the surface of the sealing strip.

- For transportation, the strip is rolled into rollers.

Short description

Waterproof, vapor-permeable membrane-type tape made of high-strength non-woven material. On one side or both sides, the tapes have an open butyl (B2) or adhesive layer (B1), protected by anti-adhesive paper. The tape is designed to isolate the joint (under the tide, as well as any other construction seams and joints) from the influence of weather factors, but at the same time is vapor-permeable. A wide range of tape sizes allows you to choose a material to protect seams of almost any size. The tape is supplied in rolls. The use of waterproofing, vapor-permeable tapes provides reliable protection of the mounting foam from moisture outside the room and helps remove moisture from the foam.

Anyone who has ever encountered construction and repair work knows how important it is to have on hand all the necessary building materials and tools in the right quantity. The most popular today are PVC products, which are not only easy to install, but also durable and affordable. But, despite the fact that these products are in great demand, until recently it was very difficult to find a place where you could buy exclusively high-quality PVC products. Today there is an online store of building materials Setdol, which is always ready to help you complete your repair and construction work with a result that will definitely satisfy you with quality.

In our assortment you will find the following products from well-known and trusted manufacturers:

- PVC window sills, including danke premium (danke ru), Crystalit, Moeller window sills;

- materials for PVC slopes;

- PVC flashings;

- PVC panels;

- siding;

- gutters and tides;

- foams, sealants, adhesives;

- window and door fittings;

- seals for windows and doors;

- hardware;

- mosquito nets and accessories for them;

- construction tools and equipment.

What benefits does cooperation with our online store give?

By purchasing a window sill from ru or a German manufacturer wholesale from us, you receive not only high-quality products, but also the opportunity to give the window an aesthetic appearance as quickly and inexpensively as possible. In addition, the window sill plays an important role in the operation of the entire window structure, because it bears a fairly large part of the load, for example, flowers are placed on the window sills, and various small items are placed. Therefore, this element must meet the highest requirements for strength, and the best choice is PVC window sills. They are not afraid of moisture, resistant to temperature changes, direct sunlight and scratches.

Technical characteristics of the tape "Germetex LM Dif"

- Vapor permeability coefficient, not less than 0.15 mg/(m.p. Pa)

- Adhesion strength when peeling, not less than 0.32 kgf/cm2

- Water permeability, 600 Pa, for 72 hours. No signs of water penetration

- Minimum installation temperature – 15°С

- With adhesive strip + 5°C

- Operating temperature from – 60°С to + 90°С

- Tape width, mm 50,70,100,120,150,200

- Tape length, m 18

Other parameters can be agreed upon upon request.

Sealing tapes

Tape LM oak (LT O)

Vapor barrier sealing full-butyl tape, covered with non-woven fabric on both sides. It is the material of the inner layer of the assembly seam. On both sides there is a mounting strip made of high-adhesive butyl rubber, protected by anti-adhesive paper.

The tape is supplied in rolls of 18 meters wide from 100 mm to 200 mm.

Vapor barrier tape LM oak has a number of advantages:

- high adhesive ability of the tape and its compatibility with various types of profiles and coatings, used when finishing the assembly joint both with plaster mortar and dry methods (plastic slopes, sandwich panels, etc.) the use of vapor-proof tapes LM oak provides reliable protection of the assembly foam from moisture from the side of the room and thereby prevents condensation from falling on the surface of the internal slopes.

- ensuring good vapor barrier and protection against leaks

- ease of installation, environmental safety

Technical characteristics of LM oak tape

- Vapor permeability coefficient is not less than 0.26 10 in – cubic. mg/ (m.h. Pa)

- Adhesive adhesion strength when peeling, not less than 0.32 kgf/cm 2

- Minimum installation temperature - 15°C

- Operating temperature from - 60°С to + 90°С

- Durability of at least 10 years

Application:

- when installing translucent structures - internal vapor barrier between the frame and the wall, finishing of slopes

- vapor barrier of internal joints of façade components.

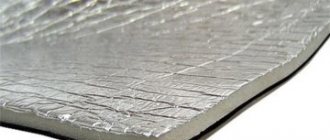

Tape LM Alum B 2 (LT (OM))

Vapor barrier tape made of metallized insulating material Alum. The tape has two adhesive strips of high tack butyl sealant on different sides. The use of vapor barrier tapes provides reliable protection of the mounting foam from moisture from the room side and thereby prevents condensation from falling on the surface of the internal slopes.

The tape is supplied in rolls of 24 meters, with a width from 100 mm to 200 mm.

Application of “Germetex LM Dif” tapes

The LM Diff tape is ready for use and does not require special tools for installation. The lower surface of the window opening must be cleaned of old building material with a spatula and dust removed with a brush. If the bottom surface of the opening is damaged, it must be repaired. The tape must be glued along its entire length. Any gap or leak is a place for rainwater to penetrate into the foam. At the corners, the tape must be bent so that the bent parts form sides to prevent leaks in the lower corners of the window opening. The tape must be cut on a flat surface. The tape is cut at both ends (along the middle) to a length equal to half its width. Next, the anti-adhesive paper protecting the adhesive strip is removed from the tape, and the tape is attached to the frame of the window structure. The notched ends are bent and glued to the side outer slopes, then the tape is attached to the lower outer slope, while the notched ends are bent onto the side outer slopes, overlapping onto those bends of the tape that are already glued. Next, the ebb is attached, then the installation gap is filled with foam from the room side.

How to choose?

What to pay attention to:

- First of all, pay attention to the size of the adhesive part of the tape, that is, its width. This parameter is determined by the distance from the top of the quarter of the opening to the seam filled with polyurethane foam (ideally, the PSUL should evenly fill all free space). The quarter, as a rule, is not made very deep - its size is on average 20-30 mm.

- An equally important property of the tape is the expansion coefficient (measured as a percentage). Optimal efficiency of the PSUL is possible when it increases relative to the compressed size by no more than 30%. Seals with a coefficient of 50% or more are characterized by low mechanical density and are not able to provide the required level of insulation for a long time.

For example, for a 13 mm seam, a tape whose folded thickness is 10 mm is ideal. The effectiveness of a seal with a maximum expansion of 2 cm installed in a 17 mm seam will be lower than if a PSUL with a working thickness of 3 cm is installed in the same seam.

Selecting the width of the “Germetex LM Dif” tape

The recommended width of the tape is selected as follows: the horizontal dimensions of the window slope plus the width of the tape.

In cases of significant contamination of installation openings, it is recommended to pre-treat them with Germetex BKV primer.

It is recommended to protect from exposure to ultraviolet rays with decorative strips, facade panels, strips, etc.

It is installed under the window drain and along the perimeter of the opening, on the outside of the window block, in the absence of quarters.

Purpose, scope of application

According to GOST 30971-2012, PSUL sealing tape is used to create ventilated assembly joints when installing window blocks. This product solves a whole range of problems:

- protects the mounting foam from moisture and sunlight;

- serves as an obstacle to the development of fungus and mold;

- thanks to vapor permeability, it removes moisture formed in the pores of the foam due to condensation during temperature changes to the outside;

- increases the service life and reliability of the seam;

- prevents freezing and seepage of water, penetration of air from the street and dust into the building.

In addition to insulating and protecting seams during the installation of plastic windows in accordance with GOST, PSUL tape is used for the following purposes:

- sealing seams of concrete parts, window sills, gaps between the wall and window and door frames;

- sealing of dormer windows, openings, roof structures;

- insulation from noise and vibration when installing air conditioners and fans;

- sealing joints of parts of prefabricated structures, roof elements, non-pressure pipelines (sewerage, storm drains);

- external insulation of wall panel joints;

- sealing the joints of wall beams made of wood and other building elements;

- filling cracks and gaps in areas where the chimney meets the roof, and ventilation duct joints.

Due to the specific properties of the material, self-expanding tapes can be used to seal joints with uneven surfaces.

DOMOSTROYPlumbing and construction

- Thursday, December 12, 2022 1:05

- Author: Sereg985

- Comment

- Category: Construction

- Link to post

- https://firmmy.ru/

Diffusion (vapor permeable) tape made of durable polypropylene fabric with two fastening strips along the edges of butyl rubber sealant on different sides. Installed on the outside of the ebb, ventilated facade.

Fully complies with the requirements of GOST 30971-2002 “Installation seams of junctions of window blocks to wall openings.”

Installation

PSUL is completely ready for use; its installation does not require the use of special tools and devices. The sealant is selected according to the width of the seam.

Installation of pre-compressed sealing tape occurs as follows:

- The PVC window and window opening are prepared for installation. To do this, dirt and loose plaster are removed, the surface is cleaned of dust using a vacuum cleaner, and wiped with a damp cloth.

It is recommended to treat the surface of joints and seams with a special dust-removing compound.

- The surface of the quarter is coated with an acrylic primer for exterior use.

- Markings are made and fasteners are installed.

- A few centimeters (3–5) from the beginning and end of the roller are cut off and not used. A piece of sealant is cut to the required length and the paper layer is removed.

- The tape is installed on the outside of the frame facing the street, with a distance of 3–5 mm from the outer edge of the quarter. The product is pressed to the surface.

Short description

Waterproof, vapor-permeable membrane-type tape made of high-strength non-woven material. On one side or both sides, the tapes have an open butyl (B2) or adhesive layer (B1), protected by anti-adhesive paper. The tape is designed to isolate the joint (under the tide, as well as any other construction seams and joints) from the influence of weather factors, but at the same time is vapor-permeable. A wide range of tape sizes allows you to choose a material to protect seams of almost any size. The tape is supplied in rolls. The use of waterproofing, vapor-permeable tapes provides reliable protection of the mounting foam from moisture outside the room and helps remove moisture from the foam.

Diffusion tape with an additional adhesive layer 100x1.5 mm (21 linear meters) PLT

- Description

- Reviews

- Ask a Question

- Additionally

- Diffusion tape 100x1.5 mm (21 linear meters) PMT with an additional adhesive layer is a vapor-permeable tape made of membrane-type non-woven material (spunbond) with strips of self-adhesive butyl sealant protected with anti-adhesive paper. Location of butyl strips: on both sides. Complies with the requirements of GOST 30971-2012 and GOST R 52749-2007. To ventilate the seam and protect it from moisture from the outside of the room. Installed under the ebb or along the perimeter of the window from the outside (if there is no quarter). Durability: at least 20 years

TECHNICAL CHARACTERISTICS: t° Use: from -15°С to +35°С t° Operation: from -60°С to +100°С Adhesive strength: not less than 0.3 kgf/cm Thickness of butyl layer: 1.5 mm

Characteristics

View vapor permeable Roller length 21 linear meters Application area for external seam Use temperature from - 15 °C to + 35 °C Operating temperature from - 60 °C to + 90 °C Manufacturer country Russia Width 100 mm Thickness 1.5 mm You can ask any question you are interested in about the product or the work of the store.

Our qualified specialists will definitely help you.

An additional tab for posting information about the store, delivery or any other important content. It will help you answer the buyer’s questions and dispel his doubts about the purchase. Use it at your own discretion.

You can remove it or return it back by changing one checkbox in the component settings. Very comfortably.

Technical characteristics of the tape "Germetex LM Dif"

- Vapor permeability coefficient, not less than 0.15 mg/(m.p. Pa)

- Adhesion strength when peeling, not less than 0.32 kgf/cm2

- Water permeability, 600 Pa, for 72 hours. No signs of water penetration

- Minimum installation temperature – 15°С

- With adhesive strip + 5°C

- Operating temperature from – 60°С to + 90°С

- Tape width, mm 50,70,100,120,150,200

- Tape length, m 18

Other parameters can be agreed upon upon request.

Indicators of water resistance and frost resistance according to GOST

State standard GOST R 53338-2009, which contains a description of the material and provides its classification, divides self-expanding tapes into 3 classes according to the water resistance limit in the state of working compression:

- Class A – over 600 Pa.

- Class B – at least 400–600 Pa.

- Class B – no less than 200–399 Pa.

Also, the specified GOST provides for the division of products into types of execution:

- I – optimal for regions with an average monthly air temperature in the coldest time of the year down to -10°C. Minimum operating temperature – -25°С.

- II – for regions with an average monthly January temperature of up to -20°C. Minimum operating temperature – -45°С

- M (frost-resistant option) - for regions with an average monthly temperature in January below -20°C. Minimum operating temperature – -55°С

Application of “Germetex LM Dif” tapes

The LM Diff tape is ready for use and does not require special tools for installation. The lower surface of the window opening must be cleaned of old building material with a spatula and dust removed with a brush. If the bottom surface of the opening is damaged, it must be repaired. The tape must be glued along its entire length. Any gap or leak is a place for rainwater to penetrate into the foam. At the corners, the tape must be bent so that the bent parts form sides to prevent leaks in the lower corners of the window opening. The tape must be cut on a flat surface. The tape is cut at both ends (along the middle) to a length equal to half its width. Next, the anti-adhesive paper protecting the adhesive strip is removed from the tape, and the tape is attached to the frame of the window structure. The notched ends are bent and glued to the side outer slopes, then the tape is attached to the lower outer slope, while the notched ends are bent onto the side outer slopes, overlapping onto those bends of the tape that are already glued. Next, the ebb is attached, then the installation gap is filled with foam from the room side.

How to work with tape

The procedure for installing a window unit using a pre-compressed seal:

- The opening is cleaned of dirt and primed with a primer;

- It is necessary to remove the protective film from the street side of the window profile, then clean the surface of any adhesive residue and degrease it with a solvent. If the film is left on the profile, then after gluing the PSUL, it will not be possible to completely remove it.

- The edge of the tape in a skein (3-4 cm) is not suitable for use, so it is cut off before starting work.

- The gluing is carried out by gradually removing the protective film (with an advance of 5-10 cm), cutting it to size directly on the frame. First they are attached to the upper profile, then to the side ones (the lower part is insulated with other materials).

- Next, the window block is placed in the opening, secured to plates or anchors, and the gaps are filled.

After fixing it on the profile, the tape will begin to expand, so you should not hesitate to install the frame, otherwise it will be quite difficult to level it when the PSUL has fully expanded.

Note. Full expansion of the tape at a temperature of 20°C occurs in approximately 20-30 minutes. In cold weather, this process can increase 2-3 times. To speed it up, the tape, after gluing and installing the window in the opening, is heated with a hair dryer.

Selecting the width of the “Germetex LM Dif” tape

The recommended width of the tape is selected as follows: the horizontal dimensions of the window slope plus the width of the tape.

In cases of significant contamination of installation openings, it is recommended to pre-treat them with Germetex BKV primer.

It is recommended to protect from exposure to ultraviolet rays with decorative strips, facade panels, strips, etc.

It is installed under the window drain and along the perimeter of the opening, on the outside of the window block, in the absence of quarters.

BUTYL TAPE waterproof adhesive.

Butyl Tape Diffusion Psul for timber Consists of an adhesive layer based on butyl with a high degree of adhesion and non-woven material based on polyester. Butyl Tape Psul Meets all its technical characteristics over a wide temperature range. Due to the excellent sealing properties of the adhesive used, butyl tape is used where protection from moisture or bad weather conditions is required.

Usage

: Butyl tapes

- at the junctions of building structures;

- as a basis for ridge beams, metal sheets and boards on the roof;

- for sealing cracks in roofs, walls, pipes, etc.

Structure: Butyl tapes

Non-woven material. Rubber adhesive based on butyl tape. A paper layer that is removed when applying butyl tape.

Before applying the tape, it is necessary to clean the surface from dirt, dust, oil, water, etc. Please consult us when using the tape for special purposes. Storage: in a dark and cool place. Size: 50 mm x 20 m Note: tapes of other sizes can be supplied upon your request.

Technical Characteristics: Butyl tapes

- Adhesion to steel: 2000 gf/25 mm

- Adhesiveness: 34 points

- Fixation strength: 13 minutes at 23°C

- Tensile force: 13 kgf/25 mm

- Vapor permeability: 3.1 g/m in 24 hours

Diffusion vapor-permeable tape made of membrane-type nonwoven material (spunbond) with strips of self-adhesive butyl sealant protected by anti-adhesive paper. Butyl strip arrangement: one-sided. Meets the requirements of GOST 30971-2012 and GOST R 52749-2007. To ventilate the seam and protect it from moisture from the outside of the room. Installed under the ebb or along the perimeter of the window from the outside (if there is no quarter). Durability: at least 20 years

Regulatory requirements

In Art. 22 of the “Fire Safety Rules in the Russian Federation” states that the heads of enterprises and organizations are obliged to organize the implementation of construction and installation work on sealing, filling the entire thickness of a fire-fighting building structure - walls, ceilings, partitions of holes, openings at the places where they intersect with engineering and technological networks, communications, incl. electrical cable routes; such non-combustible materials that will provide the necessary resistance to open fire and smoke and gas impermeability.

GOST R 57327-2016 establishes the requirements for the mandatory use of fire-resistant thermally expanding tapes as part of fire doors and the organization of smoke and gas tightness:

- As seals against “cold smoke”, it is necessary to install tapes made of elastic polymer materials without gaps in the joints along the entire perimeter, with the exception of U-shaped boxes without a stationary fire threshold. When the door is closed, such gaskets should be pressed against the door leaf without any leaks.

- To prevent the spread of high-temperature volatile products of the combustion process and open fire, it is necessary to use thermally expanding gasket tapes, the installation of which is carried out in accordance with the design documentation in the factory; technical passport for the product, manufacturer’s instructions when performing the necessary repairs during technical service by representatives of a specialized enterprise that has the right to install and service fire doors, gates, hatches on the basis of a license from the Ministry of Emergency Situations.

- Gaps at the joints of fire-resistant thermally active tapes are unacceptable, with the exception of places for mounting hinges, lock strips, and door handles; and installation of sealing and thermally expanding sealing gaskets in the production of doors, hatches, and gates must be done only after the paint and varnish coatings of the products have completely dried.

When carrying out both certification and periodic tests when checking the technical condition of installed fillings in fire barriers - at least once a quarter, it is mandatory to check the tightness of seals against cold smoke, the presence, and correct installation of thermally expanding fireproof tape gaskets:

- Visually, comparing with drawings in technical documentation.

- By applying a coloring material, for example, colored chalk, to the entire surface of the sealing gaskets, then closing the fire door, inspecting the results obtained for the presence of a continuous trace.

Fireproof sealing tape must meet the following requirements:

- This is a non-flammable material.

- It is non-toxic.

- Capable of expanding when exposed to high temperatures to the required volume, forming a foam-like solid material that prevents the passage of fire and smoke.

- Has a high-quality adhesive base.

- Wear-resistant.

- Resistant to environmental humidity and temperature changes over a wide operating range.

Manufacturers produce fire protection tapes based on technical specifications that have passed all stages of approval in the manner prescribed by law - from test samples to serial batches with receipt of a fire safety certificate.

Butyl diffusion tape technical characteristics

Waterproof, vapor-permeable membrane-type tape made of high-strength non-woven material. On one side or both sides of the tape there is an open butyl or adhesive layer protected by release paper. The tape is designed to isolate the joint (under the ebb, as well as any other construction seams and joints) from the influence of weather factors, but at the same time is vapor-permeable. A wide range of tape sizes allows you to choose a material to protect seams of almost any size. The tape is supplied in rolls. The use of waterproofing, vapor-permeable tapes provides reliable protection of the mounting foam from moisture outside the room and helps remove moisture from the foam.

| View: | Description: |

| SD (version I) | Waterproofing, vapor-permeable tape made of membrane-type non-woven material. Along the edges of one side of the tape, two strips of self-adhesive butyl sealant are applied. It is the material of the outer layer of the assembly seam. |

| SD (version II) | Waterproofing, vapor-permeable tape made of membrane-type non-woven material. Two strips of self-adhesive butyl sealant are applied on both sides of the tape. It is the material of the outer layer of the assembly seam. |

| SD (version III) | Waterproofing, vapor-permeable tape made of membrane-type non-woven material. A strip of butyl sealant and a strip of adhesive layer are applied along the edges of one side of the tape. It is the material of the outer layer of the assembly seam. |

| SD (version IV) | Waterproofing, vapor-permeable tape made of membrane-type non-woven material. On one side of the tape there is a strip of butyl sealant, on the other side there is a strip of adhesive layer. It is the material of the outer layer of the assembly seam. |

Application of SD tapes:

SD tape is ready for use and does not require special tools for installation. The lower surface of the window opening must be cleaned of old building material with a spatula and dust removed with a brush. If the bottom surface of the opening is damaged, it must be restored. Wall surfaces made of porous materials in places where tapes are glued require preliminary priming with a GSR primer or another used in construction. The tape must be glued tightly along its entire length. Any gap or leak is a place for rainwater to penetrate into the foam. At the corners, the tape must be bent so that the bent parts form sides to prevent leaks in the lower corners of the window opening. The tape must be cut on a flat surface. The tape is cut at both ends (along the middle) to a length equal to half its width. Next, the anti-adhesive paper protecting the adhesive strip is removed from the tape, and the tape is attached to the frame of the window structure. The notched ends are bent and glued to the side outer slopes, then the tape is attached to the lower outer slope, while the notched ends are bent onto the side outer slopes, overlapping onto those bends of the tape that are already glued. Next, the ebb is attached, then the installation gap is filled with foam from the room side.

Application on objects

Scope of application of fire-resistant thermally expanding tapes:

- In the production and ongoing repair of fire gates and doors.

- When constructing fireproof partitions, incl. when installed in them as a filler for fire-resistant windows.

- Fire-resistant tape for pipes and ventilation ducts is used in places where smoke exhaust valves and fire-retarding valves are connected to them.

- Filling and sealing of holes where utility lines pass through building structures, including electrical routes.

- In the manufacture of fire-fighting elevators for sealing the cabin, the production of fire-resistant fire safes.

Pre-Compressed Self-Expanding Sealing Tape 10/20 6m (Grey)

PSUL is a pre-compressed self-expanding sealing tape used to seal seams. When installing products in an opening, PSUL fills the gap between the window frame and the wall opening. It is designed to fill any gaps, within the limits of standards, in construction and is a strip of porous elastic material resembling foam rubber with special impregnations. The tape is made from modified acrylic and polyurethane. Acrylic impregnation slows down aging and extends the service life of the seal. For ease of use, PSUL tape has an adhesive mounting layer on one side. Color black or grey. It is produced in a compressed state in rolls with protective tape attached. PSUL expands under the influence of moisture in the air.

The purpose of PSUL is good waterproofing with guaranteed vapor permeability, protection from ultraviolet rays and high durability in conditions of various deformations of the window profile relative to the wall opening. Polyurethane foam is afraid of atmospheric influences, but PSUL is not. From the inside, the foam of the assembly seam is closed completely hermetically, providing complete vapor barrier to the seam and completely eliminating the penetration of moisture into the seam from the room. For this purpose, special vapor barrier membrane tapes are used. But not everything is so easy and simple. The main disadvantage of installation using PSUL is that the width of the external gap between the front surface of the frame and the opening must be maintained in the range from 3 to 15 mm. This is due to the fact that when the PSUL tape expands beyond the specified normalized values, its waterproofing ability decreases. The tape itself expands to 40-45 mm (a fivefold increase in thickness is possible). But this is a completely non-working tape and it will not perform its functionality. Therefore, you should not believe what installation organizations sometimes say about the operation of the tape no matter how wide it is.

When removing the protective packaging and sticking the PSUL onto the working surface, the tape expands to operational working dimensions (discussed above). Then, it is desirable that the PSUL fully expands before the installation seam foams. Penetration of foam behind the PSUL tape is unacceptable. The time for complete expansion of the PSUL directly depends on the ambient temperature; for example, at 10 °C, expansion can take 15 hours or more. You can use the option of gluing an already expanded PSUL tape, but then it is necessary to press the frame to the quarter with clamps, which also complicates installation and, thus, can reduce its quality (this option is not recommended when changing products). PSUL tapes come in different sizes, both in width and in the size of the “working” extension. It is necessary to select the correct size for each specific installation of a translucent structure. As a result, we received positive qualities of PSUL:

- easy to use during installation

- it is very plastic and thanks to this it can fill any cracks and gaps.

- allows water vapor to pass from the house to the outside

- UV and aging resistant

- resistance to heavy rains up to 600 Pa

- takes any shape

- and most importantly, the PSUL tape is not covered with anything, either plaster or any other material. This is simply not required.

PSUL tape is used for sound insulation of steel casting and is used, see figure