High-quality glazing requires serious consideration and is impossible without proper insulation of the gap between the opening and the window. Often, organizations that install translucent structures limit themselves to traditional polyurethane foam, which is subsequently covered with plaster or other finishing materials. This approach has proven itself relatively well and in some cases does not cause any complaints from the consumer throughout the entire service life of the window.

However, glazing with one level of sealing of the opening does not meet the state requirements for the quality of services or goods provided, that is, GOST. To comply with these requirements, additional insulation is required at the junction of the window and the opening both from the street side and from the room side. Such insulation is ensured using special mounting tapes.

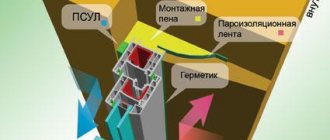

Scheme for using mounting tapes on windows

View from above

Mounting tape for windows is a self-adhesive material on a polymer or fabric basis, designed for additional sealing of window or door openings.

Types of mounting tapes for windows

The functions performed by the tapes are different and depend on the location of gluing, the condition of the opening, the features of the future finishing of the slopes, as well as the requirements for the window block. Next, we will consider the most commonly used materials common in the modern construction market.

Pre-compressed sealing tape is used primarily on the outside of translucent structures. Its main purpose is to ensure unimpeded drainage of moisture from the area where the hatch connects to the opening.

Essentially, this is a tape product made of elastic polyurethane foam (looks like foam rubber), usually gray or black. One side of the material is covered with an adhesive composition, insulated with a protective film. The tape is supplied twisted into compact reels or rolls (depending on the size), which need to be unwound only during the installation process, since the material loses its quality over time.

An example of tape expansion over time

The main feature is the ability to fill joints as a result of expansion, which occurs as a result of contact with air. The tape isolates the gap from moisture and external influences from the outside, while simultaneously allowing excess liquid to evaporate from the inside.

Scope of application of PSUL:

- Additional sealing of interfaces between elements of prefabricated structures;

- Sealing the gap between the frame and the opening when installing windows and doors;

- Insulation of joints between small-sized moving units of building facades;

- Filling the external seam between the slope and the frame during the installation of PVC windows.

It is important to understand that to fill the gap efficiently, you need a tape of the appropriate size. For example, if the task is to seal a joint with a maximum width of 40 mm, you will need a PSUL with a nominal size of 45-50 mm.

Water vapor barrier (GPL)

This type of tape product is most popular when installing window blocks. Among its main features it is worth highlighting the following:

- Water vapor barrier mounting tape is designed to seal joints on the room side.

- Polyethylene film is most often used as the basis for self-adhesive material. On one side the tape is equipped with a foil coating, and on the other - with an adhesive composition.

- The adhesive used provides reliable fixation on most surfaces (concrete, brick, cinder block, wood and others). The products of some brands have poor adhesion to foam blocks and aerated concrete, so before purchasing you should consult with the seller or read the attached instructions.

- The structure of the material prevents the penetration of moisture or air both through the tape itself and through the gluing points. This ensures the maximum possible tightness of the joint of the opening and, as a result, the structure as a whole.

- In addition to insulating from moisture, the tape does not deteriorate during prolonged contact with ultraviolet radiation and is not subject to destruction from exposure to aggressive environments (household acids, alkalis and other reagents).

GPL is used for waterproofing installation gaps that arise when installing window and door units, as well as for sealing structures made of metal, wood, concrete and plastic.

GPL-S and insulated GPL

- GPL-S its structure is identical to the GPL described above. The main difference is an additional strip of double-sided tape on the side that is not covered with adhesive. Due to this, the area of fixation of the material on the window block expands. Unlike traditional water vapor barrier tape, GPL-S can be glued to the inner surface of the profile using an additional strip, and the adhesive side to the slope.

- Insulated hydro-vapor barrier tape is an improved modification of conventional GPL. Main features: thickened base layer based on polyurethane foam or cellular polyethylene; a more durable foil component, usually made from high-quality polyethylene. As a result, the tape, in addition to its high waterproofing qualities, significantly prevents heat loss at the joints of the frame and the opening. In addition, the material is quite durable, which ensures the safety of the structure, preventing mechanical damage.

VM (VM+) tape

- VM . Vapor barrier tape designed for sealing joints indoors. It is used in cases where wet finishing of slopes is planned (plaster or tiling). Provides protection from moisture entering the joint of the opening and reliable fixation of the finishing coating.

- VM+ . A modified analogue of the previous product with similar properties. It has the best waterproofing qualities, which allows it to be used in rooms with high humidity (kitchens, showers).

VS (VS+) tape

- Sun. Material with one-sided adhesive coating on a non-woven base. Used indoors for waterproofing window and door openings. Intended only for dry finishing of slopes. For example, plastic, wooden or MDF lining, plasterboard and other sheet materials.

- BC+. Similar to the previous product, also used for dry slope design. Distinctive features: adhesive layer on one side and the presence of an additional strip of double-sided tape on the back; There are modifications with foil coating for additional thermal insulation of the seam.

Robiband mounting tapes – a course for durability

Robiband mounting tapes are tape sealants that have been produced by Robitex Group of Companies at a plant in the Moscow region since 2006. Over the course of 15 years, the company has become a leader in the production of mounting tapes and an expert in this field. More than 50 million windows have been installed in Russia using Robitex materials.

The company not only produces mounting tapes, but is also a patent holder. In 2008, Robitex Group patented a revolutionary installation device - the UFM mounting clamp. With its help, window installation can be easily done by one person. Aligning the structure in the opening takes five times less time compared to installation on support wedges. This technology is especially relevant for strip glazing and balcony blocks.

Advantages of Robiband mounting tapes:

- 3 layers vs 1 . Waterproofing and vapor-permeable tapes consist of three layers, this is the only way they can perform their function - releasing water vapor and not allowing water to pass through and vice versa.

Photo: Noname tapes consist of one layer and allow water to pass through as easily as air. And getting the mounting seam wet is a direct path to freezing and the formation of ice on the window, ©oknamedia.ru

- The durability of the tapes for at least 20 years has been confirmed by tests in Russian and European testing centers. Robiband tapes are the only ones in Russia that have a quality certificate from the European Institute of Window Technology in Rosenheim (IFT Rosenheim Germany), which is recognized throughout the world. With these tapes you can forget about blowing out the slopes for the entire service life of the window.

- Can be used in any region of the country . The operating temperature of the tapes at which they do not lose their properties is from -40°C to +80°C.

- Installation can be done all year round at temperatures from -15°C to +50°C. The vapor barrier properties of internal tapes (vapor barrier) are many times higher than the requirements of the standards. A seam protected by film will never get wet and will keep the house warm for decades.

- Installation in one day. It is recommended to glue the tapes onto wet foam and not wait until the foam hardens to finish the slopes.

- Adhesion , that is, the peeling force of the surface of the tape with the wall and window, is up to 5 times higher than required by GOST - 1.4-1.6 kgf/cm at a rate of 0.3 kgf/cm.

Photo: Robiband tapes, unlike analogues, withstand the sample peeling time required by GOST, @oknamedia

No deformation of the wall and window can lead to the tape coming off and cracks appearing on the plaster slopes.

Disadvantages of Robiband tapes:

- Higher cost compared to analogues, due to the use of high-quality materials with a long service life of up to 20 years.

The results of comparative tests of Robiband and Noname tapes can be seen in this video:

Installation features

The tape is applied both before fixing the window block in the opening, and on already installed structures. The first option is more convenient in cases with the installation of external insulation.

Let's consider the algorithm for using tape insulation using the example of gluing pre-compressed sealing tape (PSUL) and internal GPL-S with an additional strip of double-sided tape:

- We prepare the opening. If there is an old window unit, we dismantle it as carefully as possible, without causing unnecessary damage. After dismantling, we level the surfaces adjacent to the future structure and clean them of foreign contaminants.

- We perform a test installation of the block in the opening, temporarily fixing it. This is necessary to mark the edge of contact between the walls and the window, so that when gluing the tape is hidden behind the outer slopes.

- We measure the window block. In accordance with the obtained dimensions, we cut PSUL for gluing on the top and sides of the frame; we prepare diffuse tape to isolate the area where the molding profile is attached.

- We do the same with GPL-S (internal slopes) and butyl rubber tape (for the window sill profile). The material is measured for each side with an allowance of 10 cm to form corner joints.

- We apply the tape, gradually removing the protective layer from the adhesive surface of the PSUL.

We glue GPL-S to the inside of the window profile using a strip of double-sided tape (we do not remove the protective film from the main adhesive surface at this stage). - We fix the window in the opening. We wedge it, and then fasten it with anchors or using mounting plates. We fill the seams with polyurethane foam.

- After complete polymerization of the foam and rough preparation of the inner surface of the walls, we fix GPL-S on them (remove the protective paper and glue it to the slopes).

It should be remembered that the tape must be selected in accordance with weather conditions. When working in winter, it is possible to glue only material intended for use in low temperature conditions.

Useful video on the topic:

Waterproofing vapor permeable tape

Waterproofing vapor permeable tape

ROBIBAND NL

ROBIBAND NL A

ROBIBAND NL V

ROBIBAND NLP V

This material is an integral part of the ROBIBAND

, used to organize a ventilated assembly seam.

ROBIBAND

system fully complies with modern technical standards.

Robitex company in the ROBIBAND

PREMIUM class uses the latest butyl rubber adhesive layer (BKKS), which provides ultra-high adhesive-cohesive qualities and stickiness to surfaces. According to test results, the new BKKS showed excellent durability results. The conditional service life is more than 20 years.

BRIEF PRODUCT DESCRIPTION

Waterproofing, vapor-permeable tape made of membrane-type synthetic non-woven material. The tape is intended for waterproofing the installation seam of a translucent structure under low tide, as well as any other construction seams and joints. The tape has two adhesive strips on one (optional) or two sides. One strip is intended for attaching the tape to the translucent structure, the other is for attaching the tape to the wall slope. A wide range of tape sizes allows you to choose a material to protect seams of almost any size. The tape is supplied in rollers. ROBIBAND waterproofing tapes

provides reliable protection of the mounting foam from moisture on the street side and ensures the removal of moisture from the foam to the outside.

MATERIAL CHARACTERISTICS

| Indicator name | Unit | GOST requirement | According to the test report |

| Resistance to vapor permeation | (m2*h*Pa)/mg | no more than 0.25 | 0,053 |

| Adhesive bond strength | MPa (kgf/cm2) | not less than 0.3 MPa (3.0 kgf/cm2) | not less than 0.3 (3.0) |

| Waterproof | Pa | not less than 600 | impenetrable |

| Operating temperature | С° | from -36 to +70 | corresponds |

| Durability | conventional years | at least 20 | corresponds |

SELECTION OF ROBIBAND SIZE NL

To ensure reliable protection of a seam or joint, the tape must be glued to the wall or slope with the entire width of the corresponding adhesive strip. Therefore, the width of the tape is selected as follows: it is necessary to add 45 mm to the width of the installation gap (rounded up). If necessary, it is possible to use a wider

tapes. High-quality window installation

BASIC SIZES

| Tape width, mm | Length, m |

| 80 | 12,5 |

| 100 | 12,5 |

| 120 | 12,5 |

| 150 | 12,5 |

It is possible to produce other standard sizes upon request

APPLICATION OF ROBIBAND NL TAPES

Tape ROBIBAND NL

It is immediately ready for use and does not require special tools for installation.

The surfaces of joints and seams must be cleaned of dirt. Absorbent and fragile surfaces require preliminary priming. The tape must be glued tightly along its entire length. Any gap or lack of tightness is a channel for rainwater to penetrate into the mounting foam. At the corners, the tape must be bent so that the bent parts form sides to prevent leaks in the lower corners of the window opening. The tape must be overlapped. It is recommended to seal the assembly seam “on the wet foam”. This is necessary so that the polyurethane foam, when expanding, sticks the tape to itself and stretches it a little. Installation of the tape should be carried out using the “from the frame” technology, having previously glued it to the SPK box. Only the integrated use of the ROBIBAND

ensures the necessary reliability and durability of the assembly seam. The use of each material separately or their incomplete combination only partially improves the characteristics of the seam and does not provide comprehensive protection against a wide range of negative impacts on the seam during its entire service life.

ON THE QUESTION ABOUT THE UV RESISTANCE OF ROBIBAND NL TAPES

According to the documentation of manufacturers of membrane diffusion fabrics used for the manufacture of waterproofing diffusion (vapor-permeable) tapes ROBIBAND NL

, the resistance to solar ultraviolet radiation of materials from various manufacturers ranges from four to eight months, with direct irradiation.

It follows that to ensure the required durability of diffusion tapes, it is necessary to protect them from direct solar ultraviolet radiation. For example, protection is provided by using tape in the lower window installation seam, under the ebb. ROBIBAND NL

tapes as an external waterproofing, vapor-permeable layer of an assembly joint when installing translucent structures in buildings with external wall insulation.

ROBIBAND NL tapes

“Premium” class material is used with resistance of up to eight months, and for the production of

ROBIBAND NL

of “Standard” class with resistance of up to four months. The specified periods should not be exceeded, since exceeding the specified time intervals leads to destruction of the diffusion web and to failure of the tape.

Rules for using ROBIBAND NL

are described in the “Recommendations for the design and installation of translucent structures in accordance with STO 1-2006, GOST and TR 152-05,” edition 2, amended and supplemented.

The recommendations were developed by technical specialists of the ROBITEX Group of Companies. Of maximum interest in this aspect is clause 8.6.2. these recommendations, which describe in detail the rules for using ROBIBAND NL

. For clarity of what has been said, we recommend that you refer to nodes No. 51 and No. 52 of Appendix “A” of the mentioned recommendations

.

Dimensions and approximate cost

Diffuse insulating tape for installation outside (under low tide):

- Width -70 mm;

- Length in a skein – 25 m;

- The price of a skein is 436 rubles.

PSUL for use at sub-zero temperatures:

- Width – 20 mm;

- Thickness – 8 mm (40 when uncompressed);

- Length – 5 m;

- Price – 160 rub.

Internal duplicated tape:

- Width – 100 mm;

- Length per skein 25 m;

- The price of a skein is 377 rubles.

Inner metallized tape:

- Width – 45 mm;

- Length – 24 m;

- Price for 24 m – 523 rub.

Tape for window sill profile:

- Width – 200 mm;

- Length – 12 m;

- Price – 600 rub.

PSUL tape

Pre-compressed self-expanding sealing tape (PSUL) Robiband is a polyurethane foam coating that has an adhesive surface. The product is impregnated with a special neoprene type composition. The tape is sold in rolls. It comes in black and gray shades. Moreover, the latter has better characteristics than the first.

The use of Robiband tape is quite simple. It is enough to place the PSUL in a seam or joint, and it will expand on its own, filling the entire space. The surface must first be cleaned of dust. The tape is glued to only one side of the seam; it must not be pulled out or deformed.

The product has the following properties:

- resistant to various climatic factors;

- does not burn;

- has chemical neutrality;

- not susceptible to ultraviolet radiation;

- not susceptible to mold and fungal microorganisms.

In this case, the properties of the tape do not change. It is sold in lengths of 4 and 6 m. The maximum expansion can be from 1.5 to 5 cm, thereby closing a gap of 0.3 to 1.5 cm.

Waterproofing vapor-permeable tape Robiband NL

Robiband NL waterproofing vapor-permeable tape made of membrane-type synthetic non-woven material. The tape is intended for waterproofing the installation seam of a translucent structure under low tide, as well as any other construction seams and joints.

The tape has two adhesive strips on one (optional) or two sides. One strip is intended for attaching the tape to the translucent structure, the other is for attaching the tape to the wall slope. A wide range of tape sizes allows you to choose a material to protect seams of almost any size.

The tape is supplied in rollers.

The use of Robiband waterproofing tapes provides reliable protection of the mounting foam from moisture from the street side and ensures the removal of moisture from the foam to the outside.

Material properties:

- Does not burn;

- Water repellent;

- Chemically safe;

- Remains elastic;

- Not affected by ultraviolet radiation, mold and fungi.

Characteristics of Robiband NL

| Indicator name | Unit | Requirement GOST 30971-2002 | According to the test report |

| Resistance to vapor permeation | (m2*h*Pa)/mg | no more than 0.25 | 0,053 |

| Adhesive bond strength | MPa (kgf/cm2) | not less than 0.3 MPa (3.0 kgf/cm2) | not less than 0.3 (3.0) |

| Waterproof | Pa | not less than 600 | impenetrable |

| Operating temperature | С° | from -36 to +70 | corresponds |

| Durability | conventional years | at least 20 | corresponds |

Robiband NL size selection

To ensure reliable protection of a seam or joint, the tape must be glued to the wall or slope with the entire width of the corresponding adhesive strip. Therefore, the width of the tape is selected as follows: it is necessary to add 45 mm to the width of the installation gap (rounded up). If necessary, a wider tape can be used.

| Tape width, mm | Length, m |

| 80 | 12,5 |

| 100 | 12,5 |

| 120 | 12,5 |

| 150 | 12,5 |

Application of Robiband NL tapes

The Robiband NL tape is immediately ready for use and does not require special tools for installation. The surfaces of joints and seams must be cleaned of dirt.

Absorbent and fragile surfaces require preliminary priming.

The tape must be glued tightly along its entire length. Any gap or lack of tightness is a channel for rainwater to penetrate into the mounting foam.

At the corners, the tape must be bent so that the bent parts form sides to prevent leaks in the lower corners of the window opening.

The tape must be overlapped. It is recommended to seal the assembly seam “on the wet foam”. This is necessary so that the polyurethane foam, when expanding, sticks the tape to itself and stretches it a little.

Installation of the tape should be carried out using the “from the frame” technology, having previously glued it to the SPK box.

Only the integrated use of the Robiband system ensures the necessary reliability and durability of the assembly seam.

The use of each material separately or their incomplete combination only partially improves the characteristics of the seam and does not provide comprehensive protection against a wide range of negative impacts on the seam during its entire service life.

Tape NL

The waterproofing vapor-permeable tape is made of artificial membrane-like non-woven material. The use of Robiband tape ensures the reliability of the joint. It is used for waterproofing the lower construction seam.

The tape has 2 adhesive strips on one side (and can be made on both sides to order). One is used to fix the product on the structure, and the other is used to attach it to the wall.

NL Robiband tape has the following properties:

- The steam permeability index is no less than 0.15 units.

- Adhesion to the original surface from 0.1 MPa.

- Capable of withstanding pressure up to 1 thousand PA.

- Operating temperature during operation is from -45 to 80 0 C.

- Resistant to direct sunlight for 8 months.

Sold in widths from 8 to 12 cm and a standard length of 12.5 m.

Robiband NL B - External waterproofing vapor-permeable tape

Waterproofing, vapor-permeable tape made of membrane-type synthetic non-woven material. The tape is intended for waterproofing the lower assembly seam of a translucent structure (under the tide), as well as any other construction seams and joints. The tape has two adhesive strips on one or different sides (to order only). One strip is intended for attaching the tape to a translucent structure, the other is for attaching the tape to a wall or slope. A wide range of tape sizes allows you to choose a material to protect seams of almost any size. The tape is supplied in rollers. The use of Robiband waterproofing tapes provides reliable protection of the mounting foam from moisture outside the room and helps remove moisture from the foam to the outside. The adhesive layers' adhesive strength far exceeds those required by GOST 30971-2002.

Material characteristics

| Indicator name | Unit | Requirement GOST 30971-2002 | According to the test report |

| Resistance to vapor permeation | (m2*h*Pa)/mg | no more than 0.25 | 0,053 |

| Adhesive bond strength | MPa (kgf/cm2) | not less than 0.3 MPa (3.0 kgf/cm2) | not less than 0.3 (3.0) |

| Waterproof | Pa | not less than 600 | impenetrable |

| Operating temperature | С° | from -36 to +70 | corresponds |

| Durability | conventional years | at least 20 | corresponds |

Size selection Robiband NL B

To ensure reliable protection of a seam or joint, the tape must be glued to the wall or slope with the entire width of the corresponding adhesive strip. Therefore, the width of the tape is selected as follows: it is necessary to add 45 mm to the width of the installation gap (rounded up). If necessary, a wider tape can be used.

Application of Robiband NL B tapes

The Robiband NL tape is immediately ready for use and does not require special tools for installation. The surfaces of joints and seams must be cleaned of dirt. Absorbent and fragile surfaces require preliminary priming. The tape must be glued tightly along its entire length. Any gap or lack of tightness is a channel for rainwater to penetrate into the mounting foam. At the corners, the tape must be bent so that the bent parts form sides to prevent leaks in the lower corners of the window opening. The tape must be overlapped. It is recommended to seal the assembly seam “on the wet foam”. This is necessary so that the polyurethane foam, when expanding, sticks the tape to itself and stretches it a little. Installation of the tape should be carried out using the “from the frame” technology, having previously glued it to the SPK box. Only the integrated use of the Robiband system ensures the necessary reliability and durability of the assembly seam. The use of each material separately or their incomplete combination only partially improves the characteristics of the seam and does not provide comprehensive protection against a wide range of negative impacts on the seam during its entire service life.

VM tape

The VM Robiband vapor barrier tape is made of aluminum foil, which is reinforced with special artificial threads. The latter are extremely durable.

The use of VM B Robiband tape is recommended for internal vapor barrier of construction joints in order to subsequently treat the slope with plaster. There are 2 adhesive strips on the surface of the product. They are usually located on different sides, but upon customer request they can be placed on one side. One strip helps secure the tape to the structure, and the second is attached to the slope or wall.

The technical properties of the VM Robiband tape are the same as the previous one (NL). The product is sold in skeins of 12.5 m in length. The width of the tape is 8, 10, 12 and 15 cm. It is sold ready for use, so no special tools are needed.

Application of Robiband mounting tapes

External tapes (waterproofing and vapor-permeable) are designed to protect the installation seam from precipitation and exposure to UV radiation from the street. Their second important function is to remove excess moisture from the seam due to partial pressure.

This group includes:

- PSUL (Vapour-Permeable Self-Expanding Sealing Tape) - the sealing tape, expanding, fills the outer gap, eliminates cracks, which means leakage, blowing and freezing from the outside of the seam. And due to vapor permeability, the tape removes accumulated water vapor out, keeping the seam dry. Another important property of tapes is elasticity and resilience. During thermal expansion of a window or enclosing structure, the tape does not crack, but expands or contracts, reliably protecting the installation seam.

Material: made of elastic polyurethane foam impregnated with a special composition.

Application: window openings with a quarter.

Installation location: PSUL tapes are installed on the edge of the frame from the street side on the vertical and upper horizontal parts of the window. Gluing on the surface of the quarters (top and side) is also allowed.

Installation method: The tapes can be easily applied to the window by removing the protective film from the adhesive strip.

Installation at temperature:

up to -5°С – all PSUL tapes

from -5° to -15°С – PSUL grade 50+ N

Front gap width: from 2 to 20mm

Photo: Robiband PSUL tapes do not allow moisture to pass into the assembly seam from the outside and allow water vapor to escape outside. Glued to the front surface of the window frame from the street side, ©robitex.ru

- Diffusion tapes are designed to protect the polyurethane foam under low tide from moisture and ultraviolet radiation, as well as to remove moisture from the seam to the outside.

Material: made of 3-layer membrane material. The membrane contains a huge number of microholes - they are so small that they do not let water into the seam, but their size is sufficient for water vapor to escape out.

Installation location: only under the ebb or along the entire perimeter of the window. When installing without a quarter and then finishing the external slopes, it is glued along the perimeter of the window.

Installation method: The tapes can be easily applied to the window by removing the protective film from the adhesive strips. One strip for attaching the tape to the window, and the second to the wall.

Installation: standard at temperatures up to 0°C, winter - from 0°C to -20°C, the opening must be treated with a primer

End gap width: from 5 to 600mm

Photo: Robiband NL diffuse tapes are installed from the street side under low tide on an adhesive basis, ©robitex.ru

| ! It is recommended to use Robiband PBT sound-absorbing tape at low tide to avoid unpleasant noise during rain. |

- KMP is a combined multifunctional vapor-permeable tape for waterproofing external seams. In terms of properties, this is an analogue of PSUL, only the main material is in a straightened state. The diffusion membrane in the composition of the KMP limits the release of foam to the outside in crooked, damaged and uneven openings due to the loose fit of the tape.

The PVC plank is a “beacon” for subsequent plastering of the openings from the outside and allows you to make them perfectly smooth.

This development of the Robitex company is specifically for installing windows on uneven, damaged window openings or openings without a quarter.

Material: The tape is composed of elastic polyurethane, PVC plate and diffusion membrane.

Application: window openings with a quarter.

Installation location: installed on the edge of the frame from the street side on the vertical and upper horizontal parts of the window.

Installation method: The tape can be easily pasted on the window by removing the protective film from the adhesive strip.

Front gap width: 5-50mm

Installation: standard at temperatures up to 0°C, winter from 0°C to -20°C, the opening must be treated with a primer

Photo: Robiband KMP tape can be used at any temperature, ©robitex.ru Internal tapes (vapor barrier) are designed to protect the assembly seam from moisture penetration from inside the room. The insulation under the vapor barrier tapes will always be dry, which means its thermal insulation properties will be high, which increases the service life of the installation seam.

Photo: Robiband vapor barrier tapes from Robitex on an adhesive basis, ©robitex.ruTypes of vapor barrier tapes:

- Robiband VM is a universal tape for finishing plaster slopes or panel slopes. Consists of aluminum foil, reinforced with synthetic thread, with a fleece covering for installation of windows in accordance with GOST.

- Robiband BC - tapes for slopes made of sandwich panels are made of durable metallized film backed with non-woven material.

Advantages of vapor barrier tapes:

- Lungs. Weight 60-120 gr./m.p.

- Durable. Retains vapor barrier properties for many years

- Reliable adhesion to openings and windows

Disadvantages of vapor barrier tapes:

- When gluing onto “cut polyurethane foam” (cutting it is not recommended by regulatory documents), air gaps are formed between the tape and the foam.

Types of butyl tapes:

- Robiband BO is used as an analogue of Robiband VM tape for subsequent finishing of plaster slopes. This is a full-butyl tape backed with non-woven fabric for installation in accordance with GOST with subsequent plastering of slopes.

- Robiband PBA for sealing aluminum facades. These are butyl tapes on an aluminum base.

- Robiband PBT - for protecting the assembly joint near plaster slopes and as sound insulation under the slope. These are butyl tapes with a fabric backing.

- Robiband PBLN is a butyl tape for easy installation. The butyl layer has a special protective coating without paper, so the roll unwinds easily. Under “dry” slopes.

- Robiband PB is a butyl tape for sealing aluminum structures of winter gardens, balconies, and entrance doors. Used with a covering strip of the structure.

Pros of butyl tapes:

- Adhesion to foam joint. The tapes adhere completely to the foam, leaving no air gaps.

Disadvantages of butyl tapes:

- Heavier 150-400g/l.m.

- It is necessary to take into account the load on the tape when installing on “ceiling” seams.

- On windows that are too wide, the tape may fall off due to its own weight.

Sun tape

Robiband BC tape is also aluminum foil, which is reinforced with special durable synthetic threads. It has 2 adhesive strips on different sides (but the manufacturer can place them differently upon request).

The use of Robiband BC tape in a frame house is intended only for internal vapor barrier of construction joints. In this case, in the future the slopes should be finished using a dry method (for example, using plastic slopes, sandwich panels, etc.).

One adhesive strip is fixed on the structure, and the second on the wall. The product has the same technical characteristics as the previous one. The tape can be purchased in lengths of 12.5 m and widths from 8 to 15 cm.

Lenta VS+

The use of Robiband tape BC+ in a wooden house also involves internal vapor barrier of construction joints in order to subsequently carry out finishing work on slopes using the dry method.

The tape is sold in rolls of 12.5 m and a width of 8 to 15 cm. The width should be selected as follows: add 4.5 cm to the thickness of the gap. If necessary, use wider varieties.

One adhesive strip is fixed to the slope or wall, and the other full width will be attached to the structure.

Robiband NL B is a waterproofing, vapor-permeable tape made of membrane-type synthetic non-woven material. The tape is intended for waterproofing the installation seam of a translucent structure under low tide, as well as any other construction seams and joints.

The tape has two adhesive strips on both sides: one strip is intended for attaching the tape to the translucent structure, the other is for attaching the tape to the wall slope. The adhesive layers' adhesive strength far exceeds those required by GOST 30971-2002. The use of Robiband waterproofing tapes provides reliable protection of the mounting foam from moisture from the street side and ensures the removal of moisture from the foam to the outside. The Robiband system fully complies with modern technical standards.

Material characteristics

| Indicator name | Unit | Requirement GOST 30971-2002 | According to the test report |

| Resistance to vapor permeation | (m2*h*Pa)/mg | no more than 0.25 | 0,053 |

| Adhesive bond strength | MPa (kgf/cm2) | not less than 0.3 MPa (3.0 kgf/cm2) | not less than 0.3 (3.0) |

| Waterproof | Pa | not less than 600 | impenetrable |

| Operating temperature | С° | from -36 to +70 | corresponds |

| Durability | conventional years | at least 20 | corresponds |

Robiband NL size selection

To ensure reliable protection of a seam or joint, the tape must be glued to the wall or slope with the entire width of the corresponding adhesive strip. Therefore, the width of the tape is selected as follows: it is necessary to add 45 mm to the width of the installation gap (rounded up). If necessary, a wider tape can be used.

A wide range of tape sizes allows you to choose a material to protect seams of almost any size. The tape is supplied in rollers.

Basic sizes

| Tape width, mm | Length of tape in roller, m/n | Number of m/p in 1 box |

| 80 | 18 | 90 |

| 100 | 18 | 72 |

| 120 | 18 | 36 |

| 150 | 18 | 36 |

Application of Robiband NL tapes

Robiband NL tape is ready for use and does not require special tools for installation. The surfaces of joints and seams must be cleaned of dirt. Absorbent and fragile surfaces require preliminary priming. The tape must be glued tightly along its entire length. Any gap or lack of tightness is a channel for rainwater to penetrate into the mounting foam. At the corners, the tape must be bent so that the bent parts form sides to prevent leaks in the lower corners of the window opening. The tape must be overlapped. It is recommended to seal the assembly seam “on the wet foam”. This is necessary so that the polyurethane foam, when expanding, sticks the tape to itself and stretches it a little. Installation of the tape should be carried out using the “from the frame” technology, having previously glued it to the SPK box.

Tips for choosing

Before purchasing any type of Robiband tape, experts advise first asking the seller for a passport for such a product or certificates of conformity. They definitely need to be viewed and verified. This is a confirmation of the quality of the product, so doubts will disappear.

If this is your first time choosing and using such a tape, it is best to first consult with a specialist in this field. He will tell you about all the options for Robiband tapes, their features, applications, differences, and also tell you what is preferable to purchase.

Installation work can also be carried out at low ambient temperatures. In this case, it is recommended to use a special construction hair dryer to preheat the tapes if necessary (in particular, for PSUL). For her, under such conditions, the increase in size will occur 2 times faster.

Do not unwind the entire roll while working. In the future, if part of the product is no longer needed, it is quite difficult to wind the tape back, and this is wasted money. It is best to use the product by carefully unwinding the required amount from the roll.

In general, the use of Robiband tapes will help to efficiently insulate a building and protect it from the effects of negative conditions.

Robiband tape classes

All Robiband tapes are available in three classes:

Quality A – premium quality tapes made from European materials. The characteristics exceed the standard requirements by 10 times. This is a solution for homeowners who take a responsible approach to the construction and renovation of their property and are focused on long-term comfort.

Quality B – “standard +” tapes with characteristics exceeding the requirements by 2-5 times. This is the most common quality with an optimal price-quality ratio.

Quality B – tapes for object construction. Characteristics at the level of regulatory requirements and an attractive price.

The belonging of the tape to a certain class is reflected in the name - the letter A, B or C is indicated after the name.

Brands of Robiband tapes

Memo on Robiband tapes for the installer

| Types of Robiband tapes | Tape brands |

| External tapes | |

| Window opening with a quarter | PSUL, KMP |

| Window opening without quarter | Diffusion tape Robiband NL |

| Broken and uneven window openings | KMP |

| At low tide | Diffusion tape Robiband NL |

| Low tide soundproofing | Robiband PBT (adhesive to low tide) or PSUL |

| Inner tapes | |

| For plastic or aluminum windows | Robiband VM, Robiband BO, Robiband PBT, Robiband BC, Robiband PBLN |

| Under plaster slopes | Robiband VM, Robiband BO, Robiband PBT |

| Under panel slopes | Robiband VM, Robiband BC, Robiband PBLN |

| For balconies, winter gardens based on a post-transom aluminum system | Robiband PB, Robiband PBA |

Any window requires proper installation, like an expensive diamond in an expensive frame. Even the most beautiful and high-quality window will cause problems if it is installed poorly. And installation according to GOST is not a guarantee if short-lived materials are used.

Saving 150 rubles on high-quality installation materials will result in reworking the installation seam and slopes and amounts to about 15,000 rubles for 1 window! 100 times more expensive than what was saved. By choosing tapes for installing windows in accordance with GOST Robiband, you can eliminate blowing along the installation seam and live comfortably for at least 20 years.