Recently I witnessed in a hardware store how a sales consultant, frankly without understanding the issue, talked about the pros and cons of self-adhesive insulation to an elderly couple.

I stood nearby, listened, and felt so sad at how illiterate the young people were... well, if you work in this field... study everything thoroughly so as not to make a fool of yourself. Well, okay, I grumbled and that’s enough :). In general, I have prepared the material, read it. Maybe it will be useful to someone!

Sealing window openings

We will talk about sealing the window opening, which is necessary for thermal insulation (protects against drafts, prevents heat loss in winter), but not only.

Window insulation maintains a comfortable microclimate in the apartment during hot summers; prevents dust, street odors, and insects from entering the house; dramatically reduces the noise level, which is especially important if your windows overlook a highway or tram line.

First of all, window insulation is necessary for old wooden frames (a high-quality and well-installed plastic window does not always require additional insulation measures).

There is one caveat: in the old days, glass was often installed in the frame using a special mastic, and it tends to crumble over time. The paint on the frames is cracking, and the wood itself is cracking over time. Small cracks should be filled with sealant before laying insulation.

Obviously, the main requirement for window insulation is its quality. When selecting, you also need to take into account the specifics of the cracks on your window - width, shape.

Why is KBE sealant needed in plastic windows and doors?

The KBE seal is one of the main components of plastic windows and runs along the entire perimeter of the window. To guarantee protection from the influence of the external environment, two sealing circuits are used. One contour is on the frame, the other on the window sash.

Our specialists replace KBE sealing gaskets on plastic windows. The price for installing and replacing the KBE (kbe) seal is quite affordable.

Our specialists replace KBE rubber seals on plastic windows. The price for replacing the KBE rubber seal is quite affordable.

Rubber-epdm sealant KBE (kbe) is produced by:

— Semperit Germany

— Artie (trademark Elementis) Russia, Tambov

— Union Polimer Tehnologies Russia, Moscow region, pos. Sofrino

— Donskoy Profile LLC, Rostov-on-Don

Self-adhesive insulation

Insulation materials are divided into adhesive, groove and self-adhesive.

The easiest way to install is self-adhesive. It can be foam rubber, rubber, made of polyethylene foam or PVC. There is insulation for plastic windows in black, white and brown. The material is quite durable and allows you to seal cracks up to seven millimeters wide.

When choosing self-adhesive insulation for windows, be sure to look at the expiration date. If you buy rubber or plastic insulation, it is better to take a softer one.

Foam or polyethylene (tubular or rectangular) is suitable for sealing gaps up to four millimeters, provided that the gaps are fairly level. Otherwise, you need to pay attention to the brand: up to three millimeters, profile C, E, K is suitable, up to five - P, V, up to seven - B, O.

More on the topic Thermal film for windows

To seal not very wide cracks, you can use a rubber seal; for uneven and wide cracks, it is better to choose silicone, it is more flexible.

Domestic analogues

If you do not want to spend money on expensive European products, you can use cheaper Russian-made seals. Such or “Standard Prof” offer their products at an affordable price, and their quality is not much inferior to their foreign analogues. However, it should be taken into account that the shape of PVC seals for windows of some domestic models may not be suitable for foreign double-glazed windows.

On a note! If your home has branded plastic double-glazed windows from a well-known manufacturer, then it is better not to save money, but to install seals from the same company as the window.

Foam rubber

Foam rubber insulation for windows (foam rubber tapes) was used to seal windows for the winter long before the production of insulation was put into production.

The advantages of this material are known to everyone: it is easily compressed (and, as a result, installed), does not injure the surface of the frame, this method is cheap and simple.

There are also disadvantages: foam rubber for insulating windows is not the best choice; even with very good compression, air still leaks through the pores, and it is also not very durable - foam rubber comes off relatively easily.

The second problem can be partly solved by modern rubber-based adhesives. To solve the first part of the cracks (especially in hard-to-reach places), it is advisable to fill them with silicone or acrylic sealant before installing the insulation.

Insulation tape

Adhesive paper tape for window insulation is sold in any construction supply store or markets, and is inexpensive.

Previously, strips of thick paper were used instead; they were placed on soap. The presence of an adhesive layer on the tape eliminates the need to use soap, and this type of sticking lasts much better. It is usually placed on top of foam rubber.

EPDM – rubber tape. Suitable for sealing uneven cracks of small width. It perfectly seals cracks and withstands temperature changes from minus fifty to plus seventy.

Silicone insulation tape also withstands strong temperature changes and is indifferent to chemical influences. This is a very plastic material, suitable for large uneven cracks.

Vinyl polyurethane has a porous surface. This tape has good dustproof properties, but is not the best option for thermal insulation. Moreover, it is not the most durable.

TPE

It is a thermoplastic polymer—a modified plastic—that at normal temperatures has the properties of rubber.

Advantages:

- A high degree of elasticity ensures good sealing.

- Excellent resistance to welding, non-flammable.

- It can be any color, most often gray.

- It is installed automatically in production, so the defect rate is lower than that of other types.

Flaws:

- At temperatures below -20 ˚С it loses its elasticity – it “turns tan”.

- At temperatures above +35 ˚С it softens.

- Unresistant to mechanical damage.

- A soldered seal is more difficult to replace, so this service will cost more.

Laying insulation

Whatever materials you choose for insulating windows, it is recommended to glue seals at temperatures above five degrees, so it is better to take care of the tightness of windows in advance, without waiting for frost.

More on the topic: Which is better to choose - single-chamber or double-glazed windows?

First, you need to remove the old insulation for wooden windows, if any, clean the frames from dirt and degrease (gasoline, acetone, alcohol, or any composition based on them will do). It is necessary to glue in places where the sash comes into contact with the frame, removing the protective film gradually as the insulation is laid.

Source: enoza.ru/okna/regulirovka-nastroyka-i-reshenie-problem/uteplitel-dlya-okon-porolonovyiy-lenta-plenka.html

More recently, old-fashioned methods were used to insulate windows. Some people glued newspaper to the windows, and others glued strips of paper.

Cotton wool, tape or paraffin were also especially popular.

Of course, such insulation methods were not only inconvenient, but also ineffective. Everything changed when self-adhesive window insulation appeared on the market.

Cost of materials

As I noted at the very beginning, the high price of mounting tapes partially limits their distribution. But at the same time, if you know exactly what you need, there is a chance to fit within the budget allocated for glazing.

Non-woven sleep material with self-adhesive base from SOUDAL

| Name | Average cost, rubles |

| Internal duplicated tape 1.5x100 mm (12m) | 420 |

| Mounting tape for slope internal 120 mm (25 m) | 510 |

| External tape, diffuse 1.5x70 mm (25m) | 820 |

| External mounting tape for ebb 70 mm (25 m) | 450 |

| Mounting tape for window sill 200 mm (12 m) | 600 |

| Mounting tape insulated with isolon 250 mm (12 m) | 970 |

| Internal metallized tape 2x100 mm (12 m) | 320 |

| PSUL 15/6-8 gray, 6m roll | 220 |

| PSUL 20/8-10 black, 5 m roll | 320 |

PSUL from Robitex

Self-adhesive tape

Insulating window structures is a very important process that must be approached very carefully.

Uninsulated windows often cause drafts, which as a result negatively affect the health of residents.

In addition, window openings become the main bridge of cold, which leads to the loss of a large amount of thermal energy.

Today, the market offers a large selection of modern insulating materials that can reduce heat loss through window units.

All these materials are highly effective and very easy to install. Among all the options, it is worth highlighting self-adhesive tape.

It is made on the basis of foam rubber, polyethylene and polyvinyl chloride. On one side, the material is coated with a sticky compound, which allows it to be fixed in a specific place.

Advantages of self-adhesive insulation

This self-adhesive window insulation has certain advantages.

These include:

- Ability to close cracks, the thickness of which can reach 7 mm;

- High resistance to changes in temperature and air humidity;

- Various colors, which allows you to optimally aesthetically fit the tape into the appearance of the window;

- Relatively low cost;

- Possibility to open the doors.

Thanks to these advantages, this material has gained high popularity and demand among the population.

Disadvantages of the material

Unfortunately, duct tape also has some disadvantages. First of all, it is worth noting its fragility. Most often, it lasts no more than one season.

This means that the insulation needs to be updated annually. Of course, if the doors are rarely opened, then the tape can last two or more seasons.

Despite the fact that such material tolerates temperature changes very well, severe frosts can negatively affect its performance properties.

As a result of exposure to too low temperatures, the adhesive composition may lose its adhesiveness. As a result, this leads to the tape peeling off.

The main disadvantage of such insulation is that it cannot be used on modern window structures. This is due to the fact that it can cause significant harm to the performance characteristics of plastic windows.

Characteristics

It is impossible to purchase a foam rubber seal if you do not know its dimensions and technical characteristics. The first thing to note is the complete environmental safety of the material. Its density reaches 20 g/m3. It has a low thermal conductivity coefficient, which makes it possible to insulate window openings and make the room comfortable to live in. Another undoubted advantage of the material is the wide range of sizes, thanks to which you can choose the appropriate option and save on costs.

Table 1 - Dimensions of foam seals

| Size, mm | Length, m |

| 20x20 | 10 |

| 20x30 | 10 |

| 20x40 | 10 |

| 30x30 | 10 |

How to choose a ribbon

The choice of self-adhesive insulation for windows must be approached very carefully. The tape is made from various materials and can have different profiles. This is worth considering when choosing it.

If you decide to use a rubber band, it is better to choose the softest one. Thanks to this, the insulation will reliably close all the cracks and reduce heat loss from the window structure to a minimum.

As already mentioned, insulation can have a different profile. When solving this issue, it is worth paying attention to the nature of the cracks.

If the gaps between the frame and the sash are straight, you can use rectangular profile insulation. It can be used to seal cracks up to 4 mm thick.

In other cases, the optimal solution would be materials with profiles of various shapes that resemble letters of the Latin alphabet.

For example, material with an “O” profile allows you to hide uneven cracks, the thickness of which can reach 7 mm.

When choosing insulation, special attention should be paid to the expiration date.

If it has expired, the adhesive properties of the tape have decreased significantly. As a result, this can lead to it quickly peeling off from the window.

Thermal insulation PENOPLEX

Extruded polystyrene foam XPS PENOPLEX COMFORT 1185x585x50 mm

(12) 289.00 ₽ Add to cart

Extruded polystyrene foam XPS PENOPLEX COMFORT 1185x585x30 mm

(14) 185.00 ₽ Add to cart

Extruded polystyrene foam XPS PENOPLEX FOUNDATION 1185x585x50 mm

(17) RUB 319.00 Add to cart

Extruded polystyrene foam XPS PENOPLEX COMFORT 1185x585x20 mm

(17) 130.00 ₽ Add to cart

Extruded polystyrene foam XPS PENOPLEX COMFORT 1185x585x100 mm

(10) 599.00 ₽ Add to cart

Sprayed insulation PENOPLEX FASTFIX 850 ml

(12) 669.00 ₽ Add to cart

Extruded polystyrene foam XPS PENOPLEX WALL 1185x585x50 mm

(18) 299.00 ₽ Add to cart

Extruded polystyrene foam XPS PENOPLEX EXTREME 1185x585x50 mm

(0) RUB 339.00 Add to cart

Tape installation

The installation of self-adhesive tape must be approached very carefully. The quality of its fastening and the effectiveness of insulation will depend on this. Before you start gluing it, you need to carefully prepare the working surface.

To do this, the frame must be cleaned of old insulation and all contaminants. After this, the place where the tape is attached must be thoroughly washed and degreased. You can use alcohol or acetone to degrease the surface.

More on the topic How to make a heated floor on a balcony with your own hands

Once the surface is ready, you can begin attaching the material. To fix the insulation at the line of contact between the sash and the frame, the protective paper is removed from the back side.

It must be eliminated gradually, as needed. To facilitate the installation process, the tape can be pre-cut into pieces of a certain length.

The material easily sticks to the frame. But, complete hardening of the adhesive composition occurs after some time. During this time, you should refrain from frequently opening and closing the sash.

Checking the result

After replacing the seal, the sash is put back in place and the quality of work is checked.

The following criteria must be followed:

- the sash moves without difficulty;

- Drafts and sounds from the street disappeared. There is no blowing through the cracks (this can be easily checked by running your hand along the perimeter of the sash at a distance of several centimeters);

- The seal does not change its position and does not wrinkle when opening or closing the sash.

Modern film

Today you can also find self-adhesive film on the market. This material appeared on the market relatively recently, but has already gained great popularity among the population.

Using such a film, you can significantly improve the thermal insulation properties of the entire window unit. If the tape seals the cracks, then the film reduces heat loss over the entire area of the window opening.

This insulation takes the form of a regular film, which has a special coating on one side. This makes it easy and quick to mount it on a window.

To give it aesthetics and somewhat hide its presence, heating devices such as a household hair dryer are used. When heated, the film straightens and becomes almost invisible.

Its installation can be easily done with your own hands. Unfortunately, such insulation is used only for one season, or rather one period - in winter.

The disadvantage of the material is that it protects the room well from both cold and heat that comes from outside. As a result, in the spring the room warms up very slowly.

To eliminate this drawback, it is necessary to dismantle the film immediately with the onset of heat.

Source: kak-uteplit.ru/samokleyushhijsya-uteplitel-dlya-okon.html

It seems that the modern world is simply unimaginable without new products and inventions; it cannot help but create them due to the urgent need for it. In a modern economy, in repairs or construction, sometimes it is impossible to count the number of useful things that, without exaggeration, deserve their place.

Manufacturers of profile seals for plastic windows

Now there are many different types of seals in stores, but if you look closely at them, you can distinguish three abbreviations:

- KBE;

- Rehau;

- Veka.

They indicate types of products (manufacturers). All others are types that are formed on the above types of products. They differ in minor features in the configuration of the seals.

Seals

One of the start-up companies that has started producing profile seals is the German one. Its products are made from ethylene propylene rubber (EPDM).

Rehau products differ from other analogues:

- High-quality pressure over the entire surface of the window block;

- Stable operation over a wide temperature range;

- Neutrality to the effects of external precipitation, condensation and ozone radiation;

- Long service life

Rubber products are distinguished by two single teeth with a slightly curved shape. The tooth that is closer to the edge is slightly shorter than the other.

On a note! When purchasing, you need to choose a new seal taking into account the markings that were on the old cuff.

Rice. 10. The Rehau sealing collar fits tightly into the profile groove of the window

Sealing connections

The Montblanc seal is black and is intended for double-glazed windows with a profile similar to Rehau products. The products are made of EPDM material.

Seals

The German one has also established a good reputation. The products of this company have been on the market for more than 40 years, which indicates the demand for these products. Rubber seals are made for both the window frame and the frame itself.

Among this product the following advantages stand out:

- Resistance to distortion and mechanical influence;

- High protection from extraneous sounds and cold;

- Neutrality to changes in temperature and humidity.

The tooth of this product is located at an angle of 90 degrees to the base.

Rice. 11. Veka compactor parameters

On a note! If a seal from the company was previously installed on the windows, it is recommended to install a new seal from the same company: the profiles of window seal units from other manufacturers differ from each other and are not compatible with each other.

Seals from

"KVE" is a company producing double-glazed windows and accessories for them; it has existed in Germany for more than 30 years. A characteristic feature of the sealing product is that they must be inserted into the groove by rolling them with a special profile roller.

Rice. 12. The KBE seal must be rolled up with a roller during installation.

These products are made of high quality rubber and are suitable for sealing window blocks made of any material. Gaskets can last up to 10 years without changing their physical properties. The cost of one meter is 20 rubles. This product differs from other analogues by the stiffening rib, which is directed from the opposite edge.

Sealing gaskets "Novotex"

The modern Novotex system is a universal complex with three sealing circuits. The profiles are manufactured using the latest “CaZn” technology. The mounting side has depressions up to 80 mm wide and 6 mm wide - internal chambers of the seal profile.

The depth of the depressions is 26 mm and all this, taken together, significantly increases the performance of thermal and noise insulation. The seal is gray in color, which visually expands the transition and space from the window to the profile.

Rice. 13. NOVOTEX sealing cuffs - modern samples for window blocks

Seals from current products for window units are a sure protection against any bad weather, dirt and noise. You can purchase these profile products on the Internet or in a store, and replacing them yourself will not take much time and will save money.

Why do we need self-adhesive seals?

Its main functions are as follows:

- protection from drafts and wind that enter through cracks in windows or doors;

- protection from moisture, dust, pollen, smoke from the street or entrance, and small insects through cracks in doors or windows;

- reduction of external noise through sealing and complete closing of cracks and openings;

- heat conservation and maintaining the temperature inside the building;

- softening the impact when a door or window is suddenly closed and preventing the appearance of microcracks in structures, extending their service life;

- saving heating costs and energy resources;

Convenient and practical

Small accessories such as self-adhesive seals can help achieve complete tightness of the room.

They proved their practicality by the fact that despite the initial base surface of the doors or windows, be it metal, plastic, or wood.

They are easily and permanently glued to the base, do not require significant material costs, are practically invisible on structures, thanks to the maximum approximation to frequently used color tones, do not deform or damage the surface to which they are glued, after some time they are easily removed, leaving no marks on the windows and doors.

Moreover, modern self-adhesive seals do not absorb moisture and foreign odors, are not susceptible to oxidation, do not deteriorate from sunlight, do not fade, are not susceptible to damage by insects, can withstand temperatures from -60 to +120 oC, and are able to retain their elasticity and shape for a long time even at long-term use.

Advantages and disadvantages

Today, not a single installation of PVC windows in residential or public buildings can be done without the use of insulating tapes. The use of these materials provides premises owners with many advantages :

- Reliable insulation of enclosing structures from the penetration of cold and precipitation into the room.

- Ensuring additional energy efficiency of the room.

- Eliminates the risk of squeaking due to condensate retention and dew point formation.

- Protection of polyurethane foam from mechanical destruction or from the negative effects of ultraviolet rays.

- Construction of a base for fastening slopes, window sills and ebbs.

- Increasing the durability of window structures.

Among the disadvantages, experts and consumers also highlight a number of minor factors that somewhat limit the use of tape for installing windows made of PVC materials:

- Increased cost of installing window structures due to the need to purchase material.

- Synthetic components included in insulating materials can cause allergies and irritation of the respiratory tract in persons with weakened immune systems.

- The complexity of window installation increases.

- In most cases, it is necessary to contact professionals to follow the technological map when installing the window structure.

Most of the disadvantages of using insulating material are subjective and are not taken into account by consumers. Mounting tapes are used more and more often, and their manufacturing technology is improved every year.

Types of self-adhesive seals

Among the varieties of self-adhesive seals, it is worth mentioning the most commonly used rubber (low in cost, often purchased specifically for wooden structures), foam rubber (made of foam rubber), polyvinyl chloride, polyethylene foam, and the more recently appeared self-adhesive seal made of closed-cell foam rubber (porous rubber).

It is always more profitable to take a self-adhesive seal for the entire living space, which is why they are usually sold in coils or rolls of 40 meters or more.

And they will prove their practicality during long frosty winters and hot dusty days. They perfectly hide any imperfections in geometry in structures.

Rubber

Material – vulcanized rubber. Rubber bands are only black due to the color of the filler - soot.

Advantages of a rubber seal:

- reliable window sealing;

- low price.

Flaws:

- cracks and shrinks due to temperature changes;

- short-lived.

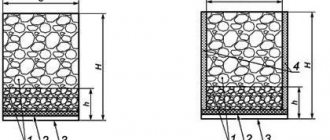

Products in profiles

Among the most common seal profiles are several:

- O-profile for large gaps (from 3 to 7 mm);

- D-profile closes gaps from 3 to 7 mm;

- V-profile for medium-sized cracks from 3 to 5 mm;

- P-profile for gaps from 3 to 5 mm;

- E (K)-profile for gaps from 1 to 3 mm,

- The C(I) profile closes small gaps from 1 to 3 mm.

Seals come in different colors (the most popular are black, dark brown, white); there are also transparent ones.

Average prices in the Russian Federation

Before purchasing a tape, the consumer should familiarize themselves with the market value of the material, as well as the dependence of prices on the chemical composition, functional properties and brand awareness. Among the most well-known manufacturers for each type of tape, the following product modifications can be distinguished:

PSUL – pre-compressed sealing tape:- WINDOW SYSTEM PSUL 30 PSUL2040 S, average price from 150 rub. for 1 roll 5 m long.

- PSUL ROBIBAND 50+, 12×30, PSUL.S.12.06.060.00.SS30, average price 200 – 250 rub. for 1 roll 6 m long.

- PSUL Bauset ST-III 20/8 (40), average price from 180 rub. for 1 roll 5 m long.

- GPL – water vapor barrier tape:

- Isostrong LK, average price from 1200 rub. for 1 roll 22.5 m long.

- Fentrim IS 20 75mm, for interior work, average price from 6400 rub. for 1 roll 25 m long.

- Fentrim IS 2 100mm, for outdoor use, average price from RUB 7,700. for 1 roll 25 m long.

- VM — suitable for vapor barrier:

- Self-adhesive tape for windows 30x2 mm “TDK”, average price from 200 rubles. for 1 roll 10 m.

- AVIORA, 50x40 mm, average price from 150 rub. for 1 roll 40 m long.

- "Sibrtech", width 50 mm, average price from 450 rubles. for 1 roll 10 m.

- Sun – tape for finishing slopes:

- Fakro Euroband S 60 mm x 25 m, average price from 2100 rub. for 1 roll 25 m.

- Bauset MR 250mm, sloped, average price from 1200 rub. for 1 roll 25 m.

- Dichtungsband 30x3 mm, average price from 150 rub. for 1 roll 30 m.

- Diffusion tape:

- External diffusion tape ST-I, 150 mm, average price from 600 rub. for 1 roll 25 m.

- External diffusion tape ST-bau 150 mm, average price from 500 rub. for 1 roll 25 m.

- Vapor-permeable tape, external diffusion, under tide, Bauset ST-I 100 mm, average price from 500 rub. for 1 roll 25 m.

- Butyl rubber tape:

- Rexant (width 5 cm, thickness 0.05 cm), average price from 1900 rubles. for 1 roll 20 m.

- Isobond LK 25 mm, average price from 400 rub. for 1 roll 25 m.

- Folder BL PRO, average price from 450 rub. for 1 roll 25 m.

Ethylene propylene synthetic rubber

EPDM, a compound of ethylene and propylene rubber (soft porous rubber seal), is most often used in the manufacture of self-adhesive seals, because the material is quite ergonomic and does not deteriorate when exposed to constant loads, which is especially important and necessary for windows and doors.

A special advantage is that rubber is a non-toxic coating that is environmentally friendly for people and the environment. It does not form mold, rot, insects, termites and other pests.

Very wear-resistant. Absorbs shocks, maintaining the durability of structures. Adheres to any surface, used for metal doors and even gates, hatches and cabinets, for industrial purposes - on electrical equipment and ventilation systems.

What should I do before installation?

If you want to ensure that when installing a self-adhesive seal on doors and windows there are no problems leading to its subsequent deformation or dismantling, be sure to follow the pre-installation procedure, namely:

- clean the surface from dust and dirt, wipe the surface with alcohol or acetone and dry thoroughly; visually mark the places where the seal will be glued and the places of contact (on the frame, sash, door or door frame);

- prepare the required length of the seal in advance; remove the protective layer gradually and press firmly to the base; after 2 hours, the glue finally sets to the base, drying occurs in temperature conditions from +5-40 degrees Celsius.

Source: vhod.guru/otdelka/uteplenie/samokleyuschiesya-uplotniteli-dlya-dverey-i-okon.html

Why is it necessary?

Tape for PVC windows is necessary when installing each translucent structure to achieve the following result :

Removal of water vapor from the junction of the window and the enclosing structure, in order to avoid the formation of mold or the proliferation of pathogenic bacteria.- Waterproofing the seam, which prevents the penetration of precipitation into the main insulation elements of the installation gap, and also prevents freezing and destruction of the porous foam filler.

- Vapor barrier of the enclosing structure - prevents condensation from falling from the interior part of the window frame.

The specified properties must be provided simultaneously to increase the efficiency of operation of the window and the room.

During installation, several types of tapes are used for each translucent structure.

Tubular self-adhesive seal

This article is intended to convey to readers information about how a tubular self-adhesive seal is used, what its features are, the main advantages and disadvantages.

As you know, many apartments in our country still use wooden windows and doors to balconies. Of course, they have some advantages over their plastic counterparts, they are environmentally friendly, and allow air to pass into the apartment.

However, due to the characteristics of wood, any such window or doorway over time begins to let drafts and dust from the street into the apartment. In order to avoid such troubles, it is recommended to use specialized types of products.

Let's take, for example, a self-adhesive seal for windows and doors, which is very popular both in our country and abroad.

Product Disadvantages

Undoubtedly, one of the disadvantages that self-adhesive tubular insulation has is its relative fragility.

As a rule, these types of seals are used for one season, less often - two; in addition, in severe frosts, the adhesive ability of the insulation can be significantly reduced, which can lead to it peeling off from the surface of the frame when the window is opened.

It is worth noting that self-adhesive sealing can only be installed on traditional wooden windows and doorways.

When used on modern plastic structures, you can cause significant damage to the double-glazed window structure, the mechanism for opening and closing doors, the correction of which can seriously hit your wallet.

Product advantages

Installation can be carried out independently, without the involvement of professional workers, and costs the apartment owner much less. The material itself also has a fairly low price and is sold in almost any finishing materials store.

When installed correctly (gluing a single piece to the entire surface of the frame, without cutting into separate strips), these types of seals have a fairly high level of efficiency and allow you to hermetically close gaps from 1 to 7 millimeters, preventing dust and drafts from entering the apartment.

GOST 30778-2001 for seals for windows and doors

GOST 30778-2001 defines the scope of application, introduces the classification and designation of seals. Determines technical requirements for the shape and composition of seals. Establishes acceptance rules and methods of control of finished products. Provides instructions for the operation, transportation and storage of seals.

Here are the most interesting excerpts for us:

3 Classification and designations

3.1 Designations of polymer materials used for the manufacture of seals

TPE - thermoplastic elastomer;

EPDM - ethylene propylene diene rubber (terpolymer of ethylene, propylene and diene with the remaining unsaturated part of the diene in the side chain);

ERM - ethylene-propylene rubber (ethylene-propylene copolymer);

VMQ - silicone rubbers containing methyl and vinyl substituted groups;

CR - chloroprene rubber.

3.4 Seals are divided depending on the types of window, door blocks and other structures for sealing the elements of which they are used:

D - for wooden window and door blocks;

P - for polyvinyl chloride window and door blocks;

A - for window and door blocks made of aluminum alloys;

C - for special (other) designs.

8 Operating instructions

8.2 The surfaces of window and door units in contact with the seals must be clean and free of scratches, sharp edges, nicks, scratches and other mechanical damage.

8.3 Installation of seals must be carried out without distortions, twisting and mechanical damage, without jerking or impact.

8.4 To facilitate installation and reduce friction, seals can be treated with a thin layer of silicone grease.

8.5 The seals are installed in the seat without stretching.

Choosing the right option

One of the main points that you should pay attention to when choosing a sealant is its shelf life.

Products with an expired or nearing expiration date may peel off from the surface over time, or may not provide proper sealing at all. In order to check the quality, it is enough to bend the material and evaluate how quickly and accurately it restores its original shape.

When choosing a self-adhesive rubber seal, it is best to opt for softer models. If there is sufficient softness, the material will be able to replicate to a greater extent all possible surface irregularities, thereby eliminating any draft.