Even the most first-class plastic windows will lose their quality if you do not take care of their correct installation. Much has been said and written about multi-layer or “warm” installation, but is everything already known? The WINDOWS MEDIA portal offers to debunk myths and find out the facts about this type of window installation. The purchase of new plastic windows and their installation can reach several tens of thousands of rubles. With this in mind, it is best to view window replacement as a long-term and well-thought-out investment, one of the most important elements of which is proper installation.

Why is window installation important?

A long and carefully considered process of choosing plastic windows can be completely ruined by their incorrect installation. The point where windows meet the external wall is a sensitive area that can cause heat loss and moisture build-up, so proper positioning and sealing of the window unit at the point where it meets the wall is very important. Installation errors, causing a weakening of the structure of the insulating layer, contribute to the formation of thermal bridges - a “path” through which heat will escape outside the house.

Many people usually focus only on choosing a window frame manufacturer and a suitable window model. Installation and selection of the team that performs it, however, is often a completely random process. Interest in the installer's work appears only when, due to improper installation, the wall of the building is damaged, the curtains flutter like sails, even with the window closed, and mold and mildew have settled on the slopes. But then the only thing left is to file a complaint with the company, which is often a waste of time, or to incur additional costs.

Therefore, before purchasing plastic windows, you should understand that installation is critical to maintaining the parameters declared by the manufacturer and the viability of the system. Of the many ways to install plastic windows, according to experts, the best and more popular is “warm installation.”

WINDOWS MEDIA recommends reading: Installation of plastic windows must be of high quality

Minuses

At temperatures below 15°C, the sealant for PVC structures loses its characteristics. When installing in winter in residential apartments, you need to take into account that the installation of one double-glazed window must be completed in 30-40 minutes. To do this, unlike in the warmer months, you will have to carry out the work in stages.

In winter, the brought double-glazed windows must be kept in a warm room for 24 hours. This is necessary for the structure to warm up. This operation will reduce the risk of possible thermal deformations.

What is “warm installation” of windows?

It is not enough for the windows to be positioned correctly vertically and horizontally to be considered well installed. Multilayer installation, better known as “warm installation,” is a reliable and effective technology for sealing plastic windows in the opening, which follows the rule: it is more airtight from the inside than from the outside.

The “warm installation” technology consists of specialized sealing of the places where the windows are built. Thanks to this, the thermal insulation properties of PVC windows can double, and the room can be better ventilated. The use of this technology will have a significant impact on energy bills and indoor climate, which will be free of fungi and other unwanted microorganisms.

“Warm” installation of PVC windows is based on the use of three layers with certain properties. The inner insulation layer creates a “protective shield” for the thermal insulation layer, preventing the penetration of water vapor and moisture from inside the building. The middle layer acts as a thermal and acoustic insulator. The main purpose of external sealing is to prevent moisture from entering while simultaneously removing it from the inside of the building - to the outside. By choosing this method of installing plastic windows, it is possible to ensure not only adequate thermal comfort, but also help prevent moisture insulating and structural materials - which can result in the appearance of mold at the junction of the window and the wall and even freezing of the walls in winter.

WINDOWS MEDIA recommends reading: Modern sealing tapes for installing PVC windows

Important points

High-quality installation of wooden windows indoors in winter requires the mandatory installation of slopes. They protect the voids that appear between the surface of the opening and the window from moisture and low temperatures.

Foam protects the room well from frost, but it is damaged by moisture and ultraviolet radiation. Without reliable sealant protection, after a month its layer loses its heat-insulating qualities, and in the spring it begins to collapse.

Upon completion of installation, the opening is finished. The slopes need to be insulated; this will not lead to large costs. But it will significantly increase the insulating characteristics of the installed structure.

Modern windows – modern installation

It can be argued that windows installed 100 years ago performed worse than modern windows, but no one needs convincing that the current requirements for building products are any different than in the past. The first energy standards in the building industry only appeared in the second half of the twentieth century, and clear rules for energy savings and thermal protection of buildings are the effect of subsequent findings. If we are planning to replace or install windows today, then why take inspiration from the ideas of the early twentieth century?

Modern architecture is different from what was popular decades ago. Changes in legislation force us to look for a new approach to the development and implementation of all elements that affect the thermal insulation of walls, and thereby the building as a whole. This applies in particular to windows and the sealing of their components.

Products that reduce energy loss in a building are the future, as exemplified by warm installation techniques and the advent of products to provide proper sealing both inside and outside the window unit. The range of energy efficient solutions, which also includes specialized products for window installation, is a response to the growing demand for sealed systems in Russia.

WINDOWS MEDIA recommends reading: Materials for installation of plastic windows

Additional work

A prerequisite for high-quality installation both in winter and summer will be the finishing of the slopes of the window opening following installation..

Why is this additional work needed? The main function of finishing slopes is to protect the gaps between the window and the opening from temperature changes and moisture. Foam is an excellent sealant and insulator, but it is very sensitive to ultraviolet rays and humidity. If you do not close the gaps, in a month the sealing layer will lose its properties, and by spring it will begin to collapse.

It is better to finish the slopes of a window opening with insulation

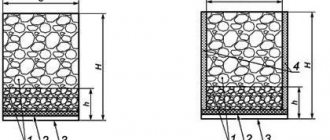

After installation work comes finishing work. It is best to make the slopes warm, that is, with an additional layer of insulation (foam plastic, mineral wool). In the schematic drawing you can see one of the options for insulating the internal opening. This is not a very big expense. But in this way the thermal insulation of the window will be improved.

“Warm installation” - energy savings at a good price

When choosing a method for installing windows, people are often guided by price, accepting as truth that “invisible to the naked eye” is not so important for the overall performance of the building that they would overpay for quality or innovative solutions. In real life, it often happens that an investor, after making a decision on “warm” installation, has doubts: either perfect filling and sealing of joints is only possible with the help of products developed specifically for energy-efficient construction, or whether “home” ideas will be as effective as professional systems designed for multi-layer installation?

Is the price of the components of a “warm” installation as high as is often believed? Is the subjective assessment of the installation cost enough to justify abandoning a modern solution that will save on heating costs for many years? Judge for yourself: if windows are sealed using a warm installation system, the cost of work compared to traditional systems can exceed 200 rubles per linear meter.

If you don't want to waste your investment in energy efficient windows, make sure they are installed using high quality window insulation products. Let’s not trust all-knowing contractors who “did the wrong things.” Look for installers who base their work on years of experience, but for whom new solutions are not just a “marketing ploy” to draw attention to routine work.

WINDOWS MEDIA recommends reading: Why you should replace old windows

Difficulties of glazing in winter

Basically, installation difficulties arise when it is done in an unheated room. Therefore, modern standards stipulate that the temperature in the rooms where installation work is carried out should not be lower than +5 degrees.

Since most brands produce plastic windows that can easily withstand any frost, problems may arise with sealing materials.

Despite the large selection of “winter” modifications, some sealants lose their properties in the cold; for them there is a temperature limit for use. This applies, first of all, to polyurethane foam. Some types of this product can be used in conditions down to -15 degrees, but not lower. Therefore, the sealing compound should be applied seasonally.

Technologies are also used that allow you to maintain the desired microclimate in the rooms. As a rule, during replacement it can decrease by 7 degrees, but if the heating system is working normally, then after installation of the structures it is restored within 1 - 2 hours.

Comparative characteristics

Since water and electric underfloor heating systems are the main ones, it is important to familiarize yourself with their comparative characteristics. Below are some questions to compare different types of systems.

Warm floor - which one is better to choose?

Table. Comparison of different floor heating systems.

| Question | Water system | Electrical system |

| Is there an EMR? | Absent | Depending on the type of cable used, electromagnetic radiation may be generated. |

| Is installation possible in apartments? | Exclusively in new multi-storey buildings, provided that there is a separate connection there | Yes |

| Are the systems easy to manage? | No | Yes |

| How long does installation take? | A lot, due to the implementation of the concrete screed | A little |

| What finishing coatings can be installed? | Almost everything | Some types of flooring cannot be installed |

| Ease of maintenance | Difficult maintenance and repair | When installing IR floors, maintenance is simple |

Choosing a heated floor

It is necessary to choose one or another type of heated floor taking into account not only your budget, but also the location of further installation. Once the system has been selected and all materials have been purchased, installation can begin.

Heated floor pipe circuit length calculator

Go to calculations

Prepare the base

Ideally, a rough screed is needed as a base, which needs to be brought into an even state. Namely, to knock down bumps and sagging if they formed during pouring. This is necessary so that you can easily lay polystyrene foam in the future. Otherwise, it will “walk” and not adhere tightly to the surface.

In principle, you can lay a heated floor cake on the ground, but it must be carefully compacted so that there is no subsidence of the same polystyrene.

TOP 3 popular manufacturers of electric heated floors

| Photo | Name | Rating | Price | |

| #1 | Devi | ⭐ 97 / 100 | More details | |

| #2 | Rehau | ⭐ 95 / 100 | More details | |

| #3 | Caleo | ⭐ 94 / 100 | More details |

Caleo

Caleo film infrared heated floor is designed for quick installation of a “warm floor” heating system using the “dry installation” method, without screed and dust. Ideal for cosmetic repairs under laminate, carpet, linoleum and parquet boards.

Caleo

pros

- high quality;

- excellent heat dissipation;

- The kit includes everything necessary for installation;

- Installation and assembly instructions included.

Minuses

- increased film fragility.

warm floor caleo

Rehau

Rehau electric underfloor heating is a system of two-core self-regulating cables of a fixed length with increased resistance. On the outside they are covered with a double layer of insulation and protective braiding.

Rehau

pros

- excellent quality;

- installation under any covering;

- optimal heat distribution.

Minuses

- relatively high cost.

rehau solelec

Devi

Devi electric heated floors are manufactured in Denmark. The company's products are distinguished by high quality, affordable price and versatility. All components of this brand are suitable for any type of heated floors produced by this manufacturer.

Devi

pros

- simple installation;

- does not dry out the air;

- manufacturer's warranty;

- service life more than 20 years.

Minuses

- high energy consumption.

heated floor devi