A bead is an auxiliary strip that is necessary for attaching glass to a window frame.

It comes in three types:

We can say that the main function of the bead is to hold the glass unit and also protect the room from the penetration of dust, extraneous sounds and drafts.

The width of this window accessory depends on how thick the double-glazed window is in the window, as well as how many cameras it has.

Typically, glazing beads are made of PVC, but recently the trend of installing glazing beads from fiberglass has become widespread on the market. But you will also have to pay 1.5 times more for it.

Let's look at what it is in more detail.

What it is?

Modern windows, made in accordance with GOST from the latest generation materials, as well as old-style wooden products as an integral part of a home or premises for other purposes, have individual technical characteristics, advantages and disadvantages.

Components play a fundamental role in the design; a special place in this list should be given to such a seemingly insignificant element as the glazing bead. As a result of errors made during the installation of such a part, serious problems may arise regarding the integrity of the entire glass unit and the sealing of the structure.

Such a part is an elongated metal, often aluminum, wooden or plastic strip, the main task of which is to create a protective barrier that prevents dust, dirt, moisture from penetrating through the window and the gaps between parts, as well as the formation of drafts.

In addition, the bead increases the sound insulation of the room, blocking the passage of extraneous external noise, and, importantly, acts as a decorative component of any type of window structure.

Some craftsmen cut shaped elements from wood that can be used in door structures, act as furniture fittings, or as a baguette-type product for exterior and interior decoration.

Window beads are made according to drawings, since such a parameter as length is of great importance. Its dimensions must exactly match the parameters of the window for reliable fixation. The element is additionally equipped with a fixed rubber seal.

Wooden products are made from various types of wood; the raw materials for plastic products are determined by each individual manufacturer.

Installation of glass and its fixation is carried out using a bead; it is installed in a specially designated groove and snapped into place with a groove plug. It can be attached to wooden window structures with small nails.

Process:

1. Clean the fold from any remaining glass and debris. The window frame must be clean and dry. 2. Cut out the glazing beads, adjusting them exactly to the size of the window opening. 3. Apply sealant around the perimeter of the rebate to a third of its depth. Gently press the glass to ensure a tight seal. 4. We nail the glazing beads into place over the sealant, recessing the heads of the nails into the wood. To avoid accidentally breaking the glass, place a sheet of cardboard or plastic on it in this place. Please note: the inner edge of the glazing bead must be adjacent to the glass without a gap - otherwise the window will rattle from the wind and allow cold to pass through. 5. Wipe off any excess sealant. The window is ready!

All photos from the article

The last stage of glazing is the installation of glazing beads, which can be made not only from wood, but also from plastic. It would seem that such a simple and inexpensive window element, but how many benefits it brings. For example, it removes moisture from the glass, preventing it from reaching the main frame, and also insulates the room by closing the gaps between the glass and the frame. Today we will look at wooden glazing beads for windows made of wood and PVC.

You will learn:

- what it is;

- how they differ from each other;

- how to properly install and manufacture.

Advantages of plastic beads

Bead strips made of PVC have the following advantages:

- Plastic. Plastic is flexible and at the same time resistant to fracture, so it deforms less when impacted than wood or aluminum. Due to its plasticity, it is easier to remove and insert PVC beads than those made of wood or metal. Due to this same property, replacing the glazing bead in a plastic window is very rarely necessary.

- Moisture resistance. Windows with plastic glazing beads do not absorb moisture; they resist street dampness. They can be installed in rooms with high humidity.

- Easy to install. You can remove and install plastic strips a large number of times. It doesn't require any special skills.

- Versatility. The design of all plastic glazing beads is similar; they are installed not only on windows, but also on balcony doors, panoramic glazing, transparent partitions, and other structures that include double-glazed windows.

- Resistance to temperature changes. Properties are maintained in the range from -60 to +60 degrees Celsius.

- Fire safety. PVC is a self-extinguishing polymer; it does not spread fire.

- Environmental Safety. Under sunlight, plastic does not emit harmful substances. The danger arises only with strong heating - an increase in temperature above 100-140 degrees leads to the decomposition of the substance with the release of carbon monoxide and hydrogen chloride.

- Resistance to microorganisms. PVC is not affected by bacteria or mold, the material does not contribute to their spread. It is also of no interest to pests.

- Unpretentiousness. The material can be easily cleaned with soapy water or glass detergents. Plastic is resistant to the concentration of alkalis, acids, and mineral oils found in household chemicals.

- UV resistance. High-quality plastic does not fade under sunlight.

- Availability. The price of plastic beads is quite low, it is lower than that of similar aluminum products, and is approximately equal to wooden slats.

- Decorative. Plastic slats look aesthetically pleasing, especially shaped or laminated options.

- Durability. Glazing beads last as long as the entire window - forty years or more. To ensure that the benefits last longer, it is better to avoid high heat (above +60 degrees Celsius), exposure to esters, ketones and chlorinated hydrocarbons.

Bottom line

I think you have seen for yourself that replacing wooden glazing beads is no more difficult than replacing plastic ones. And to install these parts, it is not necessary to call a specialist. All you need to do is carefully follow the instructions described above. And the video in this article will show visual information on this topic. If you are looking for advice, feel free to leave a question in the comments!

November 16, 2016

If you want to express gratitude, add a clarification or objection, or ask the author something, add a comment or say thank you!

A bead is a structural element of plastic window profiles that ensures strong fixation of the glass unit in the window frame. The dimensions and configuration of the bead depend on the dimensions and design of the window profile and glass.

Special grooves are used for fastening in the window frame and sash. Usually the grooves are drilled in the sash itself, but if these are solid plastic windows and the glass is installed directly into the frame, the bead can also be attached to the frame.

Peculiarities

You can highlight the main purpose of glazing beads for windows. It is considered to hold the glass in the frame. Not so long ago, various types of putties were used for similar purposes, providing a moisture-proof or sealing function. But due to the improvement of windows, such techniques have exhausted themselves.

An important feature of the products is the insulation of the window by sealing the joints. The pricing policy available on the market today invites consumers to choose products in a fairly wide range based on individual product requirements.

When purchasing, you should focus on the main property of the glazing bead - it should be fixed as much as possible in the frame, tightly pressing the glass.

The element is dismantled during structural repairs, for example, replacing an old double-glazed window with a new one, various external works, or when a part wears out over time.

Products have a specific service life, after which they cease to perform their functions. In this case, the glazing bead is removed and replaced.

The production of PVC products takes place using a similar technology as a window profile, only using different equipment.

The manufacturing process can be divided into two technological stages:

- work on the production of the basic solid part of the product;

- fusing the rubber base onto the rail.

To give the product visual appeal, the grooves are decorated with special plugs. They are a sealing cord made in light colors.

Usually it is attached along the entire perimeter of the window frame. This material protects the structure from small debris and dust particles. In addition to window structures, the groove plug is used on plastic balcony doors.

When to change

Wooden glazing beads require replacement in the following situations.

- Loss of appearance. Wood is extremely susceptible to moisture. Poorly processed material can become moldy, change color and shape. In this case it is easier to replace.

- During the installation of double-glazed windows, the glass grooves are coated from the inside with silicone to improve the sealing qualities of the window structure. When subsequently replacing the glazing, it is easier to install new ones than to remove the sealant from the old ones.

- In case of replacing single-chamber glazing with double-chamber glazing, narrow non-standard slats will be needed.

- If the seal is broken or the glass in the sash is rattling, it is also recommended to reinstall and replace the pressure strips using sealant.

Kinds

The classification of window beads is based on the raw materials that were used to produce the element.

Material

PVC bead

The most common material for making products today is polyvinyl chloride. This trend is associated with the widespread use of plastic windows.

Unlike wooden products, plastic products have more standardized characteristics, among which several should be highlighted:

- Products are divided into types based on the design features of the window, taking into account the number of cameras. For single-chamber structures, wide slats are made; for multi-chamber structures, on the contrary, narrow products are made. Windows whose design requires the presence of four or more chambers require a reinforced type of glazing bead.

- Compared to other types of products, plastic slats are distinguished by their low weight, flexibility and durability.

- To purchase products, you only need to measure the glass unit; the products do not require painting.

- PVC glazing beads are very easy to clean from dirt.

- On sale most often are individual products with a length of about 4 m, or products sold in packages of several pieces.

- Plastic slats are notable for their wide variety of profiles.

- There are several ways to install products.

Not so long ago, manufacturers began to use a new material as a raw material - glass composite. This composition includes a fiberglass filler, which is additionally strengthened with binding components.

The finished fiberglass lath is complemented by a small layer of rubber along the edge, which acts as a seal. Products made from this raw material compare favorably with glazing beads made of polyvinyl chloride in their improved qualities of heat retention indoors, as well as resistance to loads and external factors.

Wooden slats are popular for windows made of a similar material. Oak lumber is often used as a natural raw material. Products made from coniferous wood are popular, although you can find products from exotic woods.

Wooden slats are subject to increased requirements, which relate to quality, as well as visual appeal, since a regular plank is absolutely not suitable for arranging a structure.

It is very important that the product fits laconically into the overall style of the window. Wooden glazing beads are most often used in the arrangement of private homes or civil buildings for public purposes. Typically, products are sold in strips two or three meters long.

As for the profile of the wooden glazing bead, in this case the product has a classic, conservative appearance.

Sometimes you can find products made of aluminum, but due to the fact that window structures made from this material are quite rare, such products are also produced in limited quantities.

Dimensions

The dimensions of the products directly depend on the thickness of the glass unit, the size of the glass and the design of the window. Wooden glazing beads can have the following dimensions: 10x10 mm, 8x10 mm, 20x20 mm, and there is a layout of 19x19 mm.

The thickness of the products varies from 4 mm to 30 mm. The length of products starts from 1000 mm and above, depending on the manufacturer.

Form

Taking into account the shapes of the products, the following types of window elements can be distinguished:

- round glazing beads;

- square slats;

- rectangular;

- figured products.

PVC beads

Beads for PVC windows are made from the same plastic as the main profiles for assembling sashes and frames. They should have the same exact snow-white color. At the same time, some manufacturers, in an attempt to save on components, use glazing beads made from recycled materials to fix double-glazed windows. This is unacceptable, since such elements have a grayish tint and are of poorer quality. Read more about the requirements for polyvinyl chloride on OknaTrade.

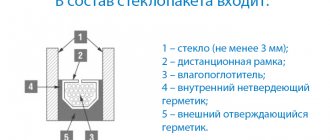

Structurally, plastic window beads are a strip that is hollow from the inside. Thanks to the presence of an air chamber, it is possible to further reduce the heat exchange between the street and the interior. The length of such profile elements is usually 6.5 m. Depending on the modification, the glazing beads are equipped with 1-2 sealing contours made of elastic materials. According to the profile cross-section, these elements of window structures are divided into:

- square;

- rounded;

- flat;

- beveled;

- curly.

For fixation in frames and sashes, the glazing beads have a special structural protrusion that fits into the profile and snaps there. That is, the manufacturers of PVC systems in this case used a classic and reliable tongue-and-groove lock. Plastic glazing beads differ not only in the shape of the profile section, but also in dimensions. When assembling window structures, they are selected depending on the installation depth of the frames and the selected double-glazed windows. If single-chamber models are used to complete windows, they are secured with wide glazing beads. To fix two- and three-chamber double-glazed windows, narrow slats are used.

In the basic configuration, windows are usually equipped with glazing beads with a rectangular cross-section. If you need another form of transition from a profile to a double-glazed window, you need to discuss this nuance with the manager in advance.

Installation and dismantling

While performing their main protective function, glazing beads fail as a result of exposure to external factors and over time. In this case, it is necessary to remove the part and replace it with a working similar element.

It is worth highlighting the main points indicating that it is necessary to carry out work to dismantle the glazing bead.

- First of all, the element will begin to allow air, dust and moisture to pass through. On the inside of the frame, without removing any parts, the accumulation of liquid and various debris will become noticeable. Such phenomena will indicate a malfunction of the glazing bead.

- During strong gusts of wind, certain sounds can be heard from the glass, which will indicate that the tightness of the structure and the fastening of the bead to the frame is broken.

- The appearance of the item will also indicate that the product is no longer suitable for use.

It is possible to carry out the work of replacing the element yourself, the main thing is not to damage the glass, performing all the work very carefully.

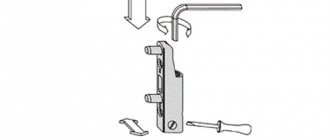

To replace a PVC product you will need the following tools:

- non-metallic hammer and spatula;

- plastic spatula.

The work technology includes the following stages:

- It is necessary to insert a spatula between the frame and the bead, gradually moving it away from the structure; you can additionally use a spatula;

- As soon as the product moves away from the frame , you can carefully remove it;

- Having cleaned the place where the element was located using a damp cloth and dried the surface, you can begin installing a new product;

- To install a new part, you need to attach it as tightly as possible to the frame and, fixing it with one hand, nail the bead to the structure with a hammer.

You can check the quality of the work done by tapping your palm on the surface of the window from the back side. A securely and correctly fixed part will fit tightly to the base.

To replace a wooden glazing bead, you will need the following tools: sandpaper of varying degrees of abrasiveness, chisel, nails, spatula, hammer.

Work technology:

- Using a chisel you need to remove the part from the frame and pull out the glass;

- clean the glass gutter with sandpaper;

- insert the glass and apply a layer of sealant;

- Next, you need to attach a new element and forcefully press it to the base;

- after which the product is nailed to the structure.

Please note that all painting work on the window must be completed before installing the glazing beads.

To dismantle an old faulty aluminum bead, you can use two methods.

- The outer seal is pulled out from one bead, after which you need to hit its corner with your palm. This procedure disrupts the adhesion of the product to the surface.

- The seal located inside makes it somewhat difficult to dismantle the part. In this option, the rail is additionally secured with clips, which should be removed first, and then proceed to removing the glazing bead.

Conclusion

From the above article it became clear that the glazing bead is a necessary structural element of any window. It allows you to protect the frame from moisture getting on it, and also will not allow cold air to enter the room. The video in this article will complement the information on the above topic.

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

None of us is immune from troubles, and at one moment the glass in a wooden window of your house may break. In such a situation, the question arises about speedy repairs, but many experience certain difficulties with this. So, how is a wooden window glazed?

Manufacturers

You can purchase glazing beads for windows from the same manufacturers where the window structures were purchased. For PVC products, you should give preference to products manufactured by the window manufacturer.

This option will help to avoid mistakes when purchasing slats, since product sizes may differ from each manufacturer.

According to consumer reviews, products from manufacturers such as Rehau and Kbe are very popular due to their high quality.

Sale of cheap PVC windows from a warehouse in Moscow.

Prices for single-sash windows Rehau Blitz Prices for single-sash windows Rehau Grazio Prices for single-sash windows Rehau Delight Prices for single-sash windows Rehau Brillant Prices for single-sash windows Rehau Intelio 80 Prices for single-sash windows Rehau Geneo Prices for

double-sash windows Rehau Blitz Prices for double-sash windows Rehau Grazio Prices for double-hung windows Rehau Delight Prices for double-hung windows Rehau Brillant Prices for double-hung windows Rehau Intelio 80 Prices for double-hung windows Rehau Geneo

Prices for three-leaf windows Rehau Blitz Prices for three-leaf windows Rehau Grazio Prices for three-leaf windows Rehau Delight Prices for three-leaf windows Rehau Brillant Prices for three-leaf windows Rehau Intelio 80 Prices for three-leaf windows Rehau Geneo

Adviсe

When choosing window beads, you need to pay close attention to the quality of the products. Because the tightness that they will provide, especially when the windows go outside, is of enormous importance for the entire window.

For parts that are not in contact with the external environment, appearance is more important. Therefore, for installing glazing beads outside, you should give preference to the classic versions of products; for installing products inside, there are products with various decorative elements.

The rail must be made of the same raw materials as the window. The exception is wooden structures made using double-glazed glass technology, where the installation of PVC products is allowed.

It is worth paying attention to the fact that fasteners are not conspicuous, since the decorative function is as important for the product as the protective one.

Glazing beads for wooden windows

Wooden glazing beads for windows are solid slats, which, by analogy with plastic ones, can have a rounded, rectangular, shaped or beveled profile cross-section. For their manufacture, the same type of wood is taken that was used in the production of eurobeams. Since it is in the area where the glazing beads are installed that the most condensation accumulates, the slats must be carefully treated with antiseptic impregnations. This procedure is necessary to slow down the processes of wood decay. Before installation, glazing beads, like all other elements of window structures, are coated several times with paint and varnish compounds and sanded.