Robiband mounting tapes – a course for durability

Robiband mounting tapes are tape sealants that have been produced by Robitex Group of Companies at a plant in the Moscow region since 2006. Over the course of 15 years, the company has become a leader in the production of mounting tapes and an expert in this field. More than 50 million windows have been installed in Russia using Robitex materials.

The company not only produces mounting tapes, but is also a patent holder. In 2008, Robitex Group patented a revolutionary installation device - the UFM mounting clamp. With its help, window installation can be easily done by one person. Aligning the structure in the opening takes five times less time compared to installation on support wedges. This technology is especially relevant for strip glazing and balcony blocks.

Advantages of Robiband mounting tapes:

- 3 layers versus 1. Waterproofing and vapor-permeable tapes consist of three layers, this is the only way they can perform their function - releasing water vapor and not allowing water to pass through and vice versa.

- The durability of the tapes for at least 20 years has been confirmed by tests in Russian and European testing centers. Robiband tapes are the only ones in Russia that have a quality certificate from the European Institute of Window Technology in Rosenheim (IFT Rosenheim Germany), which is recognized throughout the world. With these tapes you can forget about blowing out the slopes for the entire service life of the window.

- Can be used in any region of the country. The operating temperature of the tapes at which they do not lose their properties is from -40°C to +80°C.

- Installation can be done all year round at temperatures from -15°C to +50°C. The vapor barrier properties of internal tapes (vapor barrier) are many times higher than the requirements of the standards. A seam protected by film will never get wet and will keep the house warm for decades.

- Installation in one day. It is recommended to glue the tapes onto wet foam and not wait until the foam hardens to finish the slopes.

- Adhesion, that is, the peeling force of the surface of the tape with the wall and window, is up to 5 times higher than required by GOST - 1.4-1.6 kgf/cm at a rate of 0.3 kgf/cm.

No deformation of the wall and window can lead to the tape coming off and cracks appearing on the plaster slopes.

Disadvantages of Robiband tapes:

- Higher cost compared to analogues, due to the use of high-quality materials with a long service life of up to 20 years.

The results of comparative tests of Robiband and Noname tapes can be seen in this video:

Application of Robiband mounting tapes

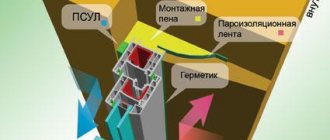

External tapes (waterproofing and vapor-permeable) are designed to protect the installation seam from precipitation and exposure to UV radiation from the street. Their second important function is to remove excess moisture from the seam due to partial pressure.

This group includes:

- PSUL (Vapour-Permeable Self-Expanding Sealing Tape) - the sealing tape, expanding, fills the outer gap, eliminates cracks, which means leakage, blowing and freezing from the outside of the seam. And due to vapor permeability, the tape removes accumulated water vapor out, keeping the seam dry. Another important property of tapes is elasticity and resilience. During thermal expansion of a window or enclosing structure, the tape does not crack, but expands or contracts, reliably protecting the installation seam.

Material: made of elastic polyurethane foam impregnated with a special composition.

Application: window openings with a quarter.

Installation location: PSUL tapes are installed on the edge of the frame from the street side on the vertical and upper horizontal parts of the window. Gluing on the surface of the quarters (top and side) is also allowed.

Installation method: The tapes can be easily applied to the window by removing the protective film from the adhesive strip.

Installation at temperature:

up to -5°С – all PSUL tapes

from -5° to -15°С – PSUL grade 50+ N

Front gap width: from 2 to 20 mm Photo: Robiband PSUL tapes do not allow moisture to pass into the assembly seam from the outside and allow water vapor to escape outside. Glued to the front surface of the window frame from the street side, ©robitex.ru

- Diffusion tapes are designed to protect the polyurethane foam under low tide from moisture and ultraviolet radiation, as well as to remove moisture from the seam to the outside.

Material: made of 3-layer membrane material. The membrane contains a huge number of microholes - they are so small that they do not let water into the seam, but their size is sufficient for water vapor to escape out.

Installation location: only under the ebb or along the entire perimeter of the window. When installing without a quarter and then finishing the external slopes, it is glued along the perimeter of the window.

Installation method: The tapes can be easily applied to the window by removing the protective film from the adhesive strips. One strip for attaching the tape to the window, and the second to the wall.

Installation: standard at temperatures up to 0°C, winter - from 0°C to -20°C, the opening must be treated with a primer

End gap width: from 5 to 600mm

| ! It is recommended to use Robiband PBT sound-absorbing tape at low tide to avoid unpleasant noise during rain. |

- KMP is a combined multifunctional vapor-permeable tape for waterproofing external seams. In terms of properties, this is an analogue of PSUL, only the main material is in a straightened state. The diffusion membrane in the composition of the KMP limits the release of foam to the outside in crooked, damaged and uneven openings due to the loose fit of the tape.

The PVC plank is a “beacon” for subsequent plastering of the openings from the outside and allows you to make them perfectly smooth.

This development of the Robitex company is specifically for installing windows on uneven, damaged window openings or openings without a quarter.

Material: The tape is composed of elastic polyurethane, PVC plate and diffusion membrane.

Application: window openings with a quarter.

Installation location: installed on the edge of the frame from the street side on the vertical and upper horizontal parts of the window.

Installation method: The tape can be easily pasted on the window by removing the protective film from the adhesive strip.

Front gap width: 5-50mm

Installation: standard at temperatures up to 0°C, winter from 0°C to -20°C, the opening must be treated with a primer Photo: Robiband KMP tape can be used at any temperature, ©robitex.ru Internal tapes (vapor barrier) are designed to protect the assembly seam from penetration moisture from inside the room. The insulation under the vapor barrier tapes will always be dry, which means its thermal insulation properties will be high, which increases the service life of the installation seam.

- Robiband VM is a universal tape for finishing plaster slopes or panel slopes. Consists of aluminum foil, reinforced with synthetic thread, with a fleece covering for installation of windows in accordance with GOST.

- Robiband BC - tapes for slopes made of sandwich panels are made of durable metallized film backed with non-woven material.

Advantages of vapor barrier tapes:

- Lungs. Weight 60-120 gr./m.p.

- Durable. Retains vapor barrier properties for many years

- Reliable adhesion to openings and windows

Disadvantages of vapor barrier tapes:

- When gluing onto “cut polyurethane foam” (cutting it is not recommended by regulatory documents), air gaps are formed between the tape and the foam.

Types of butyl tapes:

- Robiband BO is used as an analogue of Robiband VM tape for subsequent finishing of plaster slopes. This is a full-butyl tape backed with non-woven fabric for installation in accordance with GOST with subsequent plastering of slopes.

- Robiband PBA for sealing aluminum facades. These are butyl tapes on an aluminum base.

- Robiband PBT - for protecting the assembly joint near plaster slopes and as sound insulation under the slope. These are butyl tapes with a fabric backing.

- Robiband PBLN is a butyl tape for easy installation. The butyl layer has a special protective coating without paper, so the roll unwinds easily. Under “dry” slopes.

- Robiband PB is a butyl tape for sealing aluminum structures of winter gardens, balconies, and entrance doors. Used with a covering strip of the structure.

Pros of butyl tapes:

- Adhesion to foam joint. The tapes adhere completely to the foam, leaving no air gaps.

Disadvantages of butyl tapes:

- Heavier 150-400g/l.m.

- It is necessary to take into account the load on the tape when installing on “ceiling” seams.

- On windows that are too wide, the tape may fall off due to its own weight.

Ideal for sealing translucent structures under a pressure strip (facades, skylights, greenhouses, winter gardens). Used for vapor barrier, sealing and gluing of structural and connecting joints in industry and construction (glass, metal, automotive). Excellent adhesion to concrete, stone, glass, aluminum (including anodized), wood, steel, zinc sheet, almost any plastic, varnished and glazed surface, etc. It is especially widely used for sealing window and façade joints and seams.

Colors and sizes:

Colors: black butyl, light aluminum film, laminated on top with thin transparent plastic for durability.

Directions for use:

Recommended operating temperature range for installation: from -10°C to +30°C.

The base surface must be dry, clean, free of grease, without a separating layer. For very rough surfaces, it is recommended to apply a first coat of primer. The product is not compatible with all silicones.

Storage:

The product can be stored in original packaging for 12 months after production. Store boxes with butyl tape in dry and cool (from +15o to +18o C) rooms. It is advisable not to store at temperatures above +30o C.

Full butyl tapes

Description

When installing a window according to GOST , you will definitely need window sealing tapes (tape sealant) to protect the installation seam. They provide reliable protection of the mounting foam from atmospheric influences and maintain the high performance properties of the mounting joint for a long time.

Tape sealant is a synthetic material (non-woven fabric, foil or film) and an adhesive layer applied to it (butyl rubber and/or acrylic).

Tape sealants vary in application:

- • for the outer layer of the assembly seam;

- • for the inner layer of the construction seam.

For the outer layer, a vapor-permeable (diffusion) waterproofing tape is used. Provides UV protection and waterproofing of the seam from the outside and releases moisture from the seam to the outside.

For the inner layer, a vapor barrier (full butyl duplicated or economical foil) tape is used. Provides seam protection from moisture penetration from inside the room.

Vapor-waterproofing tapes (PGL).

Vapor barrier tape made of aluminum foil reinforced with high-strength synthetic thread. The tape is intended for internal vapor barrier of assembly joints, followed by plastering of slopes. The tape has two adhesive strips on one (optional) or two sides. One strip is intended for attaching the tape to the translucent structure, the other is for attaching the tape to the wall slope. On the side of the strip intended for fastening to the translucent structure, the tape is duplicated with non-woven material to create adhesion of the tape with the plaster mortar. A wide range of tape sizes allows you to choose a material to protect seams of almost any size. The tape is supplied in rollers. The use of vapor barrier tapes provides reliable protection of the mounting foam from moisture from the room side and prevents moisture from escaping from the seam on the surface of the internal slopes.

| To ensure reliable protection of a seam or joint, the tape must be glued to the wall or slope with the entire width of the corresponding adhesive strip. Therefore, the width of the tape is selected as follows: it is necessary to add 45 mm to the width of the installation gap (rounded up). If necessary, a wider tape can be used. |

Vapor permeable tapes (PPL).

Waterproofing, vapor-permeable tape made of membrane-type synthetic non-woven material. The tape is intended for waterproofing the installation seam of a translucent structure under low tide, as well as any other construction seams and joints. The tape has two adhesive strips on one (optional) or two sides. One strip is intended for attaching the tape to the translucent structure, the other is for attaching the tape to the wall slope. A wide range of tape sizes allows you to choose a material to protect seams of almost any size. The tape is supplied in rollers. The use of waterproofing tapes provides reliable protection of the mounting foam from moisture on the street side and ensures the removal of moisture from the foam to the outside.

| To ensure reliable protection of a seam or joint, the tape must be glued to the wall or slope with the entire width of the corresponding adhesive strip. Therefore, the width of the tape is selected as follows: it is necessary to add 45 mm to the width of the installation gap (rounded up). If necessary, a wider tape can be used. |

PSUL – pre-compressed sealing self-expanding self-adhesive tape . The material is a self-adhesive elastic polyurethane foam tape impregnated with a special composition. The tape is supplied compressed and rolled into rollers. A wide range of standard sizes of tape sealant allows you to select a material to protect seams of almost any size. There are two types of PSUL tape: gray and black. The tapes differ somewhat in characteristics and type of impregnation. Gray tape has better performance than black tape. The tape placed in a joint or seam expands independently, completely filling all irregularities and gaps, providing reliable protection of the seam from all adverse climatic influences.

Application of PSUL :

- • protection of the assembly seam from moisture, air and UV rays;

- • removal of water vapor from the assembly seam;

- • sealing of external construction joints;

- • additional sound and heat insulation of window and door openings.

The main qualitative characteristics of PSUL are:

- • density (from 30 to 150 kg/m³);

- • resistance to vapor permeation (no more than 0.25 m²hPa/mg);

- • resistance to UV rays;

- • water resistance limit (not less than 300 Pa);

- • adhesion (not less than 0.03 MPa);

- • durability (at least 20 years).

All characteristics must comply with GOST requirements.

When choosing a tape, you must adhere to the following rule:

The maximum degree of protection is provided by a tape whose size in the sealed seam does not exceed 20% of the height of its full expansion. When expanded by 80%, dust and sound resistance will be ensured. With any expansion of the tape, the foam will be protected from UV rays. WARNING: The use of PSUL tapes with a deliberately smaller size than necessary in a particular case can lead to undesirable consequences, such as leaks, blowing out of the PSUL by strong (hurricane) wind, as well as squeezing out the PSUL with foam. High-quality sealing and protection of the seam is ensured only by correctly sized tapes.

At PARTNER-SERVICE Group of Companies you can buy ROBIBAND steam and waterproofing tapes wholesale. You can view the assortment on our website in the “CATALOG” section. Please check the price and terms of purchase with the sales department managers by phone (8202) 26-74-90, 63-79-99 and at the sales office: Cherepovets, st. Borshodskaya, 46, office 201.

Purpose, scope of application

According to GOST 30971-2012, PSUL sealing tape is used to create ventilated assembly joints when installing window blocks. This product solves a whole range of problems:

- protects the mounting foam from moisture and sunlight;

- serves as an obstacle to the development of fungus and mold;

- thanks to vapor permeability, it removes moisture formed in the pores of the foam due to condensation during temperature changes to the outside;

- increases the service life and reliability of the seam;

- prevents freezing and seepage of water, penetration of air from the street and dust into the building.

In addition to insulating and protecting seams during the installation of plastic windows in accordance with GOST, PSUL tape is used for the following purposes:

- sealing seams of concrete parts, window sills, gaps between the wall and window and door frames;

- sealing of dormer windows, openings, roof structures;

- insulation from noise and vibration when installing air conditioners and fans;

- sealing joints of parts of prefabricated structures, roof elements, non-pressure pipelines (sewerage, storm drains);

- external insulation of wall panel joints;

- sealing the joints of wall beams made of wood and other building elements;

- filling cracks and gaps in areas where the chimney meets the roof, and ventilation duct joints.

Due to the specific properties of the material, self-expanding tapes can be used to seal joints with uneven surfaces.

Robiband tape classes

All Robiband tapes are available in three classes:

Quality A – premium quality tapes made from European materials. The characteristics exceed the standard requirements by 10 times. This is a solution for homeowners who take a responsible approach to the construction and renovation of their property and are focused on long-term comfort.

Quality B – “standard +” tapes with characteristics exceeding the requirements by 2-5 times. This is the most common quality with an optimal price-quality ratio.

Quality B – tapes for object construction. Characteristics at the level of regulatory requirements and an attractive price.

The belonging of the tape to a certain class is reflected in the name - the letter A, B or C is indicated after the name.

Brands of Robiband tapes

Recommendations for installing diffusion tape

All information on the site is the property of the group. Publishing information from the website svm24.ru without permission is prohibited. All rights reserved.

You accept the terms of the Privacy Policy and User Agreement every time you leave your data in any feedback form on the svm24.ru website

If you find an error or inaccuracy on the site, please report it by email or select a piece of text and press Ctrl+Enter.

Selecting the width of the “Germetex LM Dif” tape

The recommended width of the tape is selected as follows: the horizontal dimensions of the window slope plus the width of the tape.

In cases of significant contamination of installation openings, it is recommended to pre-treat them with Germetex BKV primer.

It is recommended to protect from exposure to ultraviolet rays with decorative strips, facade panels, strips, etc.

It is installed under the window drain and along the perimeter of the opening, on the outside of the window block, in the absence of quarters.

Tape selection

When choosing a self-expanding seal, you must focus on the following parameters:

- The width of the adhesive layer - the strength of adhesion depends on it. When installing windows, you should choose a tape with a width of 2 cm.

- The degree of expansion of the product determines the density of filling the gap. The optimal value is 20–30% of the initial compressed state, but not more than 60%.

When purchasing, do not forget to ask the seller for a certificate of conformity.

Bauset external diffusion tape MR 1.5x70mm (25m)

Attention! The actual color and texture of the goods may differ slightly from their images presented on the online store website.

Vapor-permeable (diffusion) tape Bauset MR based on a membrane-type synthetic non-woven material allows you to protect the installation seam from the outside from moisture and provides ventilation of the installation seam to the outside.

For easy and reliable fixation, two butyl adhesive strips are applied to the tape. It is recommended to install under the external ebb, as well as along the entire perimeter of the window in cases where installation of PSUL is impossible. In the latter case, the tape must be covered with a strip.

- Made from durable polyester fabric

- When used correctly, the seal is guaranteed for at least 20 years

- Ease of installation

| Material | diffusion tape (membrane type) made of durable polyester fabric with two butyl rubber mounting strips applied on one side |

| Working temperature | -10°C to +45°C (at temperatures from -10°C to -20°C, the tape must first be kept at room temperature for 24 hours) |

| Heat resistance | from - 60°C to + 140°C |

| Water absorption | no more than 0.3% |

| Resistance to vapor permeation | no more than 0.25 (m2*h*Pa)/mg |

| Adhesive strength | not less than 0.1 MPa |

- Surface preparation. The surfaces to be treated must be clean, dry and grease-free. It is recommended to pre-treat porous surfaces with a primer (adhesive mastic).

- Cut the tape into pieces equal to the width and length of the window plus 10 cm (to form corner joints).

- Glue the duplicated tape around the perimeter of the window frame with an adhesive strip, having first removed the anti-adhesive protective paper tape.

- Place the window in the opening level and secure it.

- Apply polyurethane foam to the seam.

- After 15-20 minutes, close the assembly seam with foam with duplicated tape, gluing it to the slope of the window opening using a butyl adhesive strip, having previously removed

Attention! Delivery of goods is carried out to the customer’s entrance. Unloading of goods from the vehicle is carried out by the buyer. If it is impossible to deliver the order to the entrance, delivery will be made to the nearest possible unloading location. Delivery to closed areas with paid entry is carried out only after the customer has paid for the pass. Otherwise, delivery will be made to the nearest possible location. The forwarder makes a follow-up phone call 30-60 minutes before leaving to visit the buyer. If the buyer cannot be reached by phone, delivery is cancelled.

Compound

The basis of the material is a butyl rubber polymer composition, which remains plastic and adhesive in the range from −40 to +100 °C. It can cover the tape on one or both sides, and is protected on top with anti-adhesive paper. Thanks to the properties of butyl rubber, such tapes have high performance characteristics.

Butyl rubber is a synthetic rubber based on isobutylene. The substance is characterized by high heat, cold, light and ozone resistance. Butyl rubber allows air to pass through approximately 20 times less than natural rubber. Resistant to moisture and aggressive environments - solvents, alkalis, acids, alcohols, vegetable and animal fats.

Application of “Germetex LM Dif” tapes

The LM Diff tape is ready for use and does not require special tools for installation. The lower surface of the window opening must be cleaned of old building material with a spatula and dust removed with a brush. If the bottom surface of the opening is damaged, it must be repaired. The tape must be glued along its entire length. Any gap or leak is a place for rainwater to penetrate into the foam. At the corners, the tape must be bent so that the bent parts form sides to prevent leaks in the lower corners of the window opening. The tape must be cut on a flat surface. The tape is cut at both ends (along the middle) to a length equal to half its width. Next, the anti-adhesive paper protecting the adhesive strip is removed from the tape, and the tape is attached to the frame of the window structure. The notched ends are bent and glued to the side outer slopes, then the tape is attached to the lower outer slope, while the notched ends are bent onto the side outer slopes, overlapping onto those bends of the tape that are already glued. Next, the ebb is attached, then the installation gap is filled with foam from the room side.

Description of the tape

Self-expanding tape is a black or gray strip of rectangular cross-section made of an elastic porous material resembling foam rubber - porous polyurethane elastomer. It is impregnated with an acrylic-based composition that provides resistance to adverse external influences. An adhesive layer protected with film is applied to one side.

After opening the roller, unwinding the tape and placing it in the seam, the thickness increases to the parameters indicated in the marking, while the width of the product remains unchanged.

Cost of materials

As I noted at the very beginning, the high price of mounting tapes partially limits their distribution. But at the same time, if you know exactly what you need, there is a chance to fit within the budget allocated for glazing.

Non-woven sleep material with self-adhesive base from SOUDAL

| Name | Average cost, rubles |

| Internal duplicated tape 1.5x100 mm (12m) | 420 |

| Mounting tape for slope internal 120 mm (25 m) | 510 |

| External tape, diffuse 1.5x70 mm (25m) | 820 |

| External mounting tape for ebb 70 mm (25 m) | 450 |

| Mounting tape for window sill 200 mm (12 m) | 600 |

| Mounting tape insulated with isolon 250 mm (12 m) | 970 |

| Internal metallized tape 2x100 mm (12 m) | 320 |

| PSUL 15/6-8 gray, 6m roll | 220 |

| PSUL 20/8-10 black, 5 m roll | 320 |

PSUL from Robitex

Brief Product Description

Waterproofing, vapor-permeable tape made of membrane-type synthetic non-woven material. The tape is intended for waterproofing the installation seam of a translucent structure under low tide, as well as any other construction seams and joints. The tape has two adhesive strips on one (optional) or two sides. One strip is intended for attaching the tape to the translucent structure, the other is for attaching the tape to the wall slope. A wide range of tape sizes allows you to choose a material to protect seams of almost any size. The tape is supplied in rollers. The use of Robiband waterproofing tapes provides reliable protection of the mounting foam from moisture from the street side and ensures the removal of moisture from the foam to the outside.

Diffusion tape vapor-permeable NL (low tide) butyl

Diffusion vapor-permeable moisture-proofing tape (based on non-woven material) NL butyl

DESCRIPTION of the moisture-proof vapor-permeable tape (under tides) butyl NL:

permeable (diffusion) tape NL Profband made of membrane-type synthetic non-woven material is intended for waterproofing the lower assembly seam from external moisture of a translucent structure ( under the tide ), as well as any other construction seams and joints. The tape has two adhesive strips on one side (or on different sides only on request). One strip is intended for attaching the tape to a translucent structure, the other is for attaching the tape to a wall or slope. A wide range of tape sizes allows you to choose a material to protect seams of almost any size. The use of Profband waterproofing tapes provides reliable protection of the mounting foam from the penetration of moisture from outside the room and facilitates its removal from the foam to the outside, ensuring ventilation of the joint. The adhesive layers' adhesive strength far exceeds those required by GOST 30971-2002.

APPLICATION:

permeable tape NL Profband is ready for use and does not require special tools when installing it. The surfaces of joints and seams must be cleaned of dirt. The tape must be glued tightly along its entire length. Any gap or leak is a channel for rainwater to enter. At the corners, the tape must be folded so that the bent parts form sides to protect the lower corners of the window opening. The tape must be overlapped.

Size selection:

To ensure reliable protection of a seam or joint, the tape must be glued to the wall or slope with the entire width of the corresponding adhesive strip. Therefore, the width of the tape is selected as follows: it is necessary to add 40 mm to the width of the installation gap (rounded up). If necessary, a wider tape can be used.

Material properties:

• Resistance to vapor permeation: 0.053 (m2*h*Pa)/mg • Adhesive adhesion strength: not less than 0.3 (3.0) MPa (kgf/cm2) • Water resistance: not less than 600 Pa • Operating temperature: from -36 to +70 С°

Can be produced in non-standard and custom sizes.

Compliance with these recommendations will allow you to install the PSUL tape most correctly and help protect the installation seam from harmful environmental influences. Pre-compressed sealing tape is packaged in boxes and must be shipped to the installation site while maintaining the integrity of the packaging. If the integrity of the packaging is damaged, the manufacturing company is not responsible for the further use of the product. Storage and transportation of PSUL tapes must be carried out according to the recommendations indicated on the packaging. PSUL tape should be stored and transported at temperatures from +5 to +30 C, in a dry place protected from direct sunlight. To correctly select the size of the PSUL tape, it is necessary to remember that the tape performs its functions only in a compressed state. That is, for a gap of 5 mm it is necessary to use PSUL tape, which has a maximum expansion of 20 mm, for a gap of 6-10 mm it is necessary to use PSUL tape, which has a maximum expansion of 30 mm, and so on. When choosing a tape, you need to consult with our specialist who will select the right product for you. The use of tapes with an expansion of a gap that is obviously smaller will lead to the failure of this tape to fulfill its functions, as well as to the rapid destruction of the assembly seam. If the thickness of the PSUL tape is incorrectly selected, the manufacturer is not responsible for the use of the manufactured products. Pre-compressed sealing tape is used in accordance with GOST 30971-2002 to ensure vapor permeability of the assembly seam. PSUL tape is used at temperatures from +5 to +40 C. Using PSUL tape at negative temperatures will lead to an increase in the time it takes to release the tape. To avoid increasing the release time, the tape must be kept at room temperature for 24 hours. During the installation process, to speed up the release time, it is necessary to treat the tape with a heat gun. Otherwise, the release time will increase many times over. The PSUL tape is attached to the pre-treated, free of dirt and dust, degreased surface of the window or door block (or any other material being mounted). It is advisable to treat the surface on which the PSUL tape is attached using BR-1 or BR-2 solvent. When installing the tape, it is necessary to ensure a tight fit to the surface using short-term (3-5 seconds) pressing.

Waterproofing vapor-permeable tape Robiband NL

This material is an integral part of the Robiband system, used to organize a ventilated assembly seam. The Robiband system fully complies with modern technical standards.

In its line of PREMIUM ROBIBAND brand products, the Robitex company uses the latest butyl rubber adhesive layer (BKKS), which provides ultra-high adhesive-cohesive qualities and stickiness to surfaces. According to test results, the new BKKS showed excellent durability results. The conditional service life is more than 20 years.

PSUL tape for windows - what is it? Material characteristics, GOST and scope of application

The special PSUL tape for windows will help ensure high-quality and reliable sealing of seams and joints when installing window and other structures. PSUL is a pre-compressed sealing material presented in the form of a self-adhesive tape. Let's look at the main characteristics and scope of application of this seal, find out how to understand its markings and get acquainted with step-by-step instructions that will help you carry out problem-free installation in accordance with all the rules.

Butyl diffusion tape technical characteristics

Butyl tape is a modern sealing material that is widely used in private and commercial construction. It is available in different sizes and can have a layer of aluminum foil, foil polyethylene foam and even acoustic felt. But one thing remains unchanged: the presence of an adhesive butyl rubber surface, easy to use and environmentally friendly.

Liplent SD - one of the varieties of butyl tape - is intended for sealing external joints of windows and doors

Technical characteristics and properties of PSUL

PSUL sealing tape has the following properties:

- resistance to various natural factors - precipitation, ultraviolet radiation, etc.;

- resistance to deformation;

- compatibility with any materials;

- maintaining elasticity throughout the service life;

- chemical neutrality;

- water-repellent properties;

- resistance to mold and mildew;

- ability to withstand pressure up to 600 kPa for several hours;

- high heat and sound insulation characteristics.

Technical characteristics of self-expanding material in the form of a tape made of foamed polyurethane with acrylic impregnation:

- operating temperature – from -50°С to +90°С (varies within 5°С depending on the brand);

- resistance to deformation – from 14%;

- thickness dimensions in compressed form - from 2 mm, in expanded state - up to 8 cm;

- thermal resistance – up to +1000°С;

- fire resistance class according to GOST 30402-96 – B1 (flammable building materials).

Tape marking

Tape markings should include:

- Brand name.

- The class of the seal according to the water resistance limit.

- Numbers represented as a fraction, where the numerator is the width of the product, and the denominator is the range of the optimal width of the sealed gap.

- GOST number.

Liplent PSUL A 20/8–20 GOST R 53338-2009

Tape of the Liplent PSUL trademark, class “A” in terms of water resistance, 20 mm wide, suitable for sealing seams with a thickness of 8–20 mm.

The type of product for frost resistance is indicated additionally.

Acceptance rules

6.1 Acceptance of finished assembly joints is carried out at construction sites in batches. A batch is taken to be the number of window openings with installed window blocks and completed assembly seams, made using the same technology and issued with one acceptance certificate (quality document).

6.2 Acceptance of assembly seams is carried out by:

— incoming quality control of the materials used;

— quality control of the preparation of window openings and window blocks;

— monitoring compliance with requirements for the installation of window units;

— production operational control;

— acceptance tests during work execution;

— classification and periodic laboratory tests of materials and assembly joints carried out by testing centers (laboratories).

Incoming quality control of materials and products, quality control of the preparation of window openings and installation of window blocks, as well as periodic tests during the installation of installation joints are carried out by a construction laboratory or the quality control service of a construction (installation) organization.

The results of all types of control are recorded in the appropriate quality logs.

Completion of work on installation of installation joints is documented with an acceptance certificate (concealed work certificate).

6.3 Incoming quality control of materials upon receipt and storage is carried out in accordance with the requirements of the RD for these materials. At the same time, they check certificates of conformity, sanitary and epidemiological conclusions, expiration dates, labeling of products (containers), as well as compliance with the conditions established in supply contracts.

6.4 Quality control of the preparation of window openings and installation of window blocks is carried out in accordance with the technological documentation for installation work, taking into account the requirements of the current regulatory documentation and this standard. In this case they check:

— preparation of the surfaces of window openings and window blocks;

- dimensions (maximum deviations) of window openings and blocks;

— deviations from dimensions when installing window units;

— deviations from the dimensions of installation gaps;

— other requirements established in the technological documentation.

The quality of preparation of window openings is documented in the window openings acceptance certificate.

6.5 Production operational quality control is carried out by the responsible contractor sequentially for each operation of the technological process.

6.6 Acceptance tests during the construction of installation joints are carried out by the quality control service (construction laboratory) of the construction organization at least once per shift. In this case, the following is checked on at least three samples:

quality of installation of mounting tapes, insulation and other materials (upon completion of work on each layer of the seam);

temperature and humidity parameters of work conditions.

If the technology for installing window blocks requires a two- to three-day installation period (for example, the first day - installation of window blocks on mounting wedges and laying outer layer materials; second day - application of installation materials of the central and inner layers), then quality control of the installation seam is carried out at the same window blocks.

6.7 Classification and periodic laboratory tests are carried out at the request of design, construction and other organizations to confirm the classification characteristics and performance indicators of installation joints. Tests are carried out in testing centers (laboratories) accredited to conduct such tests.

It is allowed to determine the characteristics of installation seams by calculation methods according to regulatory documentation and methods approved in the prescribed manner.

6.8 The manufacturer confirms the acceptance of assembly seams by issuing a quality document (passport), which must contain:

— name and address of the installation organization;

— name and address of the place of work;

— symbol and (or) description of the design with a list of insulating materials used, drawings, technical characteristics of the assembly seam (including fasteners);

— number of assembly seams submitted for acceptance;

— date of registration of the passport;

— stamp of the quality service and signature of the responsible person;

— warranty obligations;

— other information based on specific work conditions.

6.9 Acceptance of work on installation of installation joints is formalized by an acceptance certificate signed by the contractor and the customer, to which is attached a quality document (passport), copies of approval and measurement protocols and, at the customer’s request, sanitary and epidemiological reports on insulating materials.

6.10 In the event of controversial (arbitration) issues regarding the quality of installation seams during the warranty period, the customer has the right to demand a control opening of the installation seams. In this case, it is recommended to use the control plan given in Table 2.

Table 2

Diffusion (vapor permeable) tape made of durable polypropylene fabric with two fastening strips along the edges of butyl rubber sealant on different sides. Installed on the outside of the ebb, ventilated facade.

Fully complies with the requirements of GOST 30971-2002 “Installation seams of junctions of window blocks to wall openings.”

Differences between butyl tape and bitumen tape

Butyl tapes are a new generation of sealants that outperform traditional bituminous materials in many respects:

- Durability. Bitumen dries out and becomes brittle within six months to a year after installation, and when heated to 70 °C (for example, on an open roof) it begins to drain. Butyl rubber does not react to temperatures up to 100 °C and retains its original qualities.

- Ease of installation. Butyl tape can be installed perfectly without heating at air temperatures down to −15 °C. It is enough to peel off the anti-adhesive layer and apply the tape with the sticky side. Bituminous materials need to be heated, which requires special skills and tools.

- Environmental friendliness. Unlike bitumen with the “aroma” of petroleum products, butyl rubber is environmentally friendly and does not emit harmful substances or unpleasant odors. It can be used in residential areas, for example to seal joints between windows, doors and walls.

Bitumen-based tape will last much less than butyl tape: within a year or two you will have to repair the joints again

Indicators of water resistance and frost resistance according to GOST

State standard GOST R 53338-2009, which contains a description of the material and provides its classification, divides self-expanding tapes into 3 classes according to the water resistance limit in the state of working compression:

- Class A – over 600 Pa.

- Class B – at least 400–600 Pa.

- Class B – no less than 200–399 Pa.

Also, the specified GOST provides for the division of products into types of execution:

- I – optimal for regions with an average monthly air temperature in the coldest time of the year down to -10°C. Minimum operating temperature – -25°С.

- II – for regions with an average monthly January temperature of up to -20°C. Minimum operating temperature – -45°С

- M (frost-resistant option) - for regions with an average monthly temperature in January below -20°C. Minimum operating temperature – -55°С