mark_kr

26070 0 23

mark_kr September 17, 2016Specialization: professional in the field of construction and repair (full cycle of finishing work, both internal and external, from sewerage to electrical and finishing work), installation of window structures. Hobbies: see the column “SPECIALIZATION AND SKILLS”

The use of such materials not only optimizes the microclimate, but also simplifies installation

Waterproofing tape for PVC windows, as well as other installation materials, are used relatively rarely: their use increases the cost of work, since a set of high-quality mounting tapes for installing one structure costs approximately 15 - 25% of the cost of the entire window.

And yet, if you plan to glaze the house “for yourself,” using modern materials is not only possible, but also necessary. That is why I decided to write a short review on mounting tapes, their purpose and correct use.

Vapor barrier tape for PVC windows

Joints and seams are always the most unprotected places, including when installing windows. Moisture can seep through them, condensation can form, heat can escape and sound insulation can be impaired. Mounting tapes will help eliminate these problems. Waterproofing tape for PVC windows will not only improve the climate, but also simplify installation.

Why is it blowing

The reasons for window depressurization can be different. The plastic seals dry out and cracks appear in the slopes. In high-rise buildings, corner windows on the upper floors often suffer - the sashes become warped.

Wooden frames suffer from shrinkage and cracks when the house subsides. Seasonal fluctuations in temperature and humidity are also not good for the tree. Although the shelf life of wood treated with antiseptics is comparable to a person’s life, it also ends someday.

Problems with window sills and slopes require drastic measures - repair or replacement.

Water vapor barrier mounting tape for PVC windows

Mounting tape is a polyethylene foam material with an adhesive composition on both sides. Designed to improve the sealing of window structures. The use of water vapor barrier tapes is used quite rarely due to their high cost. When installed, they increase the cost of windows by 15-25 percent.

Experts often neglect their use and risk the quality of the work done, or find other methods. For example, they can install a plastic slope, use polyurethane foam, and cover the installation gap on the outside with plaster and paint it. This method is widespread and has virtually no negative reviews, due to the high efficiency of the materials used. However, it does not meet industry standards.

The use of vapor-permeable or vapor barrier tape for windows when installing a window mechanism is a mandatory requirement according to GOST. Since they provide additional insulation of the joints between the window and the opening from the outside and inside.

- The purpose and sealing of the window seam with the window opening is created by polyurethane-based polyurethane-based polyurethane foam. However, it is vulnerable to ultraviolet rays and therefore self-adhesive tape is used to protect it. It covers the installation seam from the outside;

- vapor barriers - necessary to improve ventilation and protect against moisture. When temperature changes in the rooms, condensation forms, due to which moisture forms in the installation seams. Tapes help to avoid this and improve the quality of heat conservation;

- vapor-permeable - used for exterior decoration and guarantee good air circulation. That is, they promote the release of moist air from the assembly seam.

Tapes perform various functions, depending on the place of their application, the condition of the window structure, the finishing of the slopes and the materials used.

Types of water vapor barrier tape

Based on the requirements for installing PVC windows, various materials are used. Due to the different features, it is possible to combine different materials to achieve a better effect:

- Water vapor barrier tape (GPL) is the most common when installing window structures. Its main features: it is a sealing material for joints on the inside of the room;

- The component of the self-adhesive material is polyethylene film. On one side, the GPL is covered with a thin foil layer, and on the other, with an adhesive composition;

- strong fixation is ensured by the adhesive composition. It is suitable for almost all materials. However, when choosing a material for foam blocks and aerated concrete, you should pay special attention to the instructions. Since not all formulations may be suitable;

- the composition of the material guarantees complete tightness of both the tape itself and the glued areas;

- GPL not only insulates from moisture, but is also not afraid of exposure to aggressive substances.

The main distinguishing feature is the ability to fill joints due to expansion that occurs from contact with air. But there are other positive aspects of using PSUL:

- seals the seams between the components of the window structure;

- seals the joint between the frame and the window opening;

- isolates gaps of small-sized moving parts of the structure;

- fills external seams between the window slope and frame.

- In addition to the listed varieties, for finishing the room side, internal tapes are used: VM made of vapor and waterproofing material, to seal the joints of rooms. It is used in cases of damp finishing of slopes (with plaster or tiled decoration). Guarantees protection from moisture in the seams of the opening and reliably fixes the finishing coating;

- VM+ is a modified analogue of the previous material, with increased resistance to humidity;

- BC - also used for interior decoration, but in a dry way (plastic, drywall and other sheet material);

- BC+ is a modification of the previous product with greater thickness due to an additional adhesive layer. They are also available with a foil layer, which provides additional thermal insulation of the seam.

Material Dimensions

For convenience, practicality and efficiency, mounting tapes are produced in rolls of various widths and lengths:

- diffuse insulating material for exterior decoration of premises: width 7 cm, length 25 m;

- PSUL used at subzero temperatures: width 2 cm, length 5 m;

- internal duplicated (width 10 cm, length 25 m) and metallized (width 4.5 cm, length 24 m);

- material for window sill profile 20 cm wide, 12 m long.

Attention! In order to properly seal joints, it is necessary to select the correct size of the material. As a rule, the width of the mounting tape should be 5-10 mm larger than the width of the gap.

General installation information

You can use GPL or PSUL both before and after installing the window structure. The sizing algorithm is quite simple:

- Preparing the opening. If available, the old structure is dismantled, very carefully so as not to damage the edges. Next, all surfaces are leveled, cleaned of dirt and dried.

- The window block is temporarily fixed to mark the edges and determine the dimensions of the required material. It is desirable that the PSUL be completely hidden behind the external slopes.

- In accordance with the measurements, mounting tapes (GPL, PSUL, diffuse) are cut. The length margin for corner joints must be at least 10 cm.

- They are glued to the window frame, and at the same time the protective film is removed from one of the adhesive strips.

- The window is installed in the opening, fixed with anchors or mounting plates, and the seams are filled with foam.

- The protective strips are removed from the GPL and glued to the opening.

- To improve the sound insulation of the external window sill, PSUL is glued under the ebb.

Related article: Electric drives for windows and transoms

Attention! When installing in winter, it is necessary to use special materials that are not afraid of low temperatures.

If the main goal when installing window structures is not to comply with GOST requirements, then mounting tapes do not need to be used. However, they can improve waterproofing, avoid the appearance of moisture, and therefore mold in the joints. In general, they increase the service life of the window structure and make the indoor microclimate more comfortable.

How to make waterproofing in a wooden frame house

The process begins with processing the wall where the installation of the double-glazed window is planned. The task is to create a layer of hydro-protection for PVC openings in a wooden or frame building.

Instructions:

- The outer part must be covered with a wind-waterproofing film, and the inside with a vapor barrier film. Both building materials must cover the entire opening.

- The edges of the film are secured with ordinary tape. Construction tape provides additional reliability.

- Using a building level, level the frame vertically and horizontally. If irregularities, even small ones, are detected, use special leveling wings.

- The frame is attached to the walls using mounting plates (they must first be attached to the frame, and then to the walls).

- Seams up to 2 cm thick are left completely along the opening, then they are blown in with foam (during the work, the PVC surface is protected with film).

- As the mounting film dries, its excess parts are eliminated.

Note: wood, even treated with good compounds, gets wet. It, in accordance with the seasons and temperature data, changes its own geometry. The use of hard mastics is destructive - they will crumble and come off the seams or damage the frame.

Mounting tapes for windows

In the online construction store "TBM-Market" you can buy mounting tape for plastic windows, professional replacement for sealing, insulation, sealing seams, joints, cracks. Compliance with construction technologies and the use of high-quality consumables guarantees a long service life of window systems.

Special window mounting tapes are designed for sealing. The external tape is intended for external waterproofing, vapor barrier, protection of assembly joints from moisture and condensation. The internal tape is used for hermetically sealed “warm” installation of window sills and slopes.

TBM-Market presents Bauset diffusion membrane tape based on tensile and tear-resistant non-woven synthetics, with the application of a metallized layer. Another option is sealing rubber tape with a one-sided adhesive layer. We also have PSUL - a sealing polyurethane self-expanding tape that perfectly compensates for unevenness, tightly closing cracks and gaps.

How to seal windows for the winter with masking tape

The work is carried out at above-zero temperatures. In colder times, due to condensation, the adhesive layer on the frames will not hold.

The surface to be pasted must be dry, clean and free of grease. The cracks are pre-insulated. First, prepare pieces of tape of the required length according to the principle “measure twice, cut once.” Then they are applied on one side, stretching a little and pressing tightly. Using the palm of your hand, iron the strips across towards the un-glued side, starting from the middle.

To glue a stepped surface, a strip of one third the width is applied to the protruding side. After carefully smoothing, run your hand along the fold to the corner. Finish by fixing the edges around the corner. All actions are carried out from the middle of the strip.

Mounting foam for windows

To install window systems, balcony blocks, glazing and insulation of loggias, you need mounting foam for PVC windows. This is a universal consumable material that has good adhesion to brick, concrete, plaster, and plastic. Before purchasing, you need to calculate the consumption of polyurethane foam for the window.

This indicator is called output volume, it is indicated in liters on the cylinder. Experienced builders say that the figure should be divided by 1.5-1.8. That is, from a cylinder with an output volume of 50 you will get about 30 liters. The foam tends to expand twice: the primary expansion occurs immediately after leaving the container, the secondary expansion occurs before it dries completely. Which polyurethane foam is best for PVC windows? Professional compositions from Bauset are considered good.

Useful tips

When working with tape, insulation, tape for sealing windows for the winter, you must follow these useful recommendations:

- If you need to cover one window, then on average it takes 5 meters of tape, so it is not advisable to buy a whole roll.

- The material will not last long on a poorly prepared surface.

- It is better to choose the tone of the strip to match the color of the window frame.

- High-quality masking tape will not leave marks on the surface.

- If the window glass is damaged, it should be replaced before insulation, as it will serve as a source of drafts.

Sources

- https://okna-dom.net/skotch-dlya-okon-uteplitel/

- https://www.PortalTepla.ru/uteplenie-okon-i-dverej/samokleushijsya-uteplitel-dlya-okon-kak-kleit-pravilno/

- https://VseProKley.ru/skotch/dlya-zaklejki-okon-na-zimu

- https://balkon4life.ru/osteklenie/okna/lenta-dlya-utepleniya-okon/.html

- https://passaz-okna.ru/raznoe/skotch-dlya-zakleyki-okon-na-zimu-pravila-vybora-i-instrukciya-po-utepleniyu-okon.html

Waterproofing tape for PVC windows: characteristics, application

During operation, window frames are subject to enormous loads. Therefore, it is especially important to install them taking into account all the necessary requirements.

If the windows themselves are made of high-quality materials, but the installation technology is not followed, there will be no need to talk about their effective “work”. In the cold season, condensation will accumulate on them, and possibly even icing. It is quite simple to avoid such troubles and at the same time create comfortable temperature conditions in the apartment if you use a special waterproofing tape for PVC windows during installation.

Silicone sealant

When installing a window sill, the use of silicone sealant is mandatory, as it fills the joints and seals them reliably. For these purposes, it is possible to use liquid plastic, since it has a more durable adhesion to the surface and does not lag behind the influence of moisture over time, like a sealant. In this case, the highest quality insulation of seams is achieved.

Silicone sealant is used to seal joint seams

It is important to use only high-quality materials and equipment for installing a plastic window, then the window will perform its functions, reliably protect the room from environmental influences and provide optimal microclimatic indicators.

Characteristics and purpose of the material

Typically, window waterproofing tape is a material with a self-adhesive backing. It consists of several layers:

- outer covering (non-woven material, aluminum foil, etc.);

- self-adhesive bitumen layer, providing reliable and easy fastening of the waterproofing film to any, even complex surfaces;

- a protective film that protects the insulator from drying out and sticking.

The main purpose of this waterproofing material is to prevent the penetration of moisture from the street between the joints of the window frame and the opening, as well as to ensure reliable ventilation of these areas. As a result, the installation seams will not freeze, and condensation will not accumulate on the glass.

Why is it needed?

After installing new glass blocks, be sure to seal the internal and external seams. Due to air gaps, heat escapes from the room, so the room needs to be heated more. During the heating season, losses increase bills, which negatively affects the family budget.

Warm room Source stroimir21.ru

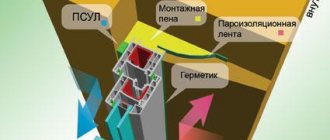

High-quality insulation of windows occurs at the installation stage. Professional sealing of double-glazed windows consists of 3 layers:

- Basic. The center of the structure is foamed with building mass. Polyurethane quickly degrades, so it must be hidden from ultraviolet radiation and temperature changes.

- External. Waterproofing windows protects against moisture from the street. Additionally, it insulates the opening and protects the foam from UV radiation. The outer layer has one-sided permeability, which improves the ventilation of the seam, preventing the appearance of mold.

- Interior. The vapor barrier is located on the side of the room. The element prevents moisture from entering the assembly seam. Due to the structural features, the liquid does not linger on the surface and dries quickly.

The polyurethane mass must be protected Source couo.ru

Window sealing does not function correctly if the technology is violated. If installers are too lazy to make the outer or inner layer, then the integrity of the system is destroyed. It will blow from the cracks, and condensation from the glass will accumulate, forming puddles on the windowsill. In severe frosts, the seam freezes, which leads to damage to the insulation and polyurethane foam.

Types of material

Depending on the place of application, the insulator can be external or internal. The first type is used for sealing installation joints from the street, so it is highly resistant to weathering and mechanical damage. For this they most often use:

- waterproofing on a polypropylene basis, which allows you to avoid expensive sealants, because thanks to its unique structure, the material effectively removes moisture formed on the polyurethane foam and reliably blocks its flow from the outside into the room;

- PSUL (pre-compressed sealing tape that looks like foam rubber). It removes moisture well from the polyurethane foam and, in addition, reliably protects it from exposure to ultraviolet radiation. The material is available in two colors - gray and black (due to its excellent qualities, it allows the installation of windows even in winter).

Related article: Tension windows for gazebos and verandas

To prevent the flow of vapors from the foam into the room, a special vapor-waterproofing type of material is used.

Fasteners

These include dowels, anchors, strips, perforated plates, supporting consoles and self-tapping screws.

Anchors

The use of anchors allows you to maintain the integrity of the window frame when installing a plastic window . They are mounted by drilling through holes in the window frame.

Window installation using anchors is considered the most reliable

The material used for making anchors is galvanized metal. Using anchors, the frame is secured to the wall so that the window is securely installed in the plane of the window opening.

Adjustable anchors

This type of anchor is used for “warm” installation, when the window frame structure protrudes beyond the wall. A leveling layer is applied to the window sill, then anchors are secured to it.

Using the anchor bolt you can adjust the position of the window frame

Such fasteners are also called anchor bolts, which consist of two parts. Each part has a longitudinal groove and holes on the edge. The presence of longitudinal grooves in the plates allows you to adjust the position of the window frame when it is secured with anchors in a certain position. This allows you to choose a perfectly level position of the window structure in space and securely fix it.

Dowels

According to experts who install plastic windows, the use of dowels ensures a more stable position of the structure than using anchors. However, they do not recommend using them to secure the bottom of the window. A dowel is a plastic sleeve with side slots and threads inside . When a self-tapping screw is screwed into it, the plastic petals open and the dowel is securely fixed in the body of the concrete or brick wall. The dimensions of the dowel - width and length - depend on the structure of the wall material. For fragile foundations, large dowels are used.

The dowel ensures reliable fixation of the self-tapping screw in the wall

These fasteners are made of elastic elastic plastic that can withstand high tensile and compressive loads. Dowels are used when attaching anchor plates to the wall surface; this allows you to rigidly install and fix the window frame.

Self-tapping screws

When attaching anchor plates to dowels, concrete self-tapping screws are used - they have large, pointed threads and a head in the shape of a star or hexagon.

The anchor plates are secured using self-tapping screws

When it is necessary to secure perforated metal strips, metal screws are used. To secure any elements using this type of fastener, you must first drill a hole of a smaller diameter. When carrying out work, it is necessary to use modern high-quality installation tools.

Advantages of a waterproofer

A waterproofing tape for windows is being developed in accordance with hydro- and vapor barrier standards. Compliance with all these requirements provides the material with the following advantages:

- easy installation on any surface and strong adhesion to almost all building materials;

- wear resistance and long service life;

- efficiency.

Although the waterproofing tape for PVC windows is completely ready for use, some rules must be followed when using it. Firstly, be sure to clean all surfaces to be treated from dust and dirt. Secondly, glue the insulator without gaps along the entire length of the assembly seam, while it is better to cut it at the turning points. Thirdly, overlap the joints of individual parts of the film.

Peculiarities

The tape used to seal joints is a vapor-tight building material. For production, foil or knitwear and a moisture-resistant coating are used. The reverse side of the elastic fabric is usually equipped with an adhesive for reliable fixation.

The positive qualities of the product include the following:

- working ductility is maintained at low temperatures;

- inertness to biological effects and aggressive environments;

- equal resistance to steam and water pressure;

- safety for human health;

- Availability of use inside and outside the building.

Due to its plasticity, the material follows smooth curves and retains its shape over time. The flexible base gives the material additional tensile strength. And also the canvas does not crack when processing different angles.

Scope of use

For the most part, self-adhesive waterproofing tape is used in construction and repair. It serves to protect the corners between the load-bearing structures of the building and the floor base, installation joints in windows, doors, plumbing, ventilation and chimney openings, and ensure the reliability of joints in the water supply system.

In everyday life, the material is used less often. For example, for strengthening and sealing an aquarium and water containers. On an industrial scale, the objects are pipelines and air ducts. In mechanical engineering, metal parts are protected from gasoline, oil and natural precipitation.