It is a combination of special mechanisms that regulate the operation of a window with an installed double-glazed window.

The fittings consist of locking elements, handles, hinges and various devices that allow you to open, close and set the position of the window structure with adjustment of the degree of ventilation.

Which kits relate to fittings, how to choose, install and configure them correctly, as well as other nuances, read more in this article.

Purpose of window products

The need for fittings for any wooden window is obvious, since it is needed in order to fully perform all actions with double-glazed sashes:

- open;

- close;

- lift up,

- let down;

- strengthen and support the structure.

An important quality of any fittings is that they do not violate the overall sealing of the window, and all its types comply with GOST 30777-2012 in terms of manufacturing quality, purpose and performance characteristics.

The fittings are suitable for standard wooden window systems, as well as European ones (Finnish, German, Swedish).

At the same time, experts divide it into main varieties and:

- rotary;

- sliding

- folding;

- tilt and turn.

Several types of fittings can be used for the same design, but it must comply with the basic requirements of GOST 30777-2012 , which include the following points:

- Providing the ability to adjust the sashes to the window frame.

- Impossibility of unauthorized disconnection of connections.

- Reliable and durable fixation of the sash in different modes, including during ventilation.

- Fixing the handles in the positions specified in the instructions.

- Compliance with the distance between the locking points (where the sash is pressed against the frame) is no more than 70 (cm), and between the corners - no more than 30 (cm).

- Adjustment of hinges in three directions, with an offset angle of no more than 2 (mm).

- Withstands the loads and torque specified in the instructions.

- Creation of reliable fastening of all used parts adjacent to the sash assemblies and the frame (frame).

- Manufacture of products from high-quality materials, in production conditions, with marking.

Regardless of the type, any fittings must first of all correspond to the frame, and not be an overly complex mechanism, and have sufficient strength and density characteristics.

The only exceptions are the ultra-modern remote mechanisms of Eurowindows used for smart windows. When purchasing accessories, pay attention to the operating cycle of the device specified by the manufacturer - it should be more than 10,000 . The ideal option is 60,000 cycles.

Popular types of fittings are products with provided rotary-vertical and horizontal suspensions, with limiters that open the mechanisms. Any fitting elements are made of high-quality metal, wear-resistant plastic, as well as a combination of this combination.

They must be made in such a way that they do not fail at the most inopportune moment, for example, they do not jam during the cold season. The surface of each product is coated with a special corrosion protection agent.

The quality of the fittings is of particular importance, since it completely determines the functional ability and service life of the structure.

Micro-ventilation mechanisms for wooden windows

Micro-ventilation mechanisms for wooden windows are climatic ventilation valves that allow you to adjust the gap for the penetration of fresh air. To avoid the appearance of condensation on the window and to ensure air exchange, it is necessary to install micro-ventilation systems. For microventilation, special fittings are installed. It allows the window to open slightly. Only the sash is adjustable. It is at 45-60o C to ensure air circulation. The micro-ventilation fittings consist of several types of fixing elements: scissors and combs. One element is attached to the end part of the frame, the other - to the sash. There are several types of micro-ventilation:

- comb – provides adjustable opening;

- valve - installed above the valve;

- slotted - opening of the doors when the handle is positioned at 45o.

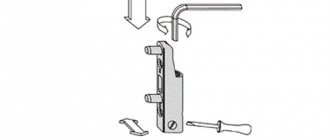

A mechanism for opening and locking wooden doors is a set of elements that ensure a change in the position of the doors in the direction of the handle. The standard mode is the rotation and tilt of the sashes. The window position is controlled only with a handle. In addition to the locking mechanism, additional modes may be provided:

Rice. 3. Hardware mechanism for wooden windows

Set

The main standard fittings set is represented by the following elements :

The handle is rotary.- Loops (upper and lower).

- Espagnols.

- Locking mechanism (trunnions).

- Mode switches.

- Planks (reciprocal, to the axles).

- Scissors for sashes.

- Hooks (pressing the sash to the seal).

- Decorative overlays.

As additional accessories I use the following accessories:

- Manual locks.

- Limiters, stoppers (blockers, combs).

- Additional ventilation mechanism.

- Security elements against burglary (adult type and especially for the safety of children).

The elements are designed to make the use of the window structure most comfortable. The description of the most popular fittings elements can be presented as follows:

Pens

The shutter mechanism is fully regulated. They help open and close the doors in a certain direction. Pens come in several varieties :

- standard (ordinary);

- removable (easy to take off and put on);

- curved (for doors opening from the outside);

- bilateral (control of functions from the outside and from the inside);

- protective (with internal blocking);

- push-button (with a locking button);

- keys (have a latch that will work against accidental opening).

Any handles regulate the desired position of the sashes by turning, tilting, ventilating, sliding, and fully control the locking mechanism.

Read more about the types of handles for wooden windows here.

Clamps, limiters

This type of fittings regulates the ventilation design and consists of two main parts - a comb and a clamp. The peculiarity of attaching the elements is that the comb is attached to the frame, with a latch installed on the sash , which moves. This helps to block or adjust the position of the window when ventilating it.

The comb teeth located on the locking pin allow you to change the dimensions of the spaces between the wooden elements. At the same time, they protect the doors from accidental opening by small children. The comb clamps have dimensions of 10-20 (cm). There are plastic and metal models in standard colors - white, silver and brown-beige.

Micro-ventilation

This element is a ventilation system of valves (climatic) that control the entry of fresh air through the cracks. This method prevents the accumulation of condensation and ensures air exchange. Micro-ventilation for sashes is installed at an angle of 45-60°.

It consists of a comb and scissors, attached to the frame from the end side and from the sash side. Experts distinguish several types of ventilation with the “micro” system :

- slotted, with the handle opening only 45°;

- valve, with fastening above the valves;

- comb, with fully adjusted opening adjustment.

The type of ventilation in a small mode is set individually.

Opening/closing

The presented fittings help to change the position of the sashes in relation to the handle. The most used functional mode in this case is rotation and tilt of the sashes. The presented locking mechanism is controlled by different types of handles. There are also additional modes. But they are installed in exceptional cases, for example, in the “smart home” system.

The mechanism is capable of performing certain modes. It has limiters and blockers that can be used depending on the situation. The element uses a universal and modular principle of using fittings.

Swivel/tilt

Such an element has a different appearance, depending on the location of the axis, the type of window structure, the control function of the sashes, the characteristics of the profile and the presence of an anti-burglary system.

The mechanism interacts with the handle and forms the sash tilt and turn, which is why it is called a tilt-and-turn mechanism. Helps set the desired ventilation mode.

The complete set of this mechanism is presented:

- reinforced loops (top and bottom);

- trunnion with locking function;

- any handles (there are also buttons and keys);

- strips with amplifier.

The package may also include a microlift system. All presented elements of this type of fittings help to tilt and turn the sashes.

Locks

Most of the presented elements are recommended for first floors and private houses. But they are also needed if small children live in the house (ensuring safe operation). The lock helps protect against burglary or accidental opening of the doors. Its varieties include the most common model - blocking and children's.

This protection element can be located either on top of the wooden part of the frame or on the handle itself. Moreover, the second option is considered the most common. A lock set always contains several keys.

Loops

Most often, this fittings are used for separate non-lifting sashes. Externally, they consist of two cards - one of which is cut into one part of the frame, and the second is screwed into the sash next to it.

There are loops:

- combined;

- invoices.

They are made from high-quality, high-strength metal with a long service life (more than 10 years). Window hinges have a cylinder with a rod that helps connect cards and paired structural wood members.

Espagnols

They are a cylindrical metal bar that extends from the made body of the window structure in the direction of the frame or sash. Most often used on old standard windows. Rarely installed on European models.

May have a rectangular shape or come in the shape of a butterfly . Fully overhead type. It is easy to install, it can be easily screwed in using self-tapping screws or self-tapping screws into the existing factory-made holes. It is installed up and down or left and right, according to the plan provided by the window design.

Supply valves

Refers to the element of regulating the ventilation of windows, providing fresh air and removing stale air. They are placed on Euro-structures, which consist of such parts as :

- air intake;

- working channel for air flow;

- nozzle with filter and adjustment mechanism.

Supply valves allow you to create a pleasant microclimate in the room, thanks to the formation of natural ventilation.

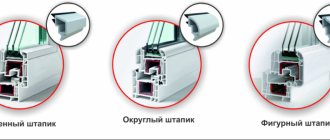

Planks

They are long narrow devices located along the window and can restore the geometry and deformation of any window opening. Window trims for window construction come in several types :

- Decorative (decorates slopes, has tiles).

- Finish (secures the window around the entire perimeter of the opening).

- Reciprocal (installed on the frame and needed to create locking points).

- Chamfer (used together with finishing and used instead of near-window).

- Platband (used in cases where the window opening is located at the same level as the wall).

- J-profile (hides siding edges).

The function of the strip is to tightly press the sash to the frame, which is ensured by screwing a fastening element (screws) into its holes.

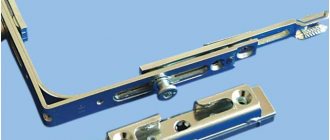

To improve the functions of the window structure, strikers are often used, available in several types :

- Regular.

- Anti-burglary.

- Tilt-and-turn.

- Shtulpovaya.

- Ventilation.

Thanks to the tight fit of the slats through the window systems, the windows are protected from dust, precipitation and drafts. At the same time, heat is retained in the room, which does not escape through the loose fit of the sashes to the frame. The strikers are installed simultaneously with the installation of the hinges.

Elements of fittings vary in price, material used in manufacturing, as well as the functionality intended for them.

Clips for wooden windows

Clips for a wooden window are limiters designed for ventilation. The clamps consist of two structural elements:

- combs;

- retainer.

The comb is attached to the frame, and the latch is installed on the movable sash. Thanks to the comb, you can adjust and block the position of the window for ventilation. The mechanism works as follows: when adjusting the degree of opening of the window, the teeth of the comb are fixed to the locking pin, due to which you can change the size of the gap between the sash and the frame. Locks for wooden windows not only regulate the degree of ventilation, but also ensure safety by protecting the sashes from being opened by children.

There are several types of latches for wooden windows:

- by material - metal and plastic;

- according to the method of fastening - screw-in and clamping;

- comb sizes - from 10 to 20 cm.

Some window manufacturers install clamps in the basic package of double-glazed windows, but you can install them yourself. Standard colors of retainers: white and brown.

Rice. 2. Main elements of fittings

Popular manufacturers

According to construction specialists and network users, the following companies :

- Siegenie;

- Maco;

- Roto.

An important advantage of the company's production is considered to be the high-quality composition, reliability, long-term operation and attractive appearance of the products, which are preserved even with large types of load performed.

Siegenia

The company is located in Germany and produces aluminum fittings. The quality of Siegenia products is appreciated all over the world. The most popular for window structures are German sliding-type mechanisms.

The following qualities

are considered to be the features of window fittings :

- regulation of ventilation;

- the presence of a fuse against unexpected openings;

- anti-sag function.

Each element is carefully thought out by the manufacturer. Particular attention is paid to hinges and components (scissors, pins, bushings).

Any mechanism is covered with three-layer corrosion protection, and is a high-tech and durable product. The price of Siegenia fittings, for different types of elements, ranges from 55 to 1,500 rubles .

Maco

The Austrian company has gained recognition in the construction market for quite some time. Its fittings are considered to be of high quality, durable and versatile. The secret of the brand’s popularity is the use of a special steel alloy, which is treated with beeswax, which is able to withstand various intense loads.

The external design of the products is quite technological, it is necessarily marked. The manufacturer paid much attention to the folding mechanism, stiffening ribs, anti-burglary protection, scissors, microlift and hinge element. The quality characteristics of the brand include :

- presence of a built-in blocker (prevention of accidental opening);

- compatibility of scissors with sashes;

- a unique template has been created that helps to drill and fasten fitting parts without any problems;

- adjustment of the key, suitable for any mechanisms.

The trunnions from the manufacturer are made with a large stroke, which allows you to effectively adjust the sash. The price for products, by type of mechanism, ranges from 181 to 4,930 rubles.

Roto

The German brand Roto is popular due to the quality and ease of installation of fittings. The company's main specialization is the improved tilt and turn mechanism, presented in seven categories. To protect the mechanism, Roto uses 3 layers of anti-corrosion protection.

Important qualities of a brand are also considered:

- high functionality of mechanisms;

- advanced adjustment options;

- versatility, as they fit any window size;

- Possibility of adjustment with different keys.

The company pays great attention to improving the locking hardware for better pressing of the sashes, withstanding significant loads for any product, a good braking function and 2 operating ranges for scissors. The price of the products ranges, depending on the type, from 73 to 3,714 rubles .

When purchased in bulk, products will cost much less than those purchased at retail.

Mechanisms for tilting and turning wooden windows

Mechanisms for wooden windows of this type differ in the following ways:

- window type;

- the method of controlling the doors (recline, swing open, move along their own axis);

- by type of profile used;

- by the presence of an anti-burglary system;

- according to the location of the axis.

All these parameters affect the mechanism for tilting and turning the window. The most commonly used mechanism is a tilt-and-turn mechanism. He tilts and turns the doors in the direction of the handle. You can choose fittings to open the doors in any direction with the possibility of ventilation. A wooden double-glazed window can be completed at your discretion:

- top reinforced loop;

- lower reinforced loop;

- locking pin;

- handle (with key, button);

- opening blocker;

- microlift;

- reinforced bar.

The method of tilting and turning wooden windows depends on the type of mechanical drive and hooks.

Rice. 4. Fittings installation diagram

Product selection rules

It is best to coordinate the specifics of selecting the necessary fittings with construction specialists. Products must be strong, durable, visually attractive, and withstand all types of mechanical loads.

The quality of workmanship must be indicated in certified accompanying documents, and markings must be present on the product itself. The fittings should be easy to install, and the instructions for attaching them should be clear to the average person, with a guarantee for operation of more than 10 years.

It is best to choose parts made of high-quality metal (aluminum, steel alloys, stainless steel), which goes well with wood and matches its color. In the instructions, you should pay attention to the number of cycles used, which is at least 10,000 (the higher this figure, the better).

First of all, you should pay attention to the availability of equipment and compliance with the declared quantity of all specified elements. You also need to look for instructions from the manufacturer that the products have an anti-corrosion coating, and select them with an additional safety margin of 10%.

After installation, high-quality fittings will work without obstacles, silently and smoothly, and will have the necessary mechanism against breaking and accidental slamming.

Window hinges are an important component of fittings

Modern window hinges are more complex devices than their basic counterparts that were used until recently. Thanks to the expansion of functionality, wooden, aluminum and plastic windows can now swing open in two planes. The transition from one position to another takes only a couple of seconds, and control is carried out using a regular window handle.

New opening mechanisms are constantly being improved during operation, which has made their operation more correct. During their existence, fundamentally new modifications have already appeared, providing a higher level of tightness and burglary resistance. Today, manufacturers have at their disposal fittings for equipping door and window sashes of various sizes, weights and purposes.

Tools for work

Companies that provide fittings installation services have all the necessary tools for the job. It may include :

- Set of adjusting wrenches (hexagonal, trunnion, loop, multifunctional, with a diameter of 4 mm).

- Straightening hammer.

- Breakout handles for removing pins.

- A set of screwdrivers of different sizes to suit the fastener.

- Glass jack.

- Sickle knife.

- Pliers.

- Pliers.

- Fasteners.

- Pencil.

- Roulette.

- Regular and rubber hammer.

- 2 types of chisels – narrow and wide.

- Drill with various attachments (drills).

- Roulette.

Fastening elements for wooden structures are often included in the kit of fittings, so there are no difficulties with their selection.

Functionality of window hinges

Hinges for plastic windows are responsible for the tightness of structures, smooth, silent opening and keeping the sashes from sagging. They are adjustable in 3 planes and are designed for different loads:

- 90 kg;

- 120 kg;

- 160 kg.

All new hinges are compatible with automatic opening systems, so windows and doors can be connected to an electric drive. This is especially important for structures installed in hard-to-reach places. These include attic models, skylights and high windows with folding transoms.

Installation of elements

Installing fittings on a wooden window begins with preparing the workplace and acquiring all the necessary elements, according to the work project. It is also necessary to make markings with a simple pencil and a tape measure so as not to make mistakes with the dimensions, attachment points and indentations from the edges of the window structure. Using suitable drills according to the markings, holes for fasteners are prepared.

Step-by-step installation may look like this:

First, loops are attached to the lower and upper parts of the opening. Here they also make locking pins (angular mechanisms), locks for tilt-and-turn mechanisms, and combine parts of the hinges with special pins.- At the same time as the hinges, stop combs, strikers, locks and anti-burglary devices are installed.

- Then additional locking devices are attached, and for those frames that do not need them, plugs are installed so that the fittings work correctly.

- With the tilt-and-turn type of fittings, they also do not forget about installing scissors, which are needed to tilt the sashes.

- When installing the trunnions, first the upper left part is made, with the installation of the middle locking mechanism and plug, and then the lower right part.

- Then the handles are attached to the internal pin in the kit, carefully securing the mechanism, depending on its type (one-sided, double-sided, etc.).

Self-tapping screws for installation are included. All types of work are carried out on the window frame itself. It is best to check the markings several times before drilling holes. After fixing the fittings, they need to be checked in action and adjusted.

Handles for wooden windows

A handle is an element of the window sashes adjustment mechanism. It contains a mechanism for opening and closing the window in the direction in which it is turned. There are several types of window handles:

- standard - ordinary handles for adjusting and monitoring the position of the sashes;

- removable - perform the functions of window handles, but are easily removed, which allows adults to control the opening/closing of the window;

- curved - designed for windows that open outward;

- double-sided - provide control of the position of the valves from the outside and outside;

- with additional protection – equipped with internal mechanisms that lock when you press the window from the outside, thereby protecting against burglary;

- locking – protects against accidental opening, fixing the position of the doors;

- push-button – equipped with a push-button mechanism that fixes the position of the handle.

Handles for wooden windows can be made of different materials. Most often, handles made of brass and steel or any other metal are used for wooden double-glazed windows. Depending on the opening mechanism, handles for wooden windows are classified into:

- rotary – open the window horizontally;

- folding - designed for micro-ventilation;

- tilt and turn – provide horizontal opening and ventilation of the sashes;

- rotary-sliding – allowing you to adjust any position of the window.

The choice of handle is of great importance, because it determines how the doors will open and close, and whether it will be convenient to operate the locking mechanism.

Possible errors and difficulties

- The use of low-quality material (the fittings themselves), additional consumables and fasteners without markings and accompanying documents (quality certificate and instructions) leads to rapid failure of any functional elements.

- Incorrect marking with a simple pencil on the window frame will lead to the fact that the place for the fittings will be drilled with a drill not according to the diagram. You will have to redo all the work again, and then start puttingtying the window.

- An unprepared surface (lack of restoration, priming, painting, replacement of damaged wood, removal of mold and old insulation) makes installation of fittings useless, since the wood will crumble or deteriorate, and the fittings will fall off.

- Failure to check the functionality of the elements immediately after installation will lead to the need to redo the installation work.

The process of working with fittings will become error-free if you accurately mark the necessary areas on the frame and sashes, which must correspond to the established work plan.

For each type of hardware product, the manufacturer includes instructions that schematically indicate the entire installation sequence. This helps to avoid difficulties and errors in work.

How to choose fittings for your window sash:

- Specify what window sash material is used: wood, PVC or aluminum

- Measure the width and height of the sash along the rebate in mm (the sash rebate is the part of the sash that faces the street, this part is narrower than the part that is located on the side of the room)

- Measure the height from the bottom point of the sash to the center of the handle, in mm, along the rebate.

- Determine the opening of the sash (left - hinges on the left, handle on the right; right - hinges on the right, handle on the left)

- It is advisable to know the profile of the window, if it is not possible to find out, then bring one of the strikers to our point of sale (retainers are small metal plates installed around the perimeter of the window frame), our specialists will most likely select the strikers to match your profile.

- Write down all the information and pass it on to the specialists.

Adjustment methods

Adjustment of fittings can be carried out immediately after installation or annual maintenance procedures for preventive purposes, after the loss of original functions.

This is done using tools such as:

- screwdriver;

- universal key;

- pliers;

- hex wrench.

Thanks to the listed tools, handles, hinges, and locking pins are corrected. To do this, certain types of impacts are performed on the fittings. For example :

- sagging sashes are restored by turning the screws clockwise (up) or counterclockwise (down);

- the hinges are pressed tightly against the frame by tightening the bolts or screws;

- a loose handle is adjusted by lifting the decorative plug, which gives access to the fastener, and turning it all the way;

- when acting on special screws for hinges, the blade is installed in a horizontal position.

Any adjustment includes tightening the element, aligning it along a geometric line, tightening it and checking the fit. Adjusting the functions of the fittings helps to remove distortions up to 2 (mm) and correct defects and looseness of elements.

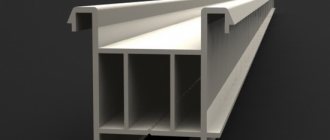

Category No. 1: fittings for wooden blocks

I'll start with the basics. A hinge is a type of fitting that connects the leaves (sashes), transoms or vents to the window frame. It also mates paired sashes of wooden window blocks and ensures opening/closing of the sashes, vents, and transom windows.

Types of loops

Awnings can have different sizes based on the weight of the sash.

The design and other features of this fittings are determined by State Standard No. 5088-2005 “Hinges for door and window units”. Based on the weight of the canvas, awnings can be designed for windows:

- from 80 kilograms to 130;

- from 50 kg to 80;

- up to 50 kg.

The document classifies hinges for wooden windows weighing more than 130 kilograms as special-purpose fittings.

Based on their size, canopies can be:

- small;

- standard;

- big.

Right-handed and left-handed loops.

According to the option of opening the sash, there are the following canopies:

- Right loops (marked with the letter “P”). They are placed on window blocks, the panels of which are covered counterclockwise.

- Left awnings (marked with the letter “L”). They are mounted on windows, the sashes of which are closed clockwise.

Universal device.

- Universal hinges (marked with the letter “U”). They are placed on blocks, the canvases of which can be covered either clockwise or counterclockwise.

Hinge design options

Regular overhead canopy.

According to the method of installation on a window block, there are the following types of hinges:

- invoices (designation – “PN”);

- mortise (marked as “PV”);

Screw-in hinge.

- screw-in (marked “PVv”);

- combined (designated as “PC”).

Awnings for wooden window structures are rotating, hinged and folding. All these varieties movably connect the canvas and the frame of the block. In addition, hinged canopies help rotate the canvas around their vertical axis, while folding analogues allow rotation around the horizontal axis.

Combined tilt and turn hinges are also produced. They serve to rotate the doors around their vertical and horizontal axes.

Hinged awnings absorb all the loads from the window panels, transferring them to the frame. This means that the larger the sashes, the greater the load. Based on this, proper installation of fittings ensures normal operation of the window unit.

Hinged canopies include combined, mortise and overhead hinges.

Differences between overhead and mortise hinges.

- Mortise hinges are an improved version of ordinary window awnings, corresponding in design to door fittings and differing from them only in size. Similar fittings are used when installing blocks with separate panels (non-lifting). When hanging mortise awnings on flaps, only movable rods are used.

- Combined loops. With this design of canopies, one of their cards (plates) is embedded, the second is only screwed on with screws with semi-countersunk heads. The option has the following advantages:

- There is no overturning effect due to the contact of the cylinder of the cutting plate with the central rod.

- Greater locking friction when coupling the mortise part due to the increased area of contact between the sides.

The difference between a combined and overhead hinge (a-combined canopy, b-overlay).

- It is possible to use such loops as left and right ones. In addition, they can also play the role of folding awnings, since their rod is removable and can be easily inserted on both sides.

- Simple and quick installation thanks to fixing the cards on the window block.

- High level of strength.

- Overhead canopies are a structure made of a pair of small-width plates with a cylinder between them. A rod is inserted into it. Similar fittings are used to connect the panels of paired windows.

- Overhead canopies can be used for both left and right installation. You just need to change the rod. In this case, the fitting plate, which has a large width, is screwed to the internal sashes (to their quarter), and the narrow plate is screwed to the overlaps of the external leaves.

- All force loads that appear during the overturning of the external sashes act along the longitudinal axis of the horizontal plane of the fastenings. Here the holding power of the canopies depends only on the resistance of the screws to being pulled out.

- Keep in mind that the fusion of the outer fabric, which is 1.2 centimeters thick, may not have sufficient strength.

Folding loop.

Folding hinges for wooden windows ensure rotation of the panels in the horizontal direction. Unlike analogues of hinged sashes installed on vertical posts, no torque is generated in folding awnings. Based on this, there are no special requirements for their strength during installation.

Product marking

Structure of the symbol on a loop.

In the table below I give the symbols that mark the types of loops.

| Loop marking | Height in millimeters or type of execution | Area of use |

| PN-1, PN-2, PN-3 | 150, 130,110, 98, 85, 70 | For curtains of window blocks. |

| PN-5 | 60 and 40 | For window vents without overlay. |

| PN-6 | 110 and 80 | For pairing paired window sashes. |

| PN-7 | Execution No. 1 | For connecting paired window panels with overlay. |

| Execution No. 2 | For mating paired transom panels. | |

| PV-1 | 100 and 80 | For window sashes with overlay |

| PV-2 | Version No. 1 and No. 2 | For window transoms. |

| PV-3 | Execution No. 1 | For pairing paired window panels with overlay. |

| Execution No. 2 | For pairing transoms and paired window panels. | |

| PV-4 | Execution No. 1 | For window sashes with overlay. |

| Execution No. 2 | For window transoms. | |

| PVv-1, PVv-2 and PVv-3 | — | For curtains of window blocks. |

I will give an example of complete marking of a canopy: PN-1/130-P, State Standard 5088/2005. This means that in front of you is an overhead right hinge of the type PN-1, which has a height of 130 millimeters and is manufactured in accordance with State Standard 5088/2005.

Another example: PV-3/90-U-1, State Standard 5088-2005. This means that in front of you is a universal mortise canopy of the PV-3 type, having a height of 90 millimeters and manufactured in version No. 1.

Requirements for awnings for wooden window blocks

All requirements for hinges for window units are stated in this standard.

Canopies must comply with the requirements of State Standard No. 5088/2005 and State Standard No. 538 and are manufactured according to technological and design documentation for their specific type.

- As for the appearance of the fittings: color, permissible defects on the surface (scratches, scratches, etc.), it must correspond to the samples that were approved in the prescribed manner. Defects and color differences that are visually visible from a distance of 80 cm in natural light (at least 300 lux) are not acceptable.

- The fittings must be safe to use and designed for operational loads based on their area of use. During manufacture and use, canopies should be calculated for strength based on regulatory documents.

An example of a working drawing for hinges.

- The dimensions of the hinge elements are established in the design documentation, and the controlled dimensions are specified in the technological documents of the manufacturing company.

- The shape of the planks of overhead and mortise canopies is indicated in the working diagrams for a specific type of fittings.

- The ovality of the semi-axes (axes) in the areas of movable interfaces with the canopy slats should not be more than 0.1 millimeters, and the card tubes should not be more than 0.3.

- The gap between the axle shaft (axle) and the canopy tube in the areas of movable joints should be no less than 0.1 millimeters and no more than 0.5.

- Deviation from the perpendicular of the supports at the axes of fittings of types PV-1 and PN-1, PN-2. PN-3, PN-4 in relation to the axes of rotation should be no more than 0.25 millimeters.

- The gap between the plane of the bar and the loop tube should be no more than 0.5 millimeters.

- The gap between the plane of the canopy plank and its tube (curved end) should be no more than 0.5 millimeters when the thickness of the plank is up to 2.2 millimeters and 1 millimeter if the thickness is more than 2.2 mm.

Now a little about the requirements for the design of loops. It must be reliable and durable, while making it possible to replace and repair canopies.

In the design of overhead fittings, it is advisable to use adjusting screws so that you can adjust the position of the window sash in different planes.

Adjustable steel hinge.

Besides:

- the design of steel canopies must allow them to be adjusted by plus/minus 2 millimeters in the vertical and horizontal planes;

- for fittings made of aluminum alloy, this condition is plus/minus 5 millimeters.

Adjusting fasteners should be located in areas that are easily accessible for the debugging process:

- The design of the fittings must ensure their reliable fixation to the frames and canvases. The location and diameters of holes for mounting canopies are shown in working diagrams for specific types of windows.

- The slats of mortise and overhead hinges, as well as rods that have screw-in counterparts, must rotate around the axle shafts and axles without jamming. To ensure this condition, it is advisable to use bearings.

- The hinge halves are fixed to the canvas and frame through fastening plates, technological holes or by welding.

Hinge equipped with anti-burglary system.

- To increase the safety and security qualities of window units, additional anti-burglary elements can be installed on the hinge plates.

- The thread (metric) on the rods for screw-in awnings must be full and free of thread breaks and dents. It must meet the standards of GOST No. 24705.

- The head of the axle shaft (axle) of the canopies must have a spherical or truncated cone shape. The end chamfer on the axis of fittings of types PN-1, PN-2, PN-3, PN4, PN-6, PN-7, as well as PVv-1, PVv-2 and PVv-3 should be equal to (2-3)×30 ˚.

- Fittings types PN-7, PV-2. PV-3 and PV-4 must be equipped with cotter pins 2×16 mm in accordance with State Standard No. 397 or thrust (quickly removed) washers No. 5/080 in accordance with State Standard No. 11648.

- Canopies of types PN-1, PN-2, PN-3, PN-4, PN-6 and PV-1 are produced both left and right.

- The couplings of the halves with the axle shafts (axles) in overhead canopies of the PN-7 type and the mortise analogue of the PV-1 type are made one-piece.

- The mating of canopy elements can be carried out using resistance welding, in accordance with State Standard No. 15878. Welded joints must be cleaned; they must not have burns or unwelded areas.

Screw for attaching hinges.

It is permissible for manufacturers to use a different method of connecting hardware elements, provided that their strength is ensured.

- As the instructions indicate, the design of canopies for turning, tilting and tilt-and-turn window units must comply with the requirements of GOST No. 30777.

I’ll tell you a little about the requirements for the reliability of the fittings and its resistance to loads

During laboratory tests for reliability and reliability, as well as during their operation, canopies must withstand the number of closing/opening cycles, based on the table below.

| Weight of the window unit in kilograms | Number of opening/closing cycles the loop can withstand (minimum) |

| Up to 50 | 10 thousand |

| 51-80 | 20 thousand |

| 81-130 | 20 thousand |

The coupling of rods with brackets or bushings in screw-in awnings must easily withstand a tearing force of at least 800 N. The resistance to static and dynamic loads of fittings in ready-made window structures is calculated, taking into account their type, material of manufacture and the fasteners used.

Prevention measures

In order for the fittings to last for a long time, in accordance with the warranty periods specified by the manufacturers, it requires periodic care, at least during seasonal window cleaning (1-2 times a year). The fittings should be wiped with a soft cloth and when checking their functionality, make sure that small objects, dust and sand do not get into the mechanisms.

If foreign bodies are found during diagnostics, the fittings must be thoroughly cleaned with a brush, and then walked over them several times with a rag. Identified contaminants, especially persistent ones, must be removed.

Damaged parts on which paintwork materials were previously applied are cleaned and then restored. Also, in order for the fittings to serve well, they must be well lubricated with suitable machine oil.

Caring for window fittings

Hardware for wooden windows is a high-quality mechanism that does not require special care. For such structures, it is enough to lubricate the hinges annually with machine oil and check the serviceability of individual elements. Be sure to regularly wipe the window from dust and ventilate the room. This will prevent condensation from forming on the windows.

Rice. 6. Accessories for wooden windows

Despite the fact that the fittings are treated with an anti-corrosion coating, the accumulation of condensation can lead to rust. It is also recommended to put the window on micro-ventilation and tighten loose elements if the window is not securely fastened when closing.

Prices for work

The cost of installation, repair or replacement of accessories may vary depending on the region of the Russian Federation. The execution of work does not depend on the season or other factors. The most expensive services are in the cities of Moscow, St. Petersburg, Novosibirsk.

Approximate prices according to official price lists , in rubles, for 1 window structure are as follows:

simple adjustment of fittings – 300-500;- complex adjustment of mechanisms – 1,000;

- installing manual controls on fittings – 2,500;

- cleaning and maintenance of elements – 150-250;

- complete replacement and adjustment of fittings – from 3,500;

- partial replacement of loops, scissors – 200;

- installation of decorative overlays – 210;

- installation of a strike plate, comb, limiters, microlift – 250-500;

- attaching a handle – 300-500.

Prices in the service market are constantly changing, companies periodically update their price lists. Private individuals work at prices that are lower than those listed, but they do not guarantee their work. They can also additionally request the customer’s tool.

Accessories and fittings

PENS

“KRAUTS Company” installs handles and accessories in its products that meet the highest quality standards.

Handles for windows and doors, aluminum covers are made from primary aluminum of the highest quality and resistant to corrosion. The surface finishing of light metal fittings is done using anodizing or powder coating. During anodizing, using a jet and sulfuric acid, produced artificially and through a purposefully controlled oxidation process (combination of material and oxygen), a protective (oxide layer) surface is created from the product.

This layer protects products from environmental influences (hand sweat, air, water and minor mechanical impact), surface damage (touching with rings or keys) and does not cause corrosion. When powder coating the surface of aluminum using electrostatic technology, it is coated with varnish particles. Then the coating is carried out at a temperature of 150-200°C, which causes the varnish particles to melt and a varnish film is formed during the reaction. Aluminum fittings do not harm human health and do not require special care (an oxide layer protects the lid material). Dirt can be removed with a soft cloth dampened with water.

Aluminum door handles can be bent on both sides. The handles are supplied with M6 bolts.

Depending on the type of product, strength tests and static tests are carried out, which show the strength of door and window handles under “everyday use” conditions, close to real ones, which significantly exceed DIN EN 1906 or RAL-RG 607/9 norms of methods and requirements. . Tests of window and door handles are carried out in real conditions, when the handles are installed on the main operational elements.

1.1 Handles for windows and balcony doors

All handles have fixed positions, every 45º degrees

Comment. Standard pens are kept in stock.

Standard colors: white, brown, nickel satin (champagne).

Other colors: gold, brushed chrome, stainless steel, copper, bronze, antique bronze, antique copper.

Color spectrum:

1.2 Handles with lock for windows and balcony doors

All handles have fixed positions, every 45º degrees

Standard colors: white, brown, nickel satin (champagne color).

Other colors: gold, brushed chrome, stainless steel, copper, bronze, antique bronze, antique copper.

Color spectrum:

Comment. Standard pens are kept in stock.

1.3 Hinge covers

Colors: white, brown, matte chrome, champagne, bronze, gold, matte gold.

1.4 Handles for sliding doors PSK

Colors:

- Simple handle - matte chrome, white, brown, painted bronze.

- Lockable handle – matte chrome, white, brown.

- Lockable handle with cylinder - white, brown, matte chrome, champagne, bronze.

1.5 Handles for sliding doors HS

Colors:

- From the inside - lockable: white, brown, matte chrome, champagne color, bronze.

- From the inside - not closed: white, brown, matte chrome, champagne color, bronze.

From inside:

Colors:

- Outside – closes: white, brown, matte chrome, champagne color, painted bronze color.

- Outside – not closed: brown, matte chrome.

Outside:

1.6. Pull handles

“KRAUTS Company” used pull handles are made of aluminum.

Colors: white, brown, matte chrome, champagne.

1.7 Ventus handles

Colors: white, brown, matte chrome, bronze.

1.9 Door handles

Classic and modern design doors are available for entrance doors. We can also offer “Secure by design” safety handles for aluminum doors.

How to choose a window comb

Before purchasing a window stop, study the characteristics of different modifications. When choosing, experts recommend adhering to the following rules:

- It is better to install activated brake mechanisms on balcony blocks.

- For attic double-glazed windows and large windows, it is necessary to select metal fasteners of increased strength.

- For active use and frequent opening/closing of the sashes, it is advisable to choose a window limiter with a cable. An alternative option is a lock with a locking mechanism.

- If there are often drafts in the apartment or the windows are located on opposite sides, give up plastic products.

- To protect children as much as possible, it is necessary to install special restrictions for safe ventilation or a child window lock.

Child lock on the sash

Types of loops

Hinges for all types of windows can be adjustable or non-adjustable. In modern designs, the first version of devices is most often used, which can be made of brass, steel or aluminum alloys. In this case, plastic can only be used for decorative overlays. According to their purpose, these mechanisms are classified into:

- overhead – a reinforced modification used to complete very heavy sashes;

- rotary - traditional hinges that are used to equip door and window sashes that open outward or inward;

- folding - devices designed to open the sashes into a folding position.

Based on the installation method, these mechanisms are divided into semi-hidden, overhead and completely hidden. The most common is the first modification, and the most promising is the last. Hidden hinges provide better tightness and aesthetics of the doors. Read more about devices of this type on OknaTrade. In turn, semi-hidden loops are divided into:

When choosing hinges, you must simultaneously pay attention to several parameters of the doors - their dimensions, weight, as well as requirements for burglary resistance class and functionality.

When to adjust or change hinges

Adjustment of the hinges is required in cases where either partial depressurization of the window structure occurs, or there is sagging of the sashes, which cling to the frame profile when opening/closing. These fittings are replaced in the following cases:

- if the adjustment did not give a positive result;

- after lubrication, the doors lock when moving;

- the integrity of one of the elements of the loop group is violated.

Although quite a lot of instructions on replacing and adjusting these components of window fittings are publicly available, it is better to invite specialized specialists to carry out such activities. Otherwise, you may not only not achieve the desired result and ruin the hinges, but also break the transmission mechanism, which is fully responsible for the tightness of the window and the opening of the sash.

Source: www.oknatrade.ru